Leaderboard

Popular Content

Showing content with the highest reputation on 04/21/19 in all areas

-

It was very erratic and hard to quantify. But I'd say around 10% of the beats were completely wrong. The replacement escape wheel and pallet fork arrived. Fitted today and wow, what a difference. I put the escape wheel under the microscope to compare it to the old one and yeah it was completely worn. Thanks everyone for the advice.3 points

-

I purchased this Luminox off ebay for parts and repair for $30. The movement got wet. I purchased the replacement ETA 251471 for $39. That was the easy part. The tritium tubes were also burnt out. You can buy the tubes for about 8 bucks each off Amazon. You can also send it back to Luminox to have them replaced for an ungodly amount. I purchased this chinese tritium tube watch for $45. The tubes are exactky the same size. Perfect fit. The tubes are held in with a recess in the dial ring so theres no glue. It was super easy to replace them. Ill have about $100 bucks in it. Not bad for a fixer upper. Sent from my SM-G950U using Tapatalk2 points

-

Horological lubrication is quite a fascinating subject. Unlike some things in watch repair that haven’t really changed in the last hundred years horological lubrication seems to always be changing. As this particular discussion demonstrates lubrication of the pallet fork pivots sometimes they do sometimes they don’t. Then the choice of lubrication’s typical responses look at the tech sheet. But the various watch companies typically all have differing recommendations and those recommendations almost always have changed with time. Then there is the missing information such as surface treatment and other stuff. Or the assumption whoever’s reading a technical guide is a professional watchmaker that knows what they’re doing. Of course we all have our personal choices and thoughts on the subject which very likely could all be different. The original title of this discussion was lubrication of the pivots the pallet fork that generally is an easy subject in that it’s usually frowned upon at least by the Swiss. Oiling of the rest of the escapement can get quite interesting. This is where time is an interesting thing or when the technical sheets came into existence. For an example of this I pulled out a couple of older Swiss technical guides and the earlier one is recommending 9020 for the pallet stones. A couple years later they switch to 941. Then I don’t remember how many years before 9415 comes into existence but it will show up eventually. Then when it does its typically for the higher frequency watches as it stays in place better. But with time even on lower frequency of 18,000 BPH watches you’ll see either or recommendation. Currently everyone seems to going just to 9415. So did you think this was confusing at all? Did you wonder what I meant by missing information other than surface treatment? Omega’s an interesting company over the years they’ve had technical information separate from their normal technical guides. Working instruction number 40 is quite interesting for instance it’s on lubrication and I’ve attached the PDF to this message. I think you'll find starting on page 13 quite interesting.. CousinsUK.com Omega 8645_WI_40_rules for lubrication.pdf2 points

