Leaderboard

Popular Content

Showing content with the highest reputation on 10/02/20 in all areas

-

2 new members, Sekonda and Lorus. Cost £2.24 + postage. The Sekonda looks nice. Works fine until the hour hand gets to 6. The minute hand and secondhand keep going but you can't adjust the time if the minute hand is between 2 and 4, the stem just spins. I tend to think Miyotas are throwaway but might have a look at this one. The Lorus looked sad, no crystal and bent hands. I've straightened the hands-ish and fitted a temp crystal made from a DVD disk to see if it worked. Surprisingly it's working.2 points

-

Hi everyone, you won't believe how silly this is, it dawned on me in the shower... I'm talking about a 12hr sub dial... for the stop watch... Not a 24hr sub dial for the time keeping... there was never a problem to begin with, i just completly misunderstood what i was dealing with. ?2 points

-

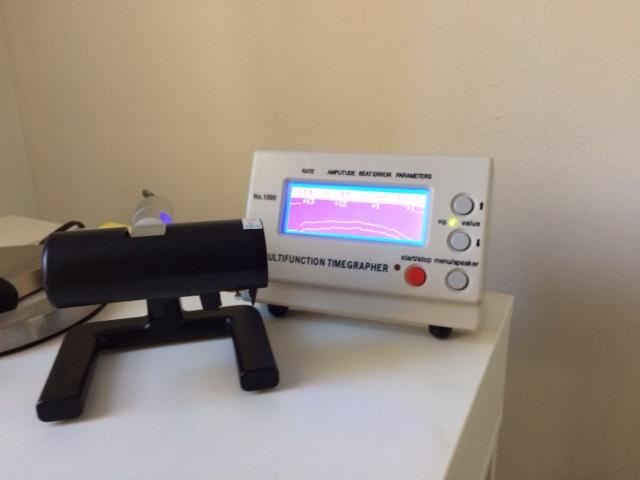

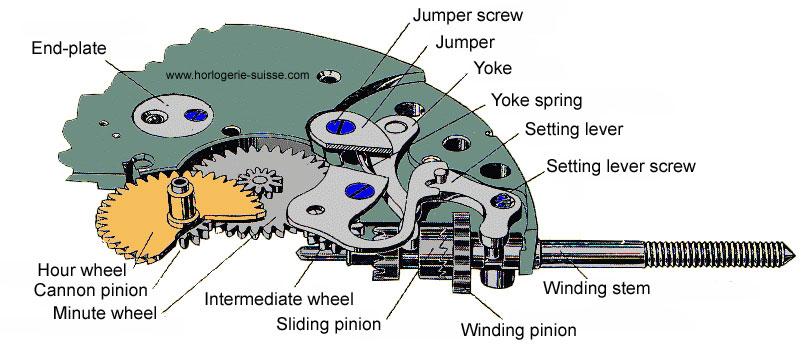

I'm always impressed just looking at these, and lucky enough to own a chronometer grade one, now finally had the chance to work on a repair, and all the positive opinions got confirmed. The owner lamented water ingress and the watch stopping all the time. Seeing no major damage on a first inspection I undertook the work with good hopes. Starting with the dial side the overall feeling of quality and maniacal height saving design becomes evident. The dial fits so precisely that a dial washer was not present or needed. This being a time only version I can't do any praising to the calendar works. As soon I lifted the hour wheel the watch started running strong in all positions with good amplitude, then I pulled the cannon pinion which was quite tight. Note to myself, MUST get a cannon pinion remover. The black oxidation on the contact section was the root cause of the fault, but after 50 years it was time for a complete service, and I have the distinct impression that mine was the first one. One incredible fact is that Omega still updates their technical documents about this long discontinued caliber, I can only think of the aeronautic industry doing something similar for certain "never old" airplanes and engines. The way I did it may be called not fully professional, as I didn't do surface treatment, and used only 9010, HP-1300, and 9415 without an automatic oiler. However I'm happy with the results, and I hope that the owner will be too. That being said I plan to upgrade on the above points in the immediate future. One tool detail that I really recommend is to use soft metal tweezers whenever possible, I have got cheap brass Indian ones which I then dressed to eliminate any sharp edge. These are OK to handle most of the screws and all the bridges and plates. Keyless and motion works are rational, and easy to work with. Some dirt and micro-spots corrosion, but nothing worrying. The stem was the rustiest part, and the crumbles are all what was left of the crown gasket. It is defintely possible with some patience to open these and fit an o-ring, which luckily I had from an assortment box. Even the stem came out very decent after the due care. Just give a tap or two to the washer to make it seat nicely again. I've even refitted the steel ring which matches well the O-ring profile. Two screws hold the automatic bridge, and one can see that also the gib screw was removed. That allows the rotor to be removed even with the mov't in the case. For regular service to the auto works it's enough to remove the larger bridge. One of its screws is thinner due to more limited space. Note the use of a single reversing wheel, yet the winding in bi-directional and the overall manufacture is just amazing. I used HP-1300 on the pivots but probably that another synthetic type might have been better. Note the space above the balance, which hosts the automatic work. At the time of its introduction this was the thinnest automatic movement with sweeps seconds and calendar, at just 4.5mm. And the Reed regulator is nothing less than amazingly beautiful. The balance is then removed and inspected. Note the multiple tiny "drill kisses" on the rim for poising. To save height, the train is different from the common design. Seconds pinion is driven by a pinion sitting above the the barrel bridge, and has a tension spring which controls its end-shake. Releasing power is not easy as the space around the click is very limited, remember to use only something soft like a toothpick to do that. Only then we can remove the pallet bridge, another beautiful execution with two locating posts and screws. Then remove crown and ratchet wheels. We start to see the