Leaderboard

Popular Content

Showing content with the highest reputation on 04/09/20 in all areas

-

Apologies for the fact that WRT was down today. With regret there was a problem in the New York data centre which caused the server this website is hosted on to not function. All seems to be well now.5 points

-

Hi @MatteoB, this forum probably isn't the place to get into such details, but very briefly, the input is first filtered (if filtering is enabled) using a 4th order infinite impulse response bandpass filter. After that, the software tracks an envelope of the signal, looking for the three distinct sounds making up each tick (as mentioned by @guidovelasquez). The time of the start of each sound is recorded, and the watch performance computed from those. Statistical analysis is applied to all the ticks within the averaging period. This, together with the initial filtering, is what produces stable results even when the signal is noisy. FFTs are not used.3 points

-

A while ago I just had to make a impulsive move at the bay. I bought a less than attractive Certina Blue Ribbon just because my inner voice told me to. So I thought I'll put out my little adventure on this one incase someone else has the same urge. Here is the potential victim. The engine. And to save place on this server the first part as a PDF it contains the strip down of this beauty. Certina 25-651 _ 1.pdf The exciting part two will come in due time when the new bulletproof crystal is found.2 points

-

Bien venido @MatteoB, pienso que tu entusiasmo es justificado. El programa es sencillamente maravilloso. Tanto para los que conocen de relojería como para los que simplemente admiramos los relojes relojes mecánicos. Qué parte del funcionamiento del programa te parece más fascinante? Welcome @MatteoB, I think your enthusiasm is justified. The program is simply wonderful. Both for those who know watchmaking and for those who simply admire mechanical watches. What part of the operation of the program do you find most fascinating?2 points

-

May I make you aware that we have a dedicated section where it's considered polite for new members to introduce themselves before asking questions.2 points

-

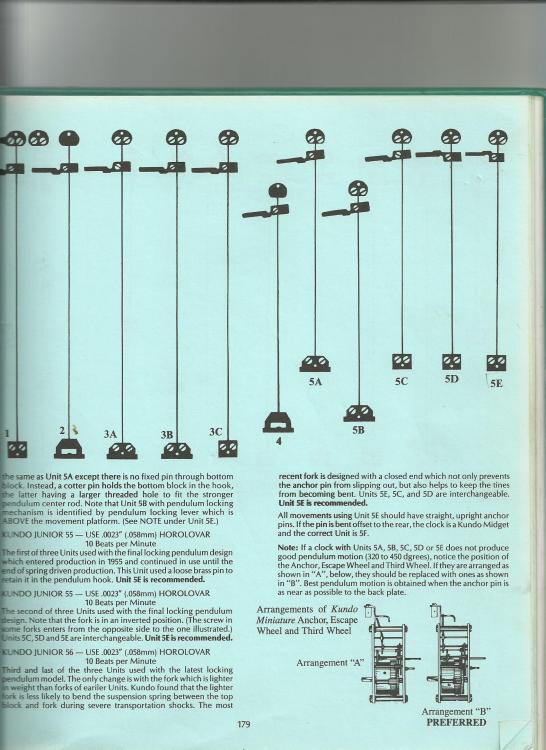

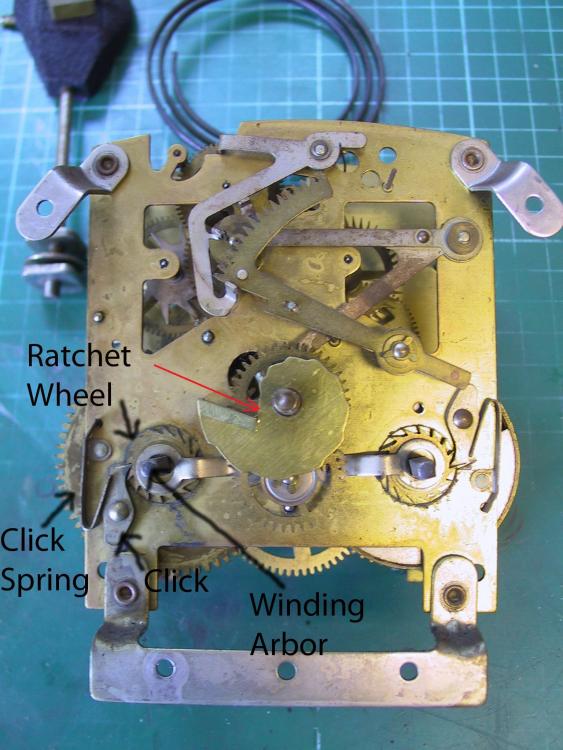

There are many types of clock mainspring winders. This is the type I have. This one will remove the largest mainsprings from fusee clocks. It will not remove open springs for American clocks, for those you need clips. The best oil for clocks I find is Windles clock oil, I never use clock grease on clock mainsprings, sometimes on ratchet wheels. Well done Moose in sorting that strike out.2 points

