Leaderboard

Popular Content

Showing content with the highest reputation on 04/19/19 in all areas

-

2 points

-

2 points

-

I'm really into machining and making my own tools (generally I spend more time doing that then the actual hobby itself...), so I thought I'd start a topic about DIY tools for watch repair. My first success has been making a watch winder on the 3D printer. Winders are one of the more expensive and difficult to find tools for me, so it really made sense to start here. Here's the watch winder, it consists of three parts (from left to right): the pluger, spring barrel, and winding arbor. The only non-printed part is to drill a small hole in the arbor and put a piece of steel through it to catch the mainspring. It's certainly more fiddly than I imagine a proper tool would be and will not last as long. But it gets the job done and you can make it any size you want! You can find the CAD files on thingiverse:https://www.thingiverse.com/thing:35406601 point

-

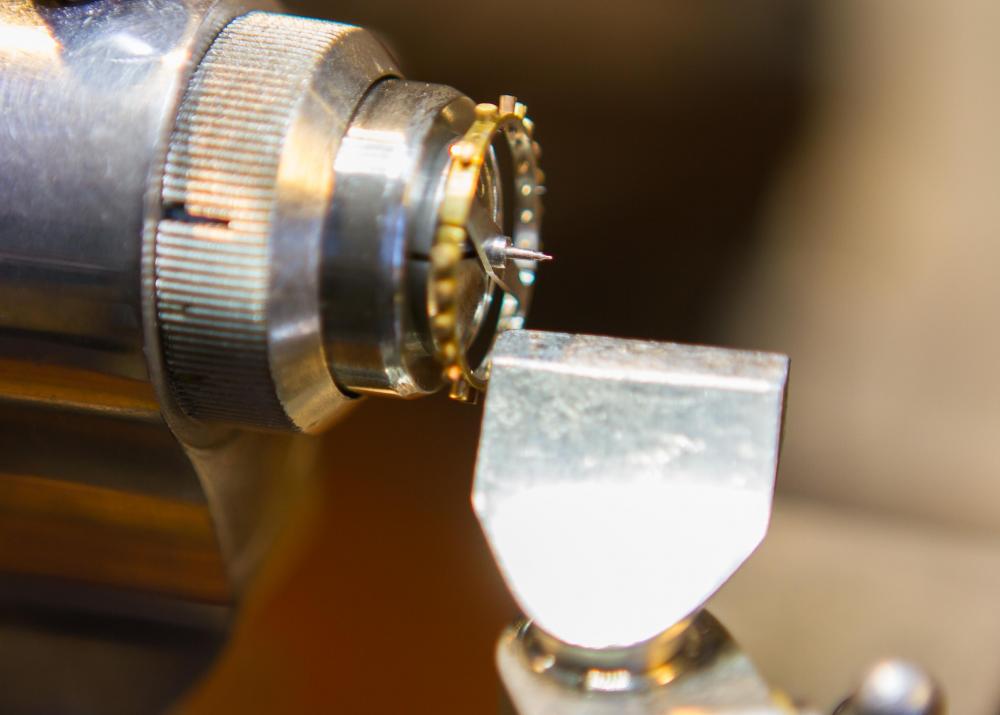

