Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/21 in all areas

-

4 points

-

I wonder if a more modern approach would work better. Use a modern microphone designed for picking up voice through bone conduction, such as Bone Conductor Sensor – Analog Piezoelectric MEMS Voice Accelerometer Or use a microphone array, like this one from MiniDSP. The array allows for beamforming: determining where sound is coming from. This way external sounds can be rejected because it's possible to determine they didn't originate from the movement, rather than filtering based on frequency, which is unable to filter noise at the same frequency as the movement's sounds.2 points

-

I use a tack every now and then. When removing the balance with spring from the cock, I put the assembly on the tack and a couple of pith wood logs under the balance to protect the lower pivot.2 points

-

Good evening, I thought I'd share my latest achievement. I'd been building up courage to take on a day/date watch after my previous success with an automatic. This unloved golden nugget came to me as a non runner and fairly grubby. With one of those Russian Slava 2428 movements with the double spring barrel arrangement. Thanks to my cheap ultrasonic cleaner and the great advice I received on the forum to safely polish it. It buffed up a treat. Sadly the innards had suffered from an excess of oil, which had damaged the balance spring, and the day wheel, where the painted finish has started to lift off. It also affected a small area of the dial. Though everything else was well preserved in the oil and gunk. In my short time tinkering, is this a common problem others come across? I found the trickiest part was the shock jewel springs. After setting time aside to only tackle these on an evening and nothing more. I managed to get them back on with a combination of tweezers and a sharpened toothpick. I had a hell of a time with even the finest pointed tweezers. The problem is I'm not brave enough to wear it out of the house. It's too extravagant for me, I may view it differently when I get round to finding a better strap than the cheap canvas one its sporting.1 point

-

Just in case anyone is waiting for them to come back in stock, they are now in stock, only 87 left as I've just bought one, need it for the DLC. Jaws are 45mm and it runs on dove tails so very nice action. It looks like a direct copy of the Bergeon model of the same specs, just £200 cheaper!!!! Also ordered the cousins mainspring let down tool, as I'm going down the clock path with the DLC so now re tooling fro watch tools to Clock specific tools now.1 point

-

Attached document is for all you lathe buffs who like to make your own tools, there are some useful/practical ideas on this one. Toolmaking.html1 point

-

Attached is the book by Hope-Jones on electrical time keeping , fot you guys who tinker with the electric clocks etc, must be a few gems in here for you. Hope-Jones F, Electrical timekeeping.pdf1 point

-

1 point

-

Hi Attached is a tool tip guide and some advice on how to use them. Useful for those starting out in the watch repair as a Hobbyist. Some of it is quite basic but from the questions asked on the forum there are some who would benifit from it, Be your own judge. Watch_tools_tipps.pdf1 point

-

There is no secret place for parts, search results are the same for anyone, starting with Ebay. And in this case finding an €1 part is more difficult than an expensive one, because quartz modules are not popular to "make your own watch". If that was an NH35, or ETA 2824 watch, you would have found many choices. You can buy quarz watches sold "for parts" for pennies and even in cheap lots, some will e using a 2035 module. Otherwise you can just design and print your own dial using the software (forgot its name) that is sometime mentioned here.1 point

-

That's normal, even a new slide might have 2-3 hundredths of play in the screw. Most small slides have an adjustment for the "bearing", usually a cylindrical portion of the screw near the crank which is captured in the slide mount with a nut, this can be brought until there is near zero play and the screw is still free. Often some of the play that's perceived as between the nut and screw is actually there. More modern slides, like later Levin and larger ones will have preloaded ball bearings here, smooth action with no play.1 point

-

It actually looks perfect for our application. Does not pick up audio which is exactly what we want. At least audio traveling through the air picks up vibrations. I was quite excited until I looked at the tech sheet. Everything was looking fine until I noticed how big it is. Yes I know we work on watches but soldering to something that tiny is quite challenging.1 point

-

1 point

-

I found this for you from another site where some posted the same movement as yours. it looks like one of the pin lever calibres that came out of the Anglo-Celtic factory at Ystradgynlais in Wales . I have seen the same movement in some Smiths Empire watches . Just after the second world war , Ingersoll , Smiths and Vickers joined to start the Anglo-Celtic factory . Later the same factory would be wholly owned by Smiths1 point

-

That's the goal with a contact mic. It picks up vibrations but not ambient sound. Exactly what one wants for a movement microphone.1 point

