Leaderboard

Popular Content

Showing content with the highest reputation on 07/23/19 in all areas

-

Today this package from sweeden came in mail, containing 11blacd escapement wheel, donor @rogart63 . Following fourteen years of in to do box I will hopefuly bring my bulova snorkel back to life and soon, I will post a picture of it on watch of today thread. Thank you Rogart63 for this gift, very precious to me. In appreciation of your generosity and in your name, I make sure to pass on three winding stems to the novices and three balance staffs to experienced learners. I have no problem shipping small parts.5 points

-

Before - and - After 107 Timex Automatic. This model orginated with a 31 automatic and was later made with the update 107. This watch insored designer Todd Synder to create a monern version. Actually quite a nice homage but saddly only a quartz https://www.toddsnyder.com/pages/the-military-watch-by-todd-snyder-timex2 points

-

1 point

-

If i have the parts i am willing to share. I can't use them in a lifetime. And lots of the movements are in bad shape .But some parts look fine. Could be hard to sell if i can't guarantee they are 100% perfect either. So as we all tinker with watches in here and can inspect the parts i send. It's nice to help out . Some other time it's maybe me that is searching for some hard to find part.1 point

-

What a nice gesture rogart63Its things like this on this wonderful forum that make the place it is.1 point

-

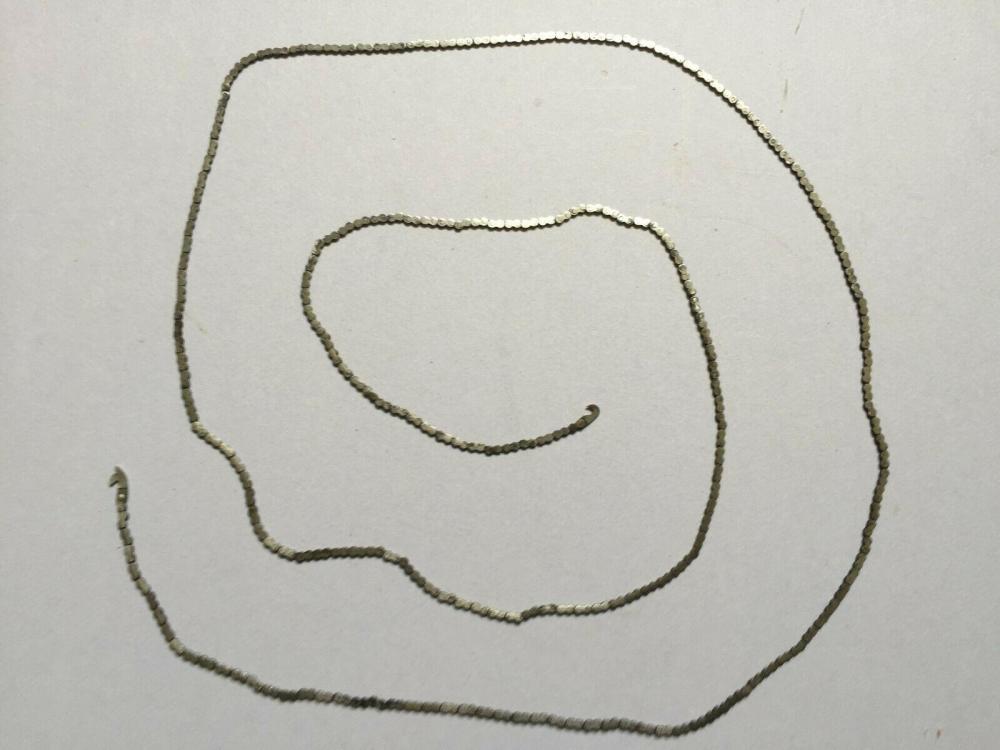

When you say flips off the barrel. Do you mean the chain unhooks from the barrel. If so make sure you have the correct end of the chain attached to the barrel. Is the hook seated down on the barrel and is well hooked in the hole. Is the hole worn or even the end of the chain worn. The chain must be in line with each wind to the fusee line so it sits in. When the watch has run right down you shouldn’t be able to move the chain on the barrel, if so it needs you need to wind it up more by releasing the ratchet wheel, give it a few clicks and test. Fusee chain. Outside hook fits the barrel inside hook fits the fusee cone.1 point