-

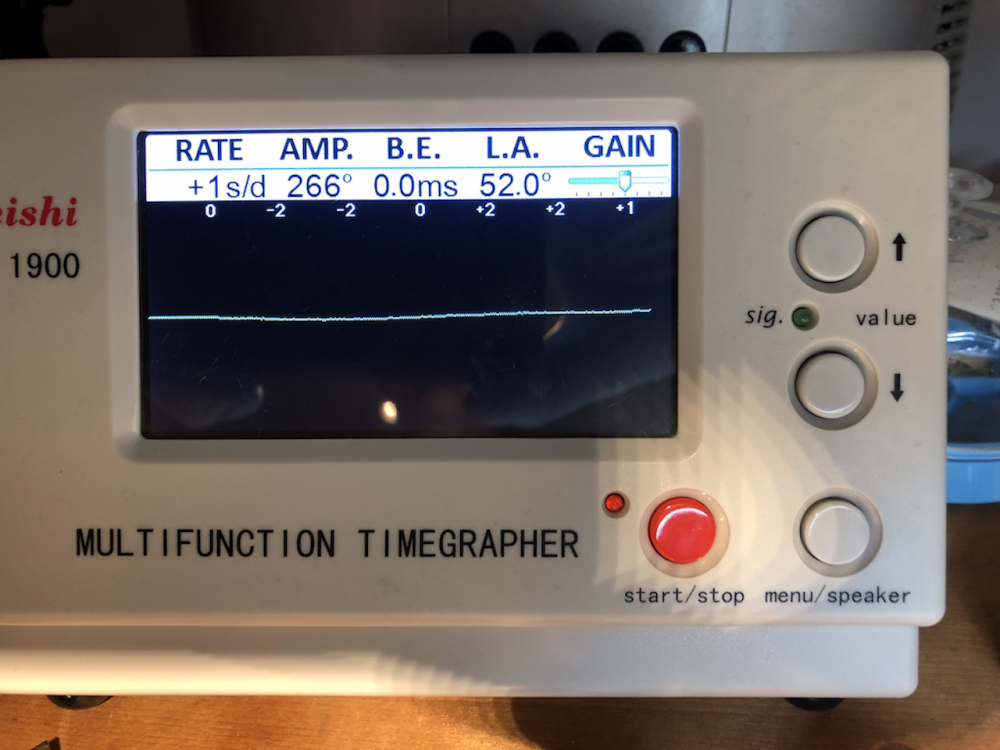

After 2 weeks of Vostok Komandirskie testing on the wrist back to a vintage watch. (Very consistent and gaining pretty much in line with timegrapher so I'll regulate it a smidge). Omax automatic winding with AS2066 movement. This one has been fun, received and tested and it seemed to be running erratically. Checked on timegrapher and the beat error was all over the place. On opening I discovered the stud lever was not correctly attached to the balance cock, so auto work off. Balance off, wheel and hairspring removed and quite a bit of fiddling with a couple of pairs of tweezers ensued to get stud lever, regulating lever and cock to fit together. Then reassemble. Set beat. Regulate, reassemble automatic work. Re case, test, timegrapher was picking up the correct rate but seemed to be only picking up alternate ticks, removed, removed automatic works, re tested, same, removed checked and reinstalled balance cock, same. Set and left it for the night and this morning checked and it's keeping decent time, then I thought, I'll just try adjusting the stud lever again because it was niggling me that it was almost at the furthest point of travel to the cock. Suddenly I've got a tick and a tock again and unlike before no movement necessary to get the balance to spin, in fact it's nigh on impossible to get it to stop now that it's correctly in beat. The moral of this? Technology is great but it isn't infallible and won't help you being a dumbass and not physically checking the impulse pin alignment! After that, I have to say I really like this watch. It's in the 'to clean and lubricate' pile.2 points

-

Well, it's even a bit more complicated. If you notice Moebious as well our expert recommend two different types 9415 and 941, even their numbering is very similar. But while the first is classified as a grease, the second is an oil with "remarkable adhesion". So which one to choose? Personal preferences aside, some difference in the application could be in the at which the escape wheel rotates, more speed more centrifugal force and more impacts. You can say that for 28,800 and up "high beats" to use the grease, while for slower moving mov.ts the oil should work fine anyway.2 points

-

To avoid guessing and mistakes our friendly experts above have mentioned the recommended types. I suggest that you click the link posted by JohnR275. Moebious is the industrious leader and is worth to spend 5 minutes learning on their catalogue.2 points

-

I put it on the impulse faces of the escape wheel teeth (all).2 points

-

Oh and you might want to reconsider your title..... we could end up with fetish weirdos finding your post through dodgy search engines2 points

