Leaderboard

Popular Content

Showing content with the highest reputation on 01/04/21 in all areas

-

I've given up on the idea of a comprehensive, affordable set of mainspring winders. A new spring is cheap and goes in so easily! By no means am I an expert with hairsprings, but repairing them is a question of the right tools and lots of practice. If you are tangling them, then you are handling the balance wrong. Watch how Mark and other professionals so it, and practise using the same techniques. Hot Tip! If a fly lands on your finger when you are working, remove the tip of your tweezers from the hairspring before swatting it with your free hand.2 points

-

Recent repair to Vintage Benrus Electronic Citation . It was listed as not working and the seconds hand haven fallen off. Wen it came in I found it to be quite a nice value with its all stainless steel front loading case. I good soaking to the case, buff to the crystal, touch up to the ring and quick clean to the movement and here it is. All happy again. I used nail polish to fill in the ring ?1 point

-

1 point

-

How do you open these? Just like the real one? I got two of them, wanted to give them to my almost 6 years old daughter who likes to play watchmaking game, but could not open them. She sits in my chair, I am the customer and she works on my watches for £1, IF she is open and not tired. What surprised me that i was also charged 50p for my coffee. ?1 point

-

What can mechanical engineers do amidst covid19 pandemic / lockdown? Correct, get active on watchrepair forum! You may want to check this link searching with your watch case number: https://www.cousinsuk.com/category/filter/seiko-case-parts1 point

-

O Canada / Ô Canada !! ? You are in the right place where you can apply everything you recently learned in school: Mechanical Engineering & Mechanical Watches - perfect combination! If you are from Ontario - here is your Tools & Parts stores short list: https://perrinwatchparts.com/ https://www.somalcanada.com/1 point

