Leaderboard

Popular Content

Showing content with the highest reputation on 04/02/20 in all areas

-

3 points

-

Mainspring can't be changed. You need a new barrel with mainspring . Zodiac use a sealed for life barrel . Problem is they are rare and superhard to find. And 86 use a thinner mainspring because they are 36000 Hz movement so can't use a 72 or any other barrel.2 points

-

2 points

-

Scruffy, but interesting. It needs a crystal (obviously), and the case needs some work. I'm intrigued to see what is inside. Well within the 404 club entrance fee rules I might add.2 points

-

The overcoil / terminal curve on your hair spring is way out of shape and doesn't appear to be between the regulator pins. The overcoil should cross over the top of the body of the hair spring (arrow A) and pass between the regulator pins (arrow B). Yours appears to go around the outside of the body of the hair spring rather like the terminal curve on a flat h/s and completely misses the regulator.2 points

-

Hi all! Just thought I would share a project I'm finishing up that I thought was kind of interesting. Hearing the name Sony I immediately think electronics, the last thing I would have thought of is a mechanical watch like this one. After a service, new stem (in progress) and a little polywatch on the crystal I think it turned out to be a great looking watch. Someone got a little ham fisted on the dial between the 5-6 markers and there's a little corrosion on the dial in the same area but that's alright. Anyone have any info on the history of Sony with Seiko?1 point

-

It appears to be that it would've been helpful if we had paid attention to a prior discussion found here? https://www.watchrepairtalk.com/topic/13746-166026-omega-case/#comment-122709 So the very last reply by StuartBaker104 Has what I think is the solution to the problem. If you enter the case number in a variety of databases the decimal point isn't really a decimal point is just a separator and you need four digits. If you don't specify What the fourth digit is the various databases will fill in a number. So we had assumed that case number 166.026 was the same as 166.0260 just because we found parts for it but it is obviously not the correct case number. So for instance in the above discussion I found a link to Omega with the case number but we weren't paying attention because the movement was wrong and of course they filled in the fourth digit which is also wrong. So if you go to Omega with what we perceive is the correct case number we get the following link which seems to have the right movement? https://www.omegawatches.com/en-us/watch-omega-seamaster-cosmic-st-166-0026 The only problem is the dimensions do not appear to be correct for the crystal? 063PX5123 GLASS PLEXI 2N RING D32.94 H4.9 REF :063PX5123 063 DIAMETER D1 :32.94 MM 063 EYEGLASS :WIHTOUT 063 HEIGHT TOTAL H1 :4.90 MM 063 PROFILE :CONCAVE 063 SHAPE :ROUND 063 TYPE :UNICOQUE DIAM OF THE GLASS SEATING D2 :32.80 MM1 point