-

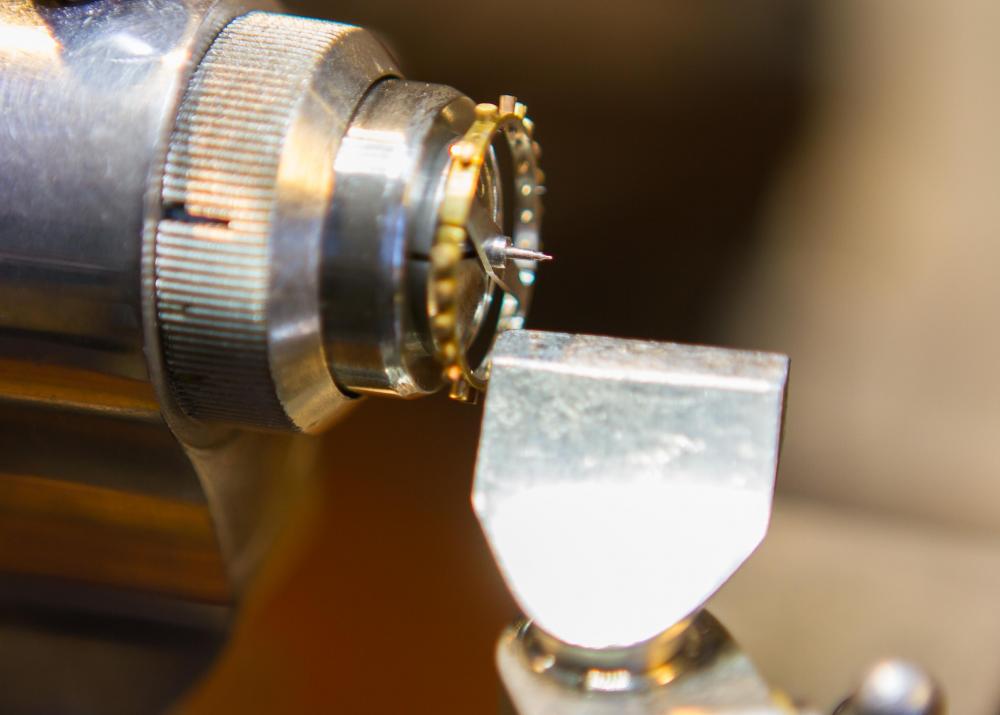

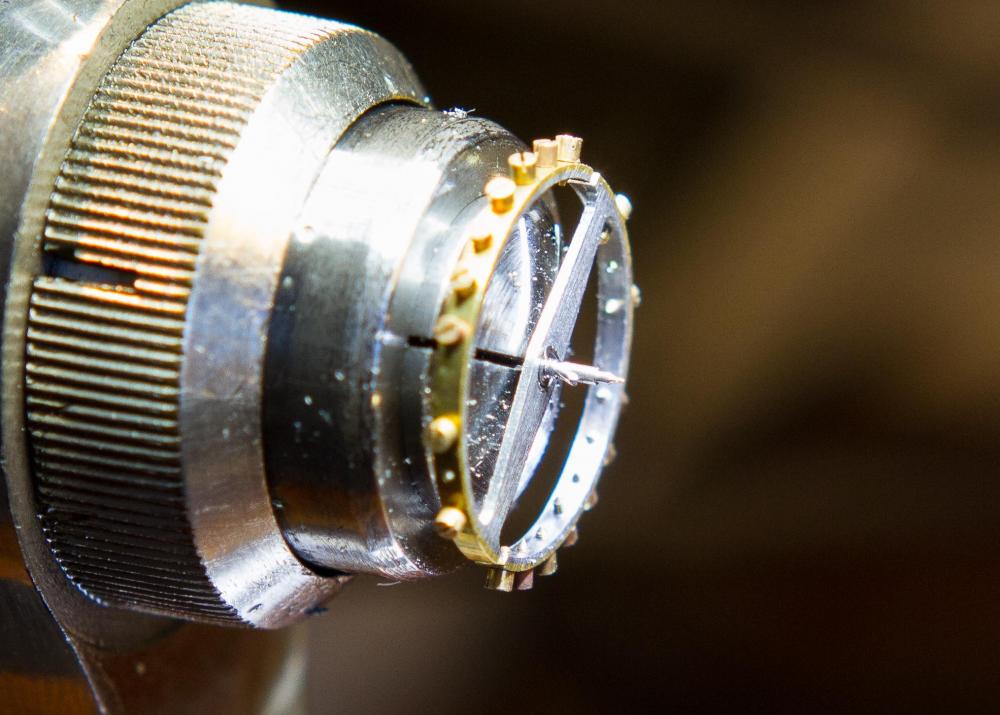

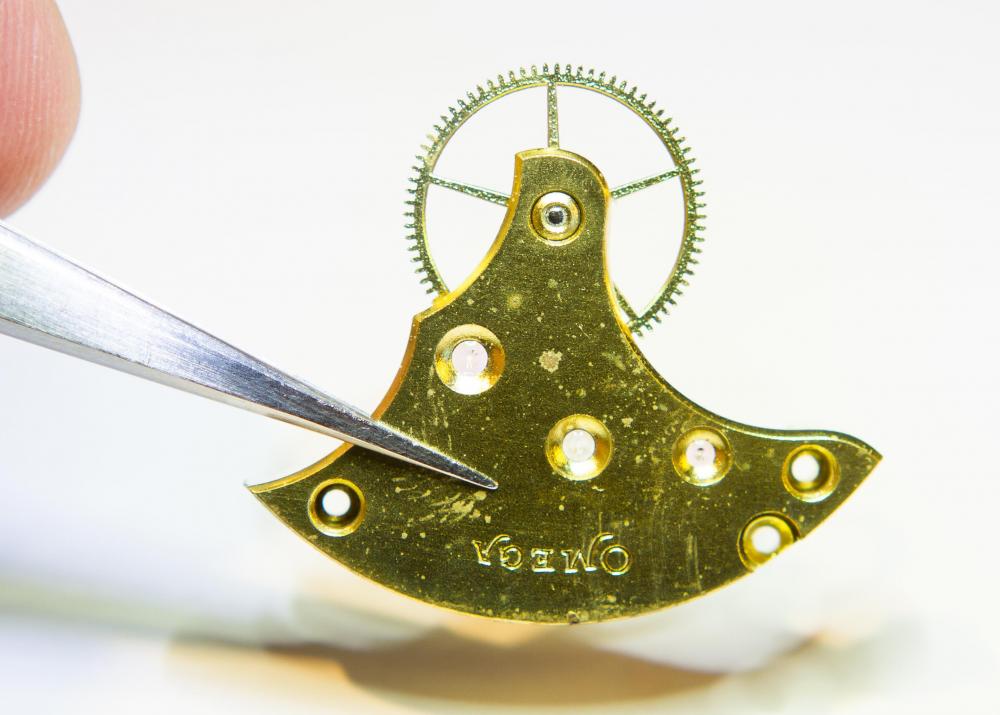

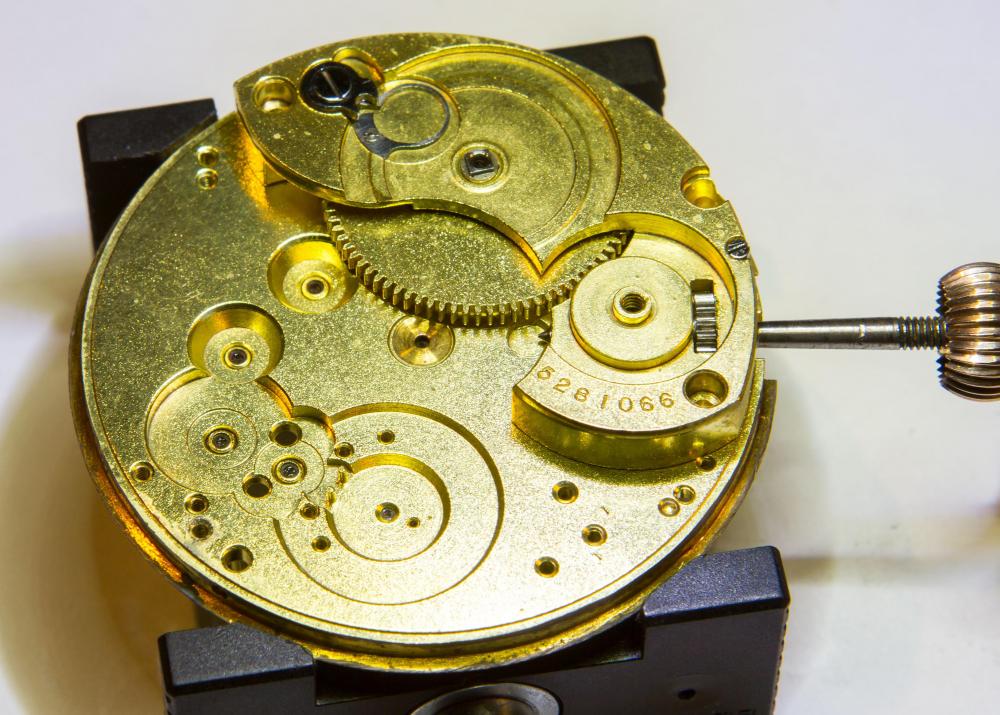

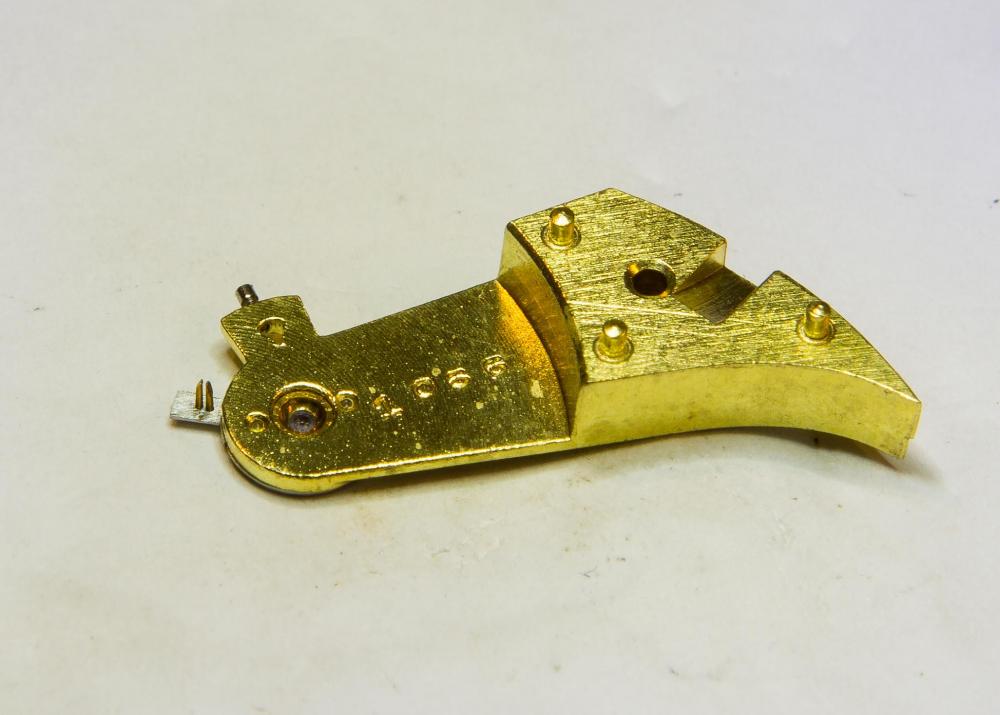

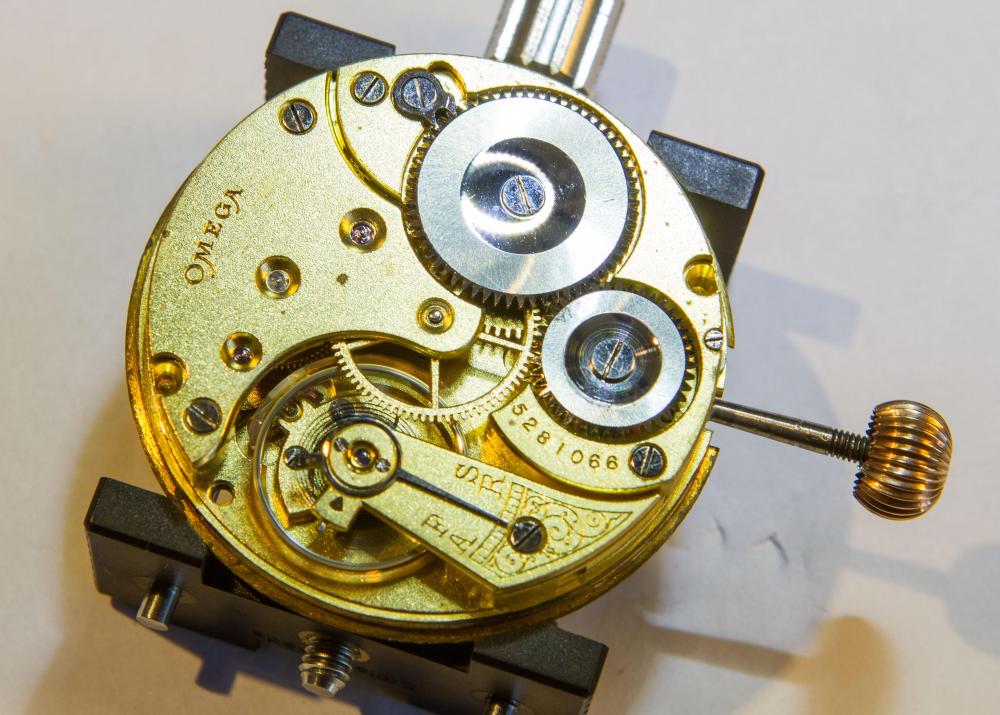

A friend asked me to take a look at a pocket watch recently which stayed in hand setting mode even with the crown pushed in. I assumed a broken yoke spring... but actually no harm done, other than dried up really sticky oil everywhere! Goodness knows when this movement was last serviced, but certainly not in the last 20 years I would guess. I didn't take any photos before disassembly as it wasn't really easy to see what the problem was just by looking. But this picture of the train bridge shows the centre wheel stuck in its bush with crusty oil Unfortunately, there are also a few fingerprints and corrosion spots on the plates, which I couldn't remove during cleaning. I found a couple of other interesting things during the disassembly. The bridle on the mainspring