-

Yes they hairspring has to be flat definitely can not be touching the balance or the balance bridge. Then even if it's cone shaped that can be an issue because it's putting too much pressure on one pivot. Then the other thing that affects this is the condition of the pivots of the balance wheel. If one pivot is not shaped to ride or trough or lacking lubrication or dirty lubrication that definitely has an effect also. Especially common on pocket watches that don't have shock protected balance jewels. Often times you can look through and see the end of the pivot winking at you because it has a flat spot. The pivots have to be right and they hairspring has to be right amongst a whole bunch of other stuff. Dial-up and dial down should basically always be identical or as close as possible.1 point

-

Since posting this, I think I've discovered the problem - Where the end of the hair spring is secured by a screw and clamp, the spring it was not completely horizontal. I loosened the screw and levelled the spring and it is much much better now! Thanks for your help and advice.1 point

-

Works with the piezo mic but not with the vibrograph. Almost no signal with the vibrograph mic. With the piezo mic it pics up my breathing and every sound in the room. But definitely is a usable setup. My piezo mic is not a clip on so it would probably work better if I had it set up like yours. I cannot use alligator type clips for regular watch work. It picked up the 18 size PW but got almost nothing from the 2892 movement.1 point

-

I've found that tons of positional variations are HS dependent... meaning, a slight asymmetry may make the HS rub on the plate on certain positions, etc. Recall that the pins don't have effect on rate on the horizontal positions... only verticals. If HS is fine, then I would look at the pivot on the affected down side (DU) as it can be worn or even deformed. This is assuming the jewel is clean and well oiled and such. Just my 2 cents...1 point

-

I have a balance tack but never thought about using pith wood to support the lower pivot, great idea!1 point

-

I doubt that they would sell an unhardenable steel, so no need to "inject carbon". If you want to harden steel, the typical alloys that a watchmaker might use would be oil hardenable or water hardenable. At watch size parts either will harden in oil just fine, so don't fret about knowing which type you may have. It needs to be heated to its critical temperature, which for practical purposes isn't a number but a color- you want to get it a dull orange color, then immediately drop into oil (about 0.5 liter is good). It can be pretty much any oil, but thinner is better than thicker. Now the steel is completely hard. To test if it did in fact harden you can try to cut it with a fine file (like a 5 or 6 cut). The file should slide and not bite. Obviously try this on a piece of your steel that hasn't been made into a part yet! Once it's hard, you need to clean off the scale and black color, then heat it in a pan of brass filings or fine sand, normally over an alcohol lamp, and bring it up to a blue color. Now it's tempered. If left in the full hard state it will be too fragile, tempering reduces the hardness, while increasing toughness. Once it's blue you can clean it up in your lathe, the blue comes right off with fine grinding or polishing paste.1 point

-

1 point

-

1 point

-

Welcome to the forum Heraldo. Nice looking watch. I cannot recall seeing those ever in Australia.1 point

-

Hi When removing a balance and cock lay it down on its back and place the balance in the jewel and cover it up placed in a safe corner untill required, JD Richard (Member), made a tool which holds the balance safely and allows you to do adjustments ( I suggest you look it up in the search ). If as Joe suggests its gone cone shaped then getting it flat will be an issue, so as joe said a complete balance is the painless way to go. But the old balance will give you endless hours of pleasure in the art of manipulation. There are Videos of Marks that cover the manipulation and plenty of books to read. Lastly do not be discouraged, Horology is 100% skill 100% patience, and the dogged determination to succeed, We have all been through the loop so take heart that all the advise you get will be from people who like you have been there and got out the other end, sanity intact. I would encourage you to watch the videos By Mark Lovick (Administrator ) on the subject of balance springs. TZIllustratedGlossary.pdf1 point

-

That's the perfect oil for this machine. It's normal for plain bearing machines to get warm*, if it's not getting warm the bearings are too loose. If it's too hot to hold your hand on for 5 seconds after 30 minutes running the bearings are too tight. But ISO 10 is just right. *When doing very high precision work it's good to let the machine run for a half hour first. A watchmaker friend who worked in the gear department at Mcdonell Douglass told me it was protocol to turn on all the machines 30 minutes at least before making parts. Another friend who was well known for handmade watches had thermometer strips on the heads of certain machines to know when they were warm enough.1 point