-

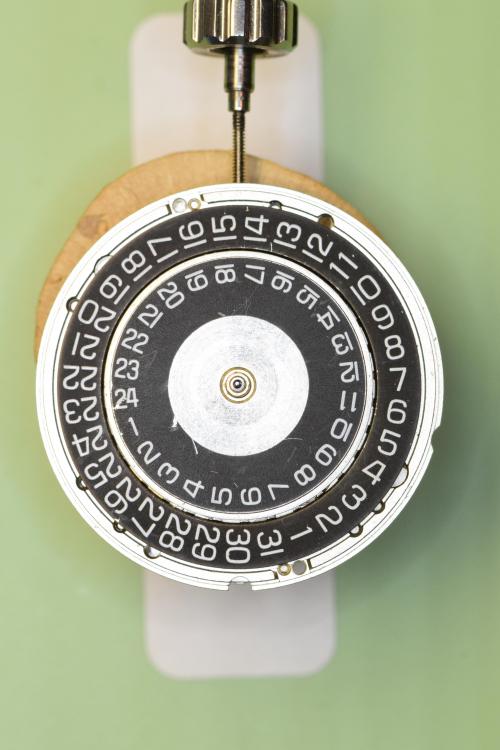

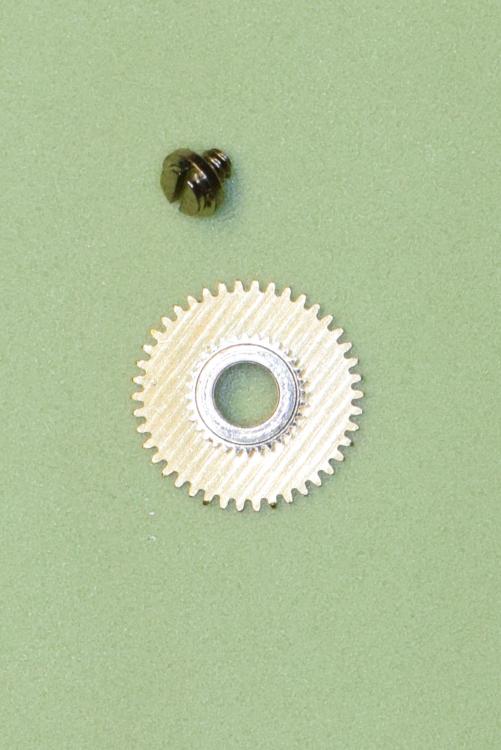

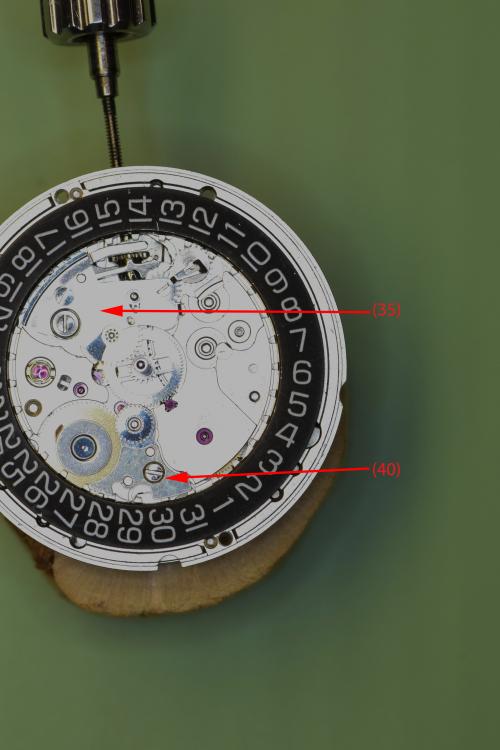

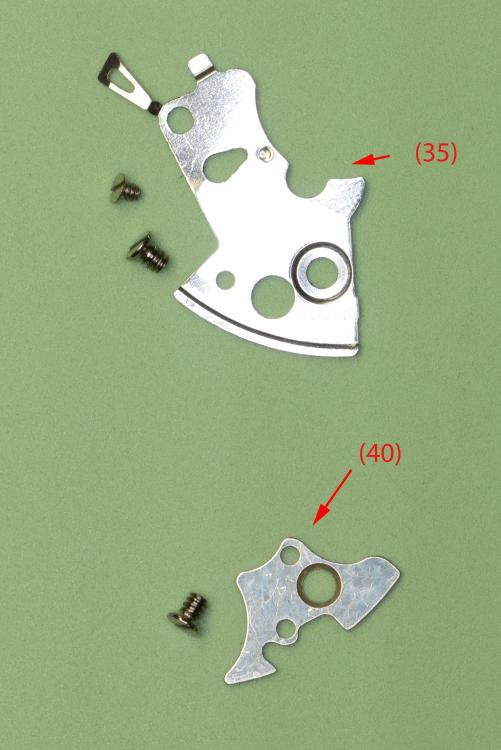

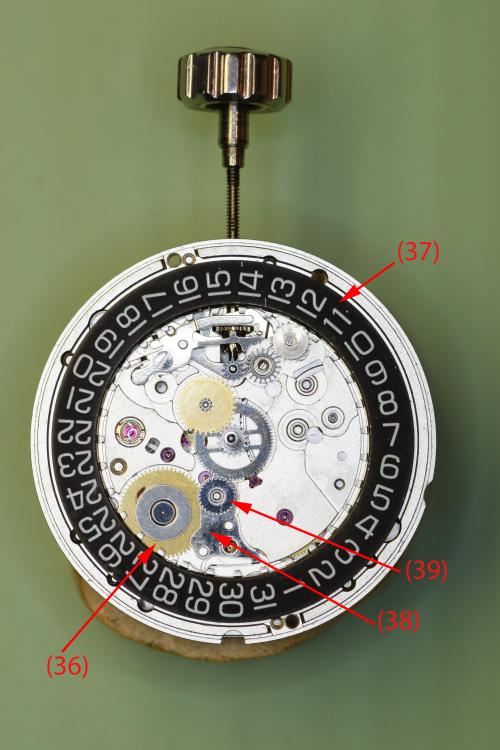

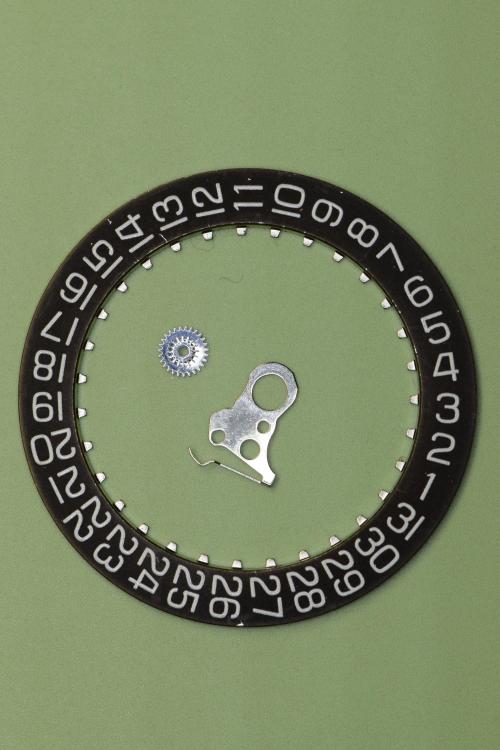

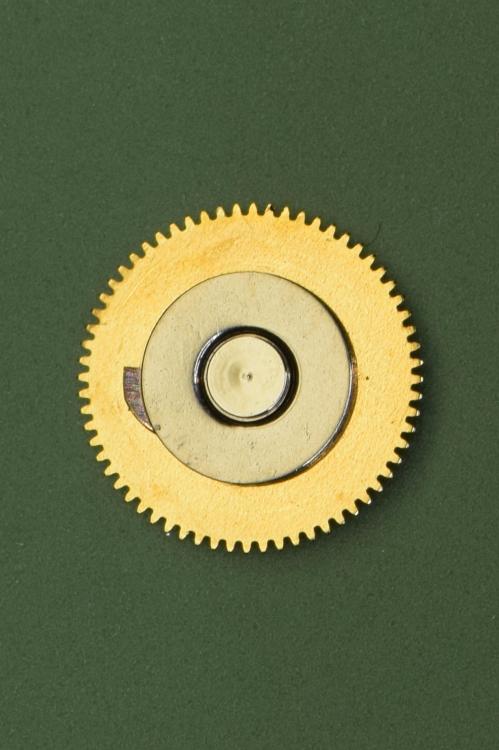

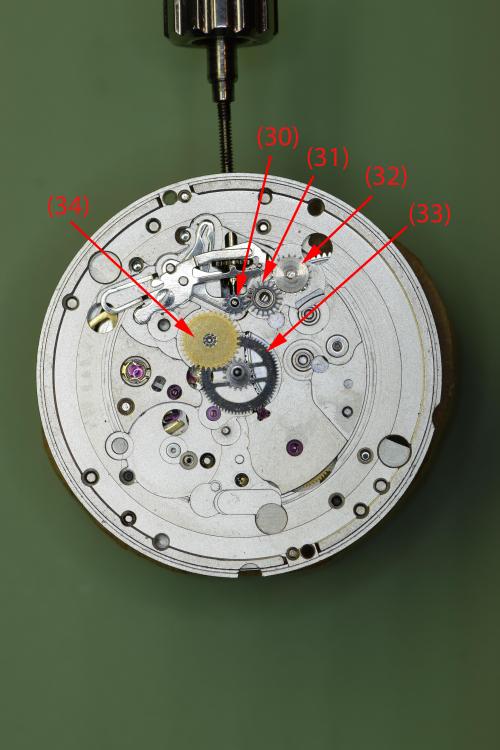

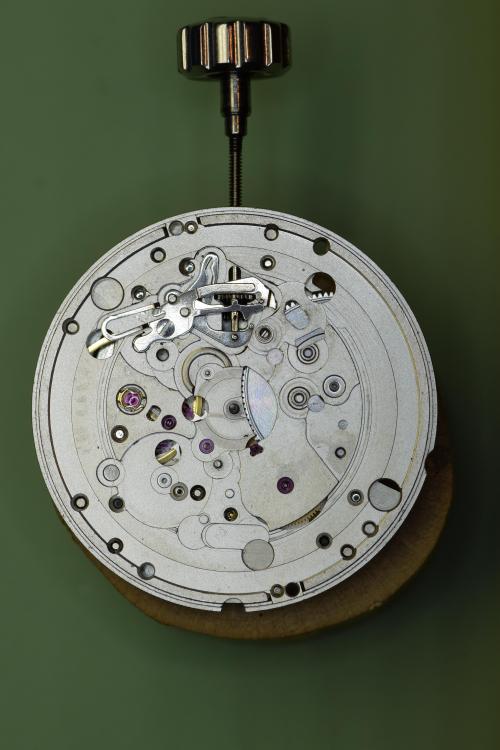

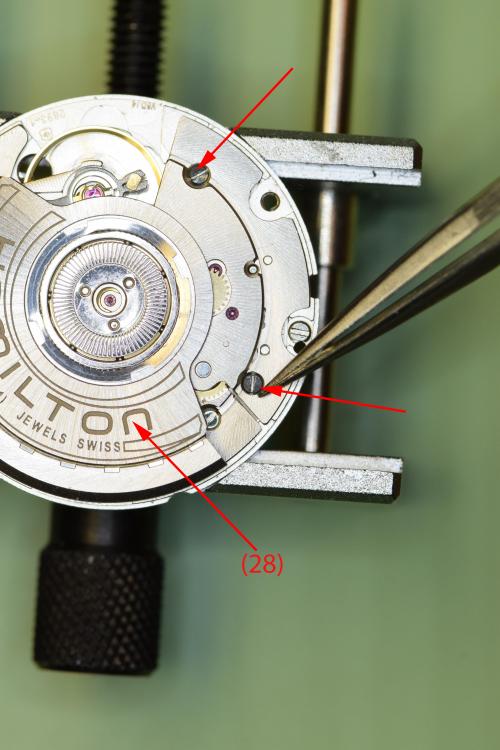

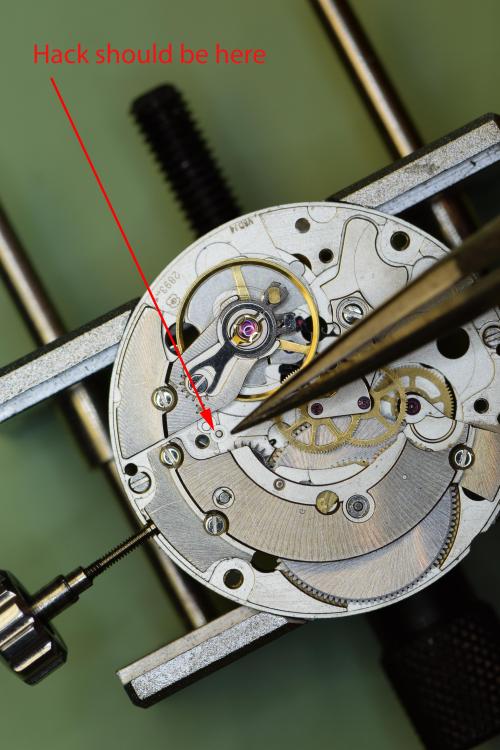

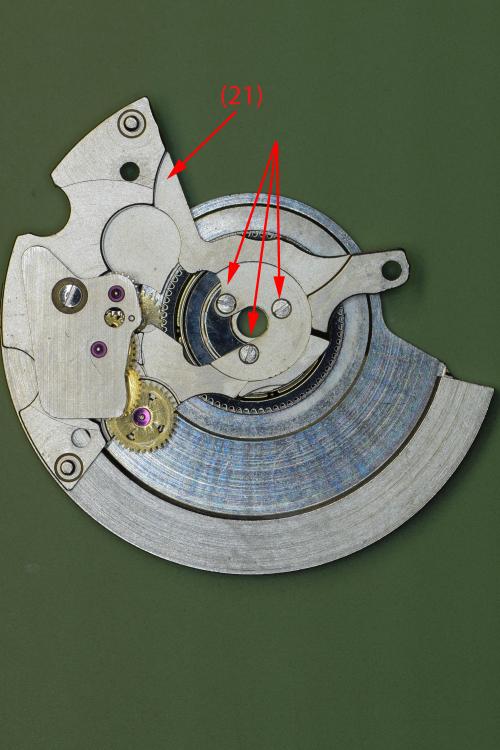

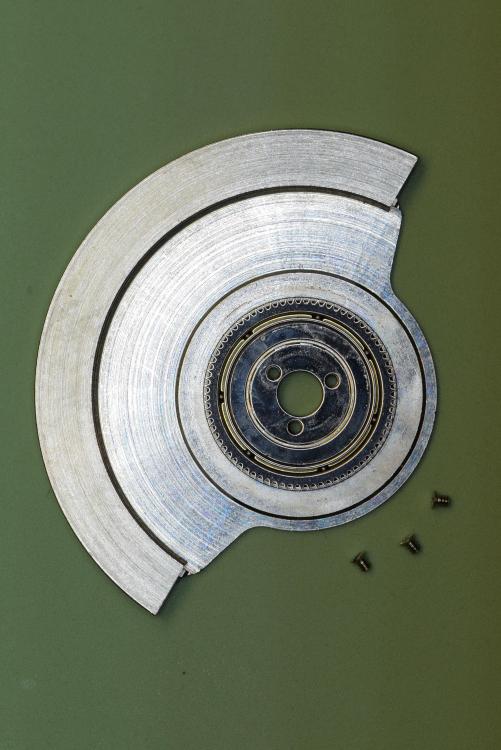

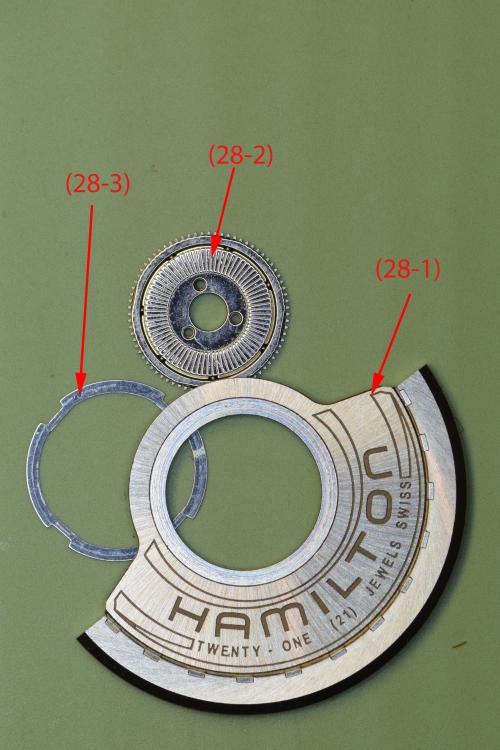

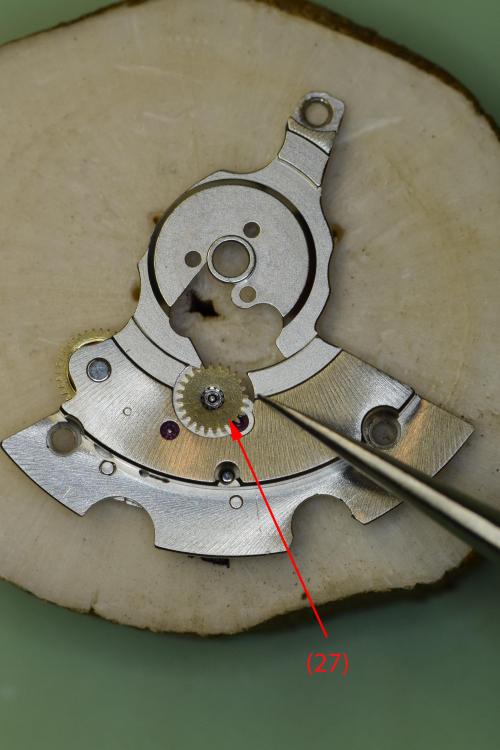

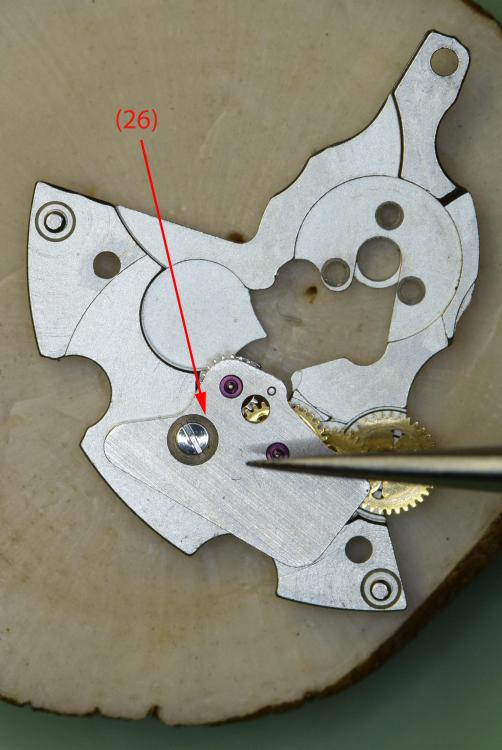

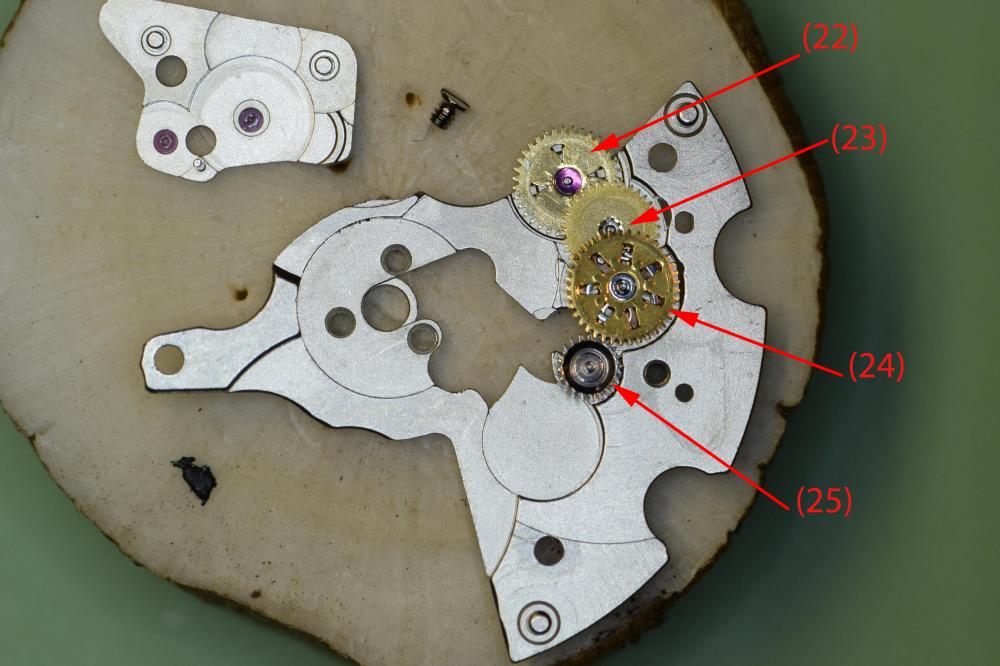

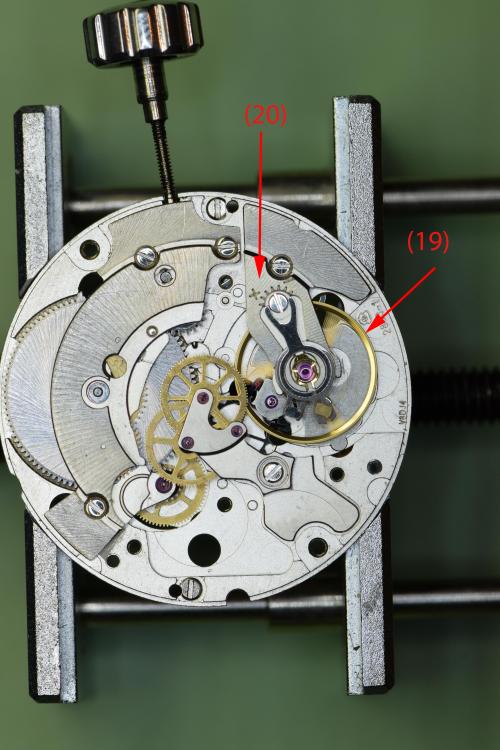

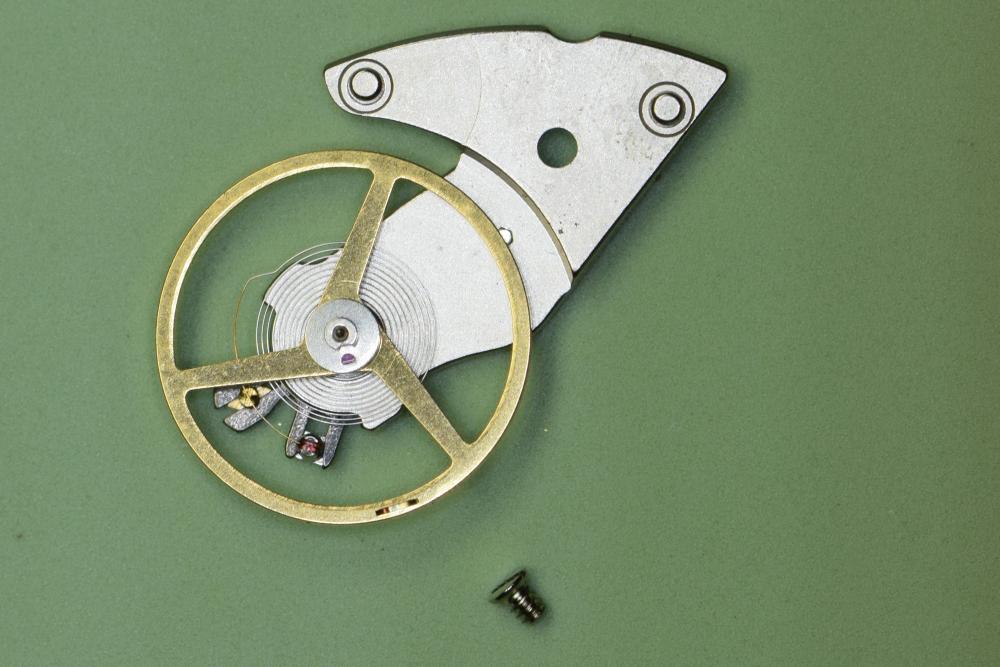

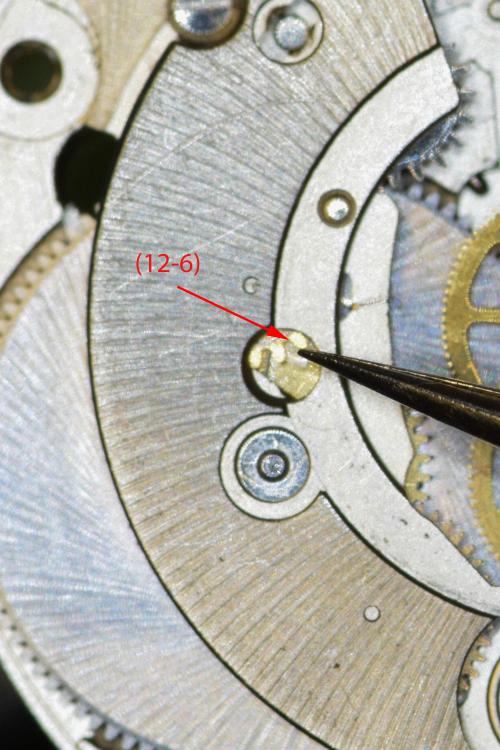

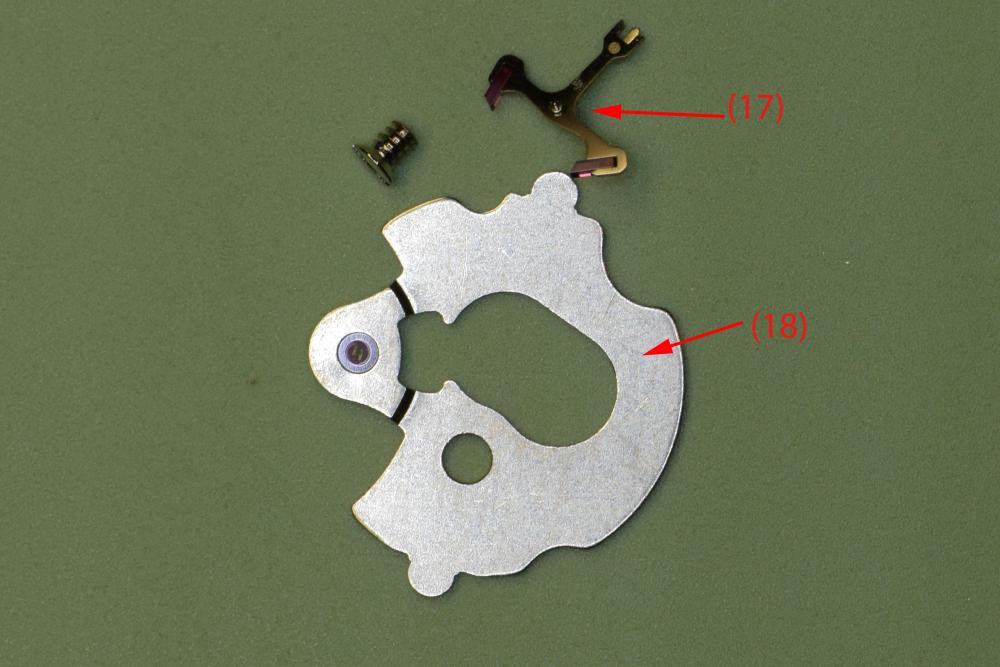

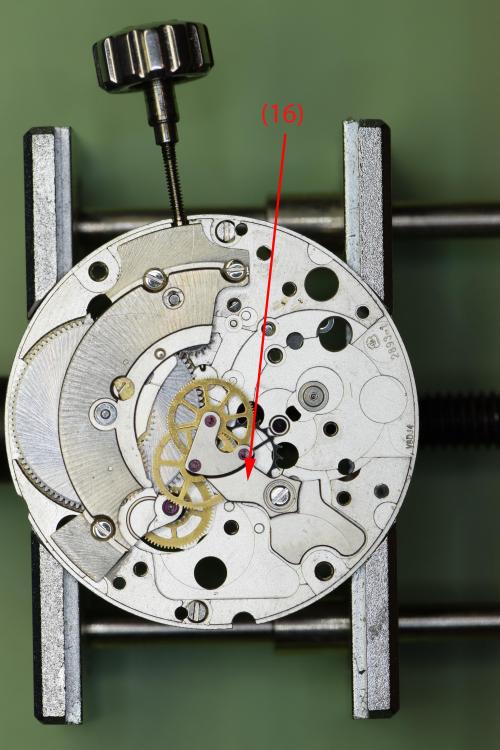

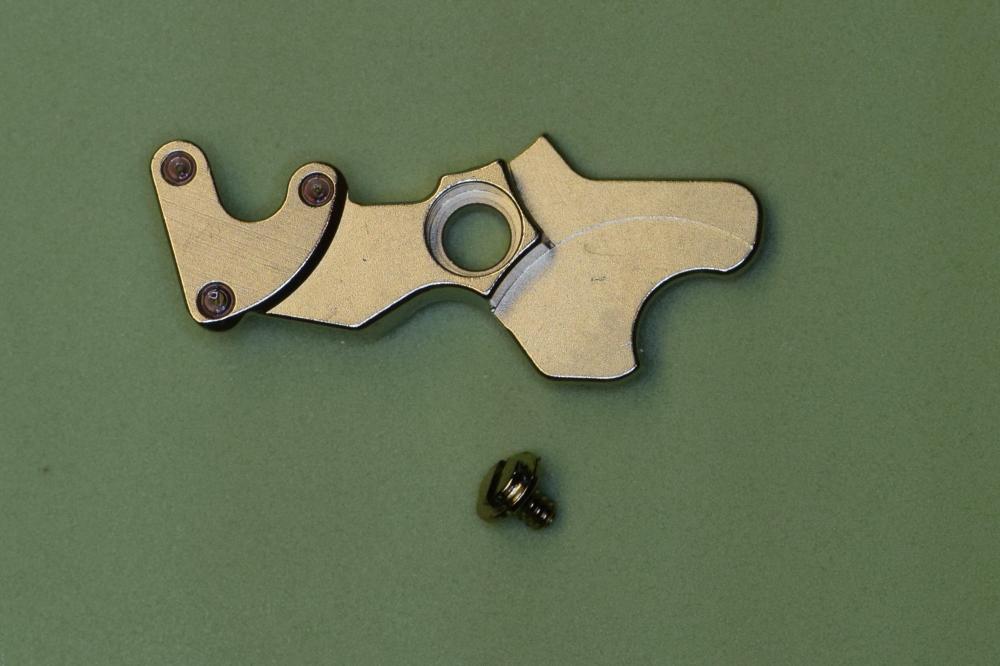

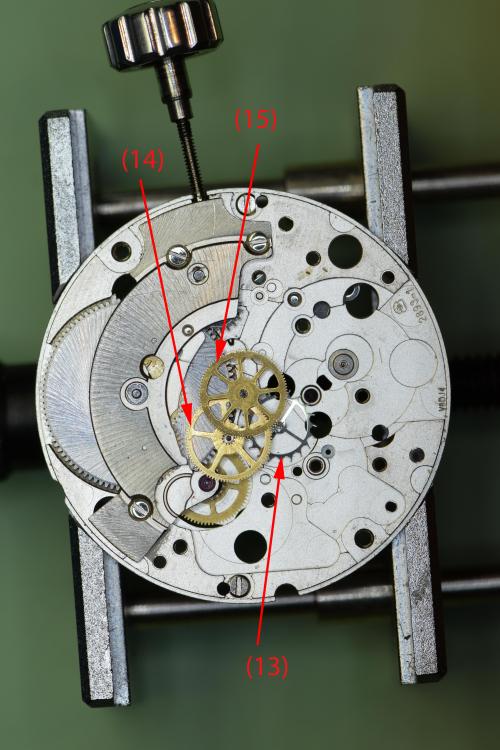

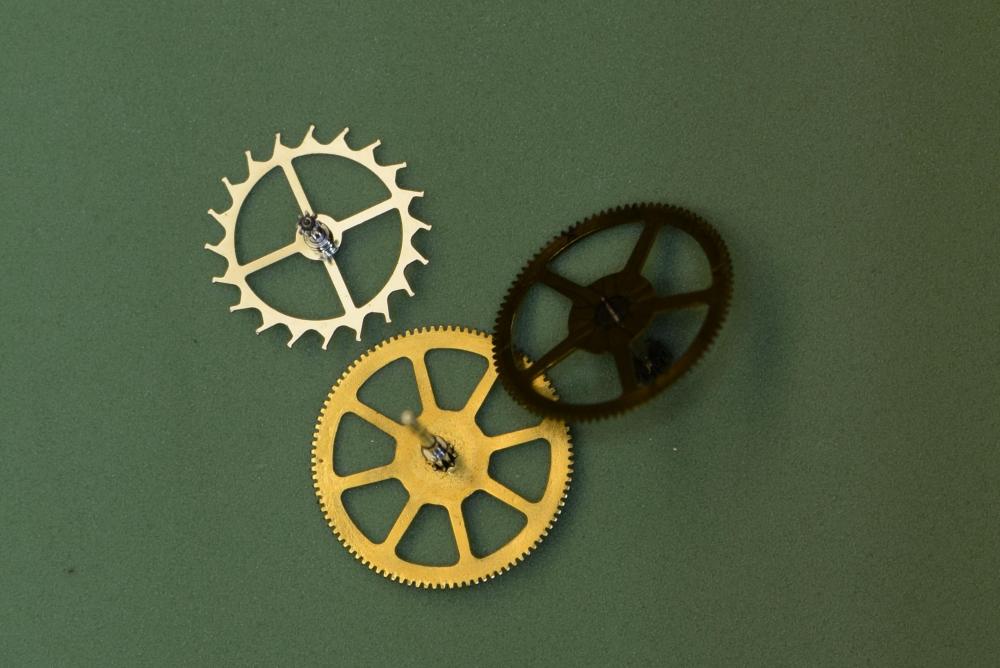

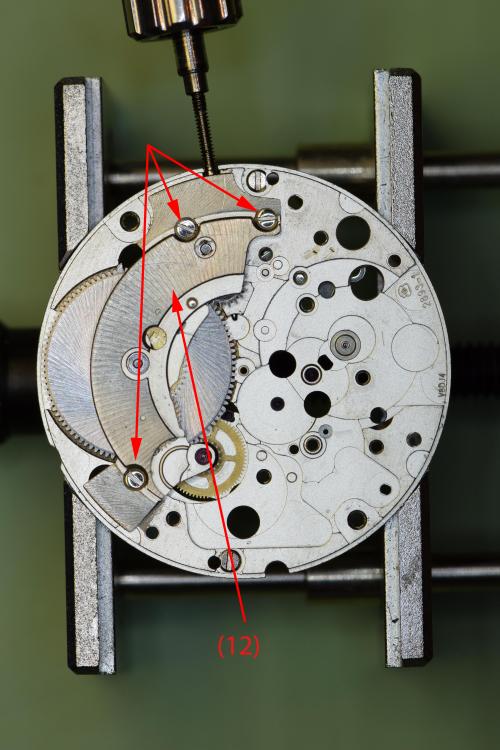

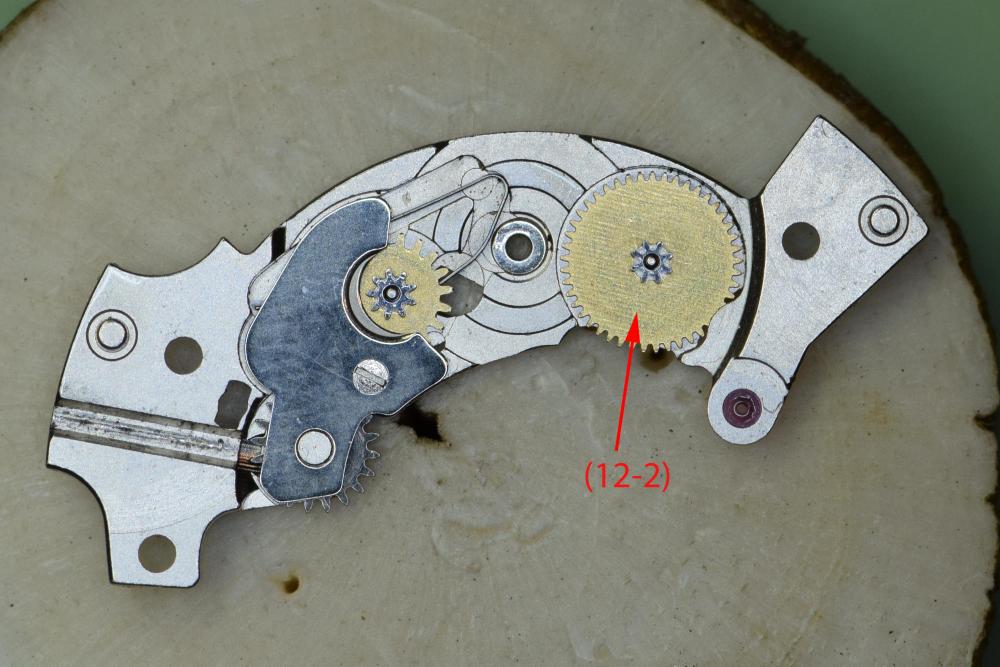

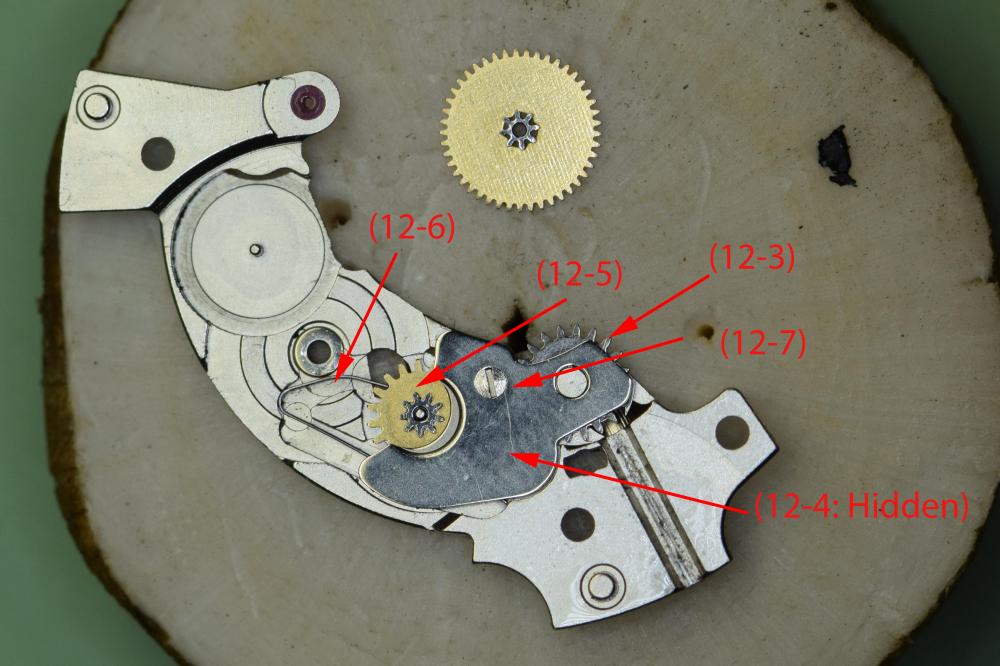

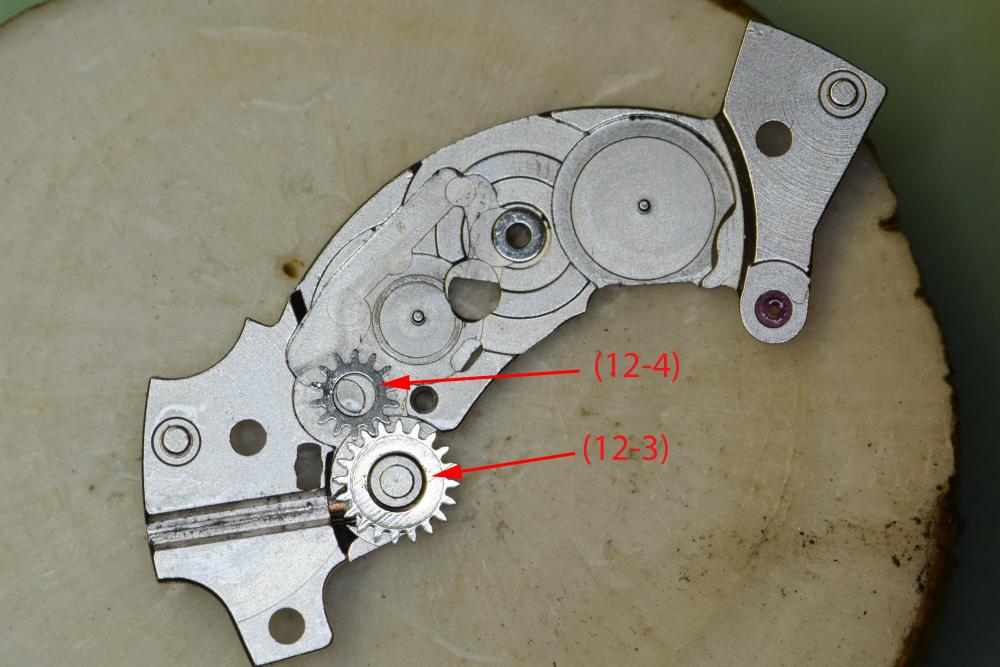

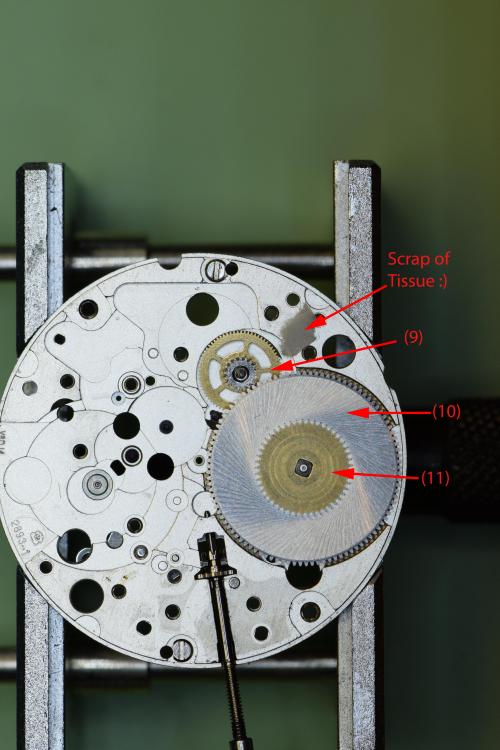

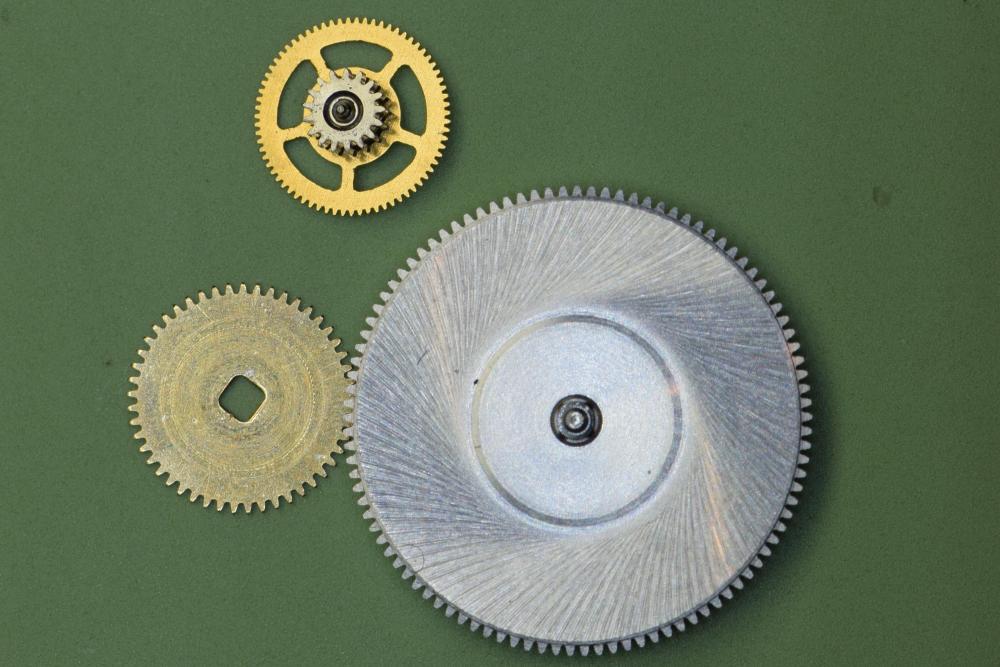

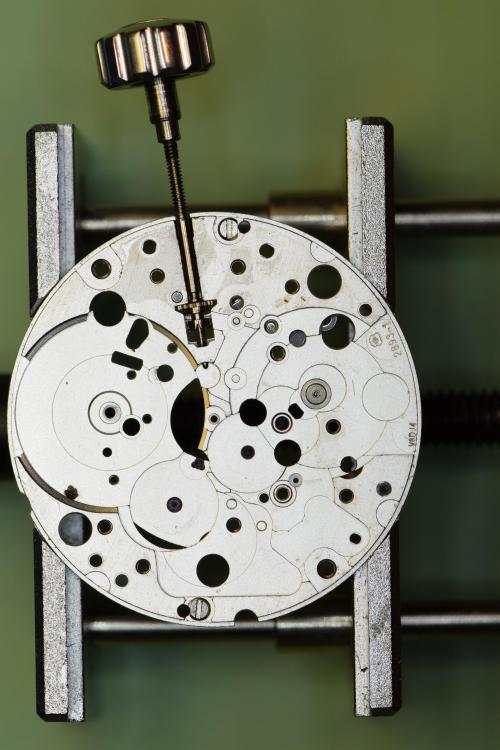

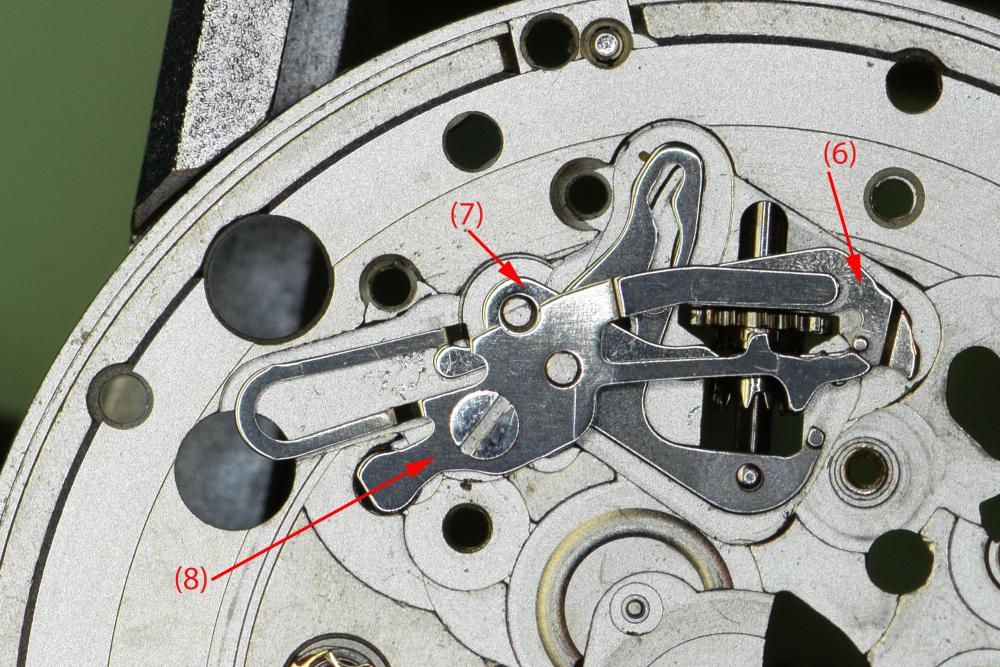

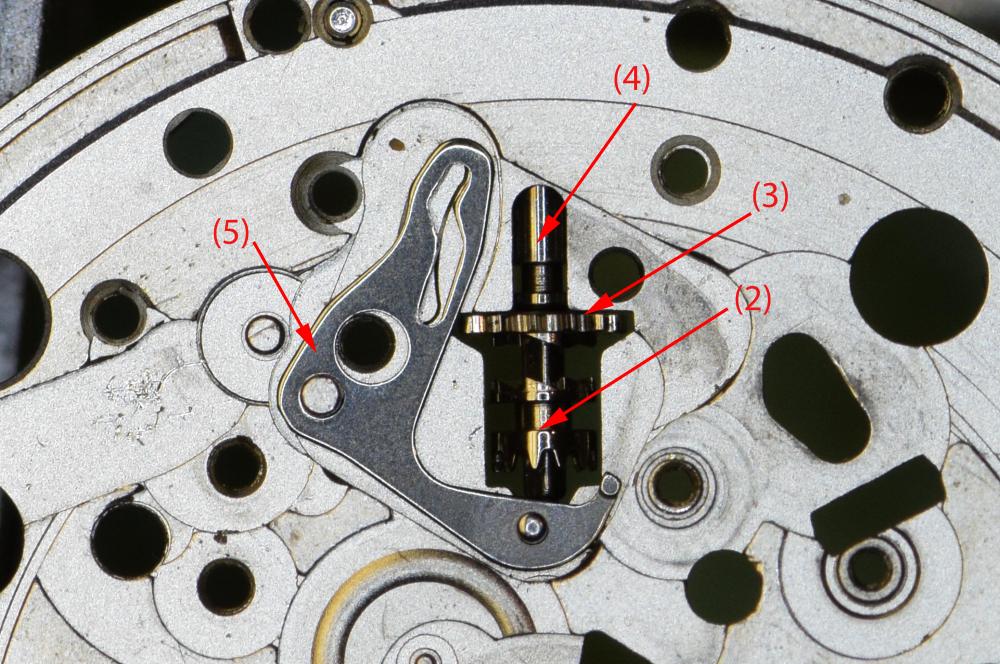

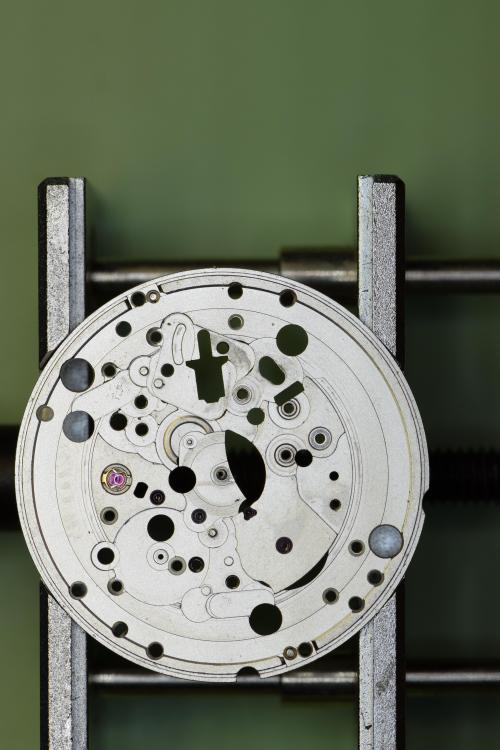

Service Walk Through – ETA 2893-1 / Hamilton Khaki: Part 1 - Disassembly This is part 1 of my service of a Hamilton Khaki – dual time zone automatic based on the ETA 2893-1 movement. I purchased the watch on eBay and it runs for a short time then stops. Looks like it could use a good cleaning. Note