Leaderboard

Popular Content

Showing content with the highest reputation on 10/27/21 in all areas

-

The punch will mark the right position of the hairspring stud by a small dot on the balance wheel. Position of the balance is secured by the impulse jewel in the slot. This tool is used for serial work only. Frank4 points

-

another reason why the pros are good at it is they went to school and they practiced. Practicing at school is different than practicing on this discussion group? This group perceives practicing is working on one watch at a time. In school here given a whole bunch of watches so each step your practiced your basically doing this all day long eight hours a day for several days. This is why the professionals make it look so simple not just the years of practice but the hours are practicing in school the classroom situation where an instructor passes or fails you by how you're doing. basically this is back to practicing again. Providing you have a replacement spring and are not worried about losing it I'd recommend taking it out practice putting it back in several times to get good at it.2 points

-

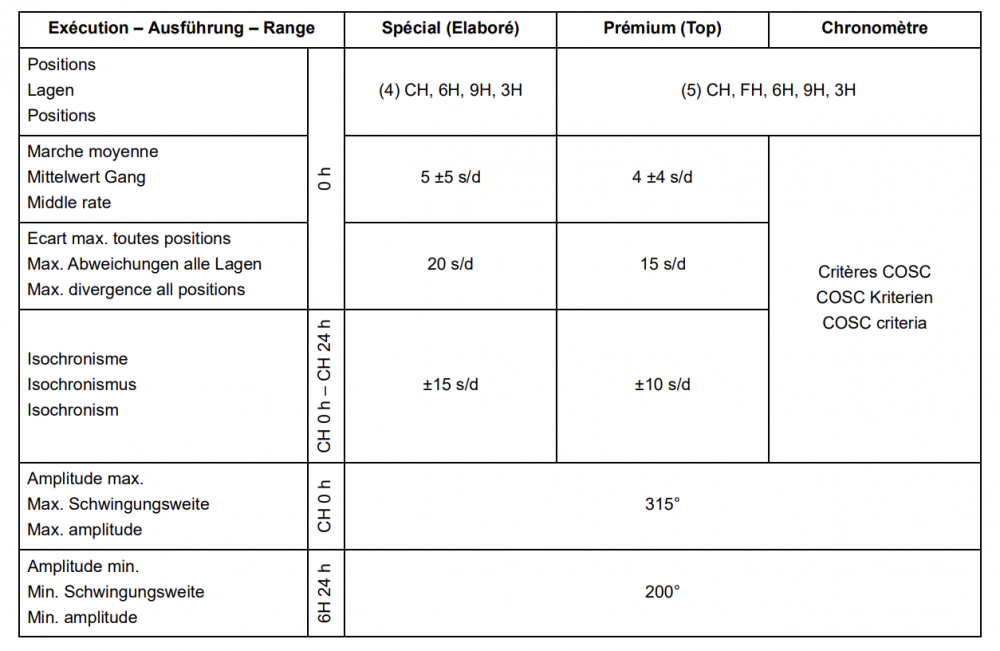

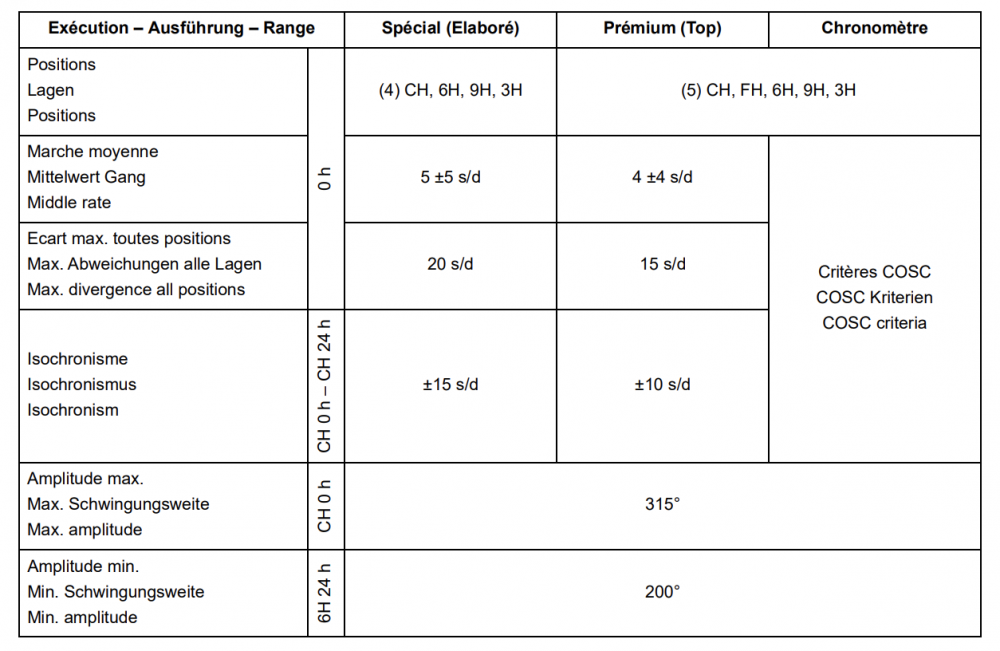

Hi, So Sellita claims their movements can be provided in three executions (performance specifications), Special, Premium, and Chronometer. I'm curious, what happens at the factory between Premium and Chronometer? Would it be possible for a watchmaker to receive a Premium movement and make adjustments to meet Chronometer specifications? If so, what kind of adjustments would one expect to be necessary? The short backstory, I've been confirming and reconfirming with Sellita the availability, terms, and pricing for chronometer (though, not COSC certified) movements for the last two years. I'm finally prepared to place an order with them last week and they changed their mind. Now I am evaluating alternative methods to obtain chronometer performing movements. One avenue is what I'm asking about above, obtaining the best possible movement then having adjustments made by a watchmaker to achieve chronometer performance. Being a hobbyist, I don't fully know what is required between the two movement grades to get there. Brochure_technique-SW300-1_2.pdf1 point

-

Wouldn't such adjustment be easier to make for the manufacturer as they have special proprietary tools, highly skilled watchmakers you name it. What does a repairman have couple of dull screwdrivers and a tweezers. oh plus a loupe. Here take a look for yourself.1 point

-

I bet they just segregate the best performing movements and charge accordingly.1 point

-

1 point

-

Hi Any problem regarding watches is always best with accompanying pictures, there are many on the site willing and able to help you with your problem1 point

-

1 point

-

I'm not in anyway as accomplished as Jun Ye either, or even my friend who built that resonator for him. I just think it's cool and applicable to horology. We may know some of the same people. Are you in the area? Since it's floated back to the top of the stack though, I saw a reference to Ye's project the other day. Seems the accuracy has been improved somewhat. Used to be it could track time dilation over a cm or so, and now it's down to a mm. An order of magnitude on something already that crazy is pretty awesome!1 point

-

