Leaderboard

Popular Content

Showing content with the highest reputation on 03/02/20 in Posts

-

When working on American pocket watches there are helpful procedures. There is the pocket watch database found at the link below which will give you all sorts of helpful information. Except I noticed a minor problem with your watch? Usually other people have pictures as examples of their watch and no pictures this time? Although that may be because people are not grasping who actually made this watch. Then normally on this site especially with Elgin you can get parts listings but I notice there is no parts for your watch? At least listed on the website. Then I'm going to overload you with technical information and pictures before we get to the classic problem of waltham steel mainspring barrels and why the spring will never hold out of the package. Okay it will hold if it's an original spring. Then yes this discussion has occurred somewhere in this group before. So in my procedure of always measuring the mainspring and comparing to the new has another purpose. One of the images I attached shows a minor problem at one time. Usually or a lot of times a single mainspring part number will refer to several mainsprings where the strength is different. Unfortunately or fortunately today that problem is solved. The modern white spring is always stronger for the same thickness then the blued steel original spring. Then the modern mainsprings typically don't have all these different thicknesses plus sometimes getting modern springs to replace original is just hard because they don't exist anymore. So the classic problem is the shape of the end of the spring is incorrect and that means it's never going to catch unless you buy an original spring. Sometimes you can buy original springs and strangely enough there still good even though they are very old. I've attached a couple more images one am slightly exaggerated but if you look at the end of the spring it has a bend. look at the spring that came out and see what the end looks like? So the modern spring is just a hole punched in that is never going to catch. Trying to bend end of the spring can be problematic because sometimes it has a habit of breaking. A compromise is to file the shape that I have in the other picture basically a taper that can catch on the hook if you're lucky. Otherwise you can do what I do is give up and go to eBay and see if can find an original spring. https://pocketwatchdatabase.com/search/result/waltham/216993474 points

-

Hi you use the winding key on the square on the min hand actualy its the front of the canon pinion to be exact and manualy turn the hands round.3 points

-

2 points

-

When I was in school I worked evenings in a trade shop (servicing multiple stores) that was for all intents and purposes a "hack" shop. No lathe, but I was required to wire brush the back of every dial (?!)... and so had a Dremel hanging at the bench. I quickly got all the restaffing work too, and found I could chuck the staff in the Dremel and stone down such diameters pretty effectively. It killed me as I'm a lover of lathes and turning, but the watches went out and ran well. My boss would just broach the roller. Usually a new one, as he'd crush the original trying to force it on. Nice guy though.2 points

-

2 points

-

2 points

-

2 points

-

I think the distinction between Fake, Replica and Homage watches needs to be discussed here. I think it's clear the OP desires an Homage above all else.There is an entire cottage industry devoted to modding Seiko SKX series watches into homages of many popular luxury brands. They're never sold as fakes and the're highly collectible and pull down prices more than double and sometimes triple the sticker price of the original Seiko. Another homage movement I've seen are based around the Chinese made "Parnis" brand. They sell complete and parts to build "Panerai" homages. There are techniques for weathering, aging and patina-ing dials, hands and cases to look old and weathered. I think with the clear understanding of the OP's desire for this watch and his statement that it doesn't have to be a real or a fake or a Replica trying to be passed off as authentic, we should ease up on the Flambe he is receiving. Just my $.022 points

-

Just remember, with tapers, a little goes a long way!1 point

-

1 point

-

https://www.amazon.com/Glide-Gear-OH100-Professional-Photography/dp/B06XPFJJ4T Marks is more functional, this should give an idea.1 point

-

Some really old watches had holes in the crystal to access the square. Later on the square moved to the back, over the center wheel, when full plate watches went away.1 point

-

I treat the pinion and spring with epilame, the oil both ends with 9010. The spring does need a bit of tension, or the hand will be unstable. I personally hate this system, and there were elegant alternatives that don't eat amplitude. Beware when you fit the seconds hand, you'll want to put a bit of old mainspring or something between the pinion and tension spring and set it all down on a bench block while pressing the hand on. Otherwise you can easily damage the spring.1 point

-

1 point

-

1 point

-

Che would have fought for those t shirt profits just the same, no matter what he intended on doing with the money. That was more the point of my comment. Communism is a mess, no doubt, lol.1 point