that the part numbers in the images and text are consistent with those found in the ETA technical document for this movement. Disassembly of this movement is quite straightforward. The only "special" tool you need would be an oscillating weight bolt tool - and you only need this if you intend to remove the ball bearing assembly from the oscillating weight, which really isn't required. In this tear down I do use the tool - only because I recently acquired it and wanted to see how it worked Off we go.... The dial shows evidence of some sloppy workmanship in the watch's past – several scratches from prior hand removal. Here you see the back of the 2893-1 with its automatic rotor - nicely signed Hamilton. Preparing to remove the hands – with a safety sheet in place. After removing the dial, remove the dial support ring. This ring keeps the dial the proper distance from the second timezone disc. Without it, the disc will rub against the dial. Remove the second timezone disc from the center. This is a bit tricky as there’s no obvious place to grip it. I used two very small screwdrivers on each side to lift the indicator straight up. Be careful not to scratch it! Disc removed. Note the following parts: Hour Wheel (42); Hour Indicator Driving Wheel (43); Corrector Setting Wheel (44); Additional Indicator Maintaining Plate (41) Pop off the dial washer – note that you cannot simply lift the hour wheel (42) off at this point. It is held in place by the hour indicator driving wheel (43). I remove the hour indicator driving wheel (43) followed by the corrector setting wheel (44). The hour wheel (42) is now simply lifted off, followed by the additional indicator maintaining plate (41). Next components to remove are the Date Indicator Maintaining Plate (40) and the Minute Train Bridge (35). We move on to remove the Intermediate Date Wheel (39). The Date Jumper (38) has also been exposed when we removed the maintaining plate, so we remove it. Finally, we remove the Date Indicator (37) and the Date Indicator Driving Wheel (36). Now on to some of the motion and keyless work. We remove the Minute Wheel (34), Cannon Pinion with Driving Wheel (33), Double Corrector (32) and Date Corrector Intermediate Setting Wheel (31). Before dealing with the rest of the keyless work, we flip the movement over and remove the automatic work. After removing the 3 blue screws we lift the entire unit up gently by the Oscillating Weight (28). With the automatic work out of the way – I notice that the Stop Lever (Hack) is missing! Will try and source one. Back to the automatic work. Removing these 3 screws will allow the oscillating weight to come off the Automatic Framework (21) and its components. Using the appropriate Bolt tool (pictured with the red handle) – I remove the Oscillating Weight Bolt (28-3) and free the Ball Bearing (28-2) from the Oscillating Weight (28-1). There was no compelling reason to disassemble this portion of the movement. With the Oscillating Weight out of the way, remove the Auxiliary Reverser (27). Flip the unit over once again and remove the screw and Automatic Device Lower Bridge (26). Remove the Reverser (25), Reverser Wheel (24), Reduction Wheel (23) and Intermediate Reduction Wheel (22). A view of the underside of these components Remove the single screw and gently lift off the Balance Assembly (20) with the Balance Complete (19). Carefully let the power down by releasing the Click (12-6) and slowly letting the crown wind down. Remove the Pallet Bridge (18) and Pallets (17). Remove