Leaderboard

Popular Content

Showing content with the highest reputation on 06/06/20 in all areas

-

Called an assortment or a mess, I,ll dig in my bag of 2000 staffs, I just may find some to suit your balance wheel. If not an exact match, you can get by with broaching for J and G while K isn't as significant. Making a staff is a last resort and expensive and whoever makes one should fit it onto the wheel and poise it as well. I,ll start digging, be happy to gift wrap and send you some, fingers crossed.2 points

-

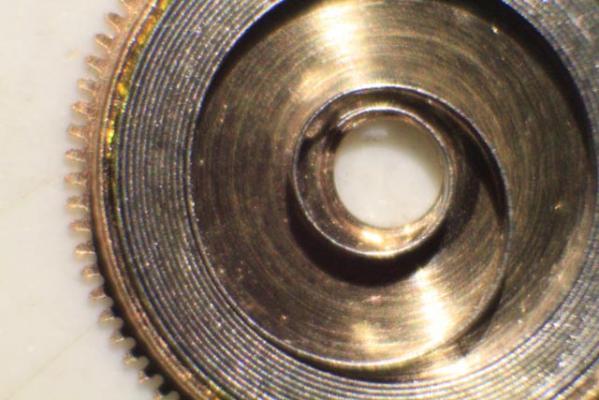

If its slipping within a half turn then I suspect it’s coming off the arbor instead of slipping on the barrel wall. You 100% need to use breaking grease but you also need to check your fitment to the arbor....which iam sure is the issue here. How do you shape the MS end. I use beading pliers to shape them some use heated tweezers but I get much better results with beading pliers, no need to heat and no need to worry about damaging burring or breaking the MS. Also I use a pair of nylon pliers and gently grip the arbor and turn with barrel lid off and I observe how the spring catches to the hook and the coiling of the MS. There you see and check for immediate slippage or disengaging of the MS. Don’t oil the MS. Some lightly oil them but if you don’t know the right amount don’t try it. Like everyone said most white alloy springs come with dry lube ready to install anyway.2 points

-

2 points

-

Hi VW I have a philosophical comment and I hope it is taken with blithe to all at WRT. I am 66 years of age and if I have learnt one thing life at the this side of 50 races by. So if you want a luxury watch to adorn your wrist and you will get pleasure from it go buy it. You will as you get older regret that you didn't if you really would like to see one on your wrist. There are many things I wish I had done when my body was in a more youthful state and yes I do regret not fulfilling some of them. I hope if you can and you want to, you will.2 points