-

Che's a communist. There would be some serious hypocrisy if he tried to make money off his t-shirts. By definition (if alive) he would have to let people profit off his likeness, not himself. They woudl of course do great thus building a t-shirt empire with an unfair compensation structure. He would eventually not be able to stand by and watch this injustice. Che would infiltrate the worker community and start a union. There would be resistance from leadership resulting in a violent overthrow. The new leadership would then run the company successfully for a little bit. Workers would eventually be disillusioned with Che's promise of a t-shirt paradise. "Why does everyone get the same pay no matter how talented or hard working they are?" Productivity would drop dramatically to where they begin to organize again, but this time under one charismatic leader. Thsi leader wants to restore the t-shirt company to its former glory, and this can only be done if he has absolute power. This new leader selects individuals who were strong in the previous regime and has them executed, Che included. The Fascist leader then starts rounding up the Chinese sub contractors and putting them in breakrooms that are inadequately stocked with snacks. The TV in the break room only plays reruns of the Mary Tyler Moore show which drives many to suicide. This outrages that international community, yet few take action to help. My point is that your Che t-shirt argument falls apart pretty quickly when you think about it for a moment.1 point

-

A couple of Timex mechanicals, possibly donor material, depending on the condition of those dials. An Ingersoll Triumph, and an Ingersoll 17 jewel Amida 562 (according to the sticker on the back, which also claims it is dunning, but I'll take both with a pinch of salt). The whole job lot qualifies for the 404 club, or if you prefer a more accurate figure 0.92p each, plus shipping. Also on its way, and also a 404 club candidate is this fine little Timex Big Q.1 point

-

On initial reflection, it seems likely that paper might make a poor dial substrate. It is thick, at around 0.1mm, compared with a a paint layer, which may be as little as 0.02 mm. The water slide transfer by comparison looks to be around 0.05mm from the limited information I can find online. Paper does have some useful properties however. For example it can be textured easily, simply by passing it through a suitably pattered roller. It can also, easily be made waterproof as I have just shown. So I decided to try texturing one of the paper dials to see how simply that could be done. I had all sorts of smart ideas, involving 3d printed rollers and etched plates, but then I noticed I had the perfect experimental roller sitting on the work bench, so rather than spend ages drafting something in FreeCAD, I simply rolled the handle of my screwdriver over the paper. The effect is far from perfect, but it does suggest this is an avenue worth exploring. I may even try it on the waterslide transfer, after clear coating it, but before removing it from the backing sheet and applying it. The paper I have used is pretty crude, cheap supermarket brand printer paper, but high quality bright gloss finish paper would probably be more suitable for experiments with textures. I was thinking of something along the lines of a 0.3mm brass sheet sunstrate, plated with nickel and then covered with a textured linen paper dial and sealed with a hard acrylic finish.1 point

-

Chrome will be attacked by acid. The higher the acidity, the faster it will be removed. Perspiration, or sweat, has a slight acidity and therefore a chrome-layer will, in time, be eaten away. How fast and how much depends on many factors like the acidity of the persons sweat, the contact duration, the quality of the chrome layer etc , etc. I don't know how the front of the case looks like, most likely the "damage" is restricted to the back-side. If you want everything a 1000% perfect, the old chrome layer has to come off and the case needs to be re-chromed. High-gloss chrome is used and that is not a DIY job. Applying a nickel layer is another story, has another appearance and is not as per original. The watch has had a life and a story to tell. You can erase all the age/life tell-tales, but where do you stop? Re-chrome the case, remove all the patina, install a new dial, new hands and while you at it, a new movement? Also, it seems to be on the back-side of the watch, a place normally nobody sees .... Polishing too aggressive and too much and you will go through the chrome layer making things only (much) worse. Considering the fact that you may do more harm than any good, I would leave it "AS IS" is .........but that's just my opinion1 point

-

What you need to do is purchase broken watches off of eBay. Watch repair is all about continuously practicing. Practicing putting the gears in and out for instance without breaking pivots. Practicing working on hairsprings much nicer if it's a disposable watch that you purchase that's never going to be fixed. So you can destroy the hairspring learning how to work on it. Versus trying to fix the hairspring of something good where it is going to take a lot of practice to learn how to fix it.1 point