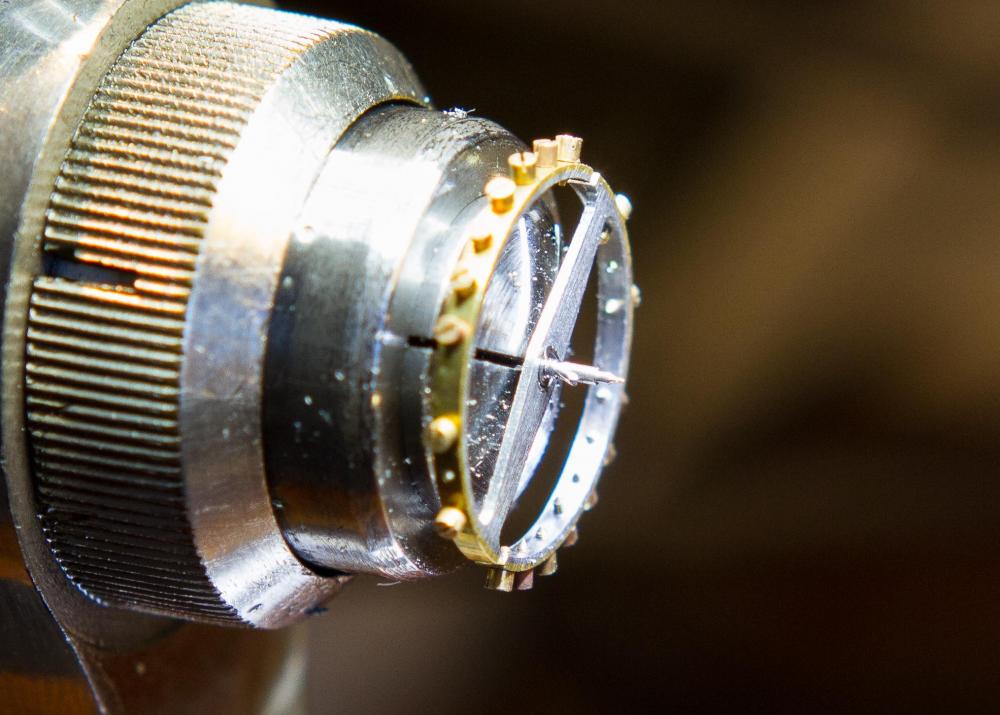

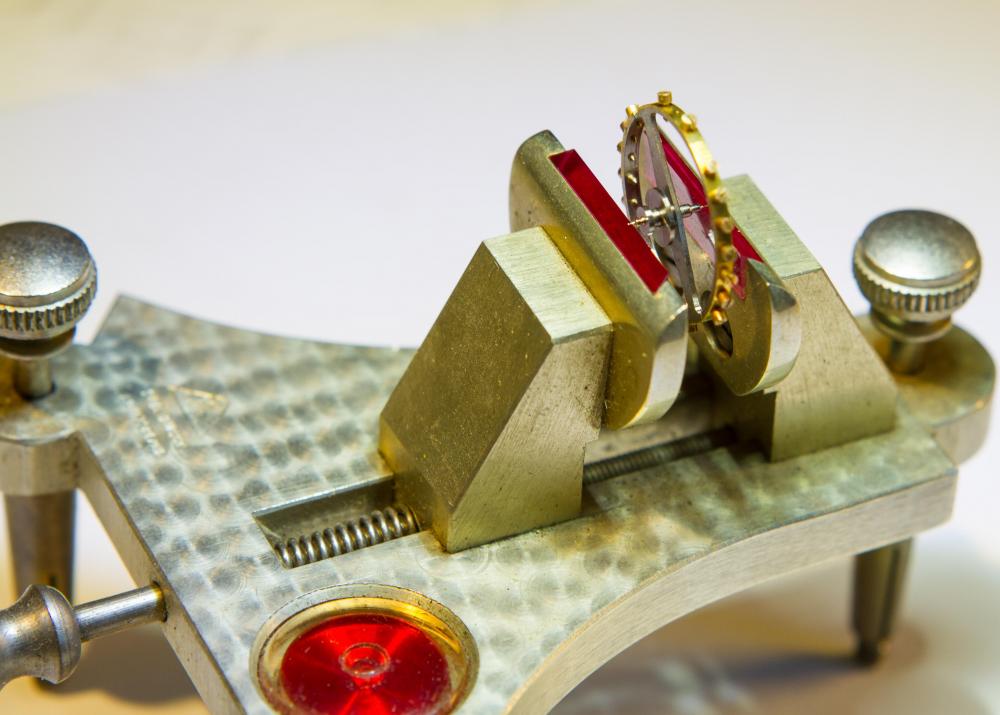

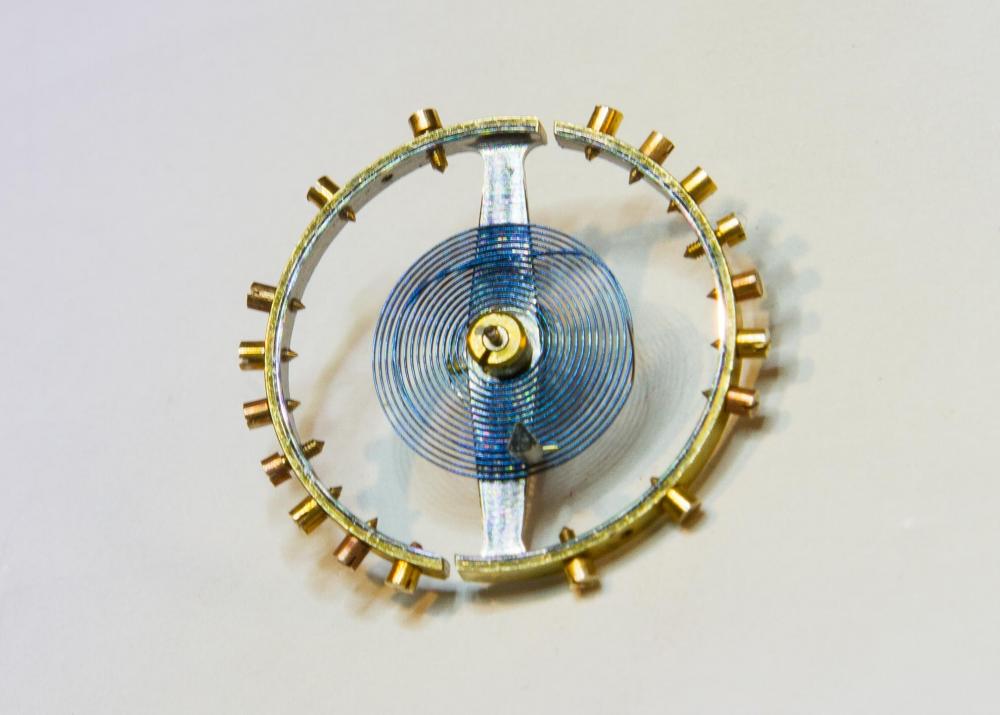

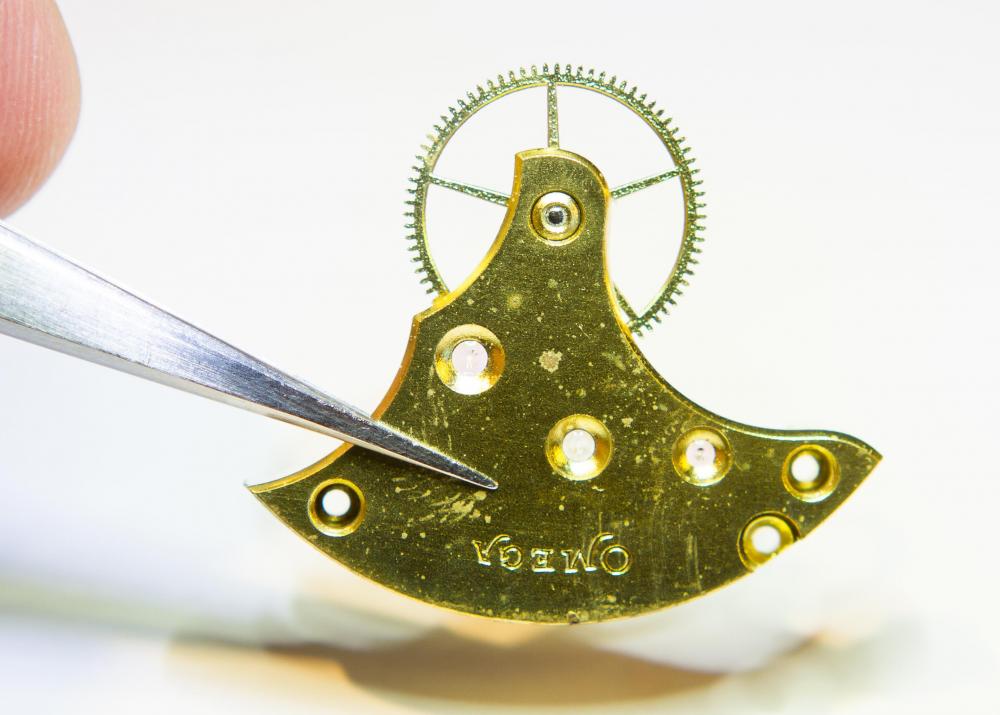

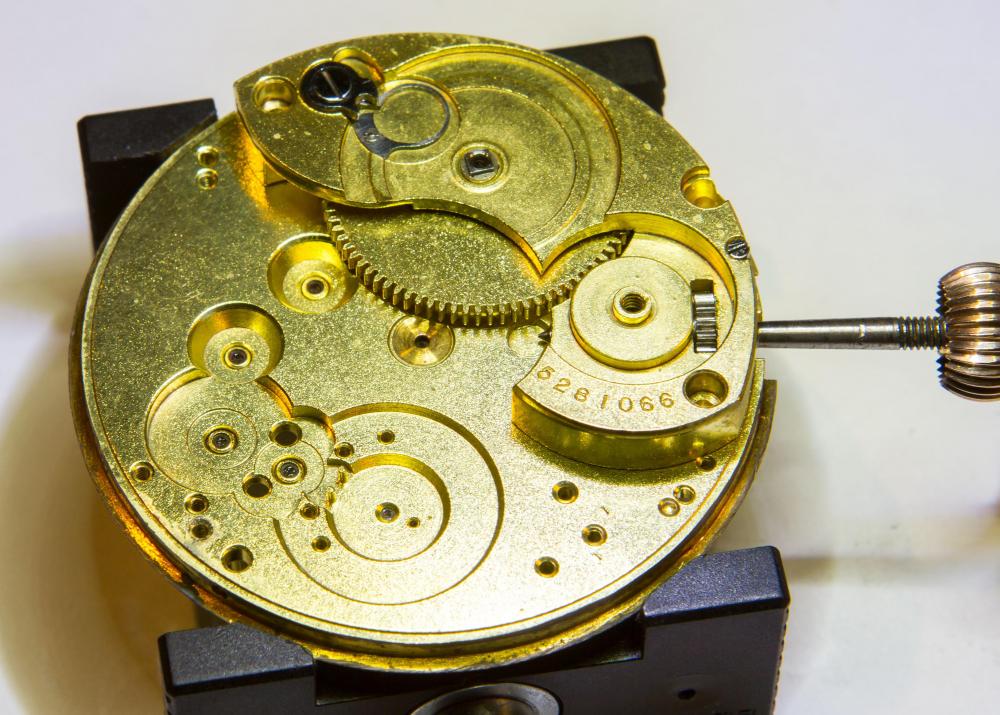

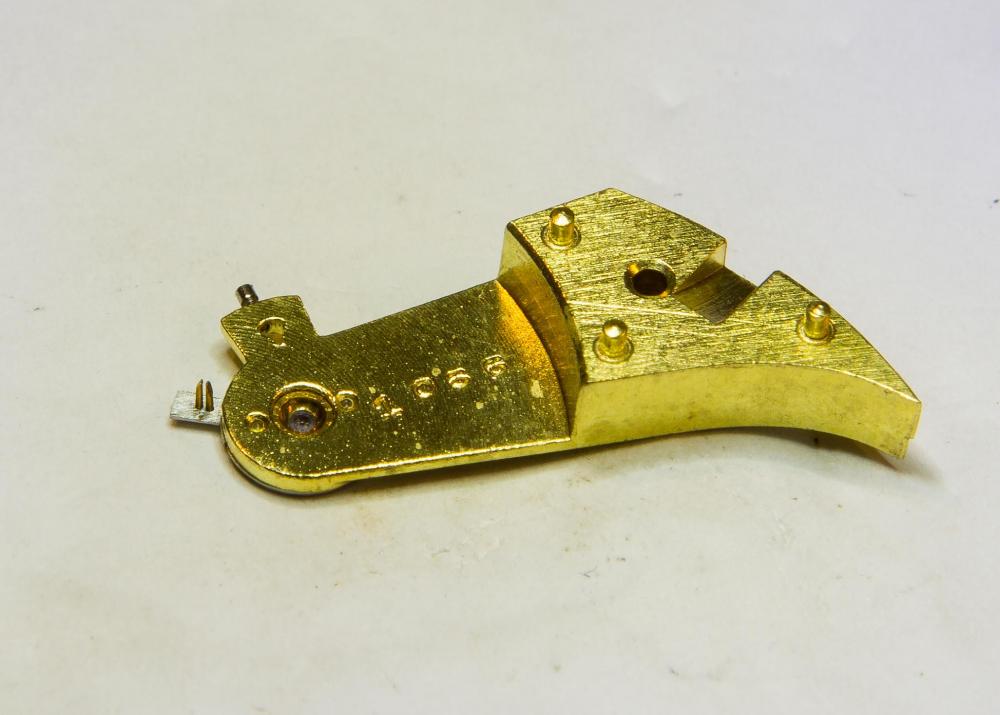

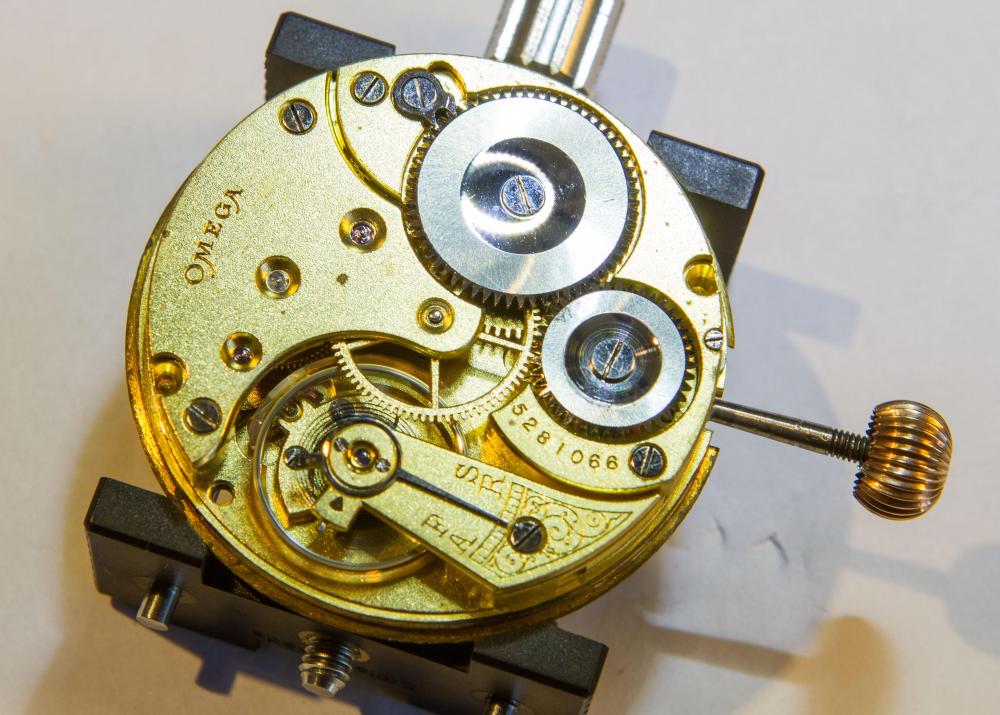

A friend asked me to take a look at a pocket watch recently which stayed in hand setting mode even with the crown pushed in. I assumed a broken yoke spring... but actually no harm done, other than dried up really sticky oil everywhere! Goodness knows when this movement was last serviced, but certainly not in the last 20 years I would guess. I didn't take any photos before disassembly as it wasn't really easy to see what the problem was just by looking. But this picture of the train bridge shows the centre wheel stuck in its bush with crusty oil Unfortunately, there are also a few fingerprints and corrosion spots on the plates, which I couldn't remove during cleaning. I found a couple of other interesting things during the disassembly. The bridle on the