sophisticated design and the one-way automatic winding clutch. The machining of a cord on the crown wheel round holds precisely the hub of the crown wheel, with an off-center screw. Wow. The auto winding wheel has special profile inner teeth which allows one-way power transmission from the ratchet wheel to the barrel arbor. The small pinion catches only one way to said wheel, otherwise it turns freely. That makes so that turning the crown in the opposite direction has no effect whatsoever, and also that a single reversing wheel is needed in the automatic work, because movement is transmitted only in one direction from the wheel on the arbor to the auto works. I for one find difficult to understand what I wrote above and the principle of operation of that mechanism. We can now remove the train bridge which only holds third, fourth and escape wheel. Al-tough, that does not make it particularly easy to fit back. Finally the seconds pivot spring, pivot, barrel bridge can be removed, followed by the barrel and center wheel. Speaking of the barrel, once opened it I found it quite dry, with the lid slightly corroded and heavily grooved. As an experiment I hand polished this surface with a wide micro-fiber stick, and car polish compound. Grooves were gone, but it remained scratched. I switched then to grade 20 or 30 of Chinese diamond paste until it got better. And better with finer paste, to an acceptable smoothness Now, I must say that I did not replace the mainspring, and not even removed it from the barrel as I don't have a winder, and wanted to avoid any distortion to it. In the end the watch performed well with plenty albeit not stellar amplitude. The stripped main plate in its equally magnificent A and B sides. Cleaning and reassembly was uneventful even if some screw are small enough to require full attention. I had some doubts about the seconds pivot being supported by jewel on the auto works when refitting hands, but in fact that worked OK. After lubricants settled the timegrapher response was completely positive, One last note, you know you're holding a genuine vintage Omega dial when it has a fine clove watermarking, a recess for the balance anti-shock device, and the feet are shaped for the screws to hold without damage. After a long time spent hand polishing the acrylic crystal and other details the complete "Omega Geneve" watch came out stunning, sorry I didn't take a picture Hope you have enjoyed this article.1 point

-

This is part 1 of my walkthrough of my Luch 2209 project, the second watch I have successfully repaired after taking Mark's course and working on the 6497 clone. This was the second mechanical watch I ever bought, and the one that marked my descent into obsession. I got into Russian watches because it's a cheap way to get started in mechanical watch collecting and repair, and because I've always been into Russian history. I confess, the kitsch factor played a role. It seems I don't have a "before" picture of the watch. Suffice to say it's a first-gen 2209 "ultra-thin" with a somewhat scratched, but still lovely, silver dial. This watch was clearly someone's daily wearer for many years. It's old and banged, but still classy, in a well-worn kind of way. The watch cost me $50 Canadian from a pretty unknown Ebay seller, so I was pleasantly surprised when the watch turned up and appeared to keep reasonable time. So how did I proceed? A simple service, I thought. I popped this on the timegrapher and saw straightish lines and good amplitude in one position, over about 20 seconds. Good enough, I thought. A first critical mistake, but never mind. Here is the watch as I'm beginning disassembly. A bit dirty, but a handsome movement. Disassembling the train. Here the Luch's key innovation is just visible below the large third wheel, i.e. the lower train running off the barrel that, by pushing the main train off to the side, allows the balance to not overlap any other wheel. There is a good history of the 2209 here: https://steemit.com/watch/@coupeborgward/history-of-vintage-soviet-watches-with-2209-movement-vympel-polet-luch . This grimy old mainspring was a challenge to service. As you can tell, it's left-hand winding, and I do not have an appropriate mainspring winder. Furthermore, the mainspring has a special bridle which must be inserted in corresponding slots in the barrel and lid. With repeated efforts and a lot of cursing, I finally got it in. I clearly pushed too hard and with the wrong finger - my right index finger was sore for several days afterward! So that's the end of part 1 - the watch disassembled and all going well. A breeze, I thought! It was not to be.1 point

