Leaderboard

Popular Content

Showing content with the highest reputation on 08/18/20 in all areas

-

I think you can get silver nitrate in most drugstores (here for sure), with that- you want it dry, not in solution- cream of tartar, and salt you can make your own. 1 part silver nitrate to 8 parts salt 8 parts cream of tartar (use a scale), it's good to grind it with a mortar and pestle. Keep in a brown glass jar and away from light. It's used the same as any silvering powder. When done, rub the surface down with more cream of tartar, wet, rinse, and you're done.2 points

-

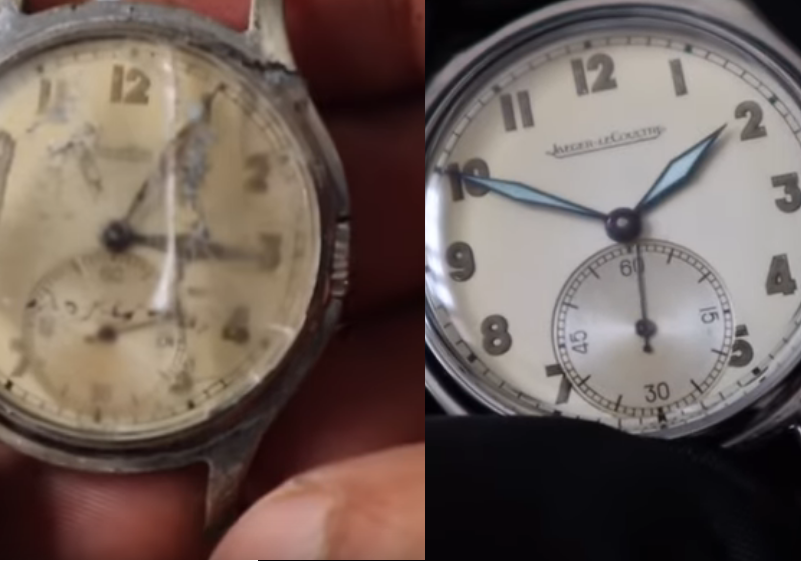

Hearing sad tales like this make me angry at businessmen who would do this to their clients. If such a technician wants to be in business to work on the kind of watches he agrees to repair, he should first learn as much as he can about them. And I think a situation like this (unassembled and unrepaired with missing and broken parts) warrants more than just an offer of money to cover future repair. He should have offered to replace the watch for you. Or offer to put a new movement in it. One should take responsibility for one's mistakes. He ruined your personal property. Saying it would take forever to fix is a poor excuse. I think he could have given more explanation and better compensation.2 points

-

Well having heard the full story and the way It was handled it smacks of TOTAL incompetence at best and deplorable at worst, To take a working watch and breaking it during fitting a stem and crown and leave it in that state. If he was a GP he would be struck off but he lives and works on to do that self same thing to others. But as Watchmakers said its time to move on as there is no way back now. Sure your Dad would understand, But keep the watch as is in the future you might try to re build the watch or use the parts case /dial with a new movement in memory of your Dad. A truly sorry tale.2 points

-

Hi Regardless of the fact it was a fake watch it was your watch ,your property and therefore what he did was inexcusable and no credit to his trade. On opening the watch ,to find it a fake all he had to do was close it up again and return it to you unrepaired explaining why he was returning it to you in the unrepaired state. I would have been up to you then what course to take but to do what he did is nothing short of disgusting leaving you with nothing useable at all. I find it sad that there are people who take it into their own judgment to be moral guardians on our account, we are grown ups and can make our own descisions. End of Rant, appologies if it offends any one.2 points