has a little Omega symbol stamped on it. Sadly, I don't think the spring is correct for the watch - it should be a double brace and hole spring, but only has the lugs to fit in the barrel slots, not the hole. It may also be a little short, but on the basis that it must have worked once, I thought I'd clean it up and give it a whirl. More problematic was that the balance staff was missing a little off one of the pivots - enough that the pivot wouldn't reach the end-stone, so I figured that had to go. Of course, not easy to track down a replacement balance staff for a 103 year old watch, but eBay was my friend on this occasion. New staff on the right, and what a beautiful blued Breguet hairspring Set in the lathe ready to turn off the hub Hub removed so I can punch out the staff Old staff out Punches at the ready to rivet the new staff in to place - one domed to spread the rivet and one flat to set it. The staff was a little loose in the balance arm, but it riveted down OK. Finally pushing the roller table back into place And checking the poise. It was a little out, but there was some dirt in a couple of the screw head slots and removing that seemed to do the trick. Hairspring back on and ready to go Keyless works back together and now moving freely Barrel bridge on Train wheels and jewels all cleaned Train in place One of the lovely things about old watches is the serial number popping up everywhere. It had been scratched inside the barrel and I didn't take a photo of that. but here is the marking on the back of the pallet cock. and on the back of the balance cock Quick wind and off she goes The case is stamped EWCCo (English Watch Case Co) and is hallmarked for 1927 so is therefore just over 10 years younger than the movement. It also has some case screw marks inside which don't line up with the Omega movement so obviously a later marriage. And just for kicks, alongside my Omega PW from the same year. I think I know which one John will want me to give back to him and anyway I'm still in love with those Omega hands!1 point

