Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/20 in all areas

-

3 points

-

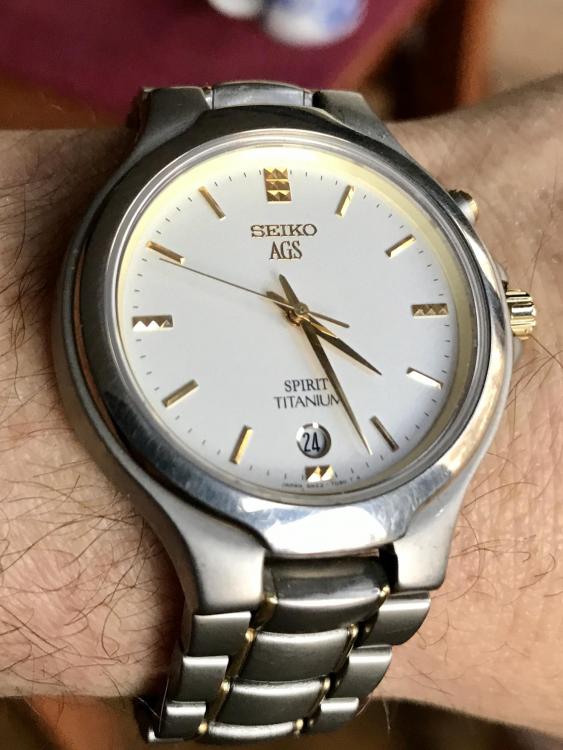

I have replaced the capacitor in this JDM Seiko AGS Spirit Titanium (5M22 movement). This is a one piece case, so the bezel has to come off to get to the movement. The bezel gasket was a bit hard to get back in (ordered two new ones and ruined one), but it all went in on the second attempt (using a drill press. Yes, I am a newb and do not own a crystal press. But I have other tools and am resourceful). Here it is. I really like this watch. It's very well made, the titanium case and band make super-light and very comfortable watch. The crystal is most likely sapphire, though it does not say so on the back. I did look up the Seiko catalog and it calls for sapphire replacement part. Also, for a watch this old (from the early-mid 90's) the crystal is literally pristine. No scuffs or scratches. Very high quality piece that I am really enjoying right now. The new style capacitors (LiOn batteries, really) allow about a 4 month reserve on these. I am very happy with the purchase and the "service" I gave it. Before serivice b After service3 points

-

2 points

-

2 points

-

2 points

-

1 point

-

1 point

-

Maybe it's the tiny sliver of metal I see at the 2'o clock position on the crown wheel? Try pushing it clear of the teeth?1 point

-

I’m so sorry to hear of this. I to lost my cat Cookie just over two weeks ago she was 23. I know what you are going through and it is horrible. I really feel for you, I really do. One thing that helps me is I keep talking to her as if she is still with me, I tell myself she is still here I just can’t see her.1 point

-

1 point

-

Hello A few years ago I had this setup for quartz watches build on the lines of the seiko test set It enables you to drive the watch from an external source, test the upper and lower voltage limits and also current consumption. the black box was connected to the meter and the readings taken. One could also test batteries and drive watches using the 3v coin cells. The circuit was designed by officers of the AWCI i think as it is quite a while ago.1 point

-

You can close the opening in the roller table with a dome stake. Sent from my iPhone using Tapatalk Pro1 point

-

Still four grades for ETA, as well Sellita and Soprod. But the full details of what exactly changes are confidential, as well the price difference.1 point

-

Good point. Hate to hang out with that bunch. I've decided a plain ceramic bezel and domed sapphire would do better.1 point

