Leaderboard

Popular Content

Showing content with the highest reputation on 04/24/20 in all areas

-

TOday will be the Heuer 73473. One of Heuer's lesser known models but no less important in my opinion. It's a great chronograph that has all of the funk of the 70's. I believe this one is from 1973. Great condition and is virtually untouched. My preference has always been'for the most part' about having the watch on a period band. I think this one looks exceptionally nice on a vintage beads of rice bracelet.3 points

-

Currently having limited space to work on watches, I decided that a portable desktop workbench would be necessary for me. I was inspired by this blog post for a similar sort of DIY setup, but was having trouble finding good sources for the individual components. Instead I used the following parts (mostly ordered from Amazon but available at Home Depot and Target as well): Carlisle CT121623 Café Standard Cafeteria / Fast Food Tray, 12" x 16", Gray 1x IRIS Desktop Letter Size Medium Stacking Drawer model DTD-L (available in clear or black) 2x IRIS Desktop Small Stacking Drawer model DTD-S (available in clear or black) Velcro 90087 Sticky-Back Hook & Loop Fastener Tape with Dispenser, 3/4" x 5ft Roll, White Everbilt #12 x 3/4in flat head phillips wood screws (SKU 284 773; from Home Depot) I paid about $32 for all of the above. Interestingly, everything except for the wood screws was made in USA. The plastic drawers do come with clips that allow them to be attached together, but the connection seemed pretty weak (hence the wood screws). To construct, I drilled through all of the holes on the bottom of the small drawers where the rubber feet would be pressed in (and ultimately ended up removing the Velcro you see in the picture below because I went with the screws instead): Next, I applied a bit of Velcro between the front edge of the two small containers. This may or may not have been necessary with the screws, but I did it anyway! To attach the two small containers to the larger drawer, I removed the top panel of the latter, marked where all of the feet align, and drilled some more holes so I wouldn't crack the plastic by driving the screws through it. You'll see where the two front inner holes interfered with molded plastic, so I didn't use screws there (also why I used the Velcro in the picture above). The screws may poke through the holes somewhat, but they shouldn't interfere with the drawers. Next I used a utility knife to shave the low feet off the bottom of the tray to make it smooth, then marked where it would be centered on the top of the small drawers. And in case you had been wondering, I chose to use the tray because it was cheap and had a decent lip around the edge to prevent things from rolling off. I then cut some lengths of Velcro in half and applied them to the topside of the small drawers. When I first ordered the Velcro, I hadn't planned on screwing it all together. The idea was to make it disassemble-able, but I changed my mind. Alternately, the Velcro could be replaced with double-sided 3M foam tape (though that wouldn't be thick enough to bridge the front gap between the two small drawers in the second picture. And now the final product, all stocked up! Esslinger's Watchmaker's Anti-Static Bench Mat Work Pad fit pretty darn well on the tray, with a little extra space around the edge to set things that might roll otherwise. The drawers have no locking mechanism, so make sure they don't slide open during transport. They do have some tabs to prevent them from falling all the way out, but that probably won't help much by that point. Final height is 7 13/16". The tray itself is textured, so a vacuum-clamp vise like the one in the blog post would likely not work. Hopefully folks find this useful. If you want, you could always stack more drawers. I find this size to be work pretty well and easy enough to store in the closet. Kevin2 points

-

2 points

-

My favorite 1960s Skindiver - Nivada Grenchen Diver. I have only seen 1 other with the cream yellow dial, and not in person, so I can assume this one a rare one. Additionally, most Nivada Grenchens in this style are labeled 'Taravana' - this one is not. The nice cushion case is quite large for the day and sports a ETA 2472 which not stainless- brass alloy?? And yes, I have replaced the gasket. It also has one of the coolest caseback designs I've seen!2 points

-

How about making Ollie Baker mainspring winders. Cousins seems to be out of stock most of the time. Whenever stocks come in, it is almost always snapped up in a couple of days. I just started making my own because the prices for a new one is crazy. Even used ones on ebay are really expensive. I already have an old English pattern mainspring winder and started thinking of making an adapter for winding larger clock springs. I've seen videos of some diy winders on YouTube and those didn't really interest me. Now I will have to figure out how to build the rest of it with readily available stuff.2 points