-

It looks like solid brass? If so, you can just take the old laquer off with paint remover, then polish it and redo the clock with laquer you buy in spray cans, wipe it over with mineral turps first to take off any resadue. Don't leave it raw brass as it will tarnish quick and you will get fingerprints all over it.1 point

-

1 point

-

I was kind of hoping the hairspring fairy might tweak mine during the night. Such an oddity. The thing that really threw me was that it set and regulated before I re cased it then after that it wouldn't. It was only because I really struggled getting the balance in and swinging second go round that made me think I'll retry setting it in beat. Good to hear your hairspring fairy visited and it's going well now.1 point

-

This should definitely be in "watch repair" section Many questions same as your over the time, so I suggest you use the search function, anyway the answers you'll get are: double check again stones and pivot especially the one supporting the troubled position, as well end-shake.1 point

-

Very well done. Watches are so strange sometime, yesterday I worked on a 7S26 which was ready to go until I decided that I couldn't honestly sell it with 30 s/d DU/DD difference. Started taking it apart and a sequence of strange mall problems ensued. At the end it was almost good on the timegrapher except for a reduced amplitude and periods of crazy beat skipping every minute or so. I was accepting that I would have had to go at it again, let it running and today at noon is was the below, no more skipping or anything. I can only suppose it managed to munch some tiny fiber or the like.1 point

-

1 point

-

Great write up. Every watch is a different challenge. I have been making balance staffs for some time now as I love making them. Sent from my iPhone using Tapatalk Pro1 point

-

Not at all, a reasoned discussion is key to understand the "why" of things, and that's the best asset in doing hobby or trade.1 point

-

Beyond the recommendations, for the best performance it's always better to examine the performance interaction between the wheels and prefer right viscosity values for each wheels in only attending on viscosity values... And plus i might also need to lubricate the pallet pivots... İt's not right to choose roughly what recommendations say. But of course most people don't need so complicated examinations but if i had an a.lange söhne watch, i certainly would do that... Anyway... I think this was an important topic to discuss on lubrication topic... So please don't think that I makelonger the discussion for nothing... Thank you very much for understanding...1 point

-

Simply try to look for a Dubois - Depraz Chronograph module servicing walkthrough or a video.1 point

-

İt's better to lubricate teeth of escape wheel where having contact with pallet stones with a thick lubricant but not grease. I don't know lubricant codes sorry... in leaving areas with high pressure it's better to use thick oils. I am not watch expert i just told this according to physical rules... I don't know how to polish the pin pallets... Actually it would be better if someone share how to polish the stones, if it's possible... I need that information too... Because it's the hardest thing to replace the watch stones in watchmaking...1 point

-

Great writeup. Is there a reason you had to turn that bit down in the lathe prior to punching the staff out? I have yet to replace a staff, although I have acquired a staking set. Cheers Alex1 point