-

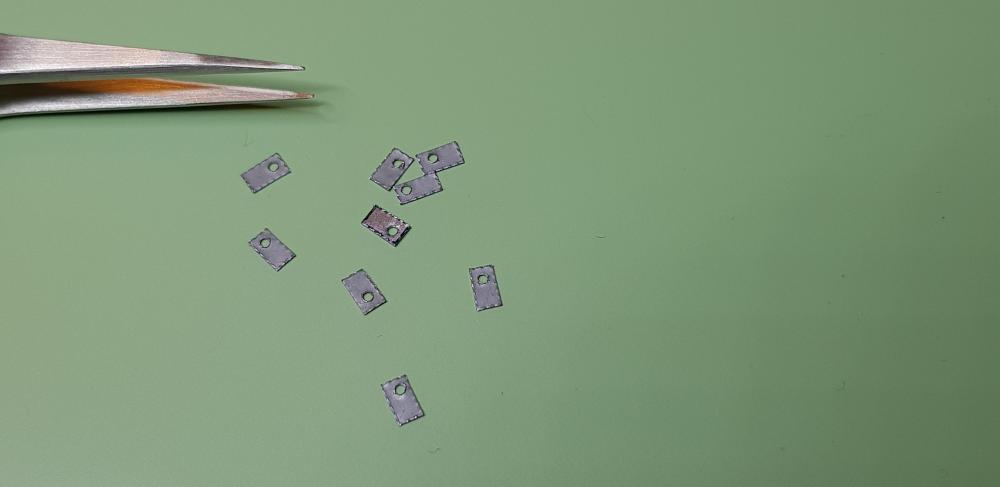

So, tomorrow it's my daughter's birthday.... Did I manage to finish the SKULL watch with the ETA 6497?! YES, but it wasn't easy, there were some hurdles missing case clamps. - I ordered them seperately but in the end, I made them myself to be on time; case clamps failing to keep the movement in place. - That took a lot of time tinkering; the winding stem that broke in two while grinding it - Luckily, I could borrow one from another movement; the brass filler ring with poor tolerance, leaving too much space for movement within the case. - Which i solved with adhesive aluminum tape. see final photos below. A watch with a real Swiss movement for my daughter...2 points

-

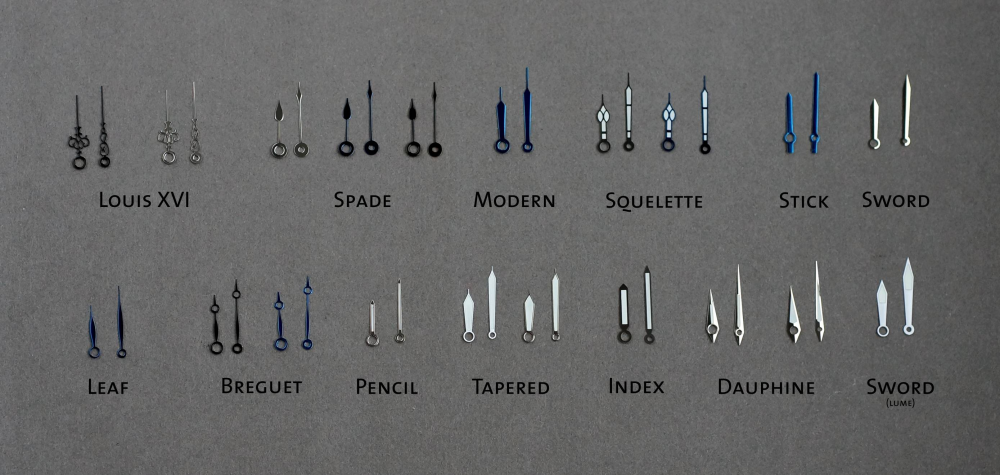

My first is a Panerai homage. All Chinese parts and I love it. The next is completely custom Frankenstein. Swiss movement, American dial, Chinese case and a Russian strap. The sub second hole had to be elongated because a 12s Elgin pocketwatch second hand does not quite line up with the 6498 second.2 points

-

Thank you sir - wishing good health to you and to the rest of the WRT members, and to all of mankind.1 point

-

Yes that is what I meant, but somehow entered the wrong caliber number. You,ll love this piece, they are jewel. Wear it in good health.1 point

