Leaderboard

Popular Content

Showing content with the highest reputation on 10/06/19 in all areas

-

Yes and yes. It is possible to make your own tool with pegwood, but fraught with frustration. Also, one can re-seat the Kiff spring in the setting using two sharp tweezers and a fair amount of profanity. The trick is to seat two lobes of the spring BARELY into the setting and then while holding the spring, gently and carefully work the third lobe into place. Hard to describe, but not too hard to actually do, but it can also be frustrating. Ask me how I know. RMD2 points

-

The hair spring has been installed 180 degrees out at some point and is almost certainly the reason the clock didn't run. The simplest fix is to remove the h/s and balance from the cock and rotate the h/s collet 180 degrees around the staff. The question is how did it come to be installed so far out of whack in the first place.2 points

-

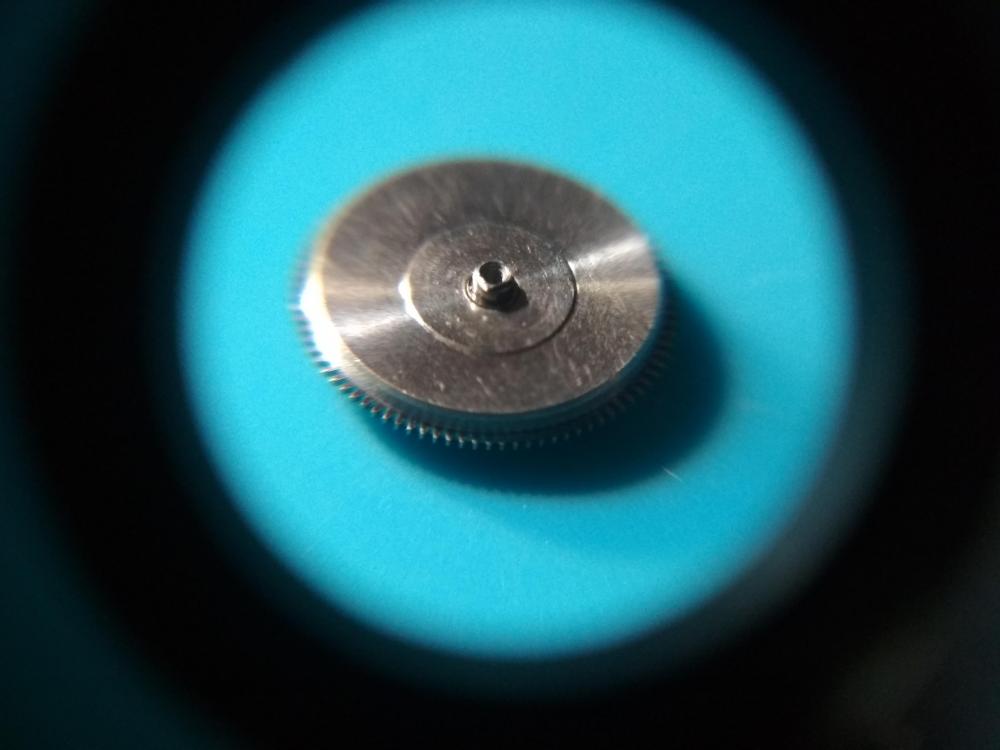

It's a truing caliper for truing up balance wheels. Looks like it includes tools for manipulating the balance rim too.2 points

-

Don't think the damaged is big . Probably only moved the arms on the balance bridge. Adjust the watch back to 0,2 beat error or better . And i think the amplitud will rise to 280. No problem.1 point

-

Thanks. It was so nice, I'm still wearing it almost three weeks later. There is something about the style of it that I like. Just that little bit different and it certainly scratches that retro itch. A little more careful tinkering and I have it around +/- 4sec per day. Not bad for a bottom of the barrel ebay watch.1 point

-

I went ahead and created an account to post my question right away. But first thing last - I'm just an admirer of mechanical watches. As Frank Seuss - a watchmaker from downtown San Francisco once told me, "at least your watch ticks, compared to most watches these days" - the intricacies of mechanical wrist watch movements fascinate me. I bought few watch repair tools last week; however I'm too skeptical to fix watches by my own - without any formal training. That being said, I'm good at fixing things. Perhaps I might learn a thing or ten from this forum.1 point