-

1 point

-

Hairsping work, or manipulation is the nightmare of any beginner and even quite advanced repairers. You can't expect, and it would not be right, that here on the occasion of your problem, (which is identical to the one that most others, including myself, have had various times), the best guide will appear. At most, you will get some incomplete advice, empaty, links, etc. Please do what everyone should, search in the box top right for "hairspring manipulation", start reading, watch the linked videos and search for more, and why not, buy some books. Just don't spend too much time on that because you will need it, and lot of, to practice. We're talking about many hours of stressing work. Sorry to be blunt, if you want the best chances for that watch to run decently again, start looking for a new balance complete1 point

-

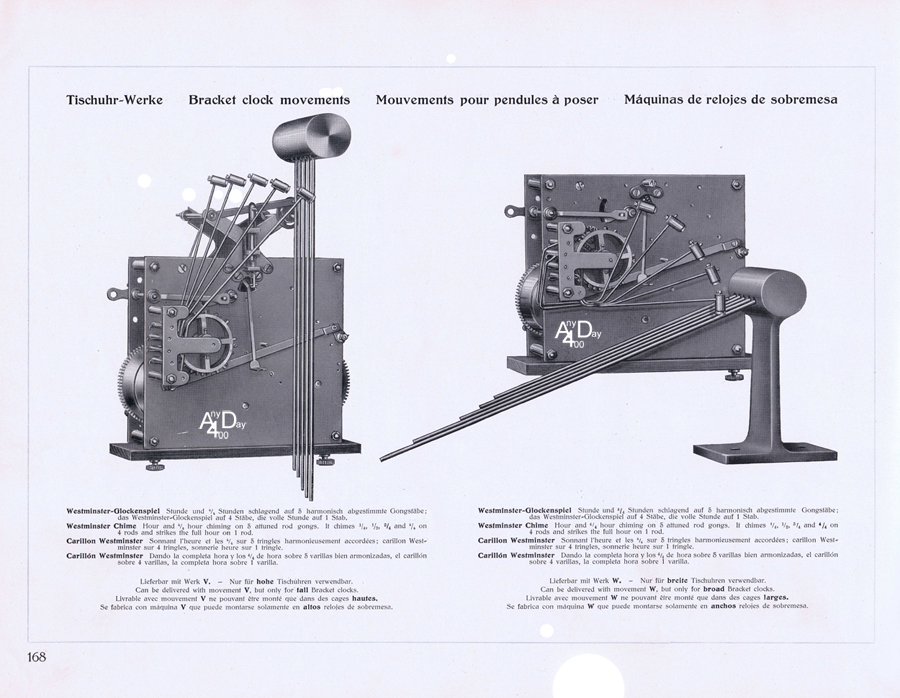

Its a Zandaam clock of which I have three in my collection, the movements are all different Regula. Urenfabrik and I think the other was a Herr from what I can gather they are reasonably modern. The following link will give a little history http://www.antique-horology.org/_Editorial/NuElckSynSin/ . There were early versions from the 1860s into the 1900s. A look at ebay on Zandaam clocks will produce the going prices. .. the two pictures attached are of a Zandaam and a Zandaam Warmink clocks the styles varied greatly.1 point

-

Two tips I forgot to mention. 1) de-magnetise the spring and make sure your tools are also de-magnetised. These blighters have life of their own. 2) as a precaution especially is this is the first time installing a shock spring cover the area with cling film.1 point

-

I will report back tomorrow, with some photos and timekeeping information.1 point