-

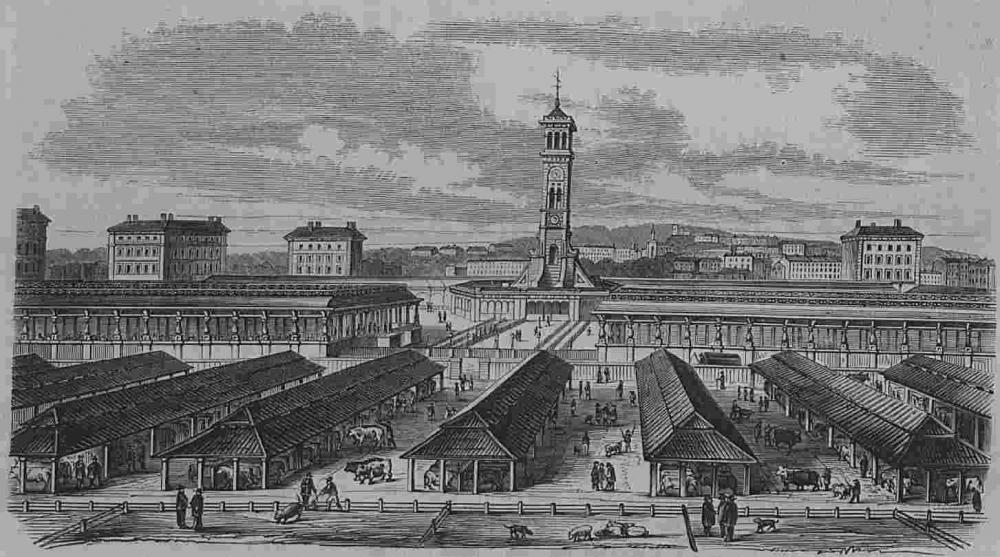

Cheers Andy, my supposition has been proved right then. Almost certainly my brother's watch was bought there as my mother was bought up in the Caledonian Road area, just around the corner, in the 'buildings' overlooking the Caledonian Cattle Market..... And how it is now, all that is left is the clock tower..1 point

-

Hi yes the pivots are missing, the only re course is a new escape wheel either from a material house (cousinsuk) or a donor watch on ebay. Never tighten the bridge screws down untill you are well sure the pivots are in. Run the screws in slack untill they just hold the bridge and then work the wheels into place, checking that they lift and drop cleanly then keep on checking as the screws are turned in.1 point

-

I will give you my explanation as a perfect layman. First the nature of the clock sound. If we want to see it like this, the waveform or spectrogram of the clock sound is very simple. It is well within the frequency limits of the human audible spectrum. In fact most of us can hear the ticking of the clock quite well as we approach one in a quiet room. The important thing about this is that the tic-tac is made up of 3 important sounds and very different in terms of time and intensity. The program, using a complex algorithm, makes it possible to locate these 3 sounds perfectly, thus obtaining the spectrogram to analyze the performance of the clock. About the algorithm, my knowledge limits what I can inform you. But by the behavior of the program, I can say that it is extremely efficient. On the other hand, it is important to mention that sound capture is a key part. A microphone with particular characteristics is required. It is actually a vibration sensor. In other words, it must capture the mechanical vibrations that travel inside the watch and its case without hardly registering the ambient noise. Something I can add based on my experience is that the software is capable of extracting useful information for analysis from poor or poor sound. I encourage you to watch the next video at this link.1 point

-

Hi I have had a look round and the closest so far is the peseux 330 I have attached the same in case its some use to you. Peseux 330.pdf1 point

-

http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&a&2uswk&Peseux_336&1 point

-

1 point

-

Welcome here. Just starting from the bare-bone approach of the below should be enough to keep a developer busy for a good while https://github.com/vacaboja/tg1 point

-

Sorry, I forgot to do it. I'll add my presentation as soon as possible! Thank you1 point

-

It is not using a press that installs hands well parallel, it's the hand of the repairer. First, check that hands are straight on a jeweller cube. Place the collet in on of its holes. If needed straighten gently with a soft tip. Then, to make hours and minutes parallel, install the hand with a properly sized (hand held) stake with nylon tips. Check and if one side is too low, incline the stake the opposite side and press gently. That won't work for the seconds hand, if doesn't sit parallel I recommend not to try to correct it while is mounted, but remove and work on it on the anvil as above. You certainly did a good work, and have learned some of the real issues when assembling a watch from parts that are not designed as an an ensemble, or aren't very precise. Compare your results to the ones of the dreamers that occasionally show up here with fantasious ideas but have never held a screwdriver smaller than 3mm, and are normally never seen again.1 point