the Train Wheel Bridge (16). Remove the Fourth Wheel (15), Third Wheel (14) and Escape Wheel (13). Remove the 3 screws and the Barrel Bridge (12) Flip the bridge over and lift off the Ratchet Wheel Driving Wheel (12-2) Remove the screw and the Click Plate (12-7), followed by the Click (12-6), Intermediate Ratchet Wheel (12-5), Intermediate Crown Wheel (12-4) and Crown Wheel (12-3). Note that the Intermediate Crown Wheel is under the Click Plate. When I removed the plate, the wheel was stuck to it due to some old oil. Here you can see the Intermediate Crown Wheel as it was stuck. This shows the proper placement of the wheels. Remove the Ratchet Wheel (11), the Mainspring Barrel (10) and Intermediate Wheel (9). Note the scrap of tissue that found its way onto the movement. I was so focused on taking pics that I didn’t notice J Pop the lid off the barrel. Remove the mainspring arbor And finally, remove the mainspring The movement side is now completely bare. Let’s flip it over and finish off the keyless work. Unscrew and remove the Setting Lever Jumper (8), Yoke (7) and the Setting Lever (6) Remove the Date Corrector Operating Lever (5), Winding Stem (4), Winding Pinion (3) and the Sliding Pinion (2) All stripped down Ready for the Ultrasonic!!! Hope you enjoyed this.1 point

-

Hi Indeed a puzzler, Have you tried removing the pallet and just fitting the balance on its own and using a small artists brush checking its action, just a thought.1 point

-

Zero to do with watches, but the place has been a bit quiet and if all we talk about is watches, well, no one gets to know anyone. Five years ago after 25 years of professional services, I completely lost my mind and bought a defunct manufacturing business and have slowly been building it up. Here's