-

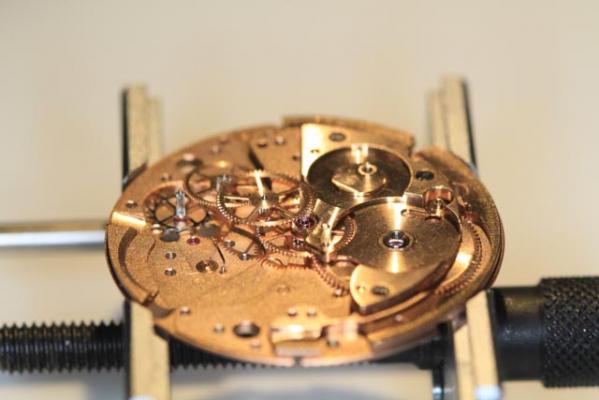

Here's the 1st part of a service walk-throughout of this 10.5''' pin pallet mov't which was barely running. It's built with some unusual characteristics for this class, like the ratchet wheel on dial side, the abundance of parts, and the use of four tally upping jewels beside the shock protection, perhaps an attempt to compete with Swiss lever mov'ts by boasting 23 jewels. I apologize for the mediocre quality of the pictures or any inaccuracy. I didn't find a service sheet, but that is not big deal really. Starting from the dial side we remove two tiny screws and the top calendar plate. Here we need to be cautious with the finger spring. You can place some rodico on it and lift where it's curved. Then remove the finger and the brass plate. Lots of more parts are now revealed, off it goes the date ring, date wheel, hour wheel, and the rocking bar Not less than three pinions on the bar, and that is without a quick-setting mechanism. Sorry I did not picture the setting spring, which is not difficult to remove safely. Having full access to the click we can now let the mainspring down. The next "dangerous" item is the click spring, again use caution. After the click we remove the setting wheel, cannon pinion, and the small plate holding two cap jewels, the lower anti-shock, according to the part list they are different from up and down sides don't mix them up. By noting the four no-function jewels around the date wheel machining we're done with this side. After pulling the stem out and storing the sliding wheel we can then flip the main plate, remove the upper anti-shock device and the balance. The massive cock it's a bit fiddly to lift. Also be aware that the dial screw can be completely removed, it's a good a idea to do that to avoid these falling at some point. Removing the pallet bridge and pallet I didn't noticed immediately but a pin had snapped. Maybe that happened in the washing jar, but the pin was nowhere to be found ?!? Fortunately a spare pallet fork was available to order. It should be also possible to make a a new, I hope to be able to cover that in a future posting. Remove the train bridge. It's possible that the barrel bridge is to be done first, but I had no problem anyway. Remove seconds, third and the escape wheels. In the best Swiss style there is no screw like another. After removing the barrel bridge we start seeing oil having left around. The thick center wheel bridge is removed with the wheel, lastly is setting lever screw and lever. I don't know why I pictured the sliding wheel with them. Opening the barrel we see that the last repairer, decades ago. liked to use a lot of grease in there. I don't guess on a mainspring's condition by its uncoiled shape, but just get a new one when possible. Washable parts go into my special machine, which is a small jam jar. First bath is horological ammonia solution, rinsed with petroleum ether, followed by distilled water rinse that is repeated until no floating particles can be seen against the light. Last rinse is with IPA. To be continued.1 point

-

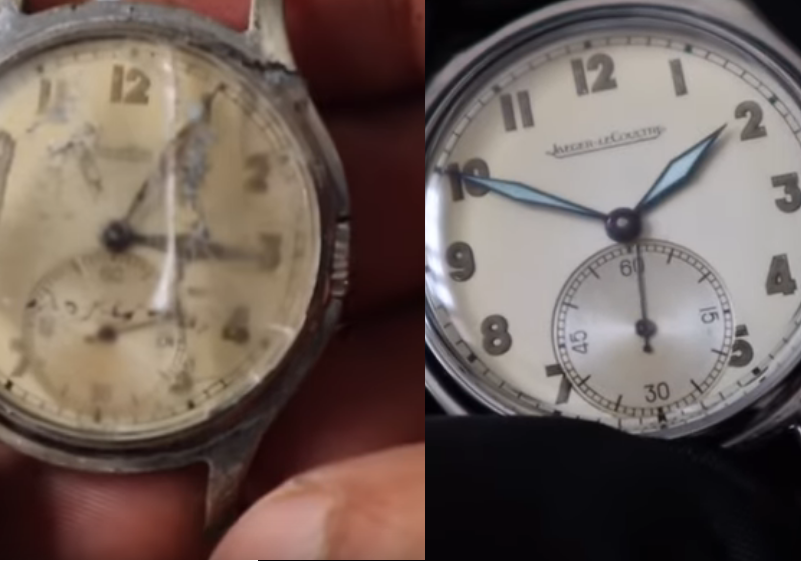

As of yesterday, the watch is completed and running. I had to back track a bit during assembly, as I forgot to install the hacking "finger". Essentially everything had to come back apart as the hacking finger sits under the gear train. Today I was able to pick up a bracelet extender so it would fit without strangling my wrist. The extender is gold tone, but I can clean that off Monday at work. I attempted to "repair" the dial with an acrylic gloss varnish, but it was sadly a dismal failure! I spent 4 hours very delicately picking the failed acrylic of the dial. In the end, it acted like a super cleaner and made it look significantly better. At the right angle you can just see the discoloration around the date window from my initial cleaning attempt. This watch is significantly smaller than any Seiko I own which is a bit disappointing. Overall I'm very happy with the watch and thrilled I was able to bring it back to life. The only other thing I want for this watch is a new crystal if I can't polish out the deep scratches with diamond paste. Gold tone extender, gets the job done, lol. For those of you with a sharp eye and a keen memory, what is significant about the serial number? And yes, this is actually the serial number on my watch, lol.1 point

-

Totally agree with Colditz. If you want a luxury watch beit 3000 4000 or 5000 bucks go and buy it while you still can. But see my earlier post (Make it a gold watch) because as soon as you leave the smooth talking salesman and walk out the door it is immediately worth around 25% less than what you paid for it and it will continually drop in value until it becomes a vintage watch. Of course gold drops in price and fluctuates but will always recover and historically will always edge up. So your luxury gold watch could be worth more in 10 years than the price you paid for it. My idea of a luxury watch is a Roger W. Smith but I know I could never afford one unless I live in a tent for my remaining years. Would'nt be much fun looking at a 110 grand watch while the rain drips on your head. Even his website ouses class.1 point