-

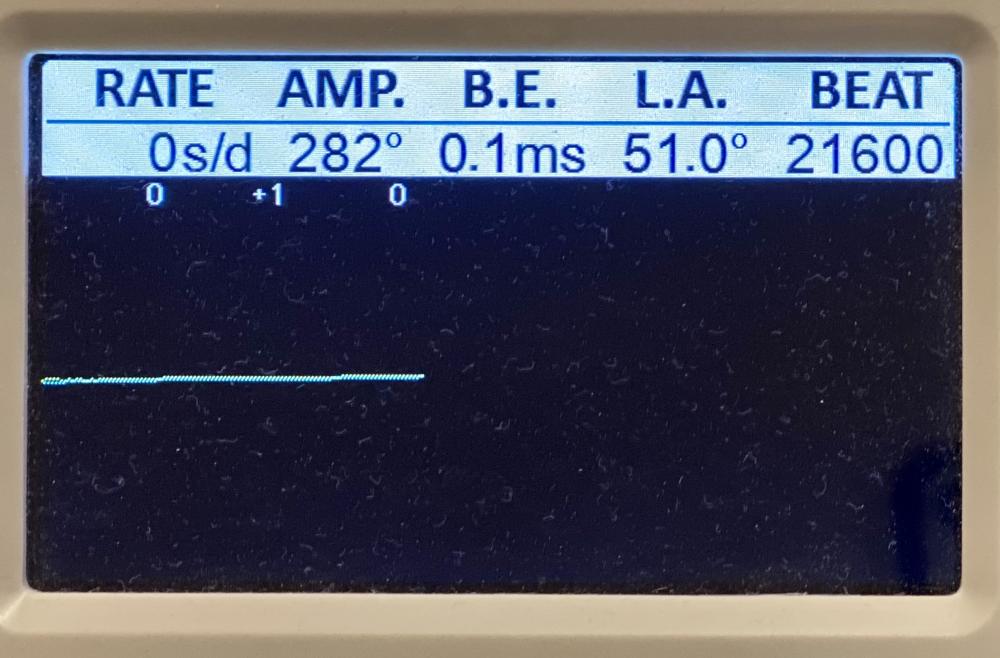

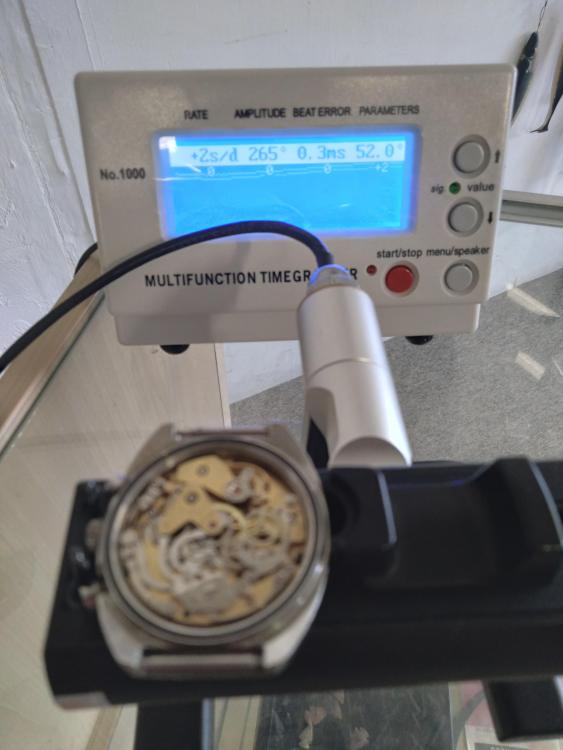

A 60 second wave would generally be the 4th wheel being out of round. Not much can be done to correct the out of round. You should see a shifting amplitude as well. If the regulator pins are a little too open then changes in amplitude will have a direct effect on the rate, imagining that the hairspring is well adjusted between the two pins (or pin and boot). The two images I am guessing are dial down and some vertical position? This would go along with the pins being too open, especially if all the vertical positions show a losing rate like that. Universal made very good stuff, and you should be able to get a good rate across 6 positions even with an out of round 4th wheel.1 point

-

Hello Brian and welcome to the forum. As you ae thinking of taking the plunge here is a couple of documents to help. 1612608791_ToolsfortheHobbyist.pdf TZIllustratedGlossary.pdf1 point

-

Hello and welcome to the forum, As you are in South America Take a look at Jules Borel, Esslingers and Timesavers Material houses. They are all located within the USA, also have a look at the AWCI site in the states they are the equivalent of the British Horological Society in the UK n who will be able to point you in the right direction.1 point