-

Just reach to the drawer and completely take apart a quartz watch with a $15 repair kit, put it back together if it runs with no lost or damaged parts you're on the good track, if not some more effort is needed.1 point

-

An hit can just move the regulator arm and would be the most benign consequence. Also the HS can suffer from a shock but there is little you can do about it. If the watchmaker (assuming you can find one able to) takes time to correct that may cost you more than complete mov't.1 point

-

As mentioned already by all means don't mess with the barrel complete. It is not needed, and your will do more harm than good.1 point

-

Well I figure to be a beginner for at least 10 more years, but: rduckwor didn't mention that they turn into position. Actually they screw in clockwise as though into threads. Tweezers or a small screwdriver did the trick for me whilst steadying with pegwood. I bought the kit of tools from Jules Borel, but mainly to get the Kifs.... Found some pinged ones later in the oddest of places! And another bit of advice learned the hard way. Save the profanity until you are a minimum 2 meters from the bench. Saves many heartaches!1 point

-

If you plan to specialize on these two brands, no sense in practicing on chinees movements then, I would get me walthams in need of repair could be pocket watch. Two waltham of the same caliber is a good start and add on as you buy more, as a result you would spend least on spare parts. You would get familiar with the culprits of the caliber, so on. Familiar with Marks teachings members here are good tutors if you take his courses. This very post gives you an idea of the bulk of responses you would receive to your questions. The more questions you ask, the more we learn along with you. Best1 point

-

Hi CalDemp, I'm over in the East Midlands of England. Until two years ago, I too was a complete novice in watch servicing and repair but have come a long way in that time with the help of WRT videos, lots of practice and sheer determination to succeed. For me it's likely to always be a hobby too though. Your passion for specialising in Breitling and Waltham watches is fine but I can offer a word of caution here. Breitling, as well as some other separate Swiss brands owned by the Swatch Group have restricted parts to materials houses (such as Cousins) and thus obtaining the parts can be very difficult - you may find some NOS parts as well as some overpriced parts on ebay but it could potentially cause you some headaches. If you're talking simply servicing and possibly replacing a mainspring as part of the service, then you may be okay. Waltham should not be as much of a problem, though I haven't serviced any of these so I'm happy to stand corrected by anybody chipping in. Donald de Carle Practical Watch Repairing is a great book to get you started. For a website, you've come to the right place as Mark's videos are the best I've found for clear guidance and demonstration of watch repair - I have seen other people trying to teach by video and got nowhere. Good luck with your new pursuit - I'm sure you will find it both an absorbing and very rewarding pastime. Kind regards, Adam1 point

-

The service manual specifies replacing the entire barrel assembly at each service. I dont think Seiko intended for these to be oiled outside of the factory. I always thought these are solid steel on Seikos but I could be wrong. I don't think it's a big deal if there is a bit of cross contamination here. There WILL be cross contamination no matter how careful you are in this case.1 point

-

Hi I don't have a intermediate wheel so I will just rebuild the watch. And when I can get a intermediate wheel the watch should be in full working order. Thanks to all for advice and help If anyone knows we're I can get a intermediate wheel please let me know. It's only that part that's stopping me successfully rescuing a nice watch. I intend to keep and wear. I was unsure I could tackle a chrono but with help and advice its well worth attempting. When I get a intermediate wheel I will of course post pics of the watch. Cheers Gary1 point

-

Unfortunately I can't really tell from that. I suspect though it has reduced amplitude, if it's keeping good time now then continue to use it but most likely will need a service sooner rather than later to restore performance.1 point

-

The impulse jewel ( in red circle) should come to rest inside the fork horn, for the escape mech to be in beat. staff, fork, escape wheel pivots should fall on a streight line. Re awmove/ reinstal , either the roller or the hairspring to bring in the said positon. It will not run as is, any inaccuracy in positioning the impulse jewel ( on midline between the banking pins will result in beat error correspondingly. Do you know how to perform this task?1 point

-

It wouldnt diagnose the fault but it would prove that the balance assy was exibiting the fault before fitting to the recipient watch therefore a fault was transferred and was inherent in the donor watch before removal and refitting, There is no way of knowing if this was the correct balance that was in the donor in the first place.1 point

-

Hi I would personally do it free hand as you have more control over the cut, Powertools will be a little too vicious, You could use an electric screw driver that runs on slow revs with a jacobs chuck.1 point