-

1 point

-

1 point

-

Yes I agree, too many uncertainties. Then, I shouldn't put all my money on excessively strong MS either.1 point

-

It seems to be increasingly common that the inner hooking on these GR springs snap. I do wonder if they aren’t annealed correctly at the factory. You could try punching a new hole. Can do that with a small flat punch on the staking set and then file rectangular.1 point

-

The issue I have with this is that (in my opinion) it doesn’t show good use of logic. I believe that is one of the points that JohnR is trying to make. I would say it’s fair to comment that the new mainspring *may* be too strong. But we do not have proof of that - too many variables. Again, the point that JohnR is making.1 point

-

OP tested his timegrapher with another watch that is keeping decent time, I guess amplitude and beat error has shown normal with the other watch.1 point

-

Hi Mark the only ones found are the AS 577 as 530 I have attached both in the hope they nay be of some use to you AS 577.301 and eta 277.001.pdf AS 530.101.pdf1 point

-

1 point

-

This gave me a good chuckle [emoji1787] I'm into soviet era watches too, we may be able to swap spare parts. Sent from my SM-G973F using Tapatalk1 point

-

Email sent to the BHI. Thanks for everyone's input and replies. As for a kit, I have now seen enough replies to not follow that path. I will now get some prices from the three places that I know of in Australia that sell equipment and go from there. I will also use Mark's information in my other thread for tools required to get started. Thanks again.1 point

-

I like the raketa 2609ha. It just might be my favorite russian movement. You can usually get good amplitude out of them and the moveable hair spring stud makes it easy to adjust beat error. I am not so fond of the 2609 however. Maybe the ones I have run across have been overly worn but I just dont seem to have the same luck.The Achilles heel of the raketa has got to be the case.As for the vostok,I will take a 22xx over a 24xx any day of the week and twice on Sunday. The vostok cases in general seal better than the raketa while movement quality is similar.1 point

-

I have worked on a lot of Russian watches over the years and have to say that I have generally been fairly impressed by the mechanics, but disappointed by the cases and dials. As far as the movements are concerned, these were often to be found in relatively low value watches here in the UK. One of the best examples that I can think of was the Raketa 2609.HA in a chrome or gold plated snap back case re-branded as Sekonda in the 1970's and '80's. One of their advertising tag lines was "beware of expensive imitations", and they would point out that you could get a complete new Sekonda for the price of a replacement crystal on a Swiss watch. As with a lot of inexpensive watches the cost of servicing would have been disproportionately high compared to the price of the watch so servicing was rarely carried out. And as with any watch that gets used day in, day out without proper maintenance it starts to wear out. And this is the state that these watches are often found in today. I would suggest that the excessive wear in the barrel arbor bearings in the main plate and bridge is more due to poor maintenance than it is poor build quality in the first place.1 point