-

Hi Tom, I’ve been toying with a similar dilemma. I work in a well paid but highly stressful job, though I’m moving towards the latter end of my career. My escapism from the stresses of the day job is to restore vintage watches, and I’ve been practicing for about three years now. I’ve taken Level 1 and 2 of Mark’s watch repair courses, and this has helped improve my techniques and skills confidence. I’m onto the 3rd level now. I think this is a great place to start and will provide certificates of achievement (a measurement of your knowledge). But some time ago I reached out to Mark regarding taking the British Horological Institute (BHI) courses and professional exams, and considering whether to do the distance learning course or the hands-on workshop tutor led course. He highly recommended the hands-on course, and since for me, the BHI course centre (Upton Hall) is less than an hour away, it makes sense all round - except for now of course, while all onsite courses are cancelled due to the pandemic! I joined the BHI as an associate member two years ago - worth it for the horological journals they publish monthly. So in my opinion, to provide assurance to your future customers, I would recommend you get professionally qualified. I sell my successful projects on ebay for next to no profit, and I’ve had a few people contact me to ask whether I’d repair/service their watches. I have always declined because I describe myself as an enthusiastic hobbyist, and nothing more. I take on some more advanced projects now that I have built my confidence and tools set up, including escapement work (refitting balance staffs etc.). Would love to get a lathe to learn those skills too. Obviously, it depends which part of the world you live in as I know there are equally good organisations to get professionally trained in the US for example. As mentioned, the BHI does distance learning courses for students worldwide as another option to get professionally qualified. To wrap up this lengthy reply, I guess we amateurs need to ask ourselves your question from a customer’s perspective. If I had a prestige sports car worth £50,000, would I take it to “Mick’s Motors” who has a back street garage where he practices motor repairs at the weekends and is unqualified or should I take it to the main dealers who are trained (hopefully!) and guarantee their work? The same would apply to an expensive/treasured timepiece! Hope that helps? It would be interesting to hear from those who are qualified for an insight into whether they have found it a rewarding career and whether it can be very stressful at times. Pros and cons and insurance advice to protect against inadvertent damage (it has to happen to professionals right?). Sent from my iPad using Tapatalk2 points

-

My main concern is to safely get the cock and balance assemly on mainplate and secrue the cock in place with its screw. Then I have no fear of mishapps, A minute rest and ready to get the roller pin inside the fork horn and slide pivot into jewel hole، loosen the cock screw so I can raise it by 2 mm, then raise the balance over the fork, get impulse jewel in fork horn and slide pivot in jewel holes, Done. You run less risk of mishapps if you devide the proceedure into two tasks, first get the balance and cock secured on mainplate with screw in place and screwed a turn or two and little can go wrong raising the balance when mounted on the mainplate by most mistakes. I have not dropped a balance in nearly twenty years. The proceedure gets difficult and risky when you try to do all tasks together in one drop of balnce in place.1 point

-

that looks like a Sprite model. the N44 is a factory number and has no bearing to this topic. is there a date ring? if so it would likely be a M25 no date ring than m24. still a guess without seeing the dial. aside from this, it sounds like the mainspring is the issue. But, that would have to be confirmed by more investigation. If your intention is to repair the watch you will be in for an interesting journey. Finding NOS replacement parts for vintage Timex is a challenge here in the US and I know it is even a greater challenge elsewhere. Best suggestion would be is to find a donor watch that has same movement and exchange them. Good Luck with the journey!1 point

-

Starting with the 1.3L model, ultrasonic cleaners come with heating. They are not expensive and ideal for maintaining a controlled temperature over time. Of course you would have to place the alum setup in bain-marie.1 point

-

Have you trued asking on SCWF - thewatchsite.com? A true collector's website with a lot of Japanese vintage knowledge.1 point

-

They say that the third time is a charm ,...I'll take it . I pulled out my Yema Meangraf from storage and discovered it had a now familiar symptom ,...The watch is running , the second hand is moving , but the minute and hour hand didn't budge . Elementary My Dear , it's a bit of slippage between the drivetrain gear on one side of the drivetrain bridge , and the mated clamshell gear on the other side of the bridge . I was down to my last set of new gears , but I got an idea , that if it worked the watch hands would soon fall in line and..........move with out using any new parts . I got a pair of jewelry side cutters and gave a sleight pinch to the top of the clamshell gear to grab and hang on to the drive train gear . BINGO , we got a winner . the clamshell guy stopped slipping . I could have used a pair of nail clippers instead , but they're in my fishing box ...1 point

-

They also turn up here in the UK with the Sekonda brand name. An ebay search for something like.... Sekonda ALARM USSR 18 Jewels ... will usually throw up a few likely candidates. Sekonda pushed re-branded Poljot and other re-branded USSR era watches back in the day, and these are quite good value if you want to add an inexpensive Soviet period Russian watch to your collection. The quality of some of these watches is actually reasonably good. Arguably not quite in the same league as top end Swiss timepieces, but on the whole, not bad, especially compared with other iron curtain time piece offerings (Ruhla and the like). The USSR watch factories often used Swiss designs, but added their own engineering tweaks and quirks.1 point

-

Unfortunately for tool buying that is going to be much worse. Quite a few professional watchmaker's work in service centers all the tools are provided. Of course that brings up the problem of why did they spend so much money buying tools to go to school and not Be able to use them? As a hobbyist watchmaker if you see something that you fancy you don't have to justify it. Although by theory business owners could write off their tool purchases watchmakers in a profession tend to be a lot of times cheap on what they do. I should go and find the book one of my books has a reference that watch repair tends to be really Tool extensive. You end up with a lot of specialty tools that you only occasionally use but when you do have to use them it's very very nice to have.1 point

