Leaderboard

Popular Content

Showing content with the highest reputation on 05/30/19 in all areas

-

You also need to check with timegrapher after servicing a movement. The day/date advance wheel changes from A to B and C. One can check my parts table for differences https://docs.google.com/spreadsheets/d/e/2PACX-1vRN2UULQKTfKmhRStZhDdIOIQrqd6sPB-g6x2SKyQQjOvTBjG_7TQXQhAT4f1WqAX5QAPkIimi-3jqd/pubhtml2 points

-

I think that's an older generation brake. The clone would have very similar geometry but be made of metal.2 points

-

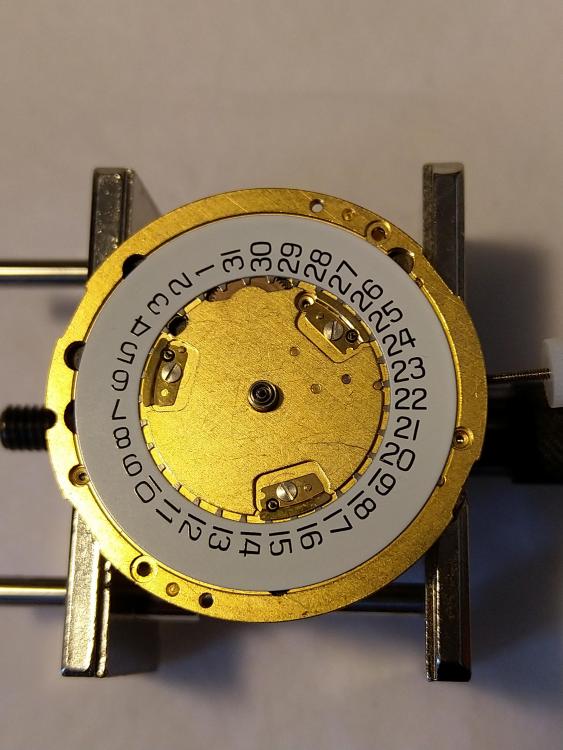

Well I picked up this little piece of machinery the other day. Ive updated the screws to the blue style. The plan is to cut a two peice divers (as my cnc cant cut threads for a screw back) made from bronze and copper. This is gonna be a challenge so group prayers please. Sent from my SM-G950U using Tapatalk1 point

-

1 point

-

Keep us updated, I and presumably the rest of the replica fora be interested in interchangeability between shock springs. I never did see it with the ETA clones. The 7750 copy is quite nice, until you get to the auto bridge1 point

-

OK re the timegrapher. My normal routine is to check the basic working rate with the timegrapher immediately after the repair (just to prove I did not nause it up during the service). Then wear it for a least a day or two, just to make sure the lubricants are all better distributed across the pivots etc. then a final check for beat error (adjusting as may be required), then rate checking across five positions on the timegrapher, trying to get an average of less than 10 secs per day, averaged across all five positions. Also ensuring that the amplitude is also acceptable. There you go, maybe a bit of a pedant , but them I’m a hobbyist and also retired, so it’s not like I don’t have the time to waste on trying to keep my work to a high standard. Good point about the day/date advance wheel though, I will check and compare to ensure I don’t introduce a new problem. Thanks for the interest and your tips.1 point

-

Just moved house which has meant a workshop/studio rebuild It's coming together but a lot to do still... will get back to videos real soon Sent from my SM-G950F using Tapatalk1 point

-

Great information to have on the 7750. I am going to test a piece of curved plexi for the crystal and also have to try the drill holes for the stem/crown. I'll let you know when I get all that sorted out. Thanks! J1 point

-

Should be. Think it's the balance and some other parts that are different. I even took the same date driving wheel from some Seiko quartz movements. That are the same wheel. Don't remember the number now. But i guess they use the same in lots of movements. Check the tiny intermediate wheel to.1 point

-

I have an MKS jeweling set. It is well made, but mine has had a hard life and as such I bought it cheap, so will probably replace it at some point, but at the moment it is still doing the job.1 point

-

If the quality of the tools that I've used on old Japanese motorcycle is anything to on, watchmakers tools of Japanese origin will be up to the job in hand. I did examine a vintage set from the 60's by MKS, which I believe is/was a Japanese manufacture, at a local auction some time ago, it look more than adequate to me. In retrospect I wished I'd left a bid on it. Sent from my moto g(6) play using Tapatalk1 point

-

Back in the 70's and 80's I bought a Japanese staking set and found it to be very good. The finish was very good , I also had a Boley set as well. Both very good. The Jap set had more verity of stakes.1 point

-

1 point

-

Its like a flat peice of plastice with a wire sticking out. Appears to be teflon or some soft plastic. I have a clone on the way so well see whats inside it. Thanks for looking into it. I wonder if itll perform as the normal one. I honestly dont see the advantage from a manf standpoint making it this way. It almost would seem like itd be more costly than the stamping that the eta parts are made from so thats why im curious. Sent from my SM-G950U using Tapatalk1 point

-

Hi All good advise already posted as Noirracj says unscrew enough to release the stem and no more as you found out it makes more work all the best1 point

-

That’s a good tip, I’ll look at when i strip it again on Friday. Thanks. I do have a spare in a donor 7S26A movement to compare it with. I’m guessing that this part is the same on the A and C variants.1 point

-

1 point

-

1 point

-

Even though the garden is screaming for attention one has some spare time to continue my magical journey through the heap of quartz movements. This time it is the ETA 251.262 Chronograph which can be found in watches like Breitling Colt Steel, Certina DS FIRST, Longines Hydro Conquest and so on.. I'm quite surprised of the amount of quartz movements which are getting a new life after a good clean and service. As usual all the files are in a PDF format, and all pictures are original. ETA_251_262_Dissasemble.pdf ETA_251_262_Assemble.pdf1 point

-

The idea was to make a movement holder and dial that are both a light press fit inside the case, if necessary they can be glued together. The back of the holder will be machined so the movement fits in snugly. There will be a small gap between the movement and the back of the case that will need a plastic or foam shim to keep everything tight. I would be relying on the stem and the shim to stop the movement rotating. For belt and braces I could also add dial dots but only if absolutely necessary. I cannot see why this wouldn't work - but you could fill a library with what I don't know about watch making Making the dial will be the hardest part of the project so I want to avoid the complication of adding dial feet if I can. I have not found any suitable ready made dials that I like and even if I do, I suspect the feet are unlikely to be in the right place.1 point