-

Making a Platax would allow one to see that the rare used ones that come up are well worth the price at several hundred bucks or more! On that note, I have made tools in the past, but really only when there either wasn't something commercially available, or making it actually is cheaper than buying. If one is a professional, then you have to count your time as you would working on paying work and see if it's worth it. I made a quick change toolpost for my watchmaker lathe, at that time I was in school and the day or two spent was far less painful than shelling out hundreds of dollars. I made a pentagonal female driver to remove the back screws on an Audemars Piguet, no chance of buying one. For basic tools like screwdrivers there are so many choices not including the Aliexpress stuff that it just doesn't make sense. For something like a staking tool which is painfully expensive new, there are dozens available at any moment secondhand for very cheap. Tweezers would be incredibly hard to make and be even close to what cheap ones are quality wise. Then there are things that might be useful enough, rare enough used and no longer made, to warrant making. In the Louis Levin book Practical Benchwork for Horologists there actually are blueprints for a screwcutting attachment that can be adapted to almost any watchmaker's lathe equipped with a cross slide. One of my old students did make one a few years back and does use it frequently; but he does primarily component making for restoration work, and encounters many odd threads that would be tricky to impossible to make without it. A few of the lathe makers offered these in the past but they were rarely bought and thus very very hard to find second hand. Something I do make quite often is special pushers and stumps to be used in a jeweling tool. Pushers with short blind holes to help push small steady pins in straight, pushers or stumps with relief grooves or holes machined in to clear obstacles, all sorts. I have hundreds and still make them once a month or so. It's handy to have some steel in staking punch diameter too, even with a large set you might find that you really want/need something special.2 points