-

1 point

-

1 point

-

Well, 0.18mm is 7 thousandths of an inch so about two thicknesses of a human hair... not going to make a great difference is it?1 point

-

Are you by any chance flipping the barrel complete over to install it on the main plate, adding the barrel bridge, and observing the direction in which the arbor turns when you wind the watch? If so then don't forget that the sense of the spring will flip too so clockwise observed from above will be anti-clockwise observed from below. Just a thought....1 point

-

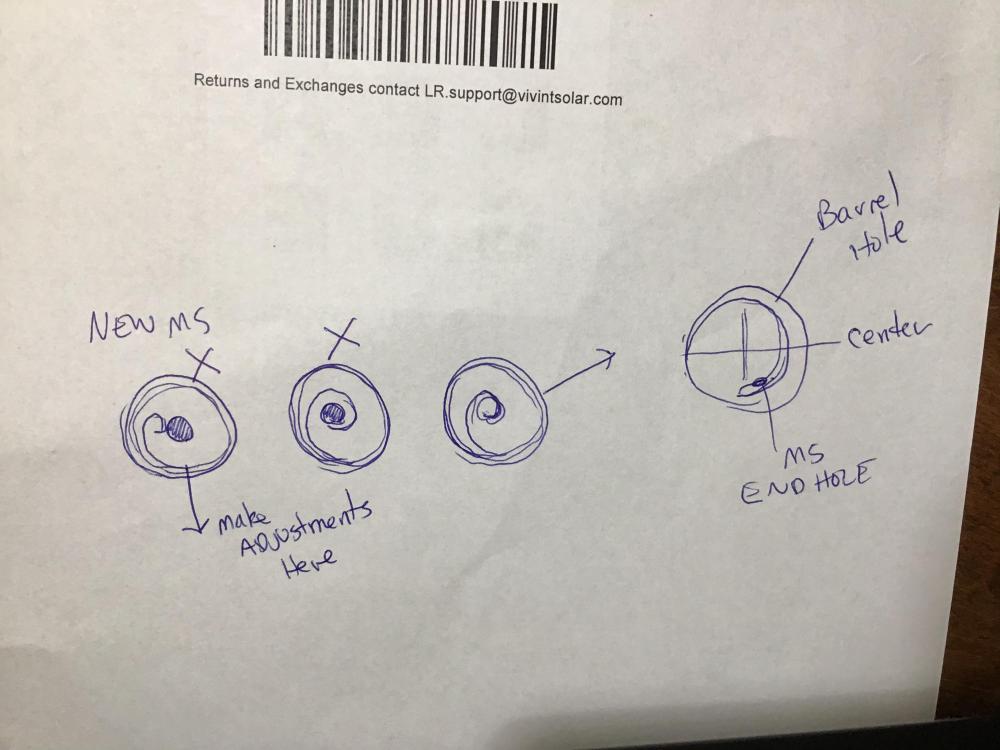

That's very helpful! Appreciate the effort to draw it out! My spring needs some adjustment then as it doesn't sit over the hole as you rightly said trying to get the Arbor hook engaged and get into its hole at the same time is what's causing my problem. I did think about manipulating the spring but didn't know if I would damage the MS. I will have a go at centering it whilst I wait for a new Arbor and spring to arrive. Thanks again for all the help, it's been invaluable!1 point

-

Glissalube 20 is 8217 and used in automatic barrels. Others forms of this grease is used for aluminum and brass barrels. The fit should be tight. If the end is not in the correct position over the hole in the barrel it could still slip no matter if it’s tight or loose. It should be positioned to where the hole end of the should be in center of the barrel slightly offset. I would love to show a pic but I don’t have any movements apart on my bench currently so I drew a makeshift diagram. As you see sometimes a new MS wont line the end up with the barrel hole so adjustments should be made prior to the end to get it centered. You are trying to hook the arbor on then trying to move it over to set it into the barrel hole which iam going guess that’s why it flew across the room. and I just realized I drew the MS backwards but you get the idea.1 point

-

1 point

-

I think you might find this helpful somebody did a walk-through and I'm attaching the parts list https://www.watchrepairtalk.com/topic/1661-omega-562-walkthrough/?tab=comments#comment-16480 369_Omega 562 NewLR.pdf1 point