-

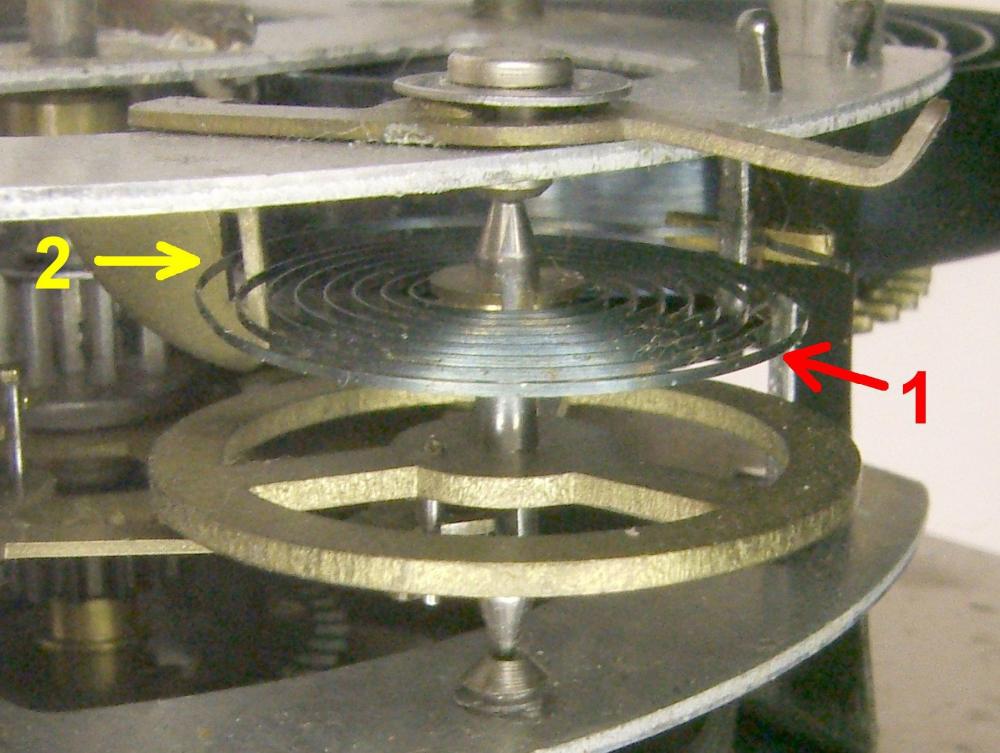

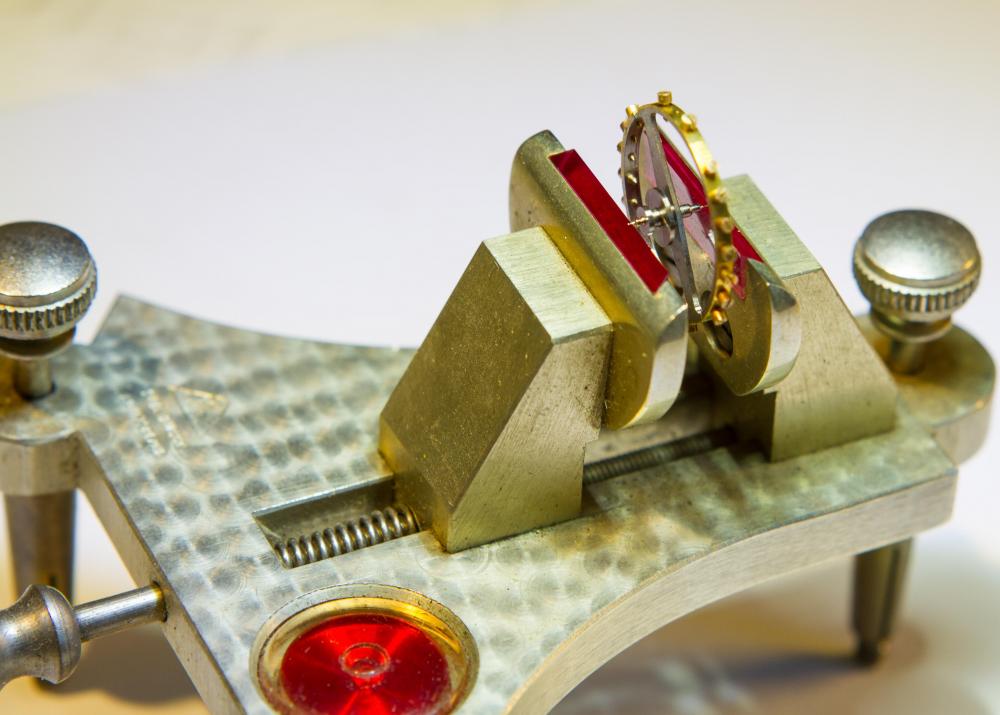

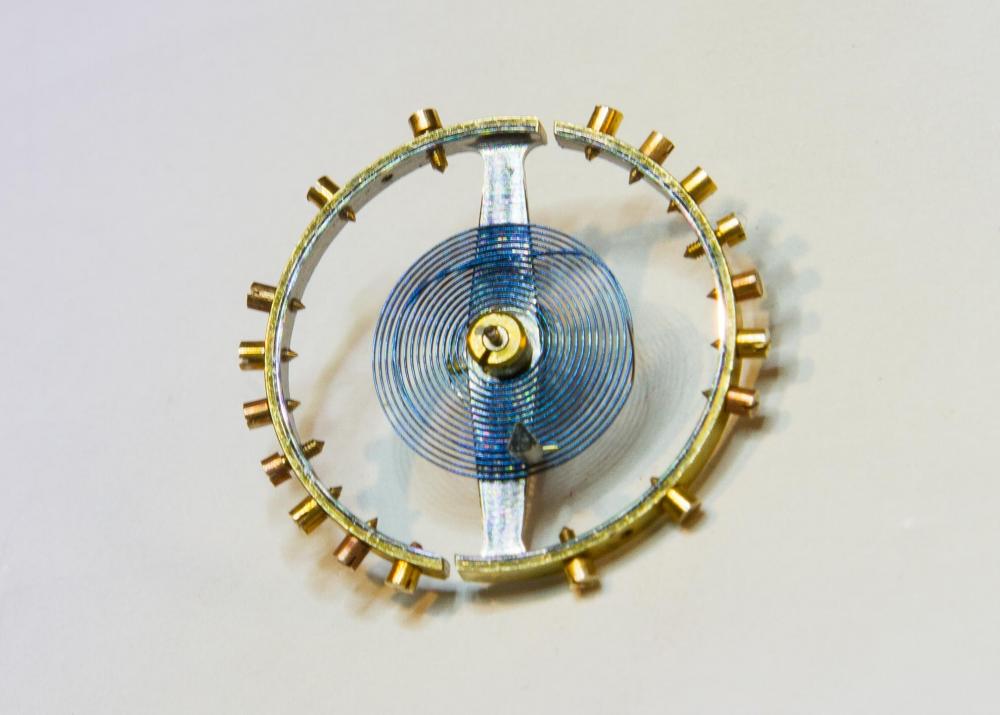

That is a 30 hour. Here is a photo of the balance wheel and how it is held between the two oil cups. It already shows you how the hairspring should be, also how it is pinned. Three things can go wrong with this. 1 The hairspring can be mangled up, 2 the balance pivots can be worn and need to be put into a lathe and re-pointed with a small Arkansas stone. Picture a blunt pencil then turned into a sharp one. 3 The oil cups can wear inside and need to be re-placed or with the right drills cleaned up. You cannot re-bush the movements the plates are too thin. I know the photo says alarm clock balance. The clock movement in what you are going for its the same.1 point

-

1 point

-

The pins need lubrication. It probably sounds crazy but 8300 is good. Oils don't stay put.1 point

-

1 point

-

Hi I'm Nigel and I'm based in Ireland, I have been looking forward to having the time to indulge my interest in mechanical watches, I am a complete newbie to all of this and have a long learning curve to follow, I have a few older watches that I've owned for some time nothing expensive but ones that have sentimental value to me, a Roamer San Marino from around 1976 and a Rotary from around the mid 80's. My main interest lies in the cleaning service and repair of watches but I suspect that, I may end up looking at pocket watches for the larger size of the movements, but we will see how it goes.1 point

-