-

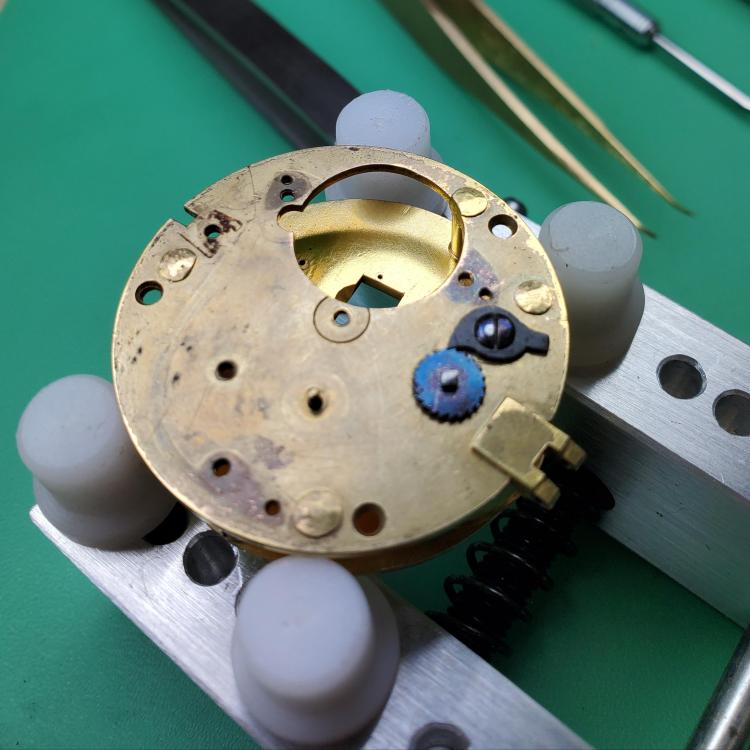

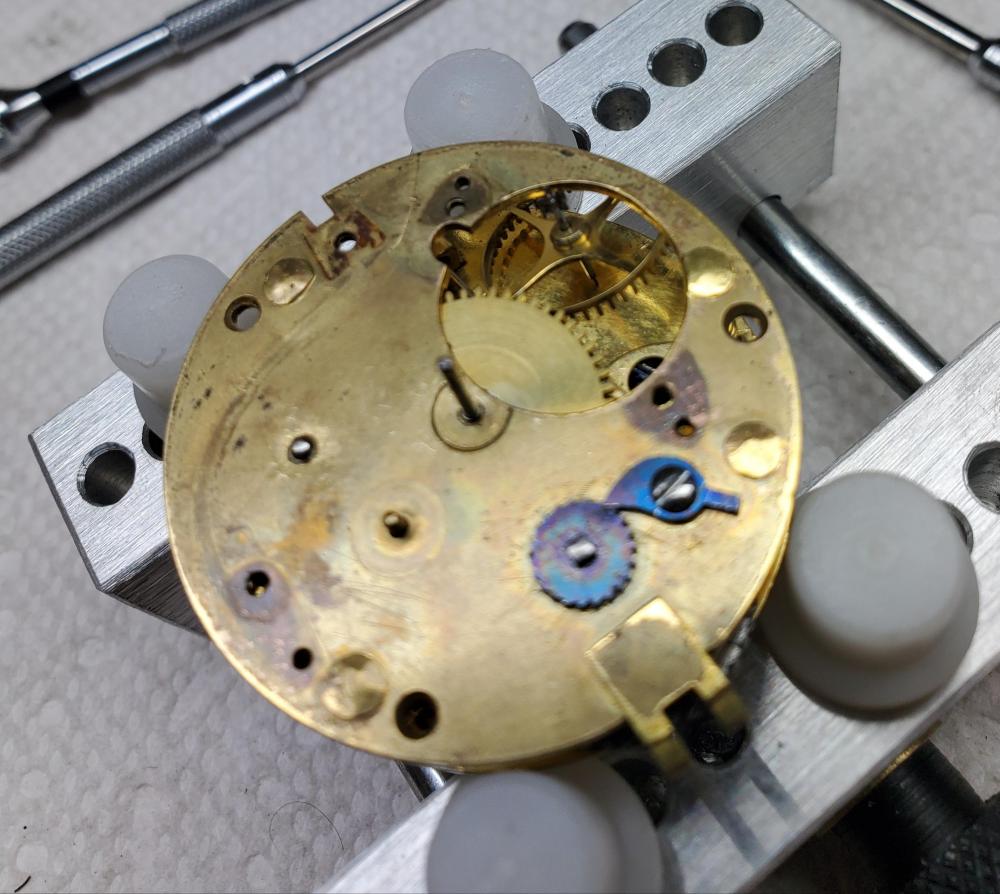

So im unsure watch the correct term for this ratchet is. Its purpose is to hold a certain amount of power on the mainspring in a fusee pocket watch when the fusee is run down. So i go to start working on this movement which i disassembled a few days ago. I had everything neatly organized in small lidded containers. Low and behold this ratchet was missing. Of course i looked everywhere but we all know how that worked out. Haha. So i made another one. I found a piece of steel off a junker gustav becker movement. Filed it to the correct thickness. Used my jewelers saw to cut out the shape. Halfway thru that, i drilled and reamed a hole to the correct diameter for the screw. I then finished cuting it out. I filed the edges to shape. Sanded it and blued it. Mine is the first pic. Not as delicate as the original, but not a bad remake. I dont think A 3 hour mistake. Working on clocks for years i have lost my share of parts. I try to keep everything enclosed and well organized, but it happens. On my first pocket watch too, no less. Haha.1 point

-

1 point

-

That is wrong . That must be made by somebody trying to make the watch run . Should be a slipping automatic spring instead.1 point

-

I hate to tell you but you are a watch collector. Are you sure you dont want to spend the $300 on repairing you 1966?1 point

-

I cannot really take the credit, I know a man who knows an awful lot about vintage chronographs, who's blog is a great reference source, who repaired and serviced mine about five years ago...... see HERE1 point

-

1 point

-

Have a look here. https://www.cousinsuk.com/product/jars-lids-spares-elma-rm90-super-elite1 point

-

Can you remove the back and take a picture and we can help you. A shot in the dark, sometimes there is a tiny screw that needs to unscrewed a little to remove the whole stem, or it could be a push in piece you need to push in. By looking at the movement we can pin point the part for you.1 point

-

Thank you for the links watchguy ! Am starting in this hobby and was not aware of these two providers.1 point

-

I make the odd simple tools when I can’t buy one. Things I’ve made recently were a specific size of rose cutter which I made from silver steel, and some tool bits for screwing down crystal retaining rings. The BHI practical courses have tools which you are expected to make at the end of each chapter, so I’ve made some of those.1 point

-

It depends if when the crown broke off how much of the stem is left. With a shorter stem and the crown screwed on it will not engage the winding and hand setting wheels. However there are such things as stem extenders that can screw onto the original stem that help repairers to over come such a problem, providing enough stem is left to screw one onto, you will need to know the correct screw size. Here is a picture of the extensions I'm talking about.1 point

-

not looking to make to sell. i've always been proud of tools I've made myself because none exists. thats the cool part.1 point