-

1 point

-

1 point

-

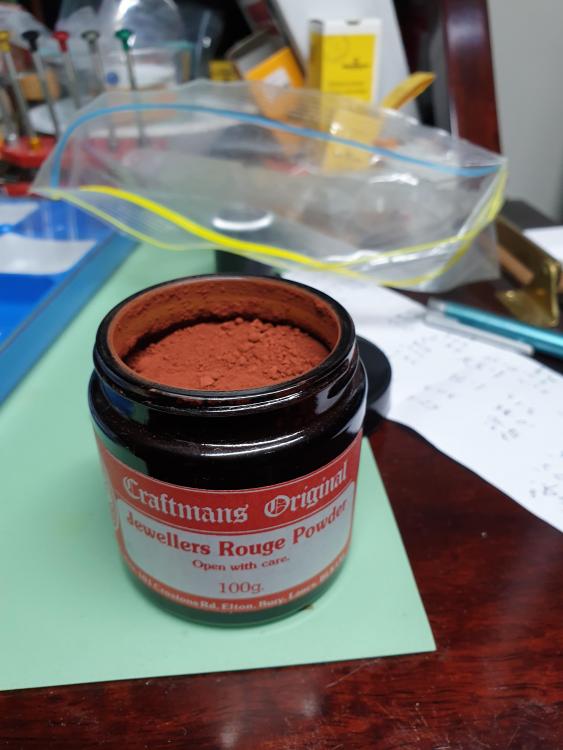

https://www.ebay.co.uk/sch/i.html?_from=R40&_sacat=0&_nkw=jewelers+rouge&_sop=15 It comes in many varieties, and many forms. Fundamentally it is rust (or to be more precise iron III oxide), often suspended in wax or other soft medium, or simply in graded powder from. It has been used for centuries to polish precious metals as it is a relatively soft abrasive. https://en.wikipedia.org/wiki/Iron(III)_oxide The term "jewelers rouge" is also sometimes used in a more generic form, to indicate any form of jewelers polishing compound, so I've seen people referring to "green rouge" polishing compound etc.1 point

-

A good watch cleaning machine will clean all parts of the watch including pivots and the holes in which they fit. If a pivot is worn the wheel should be replaced, if a replacement can’t be found, then the pivot should be repaired, ending with burnishing.1 point

-

Agreed, if you put any form of abrasive anywhere, then you need to give the part a good clean afterwards, otherwise you are almost certainly going to increase wear on the part or whatever it mates with, due to any fine particles of abrasive that remain. Cousins do the pin polishing sticks... https://www.cousinsuk.com/product/pin-polishers-eveflex .. as no doubt do a lot of jewelry supply companies, and of course ebay... https://www.ebay.co.uk/sch/i.html?_odkw=pin+polish+abrasive+silicone&_sop=15&_osacat=0&_from=R40&_trksid=m570.l1313&_nkw=pin+polishers+abrasive+silicone&_sacat=01 point

-

Just to make a distinction, this is not pivot polishing, this is pivot cleaning, there is a big difference. If the pivot is just dirty this might be ok, but not if it has wear or worse rust spots. It can not restore a barrelled or tapered pivot back to straight, for this you need a Jacot tool or something similar and pivot files / sapphire burnisher and or steel burnisher. For dirty pivots that cleaning fluid alone cant clean I personally use pegwood with a bit of jewelers rouge with oil mixed in on my Jacot tool. This will remove dirt and oxidation but no good steel. The fine grain rubber is still only 800 which in watch making terms is still very course, and if you don't clean it off completely could lead to premature wear on the jewels and pivots. I certainly looks like a quick short cut but there is a reason why you don't see this taught anywhere or in any books.1 point

-

1 point

-

Perhaps you did, but I haven't read it. Things changed after you installed the modified cannon-pinion. I guess first thing to do is to pull it again and re-checked the amplitude ? Perhaps the intermediate keyless wheels are running heavy, causing the pinion to slip in the first place. Now with the pinion tightened, you see the (power-drain) effects ? I'm sure you did .....1 point

-

I would definitely recommend pegging at least the pallet fork jewels (the hole jewels). They can look clean but still be manky, and it doesn't take much at all there to zap power. I doubt the mainspring is the source of your problem. Especially if it is a modern one. Yes the barrel should have shake on its arbor, there was a thread on that in the last week or so. 10 turns of the crown should equate to at least 1 or more turns of the barrel arbor; this should run the watch for hours, not seconds. You have a power loss somewhere in the train. If the train runs free with the fork out and just one or two clicks of wind, then you have an issue at the fork, could be the adjustment of the locks but more likely something in the jewels or on the pivots or lack of endshake.1 point

-

Today I'm wearing my Bulova accutron "hummer" This was my second electronic watch. I bought it as a bare movement, then got a case and dial combo. It's a pretty finicky movement. It will randomly stop for no apparent reason. I have to tap on the case at the 2 o'clock position several times to Kickstart the tuning fork. I'd love to get it serviced and properly tuned, but there are so few people who work on these and my finances won't allow it, so I just deal with these quirks. I certainly am not a confident enough watchmaker to tackle one of these myself.1 point