-

Usually the colored ring is up that doesn't mean you can't flip it over and accidentally put it in the other way around. Some watches the mainspring actually goes in backwards and if the mainspring is generic than the colored ring would be the wrong way up. The breaking grease issue? Marks video didn't say which one he was using and yes there is a difference. Like for instance here's a video showing how to put on breaking grease. So at about three minutes in the video he's applying an interesting white grease in a very copious quantity all the way around the outer edge. The definition a copious quantity is a huge quantity all the way around the wall? Is this the correct amount yes because this is a Rolex grease. So if you were to use the more common p125 grease in the same quantity the mainspring would never slip at all it would be too sticky. So you have to use the right quantity of whichever greaser using. We've already discussed this before there's a discussion somewhere complete with pictures you can do a search and find it. ttps://youtu.be/7KNTrHVD0881 point

-

Luckily today Mark has uploaded a video about the restoration of a Seiko 6119, a very similar movment to the 6309. You can see him applying braking grease to the barrel walls here:1 point

-

1 point

-

As mentioned in many other similar threads, all Seiko balances interchanges between 7S26B/C, as well 4R36, 6R15, SII NH2x, and 3x and even the older 7S26A or 700x if you swap the balance cock. You can use my pars document to know more details https://docs.google.com/spreadsheets/d/e/2PACX-1vRN2UULQKTfKmhRStZhDdIOIQrqd6sPB-g6x2SKyQQjOvTBjG_7TQXQhAT4f1WqAX5QAPkIimi-3jqd/pubhtml People had mixed luck with the Chinese balances, which are of inferior quality. But since the original one is too expensive when for 5 pounds more you can get a brand new NH36 from AliX, that is preferred way to long lasting, sure repair that will also add manual winding and seconds hacking.1 point

-

I understand that the BHI folks must not have much sympathy for the Swiss watch industry, despite it being the main reason for the existence of watch repairers in the UK and the rest of the world since more than a century. But, that greed and monopoly are making it to enter turmoil or even decline is far from true. The Basel show is just that, a show, and won't tell us the actual numbers. Last year the swiss recorded 21.7 Billion CHF worth of export, with an yearly increase of 2.4% .https://www.fhs.swiss/eng/2020_01_28_statistics.html There have been worse and better years, but that was the tune during the past two decades as well https://www.statista.com/statistics/435009/revenue-of-the-swiss-watch-industry/ And for a general analysis of who gets the most of all that money https://watchesbysjx.com/2020/03/swiss-watch-industry-report-2020.html We will have to see how they will do post-CV19, but my feeling is that luxury did and will keep selling big, like it or not.1 point

-

This has been an issue for number of years. In this months BHI mag it reports " Baselworld in Turmoil" with a sub heading " Demise of the Baselworld show as we know it": " Swiss Watch Industry in Turmoil" For this who don't know Baselworld is, was Switzerlands oldest and largest watch fair and was the industry's 'go-to' fair for seven decades. The worlds watch makers including the leading brands would show off there latest products. But slowly but surely it has declined in 2018 the SWATCH GROUP departed, in 2019 Breitling, Seiko & Grand Seiko departed, in 2020 Citizen, Bulove, Rolex,Tudor, Patek Philippe, Chopard & Chanel also have pulled out. The reason for the collapse it appears is greed and monopoly conditions. Hotel prices increased during the fair week by 500% and visitors were forced to book for the entire week no matter how long their stay. ALSO: "Not helpful to the Swiss is their further gouging which pervades the repair/ service industry arising from restrictive spare parts policies the SWATCH GROUP and the brands. This is destroying the domain of the independent repairers around the world and opening for yet wider sorting of in-factory servicing and thus generating wider antipathy." A really interesting article but I will be in trouble if I quote word for word from the BHI mag.1 point

-

If you want some advice on what to spend your 3000 bucks on....Its very simple even in a recession....GOLD You will never lose and when the recession is over you can buy a dozen 'luxury watches'1 point

