Leaderboard

Popular Content

Showing content with the highest reputation on 10/01/19 in all areas

-

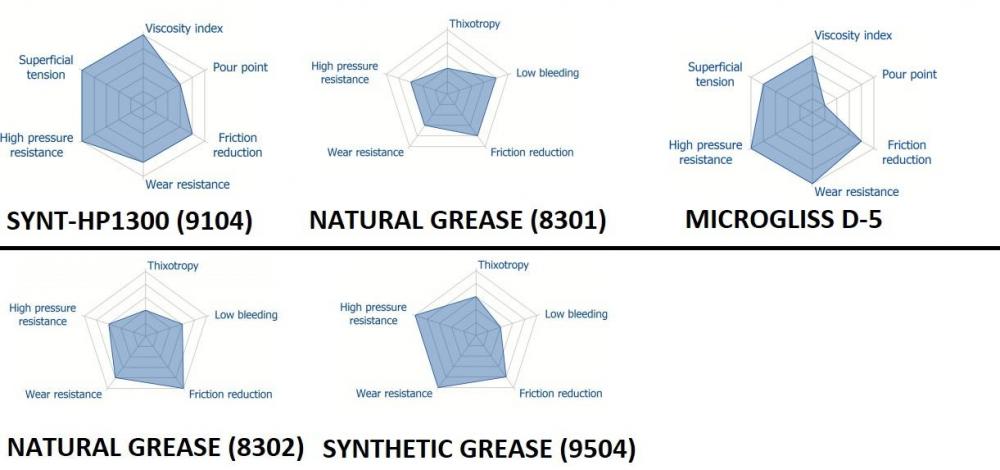

Interesting question @jdm! I also use Synt HP-1300 (9104) oil for the arbor and for general metal-on-metal applications. This is as per recommendations and since it is often mentioned that synthetic 9104 supercedes mineral oil based D-5 and thus, by implication, is superior. I've gone onto the Moebius site and compiled the radar charts for key attributes as below. Comparing an oil product with a grease product isn't quite apples-for-apples as the criteria on the charts changes but, if for the sake of this question, we take pressure resistance, wear resistance and friction reduction as the key comparators then the charts are useful. What stands out for me here is that I wouldn't be recommending 8301! However D-5 matches 9104 for pressure resistance and friction reduction and trumps it for wear resistance! We need to take into account though that, as a synthetic product, 9104 has better ageing qualities than D-5 and remains in situ slightly better. The wild card is that fancy 9504 you've found. Why does Moebius recommend 9104 for barrel arbors but doesn't even mention it in the context of 9504? I reckon it could be the viscosity. I always associate a grease having a greater viscosity than an oil but that doesn't seem to be the case - perhaps adding to lubrication confusions! Moebius measure the viscosity in centistokes (cSt) with, at 20 degrees centigrade, D-5 = 1200 and 9104 = 1250 [just for comparison 9010 = 150). 9504 comes in at a pretty fluid 305 although it's in the grease category. So for me it's still a D-5 vs 9104 situation in a metal-on-metal situation like the arbor hole. Watch serviced regularly? D-5 in theory trumps 9104 for its greater wear resistance (and could thus avoid the situations that @RyMoeller has observed on Seikos) but a more normal situation for most watch owners is to only think about servicing when a watch stops running! Whilst 9104 might not have quite the wear resistance capabilities it doesn't degrade or move so is actually likely to be superior in a lot of cases.4 points