-

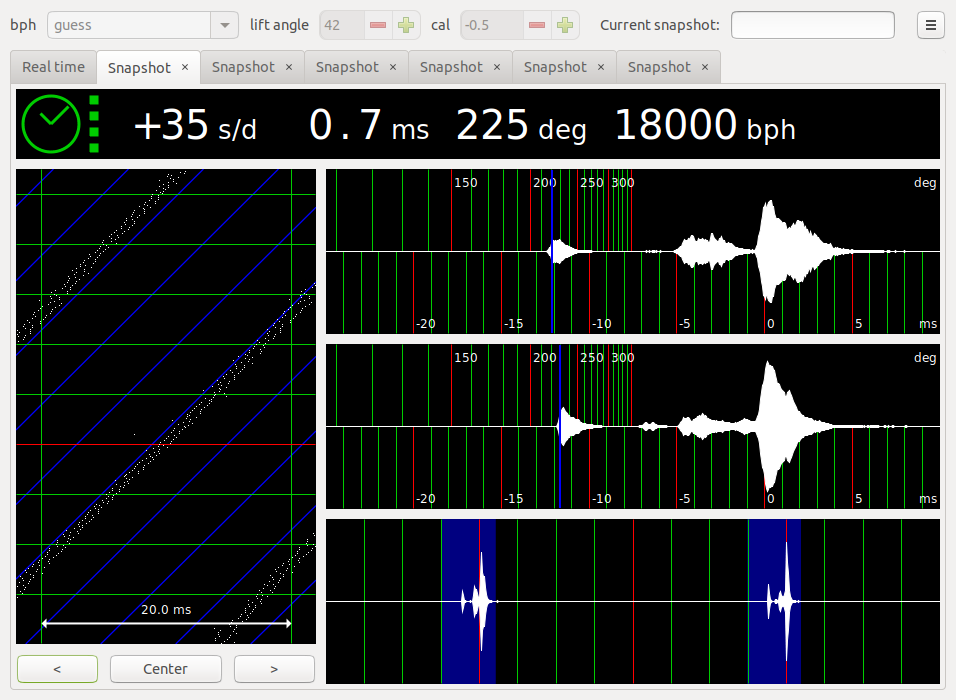

I was looking at a couple of watches last night, and at lunch time today. One of them was a "Veranda" 17 jewel EB8800 based pocket watch probably from the mid 1970s judging by the design. There is nothing particularly remarkable about this watch, or the process of fixing it, but I thought I'd share a couple of time graph results, just to show the importance of allowing things to settle down after cleaning, in order to best judge the effect of your efforts. This particular mechanism was stripped, cleaned and re-assembled at lunch time today, and once it was all back together I immediately stuck it on the time grapher to see if it was running acceptably well. This is what I saw with it fully wound, dial up at around 13:00 - not bad, considering the fact that that there was evidence that the watch had taken a serious knock, which had jammed everything up, prior to it coming in to my possession. The dots for the "tick" and "tock" are following a nice straight line, with no real deviation. The rate is a little fast, and the beat error is slightly high, but we can attend to those two minor issues later. This is exactly the same watch in the same position fully wound once more, at 20:00 after all of the lubrication has had a chance to get to work. As you can see, the swing has improved substantially. The rate is still slightly fast, and the beat error is still slightly high, but for now, I'll just carry it around with me to see that it runs consistently. Naturally the case, crystal, dial and hands all got a thorough cleaning too. The back of the case polished up so well that you can see your face in it. I wont touch anything in the watch mechanism again till some time tomorrow, probably after it has ben run for at least 24hrs, otherwise I might actually make matters worse, rather than better, as there is every chance that the rate will have changed slightly as the running gets a little smoother. The improvement is often that the rate slows down slightly and the swing angle increases. However if the rate increases and the beat error or the swing angle gets worse, then this may indicate that some oil has migrated to places where we don't want it, for example the hairspring. One thing this game teaches you above all else. Patience is most definitely a virtue when it comes to fixing old watches.1 point

-

Roger you beat me to it.. SEALED BARREL COMPLETE DISC 07/26/96 RC. CaseCaliber AS 1852 EBR 268-123 FL 1164 ZOD 72D ZOD 78 ZOD 86 ZOD 86B ZOD 881 point

-

1 point

-

Hi well done as jdm says leave it alone is part of is history, and does not spoil the look of the watch.1 point

-

1 point

-

By the way, take great care when removing the hands and dial. That luminous paint will be extremely fragile, but looks great the way it is!1 point

-

What exactly is happening with the balance wheel? Is it not swinging at all, swinging normally at first but coming to a rapid stop, or swinging erratically?1 point

-

The pivots can be moved up and down in the cylinder to adjust end shake and the correct height of the cylinder in relation to the escape wheel. You may find a makers mark under the dial. If not you may be able to identify from the keyless works and the movement diameter. The case is a generic silver import carrying the mark for George Stockwell whose sponsors mark appears on many imported silver cases of this era.1 point

-

1 point

-

Cheers guys, luckily for the height there is a stepped part on the arbor where the pallets seat so as long as I can turn to that exactly then fingers crossed we are good to go. I shall attempt to drill and fit a new pivot first, hopefully tomorrow, I will post pictures of progress. wish me luck!!1 point

-

I have done this repair. The centre arbour is friction fitted. Making a new one is a reasonably simple job with a lathe. However the height clearance is critical to get it to lock correctly with the escape wheel.1 point

-

1 point

-

They look fair, who made it one probably can see when you strip it down , a while ago I posted a stripdown of a cylinder movement maby that can help you on the way..1 point

-

1 point

-

This may be of no concern to you, but, if you remove the plating, you destroy the value and the history of the watch. I think it is beautiful just the way it is. You could always polish a bit by hand with Cape Cod Colth if you want, but short of replating the case, I would take no actions to harm the plating. Replating may well diminish the value as well. Good luck, RMD1 point

-

Put the dial and hands on and bench time it for several days. I find my Chinese timegrapher (W-1000) is terrible with vintage movements. It will predict a rate of +390 secs or more and yet when I bench time the movement is very accurate. It seems to work fine with modern movements. Go figure??!! RMD1 point

-

Are you sure you have the right hairsprings on the balance wheel, if not and all else is Ok, let maximum length of hairspring vibrate with the balance, if no change in daily rate, This hairsprings is incompatible with the wheel.1 point

-

Don’t know wether it was on this forum that I read this but I use it all the time now. Steradent dentures cleaning tablets. Now make sure that the numerals etc are under a glaze just to play safe, I have used this with the numerals painted onto the dial, just keep an eye on the task I case they get lifted by the cleaning action. 99% of hairline cracks disappear due to the dirt being removed from them, they still exist but are just about invisible to the naked eye. thought I’d share this tip whist no doubt we are all stuck indoors and tinkering away. Stay safe guys.1 point

-

1 point

-

1 point

-

Called a crystal or four glass clock. It could be an 8 day duration and it’s a strike on a gong. Pendulum is called a girl on a swing. Watchweasol is correct in saying the case is spelter, so be very careful as this stuff breaks and its very difficult to repair. Dates around the 1900’s to about 1915. Value to sell as I see it about £1,0001 point

-

Hi further data Antique Ansonia Clocks web site contains a wealth of information on American Ansonia Clocks Hope this helps.1 point

-

Hi early 19th C case is spelter which is a brass alloy, value ? need to consult Antique clock books . there is a site which will give you an approx value. look up under Antique clocks guide.1 point

-

1 point

-

1 point

-

I know how you feel Sound like a Canadian its a softer rounder accent American is too Harsh. I will always be a Yorkie I sound too obvious. cheers1 point

-

I searched the Omega vintage database (linked above) with just the cal number and it offered 166.0026 as a case option. Thee are no images, but this also works on Cousins’ site as a combination. You may need to Google some images to confirm, but I’m sure I’ve come across this leading zero issue before with Omega case numbers1 point

-

The beat error suggested sounds reasonable to me. Hairsprings often make odd noises.... Sometime a repeating "boing" sound. This can in some cases change across positions when the indexing pins are spaced too widely apart, or if the hairspring tends to sit against one pin rather than centrally..... But there may not be an actual issue here if the timing remains consistent. I would suggest it's probably fine if the timekeeping is good (which is sounds like it is). English-made Smiths from the 50's and 60's have an interesting sound. Lots of pinging from the escapement.1 point