-

1 point

-

Hi The object of the exercise is to decrease the shake, Then removing metal as suggested will do that. The medodology does not matter as long as it does the job. Reaming the tube to lower the weight will do as long as after every turn of the reamer you check the fit untlill you achieve the desired result. An ordinary chuck is like the one on a dremel to hold the bit. I would not use a power tool as the chance of removing too much metal is too high better to use hand tools for such an operation and take great care and check regularly.1 point

-

I haven't done any dial feet soldering, but I have done quite a lot of electronic soldering over the years. You might also be interested in low temperature solders. https://www.digikey.com/en/product-highlight/c/chip-quik/low-temperature-indium-solder-wire Keeping the heat as local as possible helps, when working with sensitive components, as does careful heat sinking and using suitable fluxes to minimise soldering time.1 point

-

I struggle interpreting timegrapher reults and often am wrong. I think the rate indicates imbalance wheel.1 point

-

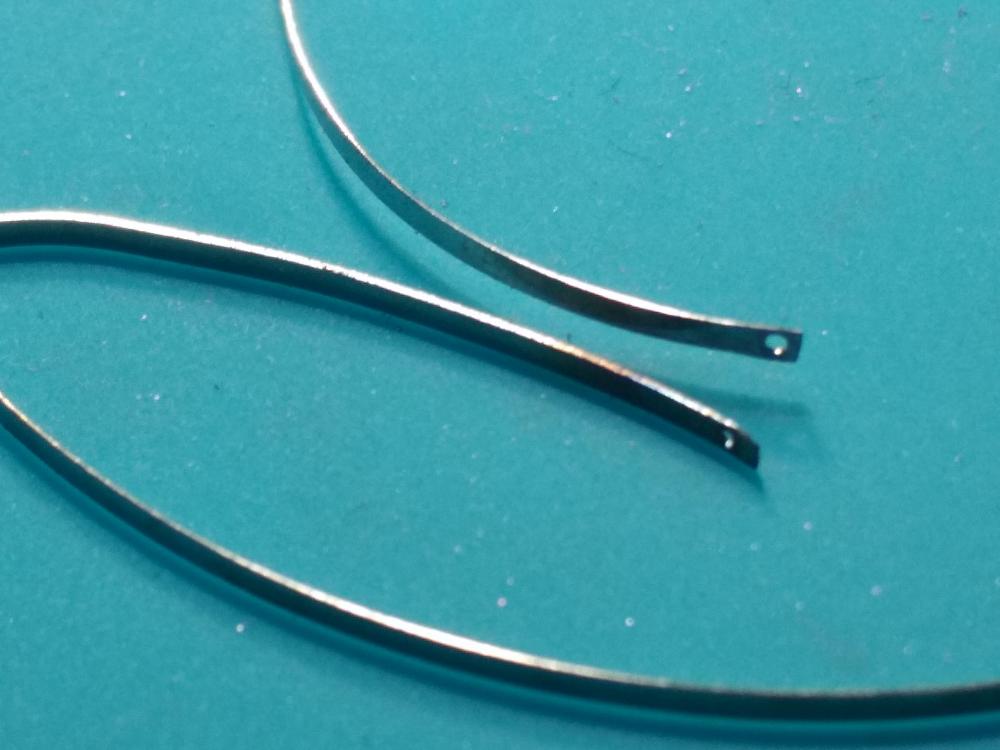

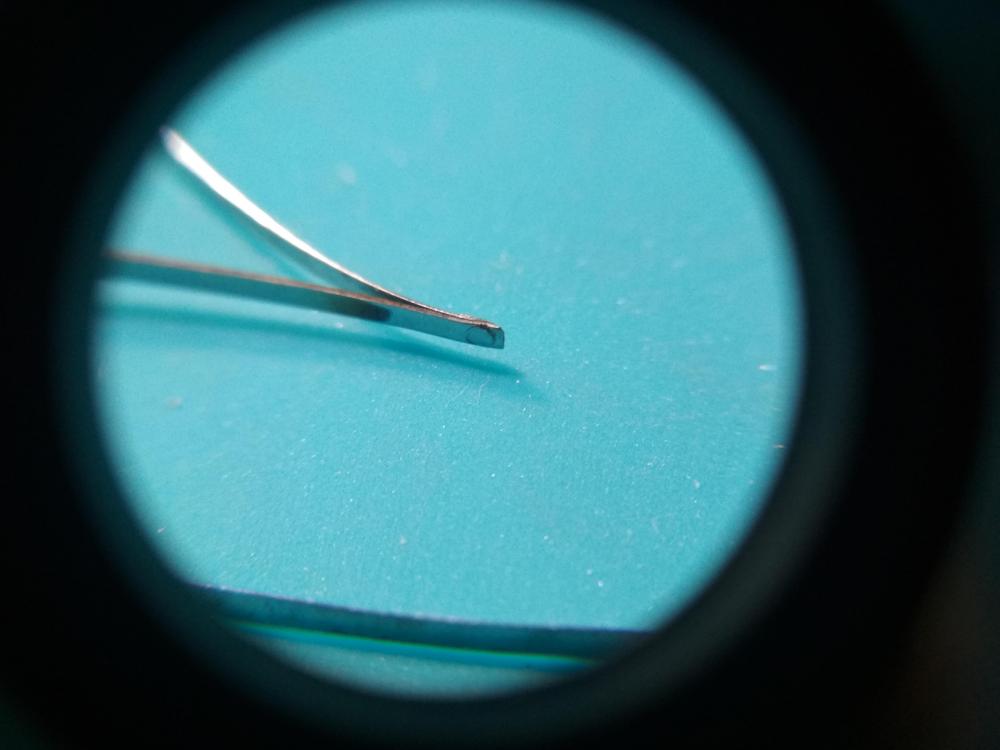

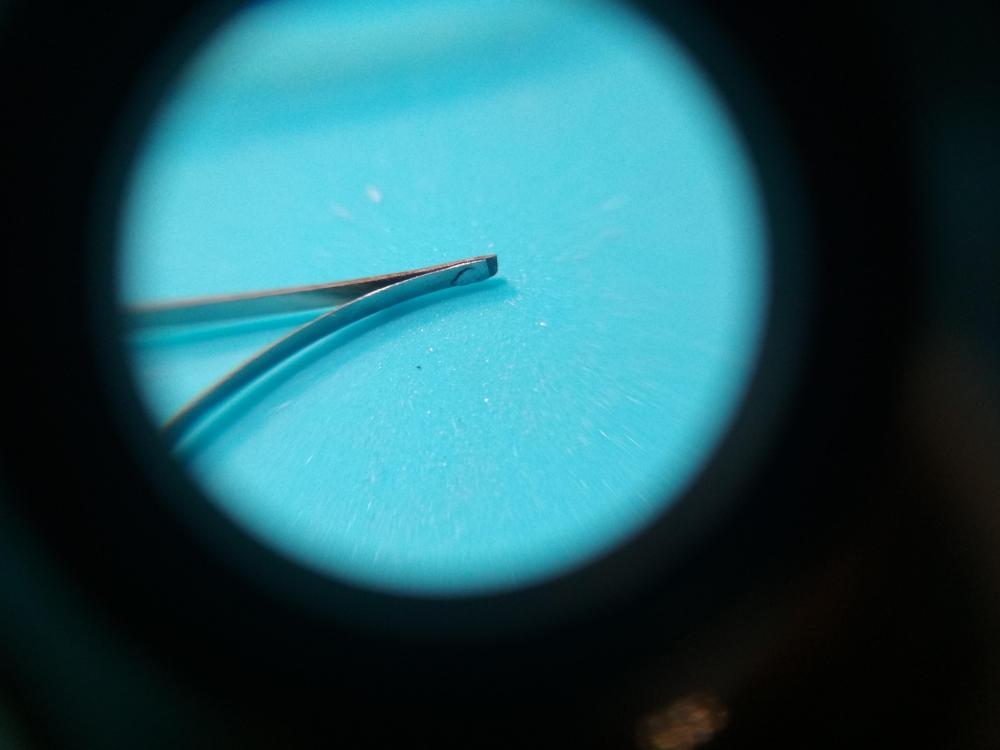

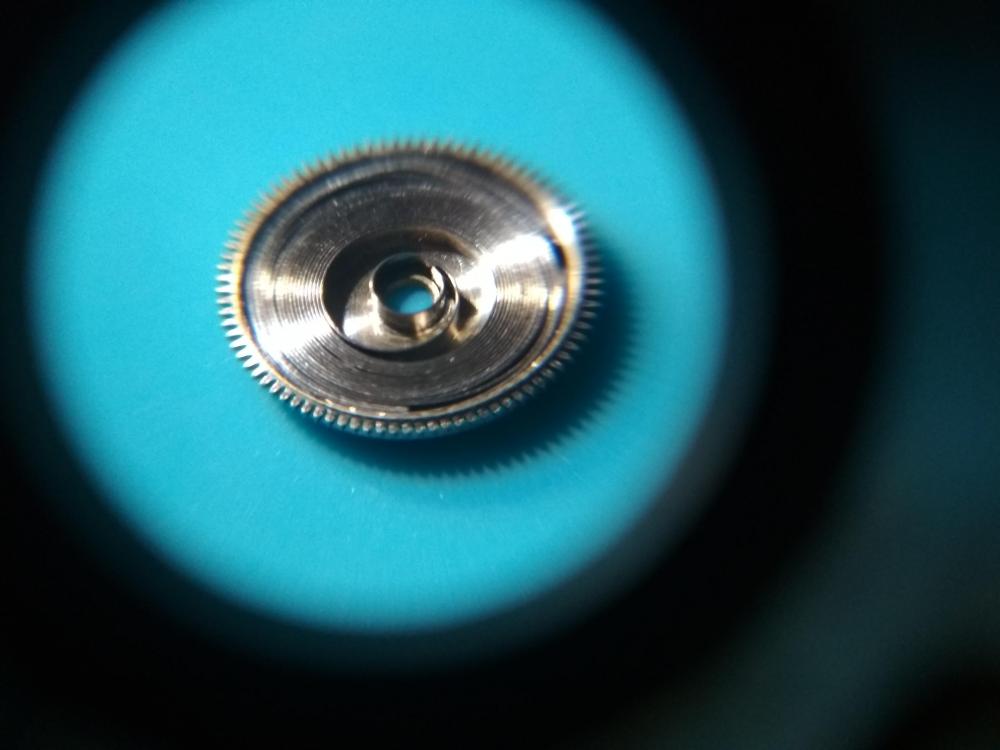

Hello, I want ot show you my way to repair broken slipping end of the automatic mainspring. 1. Firstly I drilled mainspring and slipping end with 0,3mm driller. 2. I made the rivet 3. Mainspring and end riveted 4. Clinching the rivet with pliers 5. Rivet grinding with file and water paper 6. Mainspring installed in barrel 7. Completed. I have checked if it works well. I have 9 full turns of arbor before mainspring starts to slip at the barrel wall. I think it is quite good. Some service manual says that 8,5 turns is a good result. What do you think - is it good way to repair this malfunction?1 point

-

With this sort of repair, which you have successfully managed, is making sure the rivet doesn’t rub against anything, yet still holding the spring together.1 point