Mayhap my statement of its death was exaggerated. Deathwardly direction may have been more accurate. Admittedly, I haven't looked at .NET since then (nearly ten years ago), but I've not come across another single project or engineer using it in any capacity in all that time. My wife is also in the tech industry, and I'm pretty sure it's not crossed her path ever. It may be specific to some domain or another, but nothing I've touched (web apps and sites a handful of years ago for me, and currently for wife, and hardware for me the last several years). I don't dabble on the internet side of things much any more, but I think Javascript is the current darling (it was rapidly becoming so as I was shifting toward hardware). The wife's job is a Ruby on Rails shop.1 point

-

Yes you will, it happens to all of us. I thought I was getting reasonably proficient at tweaking hairsprings - but I still have the odd accident. Still feel bad on wrecking the hairspring on an Universal Cal 267 a couple of years ago when I released one of the tweezers too early - still looking for a replacement Also made spaghetti out of an Omega Cal 455 hairspring - but as they are only 3 mm in diameter, I think even @Nucejoe would find those challenging ! If I'm working on a watch where there's little/no chance of finding replacement hairsprings, I'm not so critical in getting the hairspring perfect - especially for beat error.1 point

-

Hi you aboloutly right Roger, I did a Winterhalder/Hofmier a while back and it did strike the quarters as endorsed by Old Hippy. They are different in operation and a nice clock to work on. I suggest the OP takes Old Hippys advice and studys the manuals and the clock.1 point

-

I suppose that when a part becomes available will be listed eventually. That is more effective than going back and forth with messages. Yet, even a canned response is better than none.1 point

-

@spectre6000 Pointless name drop, but my brother was his graduate student at JILA. Don't worry, I am much less accomplished - but perhaps better with tweezers...1 point

-

He is reliable but does not answer questions. I can't say I blame him as he strips dozens of calibers and the messages must be endless.1 point

-

Hi Guys, Just an update, I found a guy in Poland on eBay (werk24watches) he is breaking a 836 & 837. Tried to contact him but he is not as yet responding, anyone come across this guy? will keep trying. Regards Graham1 point

-

Looking at the spring there does not look like to much wrong apart from the areas I have highlighted. The blue area I have marked the spring is not following an equal distance (curve) of the next coil the red circle is where you adjust to correct the fault. The fault you seem to be encountering is the coils are sticking together. If it is not a magnetic issue then contamination is happening such as over lubrication from somewhere in the movement. It only takes the tiniest amount of oil/ grease to stick the coils together.1 point

-

There is no "database of suitable bezels". If it is a plastic bezel as with many affordable watches of that vintage sold under various labels (we can't know, since you had posted no picture as it is necessary for most questions), then that has been asked before, in the end people either looks on Ebay or have a new bezel 3D printed. Being this a casing part, caliber number will not help and is pretty much guaranteed not to be sold anymore, if it ever was in first place.1 point

-

You need to study that movement. You do not need three trains. A bim bam or if you wish a ting tang movement such as this type the strike side works both the bim bam/ting tang as the hourly strike.1 point