-

Thanks all for your comments. @Nucejoe, yes, to my knowledge the Luch 2209 and Poljot 2209 are the same movement. My understanding was that the movement was first used in watches branded Vympel, and later rebranded at Poljot. The movement was also produced under the name Luch at the Minsk Watch Factory. @HectorLooi @Jon About the wavy lines. Before cluing into the wear on the mainplate barrel arbor bearing on the original movement, in desperation I started swapping out parts. Specifically: Barrel bridge - no change Barrel complete - no change Upper train - no change Lower train - no change Pallets - no change This was before I realized that the barrel was hitting the underside of the bridge. After I realized the lower bushing was also worn, I checked the barrel sideshake again and realized it could still hit the bridge even after the bridge had been replaced. On the replacement movement, the barrel sideshake is still excessive, even though it's not hitting the bridge. I suspect this is what is causing the same problem in the donor movement. @yankeedog About this Luch, and Soviet watches generally. Maybe I've been unduly harsh on this Luch. To its credit, it was still running when I got it, despite being well-worn and probably not serviced in many years. There are no service marks inside the caseback, so that says something about its robustness. And in fairness, maybe I just got two pretty worn-out movements. However, finding that the donor movement had basically the same barrel-slop problem as the original movement, in combination with the watch's cosmetic problems (dial fitting), I perhaps was maybe too harsh on the build quality of this Luch and Soviet watches in general. Maybe this thread should have been entitled, why beginners should and shouldn't work on beat-up old watches, of any origin! However, having collected quite a few Soviet watches at this point, I think I can make a couple propositions that suggest that I maybe didn't just get two bad movements in a row. Certainly I'm not the first to point out the wavy trace issue (see https://adjustingvintagewatches.com/russian-zim-2602-wristwatch/ ). However, I would add: 1. A clear, rapid decline in movement finishing across all brands, beginning in the 1970s and continuing through the collapse of the USSR. See, for example, the shocking decline of the Molnija 3602: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Molnia_3602& . See also the ZIM 2602 and Raketa 2609. 2. Simplification of dial and case finishing, in the same time period. Here pictures of two of my watches, both Raketa 2609s, both gold-plated, made approximately 25 years apart. Both of these are good runners, and I really love the 1980s one, but the difference in sophistication is obvious. Obviously there are some big exceptions. The 1980s Raketa 2628s, for example, tend to come with sophisticated cosmetics (the waffle dial is my favourite). But overall, I think there's evidence in favour of an decline in both sophistication and build quality in the 1970s and 1980s. 3. Obvious, inexcusable failures of quality control among even the top brands. Here is my one and only Poljot, a 1970s 2614. This is not a bargain-basement watch - automatic, date complication, gold plated. However, note the position of the hole in the dial. It is definitely not centered - I checked with a ruler. 4. Big variability across brands. I've had the best luck with Raketas and Vostoks, and the worst with Poljots and Pobedas (both 1MWF, if I'm not mistaken). Obviously I am relying heavily on cosmetic evidence here, and cherry-picking watches from my collection. Maybe it's just a general rule that when working on vintage stuff, you should know when to quit. I'd be happy to hear about other people's experiences with Soviet watches - variation in quality, which movements are better or worse timekeepers, etc. And I would say, despite being a bit hard on them here, Russian watches are still weird and wonderful and a great way to get into the hobby. Cheers.1 point

-

That is a beautiful dress watch, can't beleive prices have gone up so much, I bought ten brand new luch in Minsk, for about $6 a piece about twenty years ago, non is as beautiful as this one of yours. I agree with jon, power fluctuation, possible combination of effects from two faults. Regards Joe1 point

-

Great write-up! The wavy lines you have on the end movement is not uncommon on these watches. It's more than likely a fluctuation of power output in how the wheel teeth and pinions mesh and as there are so many of them in the train (as you have the two intermediate wheels with their own bridge driving the double third wheel). A little too much end or side-shake, or a slightly bent arbor and you get the wave, or even a badly tarnished pinion leaf or three, that causes a slight bind. A lot of these come with a thin berrillium bronze/brass shim under the balance cock which someone may have left off, which doesn't help when trying to get the correct end-shake for the balance.1 point