-

1 point

-

1 point

-

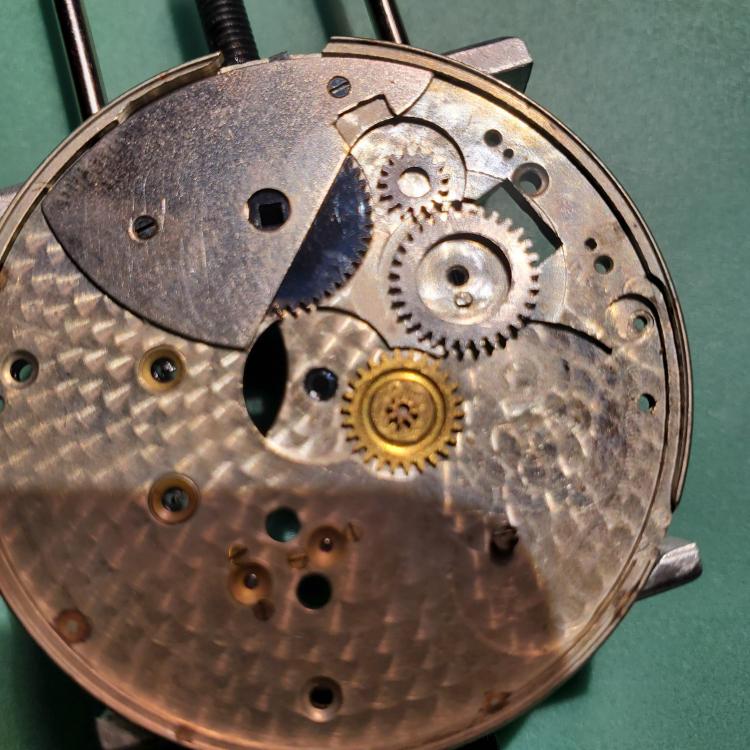

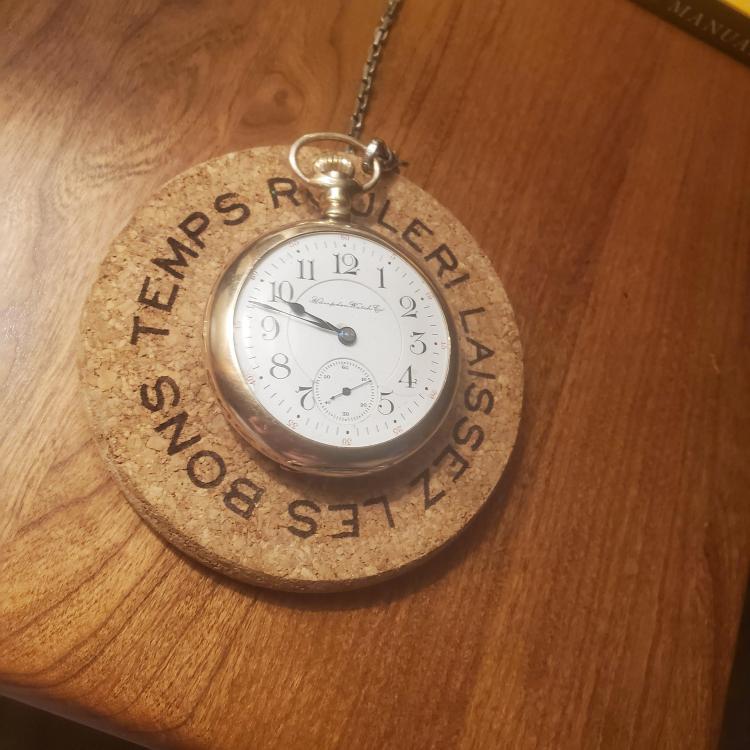

The fourth of five pocket watches my brother sent to me to service: an open-face with Minerva model #3. Straight-line anchor lever, "visible pallets", double roller, 15 jewels. The case is silver with rose gold trim, marked 0.800 fine, stamped with the Halbmond und Reichskröne of the German assay office for export to Germany, case serial #754944. I will edit, or reply, to include more details later if I am able to learn more. This one has a fine Swiss movement in marvelous shape, wheels are perfect, pivots look great, everything in there in meticulous shape and ready to run, needing only a good cleaning, lube, and possibly regulation. But the case on the other hand...just refer to the pictures below. The bow has somehow been *torn* from its pendant. The crystal looks as though it has been skittering down a street like an expensive stand-in for a hockey puck. And the face had the classic marks of some careless "tech" prying the dial off by force: divots in the porcelain directly on the other side of the dial feet (4:30 & 10:30). So for this watch, it is more in need of case restoration than any mechanical repair. But that's okay; I've been practicing this kind of thing. - For the crystal - I have been buffing it with basic toothpaste. (Chuck wanted to keep the original if possible.) And it's actually coming around, slowly but surely. - For the dial - I have already repaired it with my dial enamel and it looks loads better; barely noticeable at a foot or two away. - For the pendant - If you look at the first picture, with the dial facing you, the right side of the pendant has a kind of brass fitting, or ferule. I am turning a piece of brass to that exact size and shape. It will be mounted using silver solder, which I will build up around the edges where the original metal is absent. Then to gently file and buff down to shape. After that I will reinstall the bow. EDIT: included original photo of the movement which I forgot to do earlier.1 point

-

If the item wasn't working, then whoever owned it may simply have used it as a display piece, and in order to make it look its best (to their eye) they gave it a "nice shiny coat" of whatever inappropriate finish they had to hand. The uniform nature of it makes me think it probably came out of a rattle can, in which case xylene (dimethylbenzene) or even something like butanone, also known as methyl ethyl ketone (MEK) might be necessary to dissolve it. All of the solvents I've suggested should be used in a well ventilated area. Also... wear gloves.1 point

-

First thing is to only use brass when you need to- cosmetic parts that will show scratches. Keep them out of reach, not right next to the others. Dressing tweezers is often covered in the books, because it is like dressing drivers, and you need to do it often. Check your books, or perhaps online sources. I like to get the tips in good shape internally first- usually a piece of 600 grit folded so there is grip on both sides, is held within the lightly closed tweezers until any high spots are removed (even finish on both tips). This helps to make the internal surfaces parallel as well. Now, the most important thing is to look at the closed tips with a bright backlight. I have seen (and made myself, before I perfected my technique) "dressed" tweezers that fail this test- when you squeeze them, the very tip should always be closed (not passing any light). Often the tips can separate when closed fully, and then parts fly out when you close them. Once the inside is right, I pull 600 across (perpendicular to their length) slowly to give the tips a slight bit of 'grip'. I used to polish them with 1000 to reduce scratches, but properly dressed AND HANDLED they won't scratch, and the grip "force" is reduced, thereby reducing the chance of scratches as well. You grab screws by the threads typically and plates that are not seen in the final assembly do not need brass tweezers either. Obviously the train gears don't need brass and only the large wheels on the mainspring (which might be decorated and/or polished) I would consider brass, but typically stick with the steel ones there too. Light touch! Keep them demagnetized, or get anti-magnetic ones. I had decent tweezers before, but when I got my anti-magnetic Dumont ones, it was like going from a riding lawn mower to a Rolls Royce. Unbelievable how much that made a difference in my control and confidence. Light touch! Brass tweezers are dressed exactly the same way, but often the tips just get bent due to being sofer. Dropping them on the floor is the best way to reuin them forever. I have cheap ones that I spent an hour dressing before use, and they are fine, but rarely used- only when I have to use them. So, I bend them back into shape as much as possible before dressing the tips as I do for my stainless ones.1 point