-

1 point

-

1 point

-

Lovely clock. I have another coming now as well, this time in an oak case. You don’t need a mainspring winder, its easy enough by hand. I recommend some strong gloves and eye protection. Then I just remove the barrel arbor and take hold of the barrel in one hand making sure you are covering the outer coils of the spring with your thumb or fingers. Then with the other hand, use some pliers to slowly pull out a few of the centre coils, enough so you can take hold of them. Then, slowly begging to unwind the spring from the barrel very carefully. Tere is a fair bit on energy even in this unwound state, so take your time until it is all out. This is why you need sturdy gloves and eye protection, it case you let go and the spring suddenly releases. finally, you will be able to unhook the spring from the tag inside the barrel. Putting it back is simple the reverse of the above. Someone on here may have pictures, but I’m sure you can figure it out. Just take care not to bend or catch the spring on the edge of the barrel, as it could fracture and eventually break in service.1 point

-

1 point

-

1 point

-

Using the magic power of the internet, here is the building next door, and yes, it too has Bravingtons on the signage. Sadly, like every other shop these days, it is now a MacDonalds/Pret/Starbucks etc. Click the link below to get a full view. https://www.google.com/maps/@51.5308053,-0.1220827,3a,75y,131.45h,93.33t/data=!3m6!1e1!3m4!1sO--wFeJNM_UxkLKqFE5rdw!2e0!7i16384!8i81921 point

-

Take the movement out of the case. Move the minute hand manually for the warning and watch the rack drop, take note of where the gathering pallet engages the rack. The correct position for the snail should be for twelve o’clock it should be about, see red arrow. Forget the black ones. Try that first. Let me know.1 point

-

Today I'm sporting a Denison cushion cased Rone Sportsmans 15 jewel with bags of character most probably from the late forties or early fifties. This had been lying for quite a while in the to-do pile, as I had assumed that since it was locked up solid and had a distinct rattle, it would have a broken balance. Fortunately this was not the case, and all it needed was a thorough clean and now it is ticking away quietly. It is sitting around +10 sec/day, all be it with a relatively low swing around 220 degrees (a slightly tired mainspring most likely) but a more healthy beat error of 0.6ms. The diminutive size of this Gents watch is quite a contrast with the recent trend for wrist mounted frying pans. I had no suitable strap for it so I had to improvise from one of the straps in the scrap pile.1 point

-

What I do is this: - Before putting the bridge over the wheels I get sure that the pinion of the escape wheel is resting on the 4th wheel. It has a tendency to lean against the 3th wheel, which is not right. - I put the bridge, get sure it's aligned with the barrel arbour and the 3 posts on the main plate. I softly hold the bridge in place with a pegwood stick and test the wheels turning the barrel. - Usually all of them will turn, except sometimes the escape wheel. If that's the case, I release the pressure of the pegwood stick and carefully hit the sides of the movement holder with the back of the tweezers. Test again, it will probably be in place now. Maybe you need to repeat a couple of times. This works for me.1 point

-

1 point

-

1 point

-

1 point

-

Those are traditional ways, and not the only ways, however I just quite like them from being things I learned about early from easily accessible (hand-me-down) older books.. It took a few hours from getting my first watchmakers lathe to getting to grips with my first wax chuck as a teenager, that was a fair time ago. Probably 12-15 years ago a speaker came to a BHI meeting with his lathe and a camera or digital microscope, to show the process of making a staff in one on a projector screen. He was said to have once produced (if my memory's correct) 10 in a line, end to end. Personally, I don't feel it's really necessary (or for that matter desirable) to have to produce them in such vast quantities that saving some minutes and seconds are make or break. I'm in two minds with the Jacot tool, sort of precision and prettiness vs fiddliness. Admittedly, not really a beginner friendly option - using one is a skill, as is finding a good used example. The wax chuck method takes a bit of practice but is cheap and accurate.. I usually find it more easily effective with something like the smallest size of creme brulee burner/ gas soldering iron as seen in the Roger Smith hand finishing videos, for tempering the hands.1 point

-

Hi Cecking through my workshop laptop I came across these PDFs and thought they might be useful to the members new and old alike. I have several more and will post later. Cheers Witschi Training Course.pdf TZIllustratedGlossary (1).pdf handbook_of_watch_and_clock_repairsa.pdf Test and measuring technology mechanical watches.pdf1 point

-

I never had a tidy bench. I had bits and pieces all over the place. The more mess I had the happier I would be. People would often say to me how can you find anything in that mess.1 point

-

UPDATE: This past weekend, I picked up a NOS Waltham 4856 arbor with straight pivots and replaced the broken arbor with this part. The operation was straight forward although it took me much longer to do it because I was learning a new skill and working with new-to-me tools. I used a staking tool to press out the old arbor and to fit the new one into the original fork. The pallet fork is back in the watch and appears that it will work once I am able to replace the broken mainspring.1 point