-

3 points

-

2 points

-

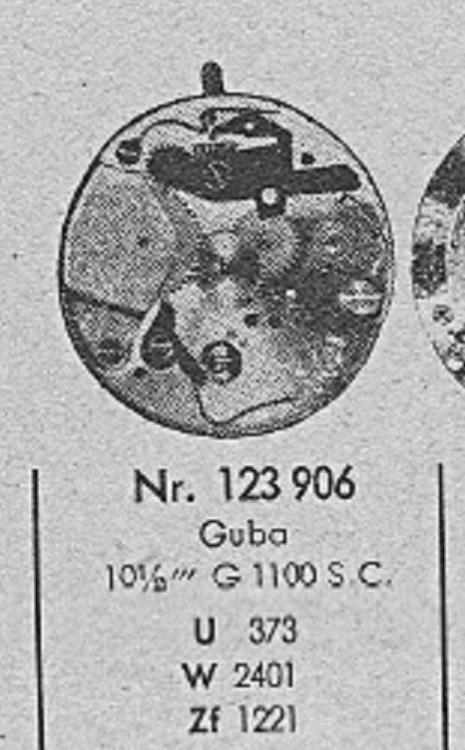

Much as I would love to be able to say that I managed to rake it out of the extensive archives stored away in my own memory banks...... I have to confess I kind of cheated I took your advice and expanded the image for a better look. Sadly the image itself offered no further obvious clues, but I did notice the image file name was "VidarGuba1100SC", so I googled images for Guba 1100SC and found a match. I'd have gotten no further than my original Kienzle guess otherwise as it does seem to be a rather obscure maker, not one that I have encountered myself. Incidentally my original thoughts regarding Kienzle were down to the use of a single large bridge for the barrel and going train instead of two separate bridges, and the slotted barrel arbor, both features that I have seen on the fully jewelled Kienzles that I have worked on in the past. I wonder if there was any collaboration between the two makers.2 points

-

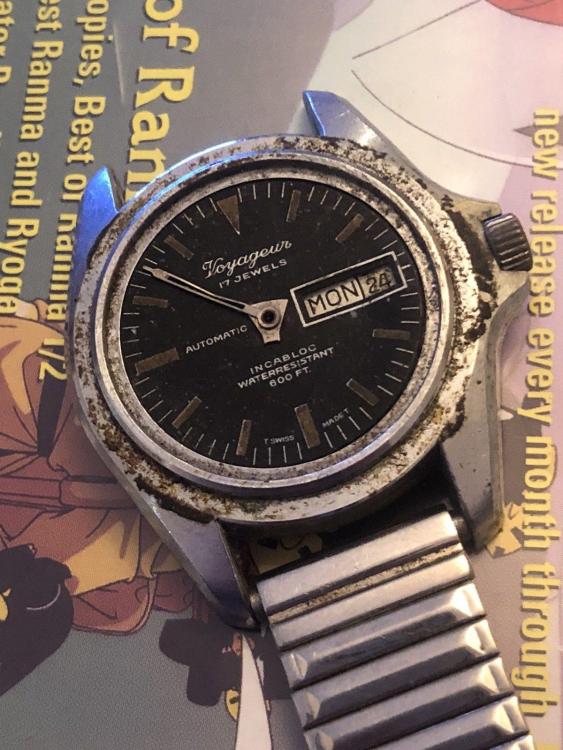

Hello from Scotland. I recently re-awakened an interest from my youth in watches and clocks. Strangely the catalyst was searching for a replacement hand for a Starrett dial indicator that I picked up for pennies on ebay and which I though might be useful for leveling the bed on my 3d printer. It was missing the dial hand, which looked very like a watch second hand, so that led to a search for a suitable donor watch. Needless to say I then got distracted by the vast array of old time pieces to be had for pennies, and grabbed a couple of basket cases. The first one was a Sicura Voyageur. It only says Voyageur on the dial, but it has all the hallmarks of a Sicura, with the seahorse emblem on the caseback, and the remains of hands that look like the Sicura "Marine Star" It was in a sorry state, but after a quick clean, polish and minor overhaul it's Rondo-matic heart is now ticking away nicely. I'm awaiting a suitable second hand for that, currently on the slow boat from China, and it has parted company with its bezel, which I may fabricate a replacement for if I get the time. The problem there is that I can't find another "Voyager" to compare with, and Sicuras had a variety of different bezels. I found WRT by watching some of Mark's many excellent Watch Repair Channel videos, many thanks for those Mark. I have a couple of other basket case watches ordered from ebay. I set myself an artificial ceiling of £4.04 per watch (although I have already blown that a couple of times), as I figured that there was a lot of fun to be had from resurrecting an item destined for landfill and costing less than a trip to the coffee shop. My day job involves computers, and I dabble in electronics as a hobby, which means I'm fairly patient, and used to dealing with very small fiddly components, and already have a bunch of small tweezers, screwdrivers, clamps, magnifiers and so on.1 point

-

Hello everyone! I have had this watch for more than 10 years, it was one of my first at $5 from Village Des Valeurs (thanks for the find dad) I can find info about the maker (Pryngeps) or the model, ive never been able to find even a picture or anything about the model. Any info would be greatly appreciated!1 point