-

Recently acquired this junker. But I quite like it, so I'm going to fix it up and enjoy it. Faux Eta 2824 inside is running fast, and presumed dry. I regulated it down to +10 (and put put a drop of oil on the dry rotor bearing so it was less noisy than my snow blower) and will either service it or replace it. Looks reasonably close to the real one, which I did try on when it was available. This is about $10, 250.00 less expensive than that one was, so I have a bit of change to cover lubricants...1 point

-

Shellac Lacquers are made by dissolving it into methylated spirits and is easy to remove from metal by using it use a cotton bud with not too much on. Spray on Lacquer depending on formulation can be removed with acetone or Xylene thinners some Lacquers are impervious to acetone and some are impervious to Xylene so it trial and error.1 point

-

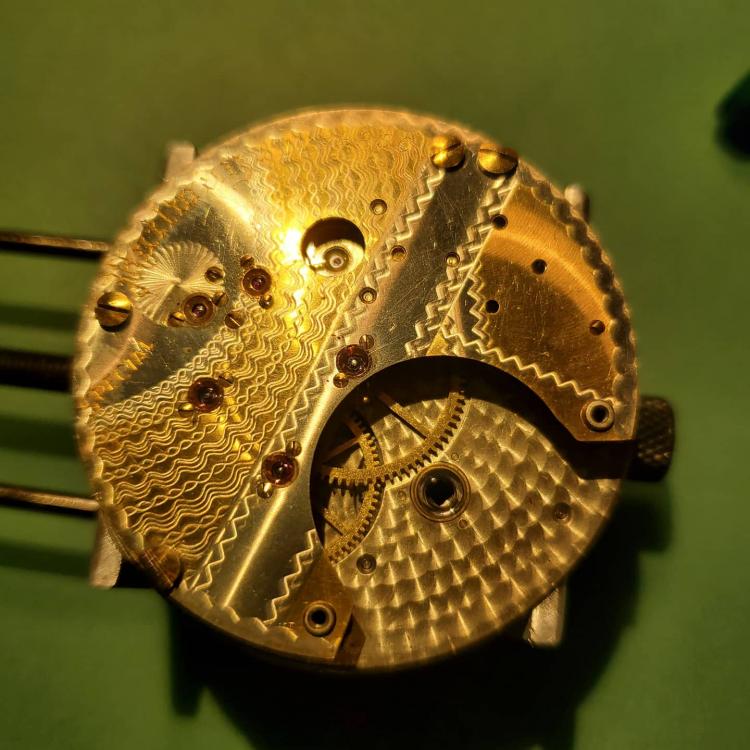

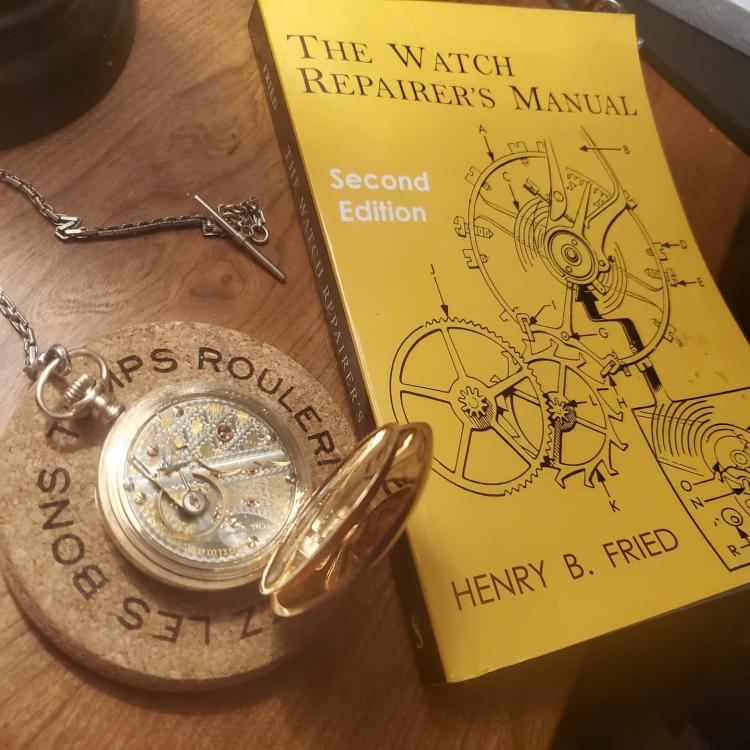

The second in the series of 5 watch services that I'm doing for my brother: an Illinois Model #1, circa 1905. I decided to get this one done while I wait for parts shipment for the NY Standard. These are the details on the Illinois: Serial #1777464, Grade 219, Model 1. Open face, screw back, screw bezel, crown wind & set. Wadsworth gold-filled case, warranted 20 years, serial #1090519 Nickel finish damaskeened movement, size 12s. Anchor lever, compensating balance with micro-metric on regulator index. Going barrel, 3/4 plate, unadjusted. This pretty pocket watch needed only the basic pentenniel service of strip & clean, oil & grease, and regulation. The case has a couple dings and the porcelain dial has a couple mild hairlines, but nothing so great that it robs from its aesthetic. Indeed, I think it possesses an appropriate patina for its age. Nevertheless, I cleaned the dial and polished the case, and I think it looks great now. And seems to be running strong. This was light work compared to what I face with a couple of my brother's other watches. And again, look how pretty this movement is! My word, I wish they still decorated mechanisms like that! And it regulated to within 7 to 8 seconds average in all positions. That micrometric regulator is a godsend. I've always liked those.1 point

-

Oh, and @Poljot has the right idea: if you're going to remove the whipspring of the micrometric regulator for cleaning, then you will definitely want to mark where the balance arm is on the balance cock scale. I do a bit of graphic arts, so I use a super-fine tip marker - a Pigma Micron 005 - which uses ink similar to that in a Sharpie and comes right off with rubbing alcohol, and the tip is so fine that you can rather accurately mark the location of the