-

Well, I have given up on the original hands for the moment. Mostly because the replacements hands arrived and they look pretty darned good and of course fit properly. The tip of the minute hand required a bit of gentle bending around some peg wood to get the same curvature of the original, and the hour hand required a little reaming of the mounting hole with a broach, but success! They are a little wider than the originals, and at the moment the lume is bright white. I bought a second set of the same hands to experiment with aging the lume. I know many have used coffee or tea to accomplish the effect, but I am also a budding fountain pen user and have a collection of a few different inks that might do the trick very well, especially when watered down. Here it is in its current state. It is keeping good time at about +15 seconds per day. I am still regulating it using the Watch Tracker app. It is effective but takes a few days of readings between adjustments. Im very happy with the transformation and the fact that it is all nice and tight in the right places. Thanks for all of the helpful suggestions and I will report back if I am able to restore the original hands to a useable condition. Another project!1 point

-

That is the clean one. The watch came to me with a pretty good (to my eye) repro dial. This one was purchased on ebay in rough condition and I took some excellent cleaning advice from this article: https://watchguy.co.uk/cleaning-and-preserving-original-finish-on-dials/ The next challenge is that the dial feet for the correct dial are in the wrong place. I can use dial dots but would prefer to put on new feet, which is another whole can of worms on techniques and tools that I do not have and do not want to invest in. We shall see. The before and after (after then before). Like many things, there was some improvement and I also did some things wrong. Thankfully the mistakes done really present themselves to the naked eye. We all bear the scars of our journeys through life, and while I am responsible for some of those on this watch, it is overall the better for it and it is mine.1 point

-

I acquired this watch not running with the stem not doing anything. I called around locally and only one person would service it for $475 dollars. I've always been afraid of working on a chronograph but after that price I decided to give it a go. Some of the keyless was rusted and I ended up breaking the setting lever removing the stem. I ordered a new one and got to work and I'm happy with the results. I also changed out the crystal.1 point

-

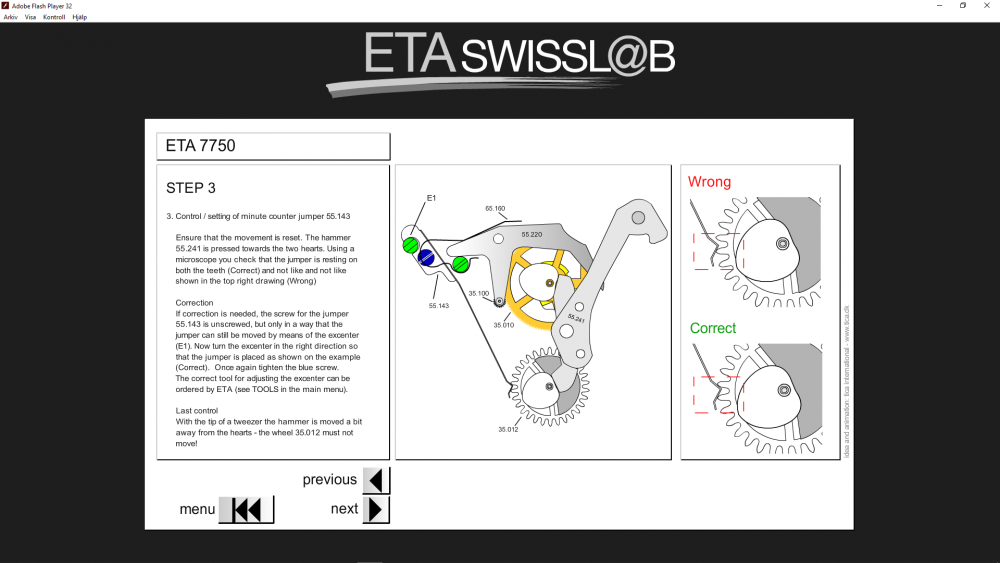

For those who were curious of what the 7750 flash-files contained and didn´t have time to download the swf files I did a small compilation of the Swissl@b application a while ago. In this PDF you also get some extra information. So no need for a flashplayer..... ETA 7750 HSL EDITION.pdf And after a quick glance at this issue here is an alternative if you really want to look at these files. For windows users I attached the reader in the zipfile. Just unzipp the zip file to a good place on your harddrive, read the attaced short instructions and happy viewing. [email protected]1 point