-

1 point

-

Don't think of it as math so much as relationships. F=KX is (F) Force equals (K) spring k/constant times (X) displacement. You're only really worried with how they relate to each other, not anything more precise. If you multiply numbers together, the result is bigger; if you divide them, the result is smaller. The end. Force is exactly what you think it is. Displacement is a fancy word for distance. The spring k/constant is how stiff the spring is. For watchmakers, the important part here is that we can split apart the mainspring into component parts of stiffness (*) and distance (effective length; effective, because it's typically preferred that a spring is never fully wound or unwound for better isochronism). * Stiffness in a mainspring is typically a function of its thickness, but if you have a really old coil mainspring vs a modern S spring, or an old school spring steel vs a modern alloy, or maybe the spring has set, these can all play a part. The gear ratios in a gear train are fixed. For every release of the escapement, a certain degree of rotation of the mainspring barrel is unwound from the mainspring. That makes analysis even easier, because X is constant per beat. You simply get more X with a longer spring in the form of more beats. Assuming everything else is in proper fettle, you have a finite amount of room in the mainspring barrel into which you can stuff a spring. That stuffing happens across the dimensions of length, and thickness; dimensions that correspond directly with X and K respectively. If it's too strong, the balance over banks, and you gotta problem. Additionally, but to a lesser degree, if your amplitude is higher than is required for isochronism, it's really not doing you any good, and is just a waste of spring. Too weak, and amplitude is low, and error creeps in (anisochronism). So you need a spring that is stiff enough to get you a good enough amplitude to ensure isochrony, but otherwise as long as you can to maximize power reserve. If everything else is good, then you add a new mainspring which measures .007 thicker and feels harder (aka stiffer or higher K) and is .05 shorter (lower X), that's the precise recipe, according to Hooke's law, for a good amplitude but short power reserve. You made K larger, and X smaller, you just don't know the precise magnitude of each change... You can see through your amplitude that F is larger than would be expected for a given distance of mainspring travel since, per swing of the balance, X is fixed, that means K is higher than it should be. You can further see through the short power reserve that the overall X of the spring is shortened. 312° is a really high amplitude; probably higher than just about any manufacturer requires for isochronistic reasons... On top of that, It sounds like Citizen kinda sucks for documentation, but they seem to be in the same school as Seiko who is good with documentation, and is known for preferring unusually low amplitudes while still achieving reasonable isochronism. Given that the point of a high amplitude is to mitigate anisochrony, they're going at the isochronism problem from a different angle (whatever that is, I don't know yet). I would shoot for a typical Seiko level amplitude, see how the power reserve comes out, then check isochronism against your preferred/available of spec or personal standard. This has nothing to do with braking grease, internal barrel features, bridle wear, or anything else. Just the isolated variables as described. Also worth noting, this is how Roger Smith (George Daniels' protegé) chooses mainsprings for his highly esteemed movements according to... him in his own lectures**. Also also worth noting... I'm about as nooby a noob that ever noobed, so consider the entire manifesto above in that light. Bottom line: Get a new mainspring that's thinner and longer. Since the alloy appears to be different, you may go more than a single step thinner, and see how long you can go and still functionally fit in the barrel. This, again, is inferred from the Roger Smith lecture, and he specifically states that he has a huge assortment of mainsprings at his disposal**, so YMMV. **I think this is the lecture, but it's not exactly the key focus, and was really just a side note at some point... I don't remember where in the hour and change it came up or why, I'm just one of those people who remembers trivial details like that...1 point