balance arm. Now, this means that you clean the balance cock separately by hand, saving that spot for last, but I don't mind that. If it was well-regulated before, you get an accurate starting point. The alternative is to photograph the balance cock, close-up and with high definition. Then use the photo as a reference for setting the balance up as it was before. Considering most of us regulate after assembly and oiling anyway, the photo should allow one to get the watch close enough to start with also. This is the method I may switch to, and see how close I can get to before-cleaning. I plan to experiment and see which works for me.1 point

-

Please practise on something else of little to no value first. You are almost certain to do serious damage. The IWC is best left to a professional with the right tools.1 point

-

Soaking the rusted steel (ferrous) parts in vinegar will work wonders. Seriously. You could add a bit of lemon juice to speed things up, but white distilled vinegar will do the job. My concern would be: are the chains rusted and pitted enough to be weakened? Is there still enough metal thickness for sufficient strength? You seem to have decided to go for it, and even have the beginnings of a game plan. I think you may pull this off, after some time of course, but I think you'll do this.1 point

-

1 point

-

@mikepilk that is a super cool tool. Sorry to hear about the Omega. I feel your pain on those small ladies watches - I recently broke a staff on a 464 and was pretty sad about it. Thanks all, I have called this one "done" until I have the scratch to buy a tool to do the screws. I had to case it up, as having it in a state of disassembly for so long was driving me insane. Here's a pic of the old fellow - to be continued.1 point

-

Congratulations Poljot to your Moser. They made lovely watches in Petersburg. Although I'm not an expert the Geneva stop work was quite popular before Guillaume invented Invar steel somewhen in the 1890s. An Invar mainspring has a much more uniform power distribution then the old blue steel springs. Hence there is no need to limit the mainspring action to the four middle turns as the stop work does. Greetings from Hamburg, Alex p.s. reassembleing is a bit tricky. First hold the barrel arbour in a vice. Then allign the maltese cross in start position. Then give the barrel half a turn. That's the end of the power reserve you don't want. Then put in the finger wheel. You are now able to wind the watch 4 turns. Plus the one unused half turn from the beginning makes four and a half. Stoping about two turns to two and a half turns before the end of the spring. All depending of course on how many windings your spring is capable of.1 point