-

Part 3 is a sort of redemption, or at least some lessons learned. The donor arrived about six weeks later (thank you Covid) and I quickly transferred the balance complete. The wavy traces quickly returned. So I stripped the movement again, paying close attention to the barrel arbor bearings. Looking closely, I could see that the barrel had actually been scraping the bottom of the barrel bridge. Manipulating the barrel with the bridge on and the train removed, I could also see that, under torque, the barrel would foul both the bridge and possibly the mainplate. Swapping in the donor movement bridge, the wavy traces continued. The free running of the train was okay with the pallets removed, but, turning my attention to the mainplate barrel arbor bushing, I could see this was slightly out of round. Under torque, the barrel would still hit the bridge. So that was it. I could not close the barrel arbor bearing hole, so after repeated reassemblies and inspections, I became convinced that the original movement was a goner. Thankfully, I had the donor, which I decided to service and install in the watch. In truth, the donor looked to have very little wear - I am unsure what kielbosched it in the first place. I serviced the donor and prepared to install the balance complete. Here tragedy struck again, as it appears that one of the problems in the donor was that the regulator arm was improperly seated in the balance cock, or the pins were just too short. Closing the regulator pins, the hairspring caught the closing arm and became kinked in the terminal curve. Here I finally did Mark's video justice, carefully massaging the hairspring until it was again smooth throughout the curve. A final hurdle: the balance on the donor movement had no endshake - none at all. Having watched Mark's video on unexpected endshake problems, I looked for a shim under the balance cock. Sure enough, Minsk Watch Factory had indeed made a shim under the cock, near the screw, which I had flattened as I had rubbed the tarnished mainplate with pegwood. So I got my screwdriver, and made a painful jab into my newly-cleaned donor movement. Reinstalling the cock, it ran strongly! Hurrah. Here are the results, positive and negative. On the positive, the watch runs strongly and relatively straight in all positions. There is also relatively little positional error (maybe 5-10 seconds a day, but I can live with that). But here's the heartbreaking thing. This donor, this seemingly babied donor with no major signs of wear, has exactly the same problem of wavy traces and variable amplitude as the original movement! It's less pronounced, sure, but it's there - a 15-20 degree variability in amplitude at seemingly random intervals, with the associated wavy lines. A reflection on that below. Battle-ready once again, but not without difficulty. Another charm(?) of the Luch is that the dial does not sit flush with the movement, so you need to be extremely careful when seating the hands to make sure they won't hit the dial. And back on my wrist, at long last. So, a summary. Why should you, an absolute beginner, try to diagnose and fix a battered Russian watch that hasn't been opened since Gorbachev? Well, first, you won't break the bank. These are plentiful, and if you get a plain dial they are cheap as chips. Second, you will use a lot of Mark's lessons. Not just chapter 2, but 3 as well. I watched every single video repeatedly, and tried to apply them all. If not for his video on barrel arbor bearing wear, I would never have found the problem. Last, I practiced a lot - a lot - of skills. I'm still bad, but getting this Luch back on my wrist has made me feel like I'm on the road to being a real watchmaker, whatever that means. And why should you avoid articles like this? One reason: poor, inconsistent build quality. From the shim, to the regulator pins of incorrect length, to the badly-seated dial, it doesn't take a George Daniels to see that these things were absolutely slapped together. This makes them hard to work on and diagnose. And even when you find a good donor that was seemingly retired after only a few years in service, you may find that it has the same fundamental problems as the donor you thought was deeply, unusually defective. So just live with it, and know when good is good enough. Don't make perfect the enemy of the acceptable, because they sure didn't when they built these things in the first place. So that's it. If you're exceptionally patient or you didn't have anything better to do tonight, thanks for reading this far. And thanks to the people on this forum for helping me out with this project - I am very glad I joined. Cheers!1 point

-

I think it's a damaged mainspring.1 point

-

Part 2 is the nadir, a true heartbreak. All was going so well. I have few pictures of the reassembly, but a few of the sad results. I cleaned all the parts by hand, twice, using naptha and a fine paintbrush. All pivot holes pegged out. I then reassembled the watch following Mark's guidelines. Oiling was a matter of instinct, with a little help from a professional watchmaker acquaintance. In particular, I was unsure how to oil the central seconds pinion. The answer is on the bushing, not anywhere else on the extended pivot. Here's the watch reassembled, before going on the timing machine. Nice and clean, with a Canadian quarter thrown in to show off to my siblings and friends. I was triumphant. Then this happened. Calamity, utter calamity. The watch would not settle into any kind of steady rate. The watch wasn't magnetized, just seemingly haunted by erratic, inexplicable rate changes. Seemingly no consistency - not down then up, and not coming regularly. Sometimes the watch would run happily for 2-3 minutes, and then, out of nowhere, change daily rate by 50 seconds or more. Amplitude was sometimes great - 300 - and sometimes poor - 170. The watch did this in all positions. At this point, I did one right thing and one wrong thing. The right thing was watching all of Mark's fault-finding videos several times, and completely stripping and re-cleaning the movement. I looked very closely at all the parts of the train, although I was too chicken to tackle the mainspring again. The only fault I could find was some slop in the barrel due to barrel arbor bearing wear, but this did not seem severe enough to cause the problem. Back together, the watch still ran terribly. In desperation, I made a critical error. The hairspring, I thought, was slightly out of poise - better adjust it, following Mark's YouTube videos. So I took the collet off the balance, grabbed carefully with my tweezers, and, with careful and deliberate effort, permanently ruined the hairspring forever. As I said, the nadir. Trolling Ebay, I found a running donor movement for 30 bucks. So I put this movement aside and went on to other misadventures.1 point

-

1 point

-

Hi You have always the possibility of a bent pivot or cracked/chipped jewel loose shock chaton , jewel which only causes problems when the watch is face up/face down . tech sheet attached. By the way we do like new members to introduce them selves, thank you. cheers 2849_EB 8800etc (1).pdf1 point

.JPG.ebf152565316568e6b415c85730d1d88.jpeg.b1d1cfd6d768d8d9530c4c4c4ffa47d4.jpeg)