It is indeed a capacitor, not a battery. The difference is that the capacitor can be recharged an infinite number of times where a battery, unless it's intended to be rechargeable, can't. Citizen would be a bit off the mark if they used batteries in an eco-drive. The whole idea is to present a package that is totally environmentally friendly. Seiko missed the mark with their kinetic drive watches. The original capacitors didn't have enough current flow to power the watch for an extended period. You never really see or hear Seiko referring to their kinetic line as "battery powered". Rather, they prefer to use the term energy cell. Semantics. The Citizen eco-drive watches are much more efficient at keeping the capacitor charged. No arm swinging required. I leave mine beneath my Dazor twin tube fluorescent light overnight and it's good for six months.1 point

-

The pallet pivots are exposed to strengthened pressure on just two directions, so they have no circular movement like wheel pivots... So, lubricating them doesn't so much effect on their performance. But, lubricant may be sticky after a time and this causes excessive friction on the pivot rather than wheels... Lubricant can also be fully sticked and that prevents the move... Lubricating them may be useful on some watches which have high beat rates, i guess...1 point

-

1 point

-

1 point

-

It's generally frowned upon to oil the pallet fork pivots. If you put the watch on a timing machine before and after you will usually see a small decrease in amplitude. If with time the lubrication gets more sticky that decrease of amplitude will be more dramatic. Seiko as mentioned above does recommend oiling the pivots sort of? If you go through their tech sheets sometimes they do sometimes they don't. The other strange thing for Seiko is if you have multiple generations of service sheets even for a particular caliber sometimes they do sometimes they don't and unfortunately they do not explain why.1 point

.thumb.jpg.b2d9433f9d45d2e4414929af0fb4f950.jpg)