-

Hi everyone, Thanks for your input. I do listen to all of it. Unfortunately, I am probably an 'idiot' like @watchweasol. I see this as a challenge. I figure that I have nothing to lose. I will take my time and begin on it. I will take photos of the connections of the movement and then get it out so that I can work out 'where to from here?' I can't bear the thought of not trying. If it goes pear-shaped on me, I will have a nice box to hang on the wall like an ornament. I have a friend that does a lot of carpentry, so I am going to bounce a lot of ideas off him as well regarding how to delaminate the ply if possible. What I did find funny was how I remembered it all being bigger than it is. I opened the back up and was quite shocked to see how small the movement actually is.1 point

-

Retired at age 82 after 62 years of service to the trade. Graduate Elgin Watchmakers College, first Job for a independent Jewelry store. Second Job with a chain jewelry store Then moving on to Sears as a division manager. Started my business as a trade shop at age 30, two leased watch repair departments in the Chain Jewelry store plus watchmakers working for me in my shop. My trade shop serviced jewelers in 5 states. I devised a system for mass disassembly of watches increasing production for my employees. I branched out to installing Grandfather Clocks and patented a leveling platform for the small Grandmother clocks that would settle into the carpet and stop shortly after install. I expanded to retail with a store that serviced both clocks and watches and sold both calling my retail store CHIMES & TIME. I started a engraving store next door to my watch and clock store ENGRAVABLES doing laser engraving and sand carving on glass. Riding the crest of the wave I worked long hours with no vacations. When the demand for watches and clocks slowed I reduced my staff and bought a building for the last 10 years of my business career. The craft is one on non essential service making us work harder, longer and for less than a essential service, we choose this life because it is our passion. The ticking timepiece has its own heart beat and we are the people that keep it beating. Now in the process of sizing down selling all my tools, parts, parts watches, collector watches and telling myself it has had its season, it is time to share with another. Cliff cme4time1 point

-

1 point

-

Go carefully, I recently trashed the hairspring on an Omega 455 (movement 16mm dia) whilst trying to add timing washers. I've never seen such small timing screws. My smallest washers were much too big, so I was trying to file them flat when disaster struck. This is where a balance holder becomes really useful : https://www.watchrepairtalk.com/topic/17417-balance-tack/?do=findComment&comment=1499261 point

-

For resurfacing my carbide burnishers I use a 45 micron / 280 grit diamond plate for my finest one, my regular burnisher is done with an 80 micron resin bond diamond wheel. I think 600 grit is too fine. To take off about 0.01mm at that diameter should take anywhere from 10 seconds to a minute depending on the burnisher and pressure. Thin oil is good, many here use almond oil, some use lavender oil. The Mitutoyo 0.001 reading mics I've seen have been digital and are even more unwieldy and have less feel than their simple brothers, I bet a coke you've squished your pivots a bit. I'd be very surprised to see a sub-0.08mm pivot in a commercial grade Japanese watch. To measure these pivots you really need a jewel gage.1 point

-

No pictures of the watch? We don't need it for the question but some of us like the look at watches. The problem is it was made at a time when modern mainsprings didn't exist. You also didn't mention the end on it? Usually the most critical dimension for mainspring is the width . I've snipped out some images to get you started with where I'm going with this. First you get the right width They go for the strength but we have a problem. Fortunately modern mainsprings are so much better than the original there are stronger for the same thickness. So you can go thinner for the thickness. But then there's the other problem noticed the length? This means you're going to have to get a longer spring cut off the end and put a suitable end on the spring. 7835_GR Pages 335 - 344.pdf1 point

-

New (technically NOS) mainspring installed and working perfectly. Balance was overbanked and filthy. But I had to strip it down anyway, so all the holes were pegged and everything got a wash, and I made use of my Jacot tool because the balance pivots looked slightly scored by some harsh dirt and grime. I runs so smoothly now. It still isn't completely done yet though; I have a new crystal on the way, so I've been keeping the lid shut (except for this pretty picture here). The case was cleaned too, but it is discolored enough in spots that the polishing goods I have at hand could only do so much. In parts, the gold was worn through, and the brass fill had darkened considerably. While the case looks loads better than it did, I kind of wish I had electroplating equipment; that's what this case really needs. It has spots that I could only lighten, but never really get to gleam.1 point

-

1 point

-

You should always spend time in cleaning any watch case after cleaning the movement, if the glass needs replacing then do it the same with wrist watches lugs might need to be replaced the same with the button if its smooth and hard to wind replace it. No point putting a nice clean movement back into a dirty case.1 point

-

1 point