-

Technically no. "Chronometer" refers to the certification. The most you're able to upgrade to with parts swaps would be top grade. In order for it to be "chronometer" you'd have to submit it for certification. That is not to say a movement of any grade can't be made as accurate as a "chronometer"-rated movement, it just has to be tested and serialized by COSC for it to become "chronometer."1 point

-

This may be of interest to those of you with an electronics background. Even those of you who don't count yourselves as Geeky may simply enjoy the stuff about using PCB techniques to produce dial. I picked up the story from this Hackaday article. https://hackaday.com/2020/02/26/openchronograph-lets-you-roll-your-own-smart-watch/ The author's github page is here. https://github.com/snietfeld/OpenChronograph ... and the PCB dial stuff is here. https://github.com/snietfeld/OpenChronograph/tree/master/Dials1 point

-

At this point I suggest to record the noise in different positions. For that it would be expedient to build the simple adapter detailed in the latest postings of the topic below. Then you, or others here, can analyze it aurally and graphysically. That will reveal is anything is rubbing, very useful in strange cases, and an important feature of the best timegraphers.1 point

-

That hairspring looks great, good job! As for the amplitude (and stopping in 30 seconds?), I suppose you've checked all the usual things, train freedom, endshakes everywhere, peg your holes especially for the fork pivots, check that the barrel has shake on its arbor and the lid is well seated.1 point

-

I also made a video on replacing a roller jewel. Sent from my iPhone using Tapatalk Pro1 point

-

It's almost a guarantee it's the capacitor. Just like a battery, they have a finite lifespan. This is the drawback to these kinetics and the citizen eco-drive. Be sure to get the exact one it calls for, they are very specific and won't work otherwise.1 point

-

Always interesting problems with old American pocket watches. Roller jewel's can fall out the entire roller table cannot. This means somebody's worked on this watch prior to you and left pieces missing. Unlike modern watches finding replacement parts is problematic. I have a website below you can find a parts list but you'll notice even for the roller jewel a reference that the size varied. Even if you had a roller table with the jewel it might not even fit. A balance complete would be a better option but you're going to have to adjust the escapement to fit the new balance because the sizes will be a little different. Even though these are mass made watches they were still hands adjusted and had variations in size throughout their production. http://www.elginwatchparts.com/1 point

-

I see the pic now, just opened. Missing the roller too. Lucky you are in the US, not many were marketted in my neck of the woods.1 point