-

I've used razors before that felt like I was shaving with a 60 grit aluminium oxide paper!!!!1 point

-

Actually aluminium oxide is an abrasive grit, not soluble in water, and pretty inert. Alum is potassium aluminium sulphate, water soluble and will dissolve steel but not brass, and not stainless steel. I would be surprised if the crown were a plain carbon steel as this would make it rather prone to rusting as it's exposed to the outside world. If it's stainless or brass though then alum is your answer.1 point

-

I don’t think you want to attempt to cut into the existing stem as it will likely be harder than the crown pipe. If it’s any consolation, I recently repaired an original irreplaceable crown on a £7k JLC Mk11 and it worked out fine. There are many ways to skin a cat, but here is what I would do: Firstly, I’d find out if the crown pipe is stainless, or at least significantly less likely to corrode than a carbon-steel stem. Usually this will be the case. Which opens up the opportunity to dissolve the stem in acid. To dissolve with acid, you can suspend the crown such that only the end of the pipe is sitting in the acid. You can use an oiler to spread the rest of the pipe with silicone grease to acid-proof it. I’ve attached a photo of a crown from a 1980’s issued Precista military diving watch having this done just now. The corroded stem gathers at the bottom of the container.1 point

-

1 point

-

I find this interesting timing this morning? I was searching for something else in my horological folder of downloads stumbled across this PDF. The PDF title is educational opportunities. Seeing as how I had zero idea how or why I acquired the document I did a search I found the link where it came from that's attached down below. So if you're in the UK names to cover quite a few opportunities. http://www.clockmakers.org/wp-content/uploads/2017/03/A-Helping-Hand-for-Students-56-Version-4.pdf1 point

-

In the UK I would have thought the BHI would be best if you are intending to service high end watches or go pro.If you intend to become a competent amateur then Marks course is perfect. However making a living from Horology is now tough because for many customers their vintage watches & clocks the repairs/servicing costs are more than their value. Apart from sentimental reasons many just decide to either sell them or just discard them. Most now look at there mobile if they wish to know the time.1 point

-

By now we all know that you're an opponent of searching before asking, and if we had a FAQ (which we haven't) you would be incensed at only naming it . To make your and OP's education easier here's few links from previous threads about the topic at hand. Perhaps some useful crumble of information is in there, despite the world changing and new schools opening every day. Feel free to come back with more polished aggressiveness if that makes you feel better but forgive me if it will be you having to conclude with empty bickering.1 point

-

Personally I don't care much for this type of exhortation which, moreover, can be perceived as condescending and not very friendly, even if it's not your intention. It could intimidate members, especially new members, and result in refraining from asking and writing. I give you that the question have been discussed and answered many, many times on the Internet, but the world is ever changing and there may very well be new information today that wasn't available yesterday. Also, and that's perhaps the most important aspect, the question from the OP made @AdamC write a personal, informative and interesting post in reply to it, and it made @JohnR725 provide some aspects that may not be obvious to everyone (certainly not me) in addition to some interesting and useful links. Without the OP's question I'm not sure any of those posts would have seen the day.1 point

-

I found you a few links you can do some reading. Unfortunately no simple answers here? A lot of it depends upon what you want to do. For instance you're working on vintage American Watches a certificate is a waste of time it won't help you with anything. On the other hand if you want to do modern watches Want to get spare parts you're not going to get the spare parts unless you have a certificate. But even that's not clear-cut some of the companies will still require you to take their class with their test and get a certain score or else. Oh and for spare parts even if you complete the test and all of that is still need to buy a heck of a lot of expensive tools because expensive tools indicate that your qualified professional person. But If you just want to walk in and take a exam except you can't walk in you have to look at the schedule when the exams are given I believe both the BHI and AWCI have exams you could take. Then the other two lengths wostep and sawta These are basically schools and if you want to complete their tests and have one other certificates you really should take their classes. http://www.wostep.ch/en https://www.awci.com/ https://bhi.co.uk/ http://www.sawtacertification.org/ Then we have things like this a wostep school with a one year program versus the normal two-year program. Also the programs interesting in that is free tuition free the only need to buy a few tools for about $3000. That tells a little about the skill set you going to learn and become a technician and it does mention something about swapping movements I'm not sure is a technician with your authorized actually disassemble a movement. http://www.nghayekwatchmakingschool.org/The-Schools/miami/Schooling-Programm.aspx1 point