some shots I took yesterday of a couple of current projects we're just finishing up; a medium size box girder overhead crane and a lugger truck body. Apparently we've got an 80ton crane coming in; 110' long, 5' box girder - that's a large crane! I mess about with machining, welding, electronics and bit of clocks and watches for kicks in my home shop, but I've a lot pride in the team here, these are the people who really know what they are doing. Hopefully we get some more day job "show and tell"s....1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum.1 point

-

1 point

-

1 point

-

Thank you ! :), it works. I aligned the jumper, and when I rotated the calender wheel manually it suddenly snapped in. Now the date has is nice "snap" once it changes the date :).1 point

-

if has been repaired, it MIGHT be atached wit double back tape. vin1 point

-

I recently got a nice set of dust covers [emoji1] Envoyé de mon moto g(7) power en utilisant Tapatalk1 point

-

Have you checked mainplates side at 5hr and at 2hr for little screws holding the dial feet? If they don,t unscrew peacefully, put penetrating oil on them, let soak over night, sharpen you screwdriver to perfect fit. If you can,t find the screws, give claiber post pix of MP sides( outer circumference) Good luck1 point

-

The Spiedel wasn't really doing it for me, so I popped it on a plain leather band, somewhere between rosewood and burgundy. Much more appropriate I think, and a sight more comfortable I might add. I was almost tempted to post it in "Watch of Today" again, since I'm still wearing it. Not a single issue so far, and hovering somewhere less than +20s/day aver the last couple of days.1 point

-