-

1 point

-

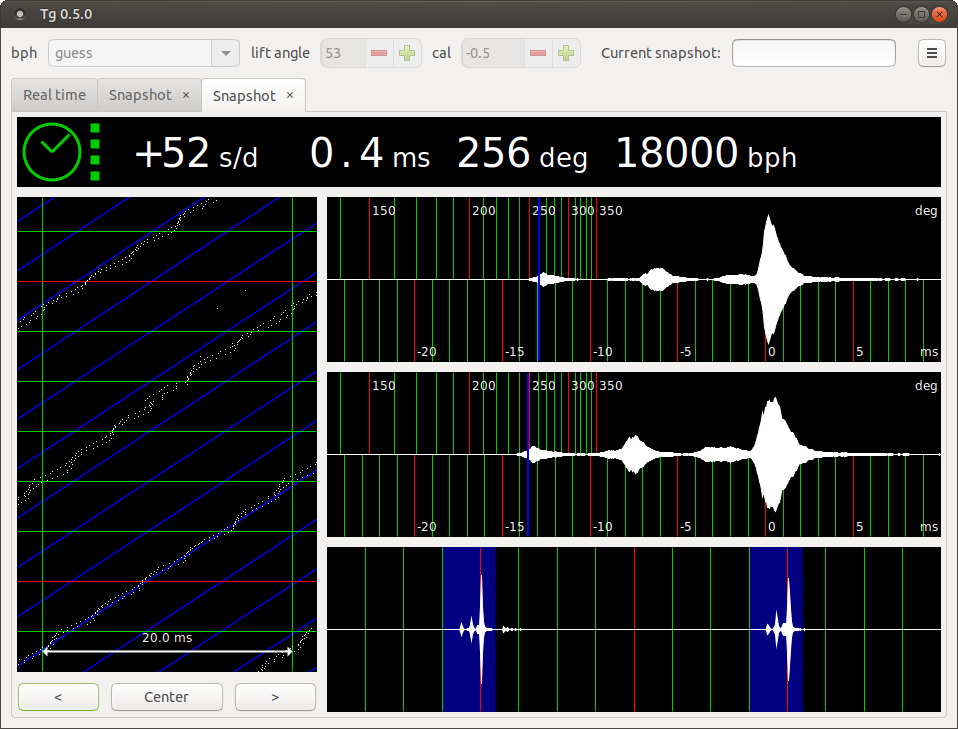

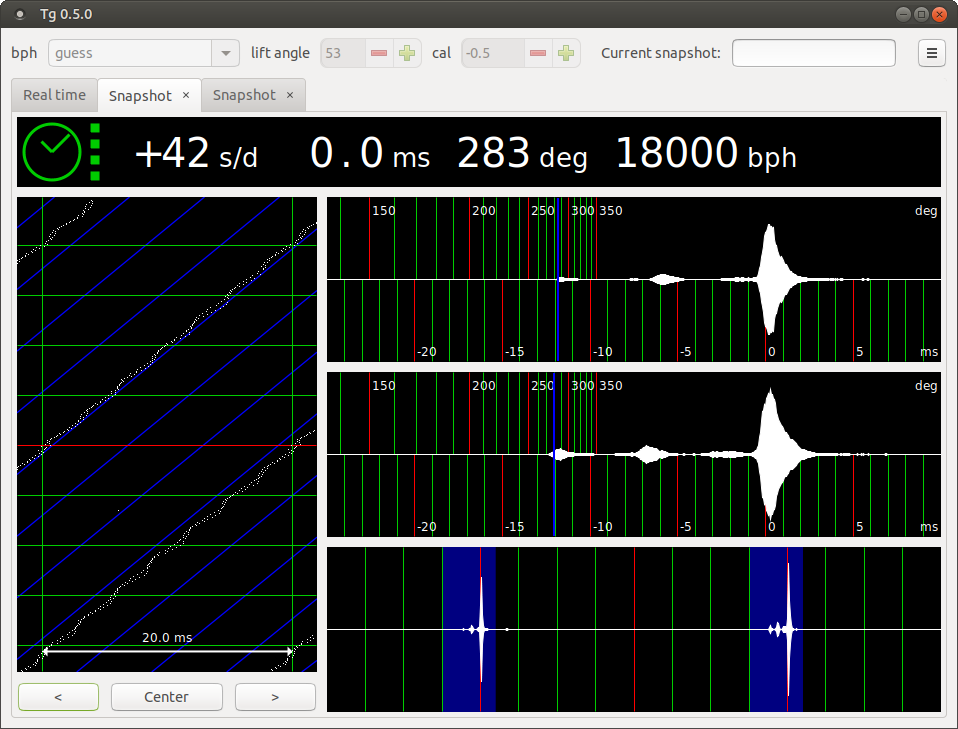

More Russian fun. A before and after picture of the Sekonda which I posted about previously. This arrived as a non runner (as most of my watches do). I cleaned and serviced it yesterday and have been wearing it most of today, to let the lubrication bed in. When I got it going initially it showed evidence of previous tinkering and was sitting with a beat error of 14ms or more and rattling away at +85 sec/day or so. I just checked it again, having left it at +70s/day yesterday, in the hope that as the lube settled, the rate would fall, as indeed it has. Dial up Dial down As you can see it is slightly stronger dial up, but I'll let it run a bit longer, then set it around -5s/day dial up and see how it goes for the next 24hrs. I'm pretty pleased with the results so far, including the date change which fired at almost exactly midnight last night. Yes, I am sad enough to have sat and watched it. This particular caliber the Raketa 2628.H also has a date quick change by pulling the crown to position 3 returning to 2, rinse, repeat etc.. A bit of a novelty when you have been dealing with ancient Timexes, with all of their fiddling with spinning backwards and forwards of the hands round midnight to get things set correctly. The 17jewels.info page has a partial tear down which gives a hint about this feature, which you might not be aware of. All in all, this is another pretty nice watch, especially considering its pocket money price.1 point

-

Now all we need is a good 5 cent cigar!1 point