-

I'm just an enthusiast but I'll share my thoughts on this anyway. If you're looking for employment I believe a certificate would be very helpful if not a requirement. I haven't researched the topic too much but I think Googling "wostep watchmaking school" could provide some interesting reading. If want to start your own business it will of course be more a matter of building customer relations and trust in your own work. That will of course be very hard work and time consuming and perhaps something to pursue after a few years as an employee, which will also provide valuable contacts in the business. However, be aware that as an independent watchmaker it will sometimes be very difficult and sometimes even impossible to source spare parts as the brands for the last 35 years have been increasingly restricting the supply of spare parts with the goal of killing off the independent repair trade. It's a very sad situation. Anyway, best of luck with your endeavours becoming a watchmaker, and remember, "where there is a will there is a way"!1 point

-

Discussed various times already, please search. And which country are you from? If the UK, NHI offers long and costly distance learning with exams in person. That school is not as you may expect becuase for the firts two years or so you are only taught to file straight. If you want to learn quiacky to get on your way to be a professional I recommend that you enroll in our host Mark Lovick training at watchrepairlessons.com, and practice, practice, practice.1 point

-

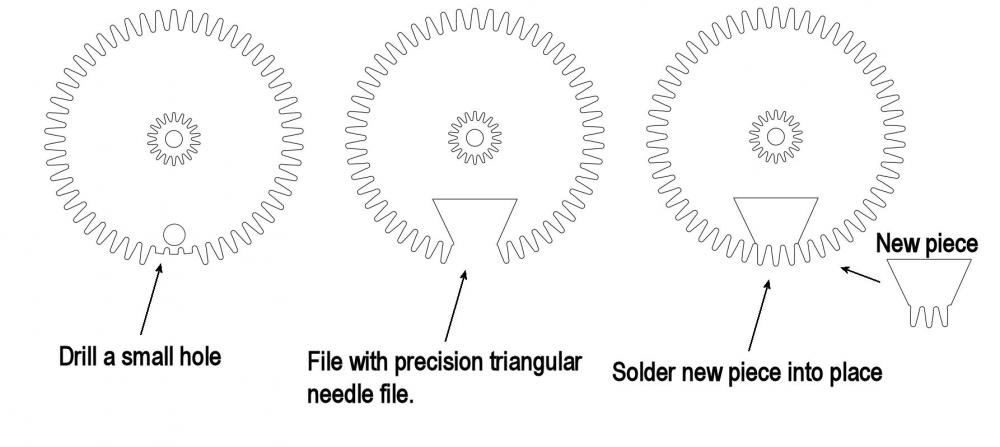

I think @oldhippy is right. From wrestling with hairsprings this is one of the trickiest repairs to do, and when doing it one whish one saved the previous discarded part in the “good to have in the future box”. When it comes to replacing the teeth the donor piece has to come from a wheel not only with the same diameter but also the same type of teeth and depth on them, this is so you will get the correct amount of freedom for the wheels to rotate in a correct way. Even small differences like these ones will make the wheels not to run correctly in the length. Another thing to consider is how to put the new piece in place. One should avoid making a rectangular shape to fit with and instead make a “dove tail” shape with a precision triangular file. Since the teeth on the wheel is subjected to lateral driving pressures a rectangular shape will eventually cause it to wriggle free and fall out, the solder hasn’t a very good mechanical resistance. This is just some small tips and tricks to think of when repairing wheels.1 point

-

1 point

-

1 point

-

Help! I need parts for a 1905 Hamilton 946 pocket watch size 18s. Specifically I need a lower balance jewel, upper center wheel jewel, and a mainspring. I know these are hard to find. I will consider buying a "parts" watch if it has some or all the needed parts. Any and all help appreciated.0 points

-

All I told him . " I have a watch it missing the crown , and I wasn't have the watch with me at this time " . He said " ok but I need to see it first cause every watch have specific crown not all is same " . I take the watch to him again and it was working just fine even with the missing crown . " He see it and told me "" ok leave it to me and I will get new crown to it "" . I left the watch with him for over 2 weeks . Then I go to him and ask for the watch and he said " there are some broken parts and it will take too long to fix " at this time I know that he can't fix it . So I ask for the new crown if he get it ( after 2 weeks ) and he said no not yet . So I ask him for the watch and told him I will not fix it and I will accept it as it . He give me the watch like you see . And when I ask him to get it back together he said " I apologise for you but really I can't get it back together it will take for ever so if you need money to give to another watch repair man to get it back together I will give you " and I refuse his money and get my watch back . This is the all story for this watch .0 points

-

Did the watchmaker know it was a fake before he accepted the job. Some watchmakers are known to destroy fakes when they see it. So sad.0 points