-

I hope you'll be patient with me, as I simply saw a solution and went at it, a bit hurriedly. I'm at the very beginning of this hobby, and after disassembling about 5 movements (orphaned movements, bought inexpensively on eBay), I've had success with reassembling only one and getting it to tick. I disfigured the hairspring on one, and the other 3, lost parts to the floor. So on this FHF 96 ST movement, I disassembled with care, cleaned all parts with naptha and rinsed in isopropyl alcohol; only to find upon reassembly I lost another part. Despite my best attempts and using the standard compartmentalized container with plastic bell cover--the setting lever screw had gone missing. I took a screw from a similar movement (I bought 10 orphaned movements from eBay a couple of months ago as "parts only") with the intent of taking apart and putting back together. But the head was quite long, and the threaded portion not long enough. As a result, the end sat flush with the main plate, and didn't reach the setting lever. After confirmation it was the correct thread pitch and diameter for the setting lever, I placed it in a chuck with the intention of removing some shoulder from the screwhead's bottom, so it could sit proud enough to engage the setting lever. I used my lathe for the first time, and using a graver for the first time, I sloppily cut the screw. You can see I unintentionally removed some threads close to the botom of the screwhead, but it wasn't a critical area, and there were enough threads to fully engage the setting lever. The screw now sat proud enough of the main plate, to work. I have a lot of practice ahead. I'm sure my work will improve. This was my very first project, and although it's a bit lacking in quality, from a utilitarian point of view; it worked, and will get the watch ticking.1 point

-

My wife has had a jumbo size jar of pickles of the bench for the last 2 months that has defied all efforts to open it. Bought a new Silicone jar opener, made no difference. Holding the jar at 45 degrees and slapping the bottom of the jar to use the 'water hammer' effect didn't work. Me holding the jar and my son trying to open it didn't work. Heating the jar lid with me holding the jar and my son trying to open it didn't work. After coming home tonight from the pub I could see my wife had tried to open it again without success. I gave up and searched the web for how to open stuck pickle jars and one suggestion was use a bottle opener on the side of the lid. I very carefully used my best bottle opener (Hand forged by a blacksmith) on the edge of the lid and 'pop' went the lid without the lid being damaged. The jar is now open after 2 months of trying, is there anything the web can't help you with?1 point

-

1 point

-

Pulleys for high-confidence applications with wire rope (cable) are often round looking in cross section but there's a fair bit of engineering in the actual shape. All pulleys wear over time, I can see a round-ish wear pattern on many of my old machines and motors. I don't recall any watchmaking equipment that came with round grooves though.1 point

-

THANK YOU!!!!! That is the most info ive ever had about this watch.1 point

-

Thanks. Looks like a Peseux 320. Regards.1 point

-

One of the minor problems with lubrication requirements are that the tech sheets don't always tell the whole story. So for instance Omega has a separate document just for mainspring barrels so I went to look at what they recommended. Their recommendation is 1300 on the arbor of the barrel. But they also recommend after cleaning that the barrel, arbor and lid all be treated with epilam. Then at work we use 9501 on the barrel and arbor as I like the idea of using a grease on a high-pressure load. Although I think the 9504 would be better for a lot of applications it is thicker at least from my memory unfortunately at work I can't compare the two because I suspect my boss would have sticker shock on the price the 9504.1 point

-

I was to make the same comment but I didn't, as jdrichard is an able machinist and will figure out, without the need for any book. However it seems to me that the original pulley have radius concave grooves, but the pics don't show clearly. I suppose that turning Acetal that can be easily achieved by grinding a round nose tool. Please excuse if I'm talking without sound experience, I still have to resume my machinist self-learning with the new steel bars that I just bought for an hefty price to me.1 point

-

Is the stem/crown moving in and out? From the information given I'm assuming yes as you're implying the hands can be set ('crown out') but will not wind ('crown in'). In this case the keyless works aren't rusted solid and all that should be holding the stem in is the setting lever. Normally someone would only want to undo the setting lever screw far enough to allow the stem to pull out but in this case, since you'll be dismantling the watch anyway, then it doesn't matter how far you unscrew! The screw on the 920 should not be 'captive' so should actually be removable in itself. So remove it; use tweezers or hold the movement upside down and gently tap; hopefully the screw should come out. This should free things enough so that setting lever is no longer holding the stem. If, once you've removed the screw, the stem will still not remove then it indicates the setting lever is somehow jammed; consider pushing a small screwdriver into the screw hole and gently pressing down on the lever whilst pulling the stem to see if that frees things. Good luck! [Just as an aside since I'm replying ... I note you ask a lot of questions but I rarely see any 'thanks' and/or follow up on results! Things like that are important on a forum like this where people are taking the time to read your many requests for help and giving their advice for free ... or other people have the same questions but can't see if the advice was successful or not. Hopefully other contributors agree. ].1 point

-

The best solutions are normally found after a visit to the pub. I've watched enough episodes of Morse to know that there's not a problem known to man that a beer can't help to solve.[emoji3] Sent from my moto g(6) play using Tapatalk1 point

-

You might find that the belt slips with that groove shape, generally for pulleys used with round belts the angle should be between 35 and 60 degrees, more towards the smaller angle. Most I've actually measured have been between 40 and 50. The smaller angle makes the belt wedge into the groove, so you don't need excessive belt tension.1 point