-

Just finished this 1970's Timex Q quartz divers watch.Surprisingly for Timex in the period this appears to be a genuine attempt to create a watch that could actually be used for diving! It is marked '100 metres' and to back this up has a screw back with 'O' ring seal and a screw down crown, again with a seal. It came to me a few weeks ago in a very sorry state.... The back and bezel appeared to be firmly cemented in place with what looked like a mixture of porridge and plaster of paris. Also I don't think the crown has been screwed down for quite a while as the crown tube threads are under this somewhere!...... The clean up was fairly straight forward and a 2mm thick replacement crystal was easily sourced. The real problem was the bezel insert.... Initially I just removed as many scratches as possible and polished it. The nearest insert, in size, that I could find is the Seiko 4205 mid size diver one, but whereas the inside diameter was near perfect at 28mm, the outside diameter is 34 mm and the original insert is 32.8mm. Also the original insert is convex and the Seiko on is flat. Not to be put off I obtained one and sorting through my nylon crystal press dies I found a combination of concave and convex ones and with them in the press managed to reform the Seiko one to match the concave Timex insert. The next stage was to find two other nylon dies to clamp the two inserts together with an M6 bolt which went in the electric drill to make a lathe of sorts. About an hour or so reducing the outside diameter of the Seiko one down to the original Timex one, finishing of by hand with fine needle files did the job. The final result here:-1 point

-

Under magnification, I can see that the catch on the arbor is Badly worn, and slips out of the notch on the spring when under tension. So I’ll get that replaced as well. Thanks for the tips.1 point

-

Further investigation revealed that the Crystal I initially suggested may not be correct. Boley in Germany has all cases and crystals listed for nearly every model and brand of watch. Please see the screenshot and link below. I would trust the accuracy of Boley's information over anyone on eBay. https://boley.de/en/case-parts/seiko/20719.6600-9990?q=9990&p=0&s=50&l=18 That said, Jules Borel in the states lists the original part number I posted. Jules Borel is also very reputable. Looks as if the original part number is easier to come by though. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=W]bcWFdcTH1 point

-

Here's the "all the others" https://www.aliexpress.com/item/4000117113805.htm Not cheap and I would love to see someone beating the Chinese at their own game. And hats off to who's able to make for his own use, micro internal impulse cutting ... hmmm..1 point

-

Wow, good to know about those drivers! I made mine probably 12 years ago. My friend does make taps and dies, but you still need the ability to match the thread pitch thus the threading setup. He's a maniac though, he often just directly grinds the threads on the part with the threading setup.1 point

-

It would be nice if you would could take the dial off so we could look at the setting parts. Then we may be able to perhaps identify the actual caliber and see if the staff is available.1 point

-

That must have been before "China AND CNC" https://www.aliexpress.com/item/4000745105373.html That's just an example, there was another seller with many more types sold (not cheaply) individually, Now that Cousins UK sells unbranded AF for cheap, that is even more correct. Previously I've got the below and very happy with. https://www.aliexpress.com/item/32565947452.html I'm the first being intrigued by screwcutting but I remain a bit skeptical about the utmost importance of having a complicated threading setup on a (small) watchmaker lathe to make small threads. Change gers copiers, etc everytime a new job shows up. Better maybe bite the bullet (steel bar) once and make your own tap or die with the hope of reusing it the future1 point

-

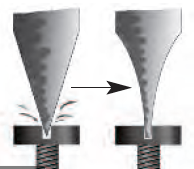

The one tool used the most by an horologist is the screwdriver and keeping them in good order is important for quality work. I am greedy because I have two sets of screwdrivers. One set are sharpened in the conventional chisel shape and another set are sharpened using the "horotec" MSA 01.504. sharpener. I have found that if not carful using the "Horotec" sharpener it is very easy indeed to make the tip too thin and brittle. I therefore tend to use the conventional sharpened screwdrivers for the bigger screws and also for some vintage screws which have very narrow slots. Another issue to be considered is the quality of the blades. The cheaper screwdrivers I have found are made of a softer metal and tend to break more readily. The pic below shows the benefits of the "horotec" shaped blade.1 point

-

If you want to make a useful tool start making Platax tools seeing Bergeon stopped making them, but that in itself says a lot if its not worth their while making them it's probably not worth anyone else's.1 point

-

Only some tools are patented, and when they are be that is generally shown on the item. And, patents may have long expired, either because of statutory tems, or failure by the owner. Also, patents are generally enforceable only in the issuing country. It is a complicated matter, I think when it comes to the small sector of watchmaking tools it is not something that a guy making stuff in an home shop should worry about.1 point

-

Hi like jdm says the most used and most likely tools are copied with just enough difference so as to avoid infringment of the patent rights and there fore the drawings are again copied. Wether these would be put on the open market I dont think so. One could always make inquiries through the patents office on tools that are out of patent. It also depends on the machine tools at your disposal to make or reproduce the product. And if selling the product at a competitive price1 point