-

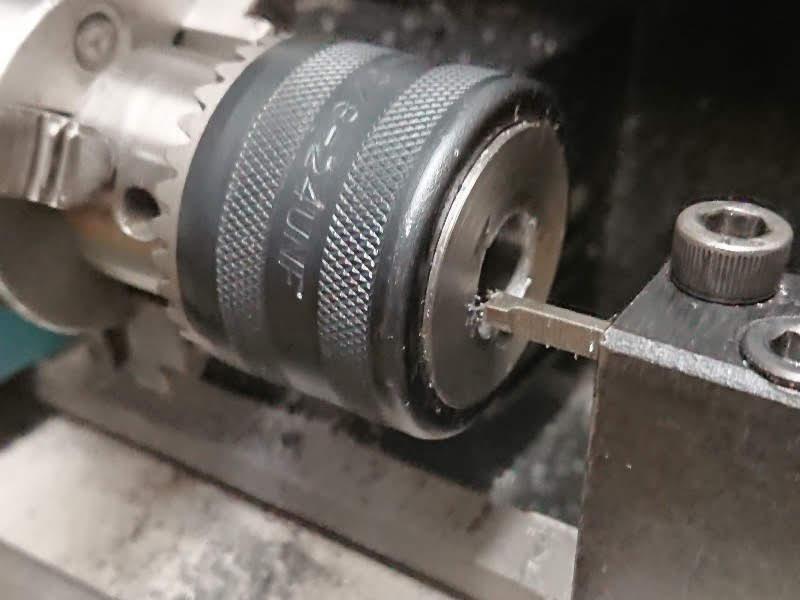

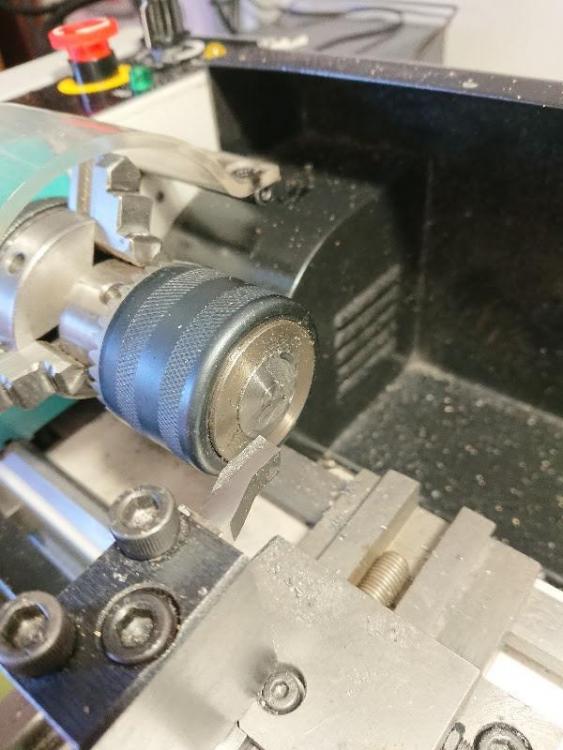

So far I don't have a tailstock chuck. The original one is stupid expensive and only 6mm max. So I got a cheap 13mm one and tried to re-thread to M14x1. The first attempt came so much off center and crooked that I was ashamed to post about it. I could not throw away such a valuable part, so put it on the the lathe securing it with a 10mm threaded rod through the spindle, to a female threading section in the drill chuck I bored the mounting hole to 19.5mm, turned a matching plug, pressed it in and gave it a first facing. The friction fit was perfect but being the plug not tapered I wanted to stay on the safe side, so drilled 3mm centered on the edge of the edge, and pressed in matching pin. I felt like having invented the steam engine in doing that. To avoid repeating my earlier mistake I decided to bore not just drill the hole. That involved a short fight to replace the press drill chuck with a shorter one, drill 12.5mm then move again to the lathe At this point I ran out of time, I'm a very very slow machinist.1 point

-

As Nucejoe said replacing it requires some shellac and a new roller jewel, thats the simple bit fitting it in the right position is another matter. It has to be vertical and in the correct location to drive the pallet. Therefor the suggestion of a new roller with jewel is the practical solution and will cause you less grief. cheers1 point

-

I have used these with a drop of epoxy and these feet were very successful. My technique was to put the feet into the movement, for a couple trial runs of setting the face in place on the movement resting on the feet pads. In my case I used a small O-ring around the Cannon pinion output that the dial hole would center on. I would then put a drop of epoxy on each pad and lower the dial into place, centered around the pinion o-ring. I should note that I put a thin layer of cellophane (saran wrap) down over the movement pressing the feet through it so that there was no chance of epoxy squeezing out onto the movement. Having an engineering background I understand sheer force, and there's a lot of surface between these pads and dial-back, providing more than enough strength to hold the dial for many years (providing the epoxy does not give out). Not as good as welding but second-best and I was very happy with the outcome.1 point

-

1 point

-

Model M63 then with the M40 style movement but with a small circuit board, with discrete components mounted on the side? Early one like this, with the rheostat trimmer...... Or the later type with the variable condenser trimmer?1 point

-

Before you judge me hear me out. I saw that that Marlon Brandos GMT from "Apocalypse Now" recently sold. I though it was a very cool moded watch. It was modified to look like a military field watch. With Rolex's roots being in robustness and heavy active use this seemed like a cool idea. The watch had the bezel removed and a non metal band. Definetly looked like it was a tool more than a fashion accessory. I wanted to make one like that for fun, but of course wasn't going to trash a real one. So I am looking for a high end replica GMT or regular Sub to do this to. I plan to remove the bezel, put a leather or fabric band on it then scratch the stainless case and fill the scratches with grease or paint to make it look like it has seen some action. Wearing it I won't feel like too much of a poser because most people won't think it's anything other than an old beat up watch. Those that do notice that it is a Rolex I will explain about it as I did above. So definitely not a fake status symbol. I know there are some replicas out there that are almost indistinguishable from a real one both internally and externally that go for over $1,000. i don' t need one of those. It has to be made of good rugged external components so I can really beat it up. I imagine this can be found in the $250 range. Thanks, Adam0 points