-

1 point

-

1 point

-

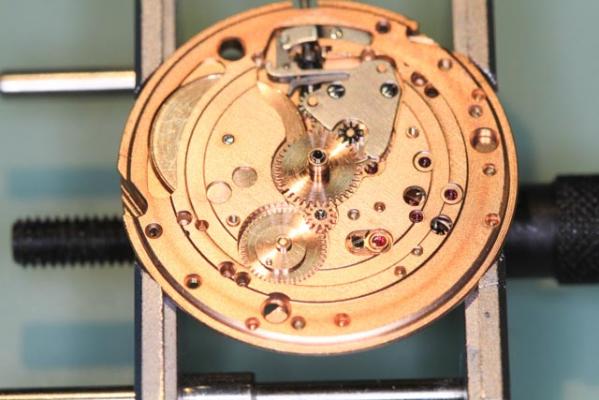

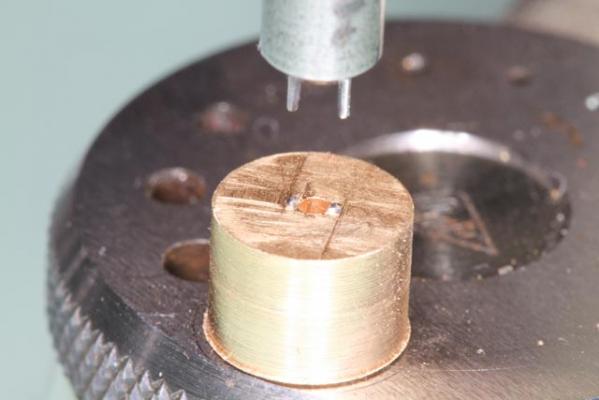

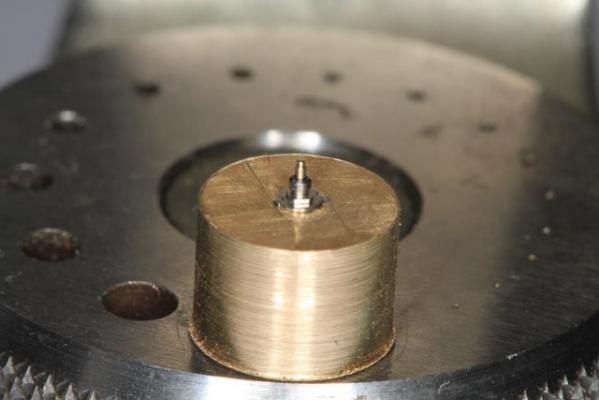

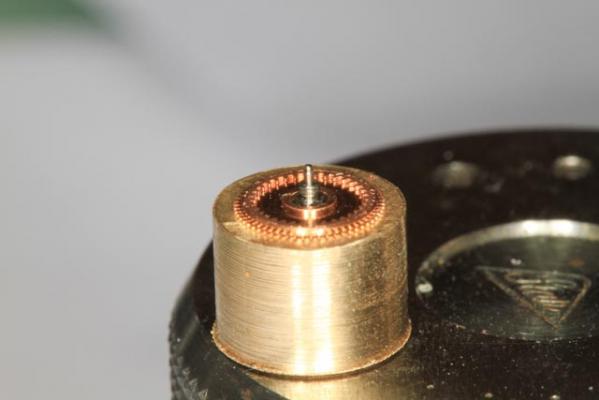

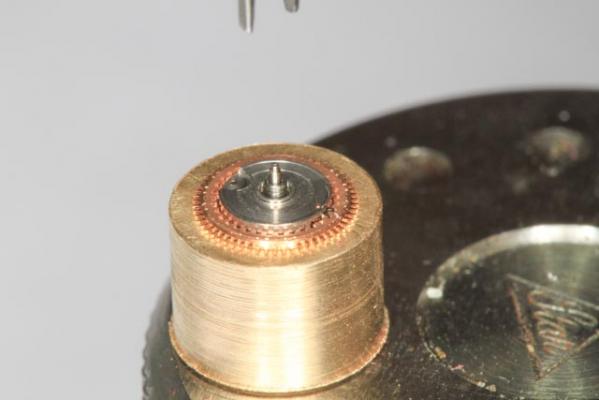

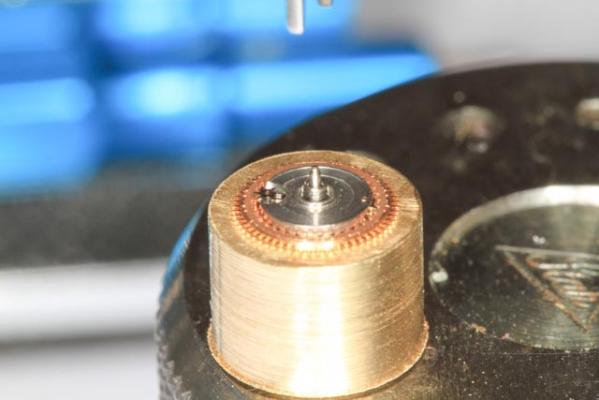

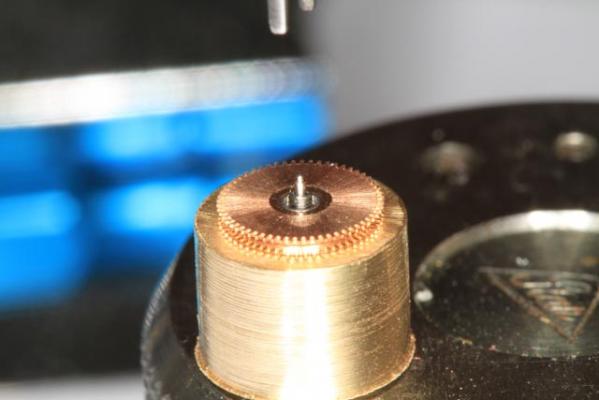

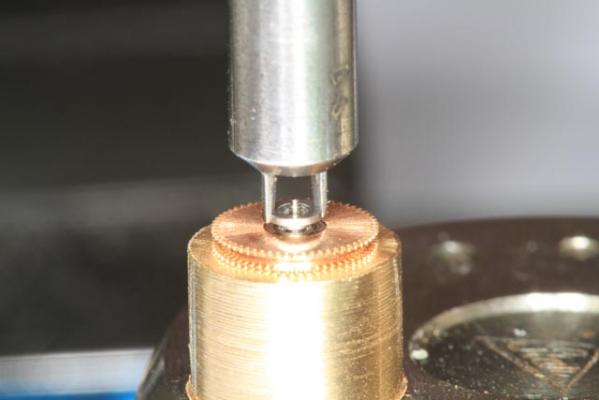

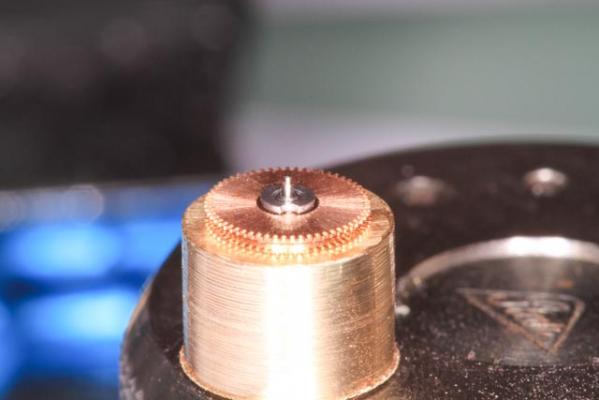

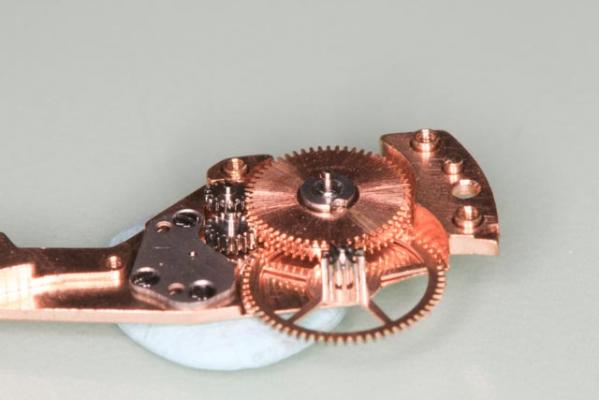

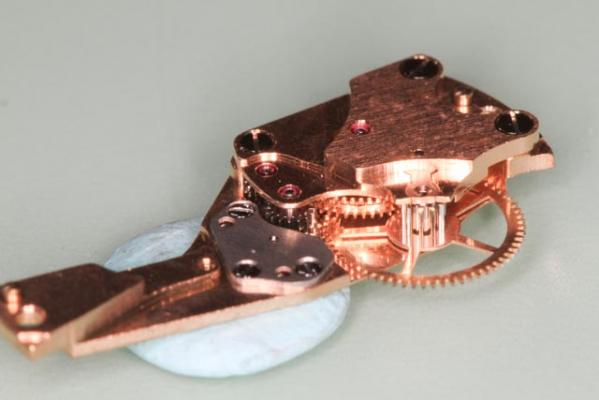

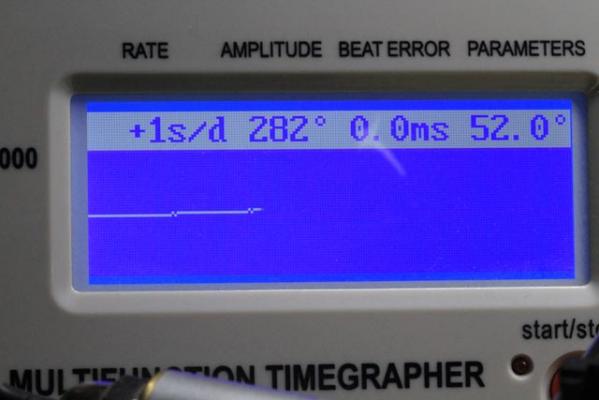

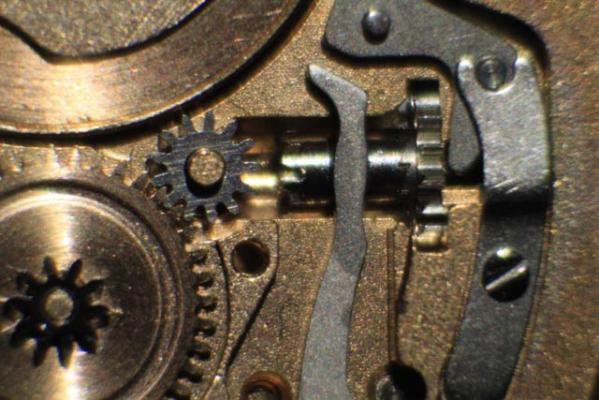

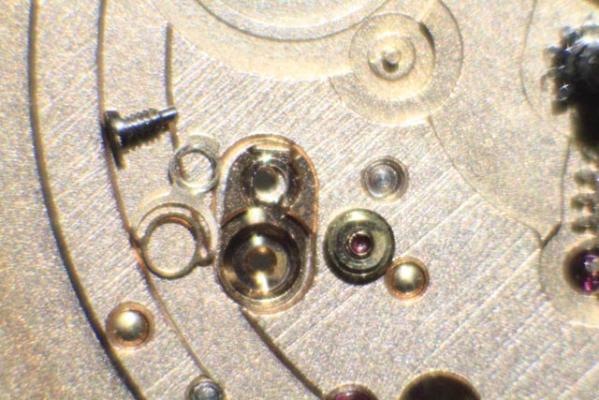

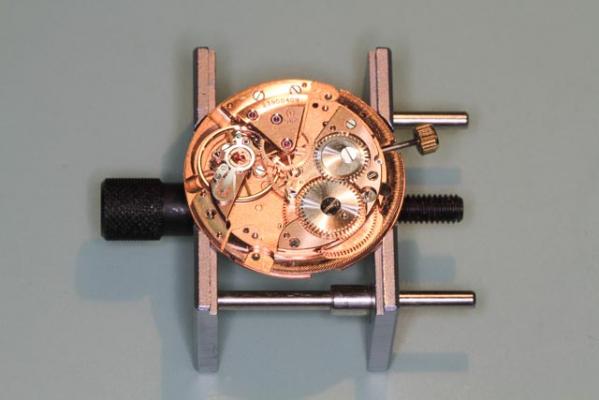

Here's a quick walkthrough of an Omega cal 562 I've just finished. Prior to the photos, I've stripped the movement down and cleaned it, experimentally, in Zippo fluid in an ultrasonic bath, which seems to be extremely effective and quick. I don't have a watch cleaning machine. Comments and criticism most welcome. First, I lubricate the barrel wall with braking grease 8213, and I add a dab of 8200 