-

Thank you for your introduction and welcome to this friendly forum. When it comes to tools I always advise members to buy the best they can afford. To start with a good set of watchmakers screwdrivers and Dumont tweezers are a must have.1 point

-

1 point

-

One thing to remember for amplitude you have to get the lift angle correct. American pocket watches are seldom 52°. As the English lever escape wheel teeth are different shape I don't know if that would change the signal timing which would definitely cause the timing machine to have an issue. At least for amplitude rate should be fine. Then on pocket watches very important to do your escapement checks. Make sure your banking pins are where there supposed to be unfortunately American pocket watches with the movable banking pins they've probably been moved not always for the best. Then occasionally the pallet stones are quite not where there supposed to be either. It's amazing how poorly the watch to run if the escapement isn't correct.1 point

-

1 point

-

Perhaps that pallet fork arrangement can’t put enough force on the impulse Jewel to get a high amplitude. I do however have a RR grade Elgin that is full plate and has excellent amplitude. My wife is still looking for Unicorn Poop. Sent from my iPhone using Tapatalk Pro1 point

-

I recently had a 1920's Waltham 8 day car clock that I couldn't squeeze any more than 220 amplitude out of after fully servicing and replacing both mainsprings, which incidentally was like trying to find unicorn poo. Timesavers had a set thankfully. Nice job JD,,, always a pleasure watching you work!1 point

-

Another good one JD. Low amplitude seems to be an issue with some vintage pocket watches. Recently I had the same issue but a lot worse than the Waltham. On an English lever pocket watch I changed the balance staff & hairspring and it was spotlessly clean but still gave a low amp certainly no more than 180°. Wondering if these vintage watches were never designed to gave a high amp.1 point

-

Your clock movement is known as a rack striking movement. It’s a strike, the hour wheel with those ridges on it to determine how many times it will strike is called a snail. The strike side wheel next to the fly (that’s the flat one right at the end of the train, the wheel with the little pin in it, that pin needs to at about a quarter to or 10 to so it has good warning, make sure the hammer doesn’t start to lift in the warning passion. There is no easy way of regulating a clock it depends on the mainspring it is a trial and error, this sort of movement should go for 8 days on a single wind, if you can get it down to a minute a week that would be good.1 point

-

First things first. That hole for the large wheel needs to be re-bushed. You also need to make sure the pivot is burnished, so any marks on the pivot will need to be removed. You do not need one of those horrid bushing tools, they are a waste of money, do the re-bushing by hand. The reamer if used correctly will self center to the hole. The power is shutting off because of the angle of the wheel, it can not mesh correctly with the other teeth/ wheels. this will cause the beat of the clock to become shallow and stop the clock. I'm sure once this has be repaired the movement will have a better action from the escape wheel to the pallets, at the moment I can tell the power is shutting off causing the escape wheel teeth to become shallow to the pallets and it stops. The best clock oil to use is Windles.1 point

-

Like others on here I don't restrict myself to just one set of screw drivers. I have one set ground to a thinner profile, and another set ground to a slightly fatter profile. I also have numerous screw drivers ground to extra thin and extra fat. As a rule I find that Swiss screw slots are thinner than Japanese, Quartz movements tend to have a few have extra fat slots, very old pocket watches seem to have extra thin slots. This sounds like an expensive investment in screw drivers but I have probably spent less on my multiple sets than many others have on just one as I have picked them up second hand and in job lots from all over the place. They are good quality, vintage, French or Swiss. They don't necessarily have the silkiest smooth ball bearing tops to them but they are perfectly functional. If you generally work on the same type of movements (pocket watch, or Japanese, or Russian for instance) then one set of screw drivers tailored to that specific family of watch movements is all you need. As for throwing away old blades it does seem a bit of a shame. Generally speaking all that is needed to bring a chipped blade back into trim is 5 minutes on a stone (or decent quality wet & dry paper on a sheet of glass, or your diamond stones). If you find that you are regularly suffering from chipped blades then it might well be worth exploring the possibility of adjusting the temper of the blades. If you get it right you not only get more resiliant blades which are less likely to scratch movement plates, but you also gain an understanding of heat treatments for steel on a macro or even micro scale. Useful stuff.1 point

-

For sharpening the blades I always used an arkansas stone with a little 3 in 1 oil with the same tool that sstakoff has posted. It takes a lot of practise to get it right. If you're like me when I first tried I messed up many. Make sure you have the correct size blade for the screw again its practise, first make sure you hold the screwdriver dead upright and not leaning to a side, master that and your screwdriver won't slip out of the screw slot.1 point