Especially when you fill it with whiskey. But in seriousness it is a generally accepted practice to use a shirt glass shut as a whiskey tumbler to cover the movement if you haven't bought a domed cover to keep the dust off.1 point

-

I've successfully repaired similar breakages with superglue mixed with baking powder to build-up the area and then filed it to shape. Apply light layer of super-glue, sprinkle baking powder over it..repeat. Use a piece of pegwood where the springbar goes so that once the glue sets you can dig out the wood, easier than messing with drills. Also is the screw showing is only cosmetic? If yes then let it be in place when you apply the superglue/baking-powder. Using super-clue with baking powder creates a hard structure, to make it stronger I suppose you could heat and embed some steel wire in the case a reinforcement. Good luck Anilv1 point

-

Some parts are interchangeable between calibres in the same model family and some aren't. The Jules Borel web site has a very useful facility for working out what parts will fit what movements. http://cgi.julesborel.com/ The beat rate of a movement is determined by the balance assembly and is primarily a function of the inertia of the balance wheel (determined by the size and mass of the wheel) and the length and strength of the hair spring. It is a specific design feature of any given movement. So I happen to have an 1803 and a 1950 in my to do box at the moment, so with a spare half hour this evening I did some tooth counting..... With both of these movements the center seconds wheel drives directly off the escape wheel pinion. On the 1803 the the Center seconds wheel has 80 teeth and the escape wheel pinion has 8 leaves, so the escape wheel rotates at 10rpm. The escape wheel has 15 teeth, so that's 150 teeth passing through the pallet per