-

This evenings victim is a Seiko from December of 1970. The only issue other than being a daily wear for some mod rocker back in the day is the crown has no click. Winding, time and date changes as normal but something is amiss in the keyless work. My fabulous-ly inexpensive tool for unscrewing casebacks will not shrink small enough to capture the grooves so a moments thought and some rearranging of the bits allows us to get started. Checking the inside of the back for service marks shows no entry, screw heads seem undisturbed by other rookies such as myself and of course I have forgotten to set the time to allow easy removal of the hands. Reinserting the crown and stem and using hand pullers with plastic bag leaves the dial in pretty good shape even with my clumsy handling. Of course you folks see it although I didn't: the adapter ring is still around the movement barring access to the dial feet screws. Looking around we see two screws at the tip of the tweezers that look like they will do the job. Sure enough the ring drops away and the foot screws can be loosened on either side of of the dial. Removing the dial while looking for a washer underneath we see the broken spring end laying on the date wheel. Of course all this manipulation without a movement holder will probably cause more trouble later. But at least without the dial getting squished we now secure this tiny movement a little more properly. Removing the weight reveals the winding mechanism. Depressing button just above the crown allows stem to be replaced, then held while holding the click just below the stem to take the small residual power away after all this abuse. Amplitude seems quite minimal but not unexpected since I've probably squished things pretty good a few times up to this point. Feeling pretty intimidated at this point, put everything away until tomorrow night. See you then!1 point

-

The click on these is Seiko's typical sheet steel. I had a 4205 (similar except the 4205 uses a balance bridge, not a cock) where the part the holds the ratchet wheel was worn and not holding back the ratchet wheel. I gently bent the click into a 'V' shape to bring it in closer and problem solved. I usually have organ donors for other Seiko movements but not for these. Something you might consider if yours is similarly worn. Anilv1 point

-

Hi, yes, it's pretty frustrating. These are base metal (brass) cases with a chrome plate over them. I personally have never found a satisfactory solution as the pitting goes pretty deep. Good luck with finding a workable solution. Maybe finding a junker watch with a decent case? I've had some luck with that. Anyway, the case back looks beautiful! Nice job!1 point

-

1 point

-

Hi Gina I posted one on balancespring needles, lookup "balancespring needles" there was some response to that.1 point

-

Hi Gina there is a time when the spring is beyond saving usually when its a rats nest or the kink is so sharp that the molecular structure of the metal is damaged and any further flexing will cause it to snap. Most soft distortions when the spring is not flat or the coils are not even causing them to touch and that causes rate errors are in all probability salvageable with care and deft use of the tweezers or manipulation tools. The subject has been covered before and the references can be found via the SEARCH box at the top right of the home screen. We have all managed to butcher a spring or two during our carees. Cheers1 point

-

1 point

-

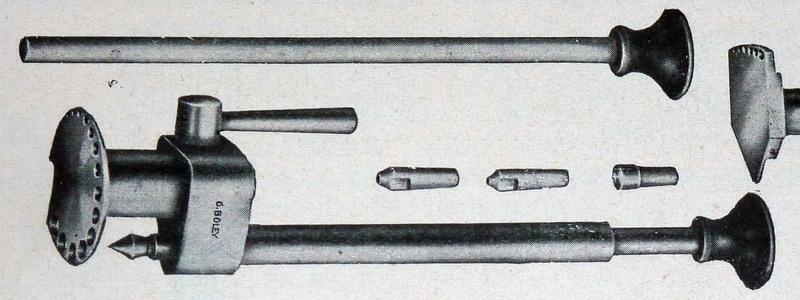

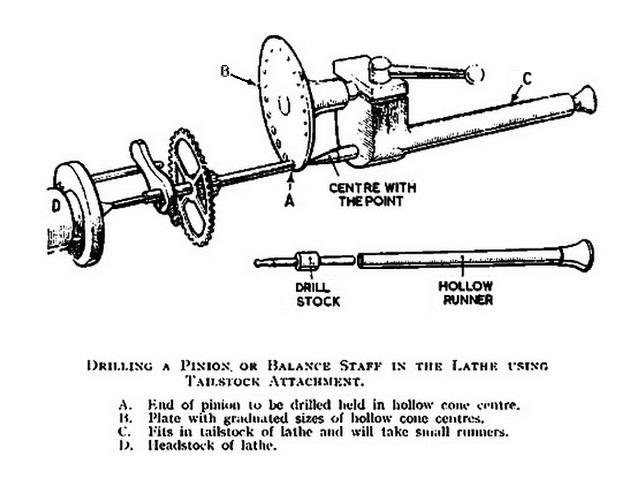

Should be pretty hard to find. Horia makes one that takes little collets, wouldn't be surprised if the shaft diameter is the same and you can get just that part and a couple little collets and be set. I use these often just hand holding the drill, the setup is almost essential for many repivoting jobs.1 point