on the spring itself (not sure if I need to or not) Fit the barrel bridge and centre wheel. Lubricated with HP1300 Adding the train wheels - these are fiddly (i think because the jewels are all olives) Fit the train bridge. Lubricated with 9020 Fit the centre-seconds spring. I lubricated the seconds arbor with a tiny dab of 9020. I left the spring dry (vaguely remember reading that somewhere) Separate the ratchet from the manual winding wheel to lubricate it (HP1300) ...and reassemble Winding gear all back in place. Rodico will clean this up... Pallet fork in place. Strictly no lube! Tiny dots of 9415 on the pallet jewel faces, and worked the escapement round until there was reasonable coverage. Fitting the keyless work. 1300 on the wheel arbors, 9501 grease on the yoke and castle pinion Disassemble the lower incabloc setting. Lubricated with 9100. Train all together And running quite nicely Time to fit the motion work and the date-setting stuff. Completely forgot to take any photos! Now the fun begins. Assembling and disassembling the reversing gear isn't trivial. I made a tool that sits in my staking tool to screw it all back together. Here are the components of the reversing gear ready for reassembly I sit the winding pinion on my homemade tool: Then add the superior winding wheel (tiny dot of 9020 in the hole) Fit the superior satellite pinion to the winding wheel core. A dot of 9020 keeps it in place... ..when you sit it in the winding wheel Then add the inferior satellite pinion (their name for it, not mine) And place the inferior winding wheel over the top Then screw the inferior nut onto the winding pinion using another home-made tool: ...and we're done. Putting it all together on the automatic bridge Lubricated with 9020 And fit the whole lot to the watch. The instructions tell me to dip the rotor gib in a piece of elder pith moistened with oil (9020 again) Finally, fit in to the case. This takes several attempts since every time I attached the case clamps, a new hair or dust spec would magically appear behind the glass. Job done. Hope that was informative.1 point