minute, which is 2.5 teeth per second. It takes 2 beats of the balance to get 1 tooth through the pallets, so that's 5 beats per second, or 18000 BPH. On the 1950 the Center seconds wheel has 72 teeth and the escape wheel pinion has 6 leaves, so the escape wheel rotates at 12rpm. The escape wheel has 15 teeth, so that's 180 teeth passing through the pallet per minute, which is 3 teeth per second, so that's 6 beats of the balance per second, or 21600 BPH. If you use a 1950 escape wheel in an 1803 without changing anything else then you have the escape wheel turning at 10rpm (determined by the beat rate of the balance) but only 6 leaves instead of 8 leaves on the escape wheel pinion. This means that in 1 minute the escape wheel turns 10 revolutions, or 60 leaves leaves worth of engagement with the center seconds wheel, which has 80 teeth, so the seconds wheel will only make 0.75 of a full rotation. You need another 20 leaves worth of escape wheel pinion rotation to get one full rotation of the seconds wheel, which takes an additional 20 seconds. So with this combination it will take 1 minute 20 seconds for the seconds hand to make 1 revolution of the dial when the balance wheel rate is correct (18000BPH).1 point

-

Really nice GMT... seems the datewheel has nice serifs ... congrats. From my little experience (I have 3 of these) the DG3804B can be really reliable if you take care of it and it keeps the GMT hand pretty well synchronised. Just take care of not changing the date or adjust the GMT hand after 10h00 PM and before 2:00 AM and you could keep it for years. While building a watch with a 6497 you'll see that those "big" movements are pretty easy to work with, much more than DG2804Bs and DG2813s ... now waiting for your next thread1 point