-

Serial number shows it as a 3/0 size Waltham Equity. My Waltham parts book from shows the 1907 "O" size, which I believe shares parts with the 1907 3/0, as having a mainspring number of 2230. The 2228 is for the model 1900 "O" size, and is narrower/shorter and thicker. The serial number shows as a 1907 model 3/0 in my serial number book. Good luck.1 point

-

New evil plan. I will create a sheath over the broken shaft and pivot by drilling a hole in a piece of blued steel, just smaller than the shaft. Then I will friction fit the shaft inside the new steel part. Then I will grave down the long pivot to .24mm for the second hand pivot. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

Apparently, it looks like this. Yes, that brownish red disk in the thumbnail above, is iron oxide suspended in a light mineral oil. So not only can you polish your watch cases with the stuff, but you can actually "see" audio recorded on magnetic media with it. Incidentally this is not the first time I've encountered this trick. Back in the day, when people (old farts like me) actually repaired floppy drives and hard disks, rather than throwing them away, you could buy a similar fero-fluid filled contraption to assist you in aligning the heads of 8" and 5 1/4" floppy disks and single platter hard drives. The tracks on these ancient drives where pretty massive compared with their modern equivalents. Needless to say since it cost an arm and a leg, I never actually bought one. It was actually just as easy to use an oscilloscope, which I did have, but the gadget was a lot more portable than a 'scope.1 point

-

Some of the custom dial designs I posted are most certainly homage, since the original manufacturer did not produce anything similar (although other manufacturers did). This for example. I guess the issue really boils down to motive, and if the motive is to create a fake, and pass it off as the real thing, in order to con someone in to parting with the value of the real item, then there is a problem. There is a fine line between what is art, and what is not. Even the use of trademarks is legitimate if the result is unique and interesting as Mr Warhol demonstrated. It may not be to your tastes and may in fact annoy you, but motive is everything here.1 point

-

1 point

-

Hi I've been wearing a couple of recent incomings! Dan henrt 1963 Pilots Chrono, It has the SR71 Lockheed Blackbird on the case back! This is number 0348 of a run of 1,963 pieces Also been alternating bewteen this Dan henry 1968 Dragster chrono This one is number 0318 of 1,968 pieces.. John1 point

-

1 point

-

I could not center the work decently on the three jaws, so took out the four independentant. But on the base of the drill chuck there is no usable surface, and on the body the dial was hitting the on the jaws, So I had to make a spindle extension, bottom left. Drilled a center, turned a 5mm rod with the rolling dead center, drill on the press, then tap and thread. A cheap set worked well. There is about 0.1mm clearance between the tip of the spindle and the parts next to it, and about the same betweek the chuck jaws and the swarf screen, but it worked to an acceptable centering. I was also able to tighten the work with the thread rod. Bored to size and chamfered the work, I still have a problem to solve before tapping, but that was enough for today.1 point

-

Difficult to argue with that since you are unwilling to share your "method", however, since the subject of this thread is "CUSTOM DECAL DIAL TUTORIAL", and not some mysterious secret "method" let me address the subject of longevity of decals. Decal making has a long history, dating back through the centuries, and is arguably as old as the act of tracing an image on to a substrate, however the modern process, it could be argued really took off some time in the late 18th and early 19th centuries. (19th century "Decalomania" Vase) One of those credited with its invention was the engraver Simon François Ravenet ( a contemporary and assistant of the English painter, print maker and satirist William Hogarth). The process has evolved into a stable of modern industry, with decals appearing on all manner of substrates and in all kinds of processes. The process used in the waterslide decals described in this thread, for use on watch dials is almost identical to the process used on children's toys throughout the 20th century, with everything from clockwork tin plate Hornby locomotives to Matchbox and Dinky cars being adorned with water slide decals. Any process that can survive the actions of a child playing with it could hardly be described as anything other then very robust, assuming the surface on to which the decal is being applied, is clean and blemish free, and the decal is applied according to the prescribed method. Clearly the only way to know if these dials will stand the test of time is to wait 100 years and see if they are every bit as legible as their early 20th century counterparts, however, considering that they will generally not be subject to abrasion, moisture, harsh UV light or solvents, and that their surface is sealed with a waterproof lacquer, I have no reason to doubt that they should bear up just fine.1 point

-

Remember watch, tools, hands in bag. Head outside bag.1 point

-

1 point

-

1 point

-

Someone has to have this part before I seriously damage myself trying to repivot the current one. The Jewel hole is around .24mm Sent from my iPhone using Tapatalk Pro0 points