-

I am afraid Old Hippy got it right. ting tang Ist quarter, and so on. It does not need a third train to accomplish this. The control is from the rack, The first three teeth are on different arcs from the pivot point, the first tooth lets the rack fall allowing two strikes the next tooth three, third etc. the canon pinion has four lifters, when the first pin lifts at the quarter only one tooth on the rack falls and we get ting tang. At the half hour there is a higher lift allowing two teeth to fall giving two sequences of ting tang. The third quarter is triggered by a higher lift allowing three teeth of the rack to fall and we get three sequences. At the hour the lift is even higher blocking one hammer and releasing the other to strike the hour. the snail cam is modified to cope with the different teeth profiles and care must be taken when re fitting the hour wheel. So check the profile of the rack and the snail cam also the canon pinion.1 point

-

A little background... My wife discovered this resale shop in a city we have been visiting a lot lately. The owner had bought some stuff from a watchmaker/jeweler. Most was not displayed. That is where I got my Witschi quartz tester for $20. The guy had this watch that he was going to give to a friend but the watch did not work. So, I said I would fix it for him. What I found was the stem had been replaced incorrectly and instead of placed in the hole, was shoved under the top plate. I further discovered that the crown extension was slightly bent. The watch seemed to work out of the case, but since it was a cheap Ronda, I bought another movement on ebay for under $10. When I installed the movement, the stem would NOT stay in place when setting!! Fortunately the new Ronda movement had a stem with it so I sized it correctly, and the watch is now working properly. I got to thinking...I bet this stem was never sized properly! It probably had come out on multiple occassions...falling on the ground or whatever and the last time it was inserted, it was done incorrectly. That is my theory. Interesting.1 point

-

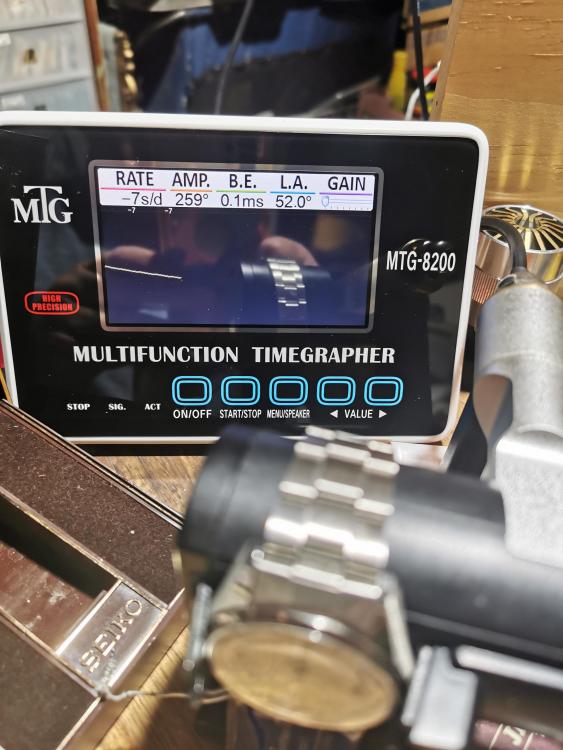

Hello everyone,digging through my hidy holes I found a nos Seiko 6602 7040 in box with label from July 1971 and through it on the timegrapher and I couldn't believe the results, so I will share with you. This watch has never been opened and as you can see it doesn't run to bad in 4 positions. I have a few more nos Seiko 's somewhere I shall turn the joint upside down now out of curiosity. Thanks everyone1 point

-

I quit 5 times and start again 6 times. The ruby underneath the escape wheel kept coming out so I took a main plate from another 2824 that I broke previously and move all the parts over it, I ended at 3 am. Now, in the morning it looks fine, it hasn't stop during night and it keep good time. We'll see. ¡Thank you!1 point

-

The pliers that LWS bought is a bird beak plier. This has a conical beak on one side and a flat beak on the other side. This works well for round wire but if a flat wire is used, it will develop a conical twist in the bend. Spring grade wire is very elastic and to get the radius that you want, you have to use a smaller radius former because it will rebound and open up. It is usually easier to bend the curve to a smaller radius, then use the bird beak plier to squeeze the curve to open it up to the curvature you desire.1 point

-

Hey So if the hook turns anti clockwise it's right handed winder and if hook turns clockwise it's a left handed winder? Cheers Gary1 point

-

The way I figure out which way to wind a spring (I'm still doing them by hand) is I figure out which way the barrel/arbor goes in, look at the hook, and that tells me which way it wants to wind.1 point

-

Hi all , Just thought I would share with you guys and gals a video of a Seiko Pressure tester purchased some time ago .Its part of the traveling tool kit that I take to service friends and relatives watches on the go . Anyway it's a Seiko S-451 pressure tester and it is probably from the 80s or early 90s and very useful for vintage water resistant watches and quarts . I had to upload it to youtube so I could paste on the forum .I restored the Tissot Seastar that you will see as it was a complete no runner with numerous problems .Anyway check it out and enjoy a cigar and a vino rosso https://youtu.be/n8dbQLwsHbg1 point

-

0 points