-

Check out the link for a 21 jewel version. Google translate is your friend here unless you are multi lingual. https://uhrforum.de/threads/herrenuhr-marke-falta.400357/1 point

-

Ha! - I wondered if my images named the subject matter which, of course, now precludes me from offering up any more of my little mysteries! Anyway, well done that man. I'm a member of another watch site forum and had sought help with ID-ing the Guba (Gustav Bauer, as I'm sure you know). A fellow-member who also maintains an archive of movements not represented in Ranfft, Lorenz or Watch-Wiki found the attached image in a 1957 Flume but it was so rare that not even he'd ever seen one before. I was more that happy for him to include my movement and dial side images in his database. I get what you mean about the Kienzle's configuration. Here's an image of my 17j 058b25 pallet lever job by way of comparison. Cheers, Bryan1 point

-

the proper name for the "good book" - as i remember is Machinery hand book. it weighs about 5 pounds and has been used in aprentiships for years. vin1 point

-

Neither Dubois Depraz or any watch manufacturer that uses his modules do sell parts to anyone. So either you fabricate or adapt one, or buy another module in whatever conditions to get it. The last alternative is to send the watch to an official service center where after a comprehensive estimate they will replace the entire module as per standard practice..1 point

-

The reason I thought it might be Russian is because the shock protection looks similar to this little Sekonda ladies movement that I serviced a while back. Kienzle is also a good guess. They did some fairly sophisticated stuff as well as the pin levers. I have a Kienzle automatic movement sitting in the todo pile at the moment (with a pretty spectacular hairspring salad as I recall).1 point

-

1 point

-

How do you know it is the wrong stem? From what I can see I suspect rust is preventing it from being removed. So as not to damage the movement, put penetrating oil on the stem and let it run into the keyless work. Have you tried to unscrew the button from the stem?1 point

-

I understand your scenario but then the main issue would be the click releasing and not locking fast enough. This would happen even if the clutch wheel and winding pinion were in good condition. The sharp noise could also be the mainspring slipping, I assumed you greased the barrel wall with suitable oil? Another test you could do is remove the clutch wheel ,stem etc and wind the ratchet wheel with a screwdriver and see if the same thing happens.. be careful as potential for the screwdriver to slip is very high! Goodluck1 point

-

Phase 2 - Drill a hole Phase 3 - Put in 3 Jaw Chuck Phase 4 - Grave Pulley Slots Phase 5 - Install Sent from my iPhone using Tapatalk Pro1 point

-

An Ronda 1217-21 (pin lever version) Ingersol with a very attractive sunburst grey dial got a clean and service today. Its a pretty good looking watch, up close, almost perfect. If only they had pushed the boat out a bit more on the mechanism. Its running well now, with a good solid swing, and a steady rate. It arrived DOA. Old oil, filth, a cracked crystal and a deformed hairspring all had to be attended to.1 point

-

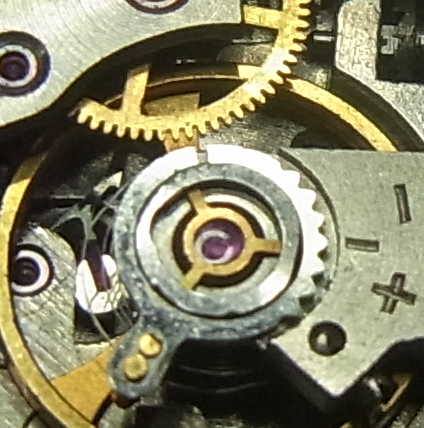

This is the DOF module for the M5 with the aperture stopped down. The M5 without the module fitted... ....and with the module in place. Excuse the missing stage plate. In this set up it's a bit cumbersome and impssibe to use on the bench it's siting on. To the right of this bench is another desk about 12" lower though which accomodates it nicely. The camera on the stand to the left is an old Nikon D100 fitted with a 2x teleconverter and a Helios 58mm f2 lens which I use for my reference photos. It is a totally manual set up so once set I can just place the watch on the base board and push the button. I don't even look through the viewfinder. This is what I use for my close up shots. It's and old 6.1mp Kodak bridge camera. It has aperture priority auto so I can set the smallest aperture for max DOF, and a good quality Schneider lens. I have taped an objective lens from an old pair of binoculars to the front to improve its close up capability. As you can see DOF is limited at the closest focusing distance and max zoom. But still useable. By moving further back though DOF is greatly improved and the resolution is still good enough to crop the shot. All the above are full frame. This one is a crop of the previous shot.1 point