mainspring has a little Omega symbol stamped on it. Sadly, I don't think the spring is correct for the watch - it should be a double brace and hole spring, but only has the lugs to fit in the barrel slots, not the hole. It may also be a little short, but on the basis that it must have worked once, I thought I'd clean it up and give it a whirl. More problematic was that the balance staff was missing a little off one of the pivots - enough that the pivot wouldn't reach the end-stone, so I figured that had to go. Of course, not easy to track down a replacement balance staff for a 103 year old watch, but eBay was my friend on this occasion. New staff on the right, and what a beautiful blued Breguet hairspring Set in the lathe ready to turn off the hub Hub removed so I can punch out the staff Old staff out Punches at the ready to rivet the new staff in to place - one domed to spread the rivet and one flat to set it. The staff was a little loose in the balance arm, but it riveted down OK. Finally pushing the roller table back into place And checking the poise. It was a little out, but there was some dirt in a couple of the screw head slots and removing that seemed to do the trick. Hairspring back on and ready to go Keyless works back together and now moving freely Barrel bridge on Train wheels and jewels all cleaned Train in place One of the lovely things about old watches is the serial number popping up everywhere. It had been scratched inside the barrel and I didn't take a photo of that. but here is the marking on the back of the pallet cock. and on the back of the balance cock Quick wind and off she goes The case is stamped EWCCo (English Watch Case Co) and is hallmarked for 1927 so is therefore just over 10 years younger than the movement. It also has some case screw marks inside which don't line up with the Omega movement so obviously a later marriage. And just for kicks, alongside my Omega PW from the same year. I think I know which one John will want me to give back to him and anyway I'm still in love with those Omega hands!1 point

-

Hi johhnie, FHF produced 96 caliber as well, ranfft is always helpful. What I am trying saying is, the sorted out HS never gets to be as good as new. Your Oris for instance looks good enough to get reconditioned and join your collecrion, certainly not with an imperfect HS. It is not a question of your competence rather the fact this HS is not worth all the work involved. Parts for FHF or ST are available. If the prices turned out outrageous, I,ll dive in my bag of tricks. Regards1 point

-

Back in the early 2000's I took a job with the WAGR (Western Australian Government Railways), between my interview and me starting work it had a name change to the Public Transport Authority, which saw it take in public buses and school buses too. I only worked there for 3 years in the telecommunications section, but I still have a soft spot for the railways and over the years have collected a few WAGR artifacts, but a WAGR fusee clock or pocketwatch which is what I really want I don't have yet. I just stumbled across 2 watches said to be WAGR watches from the late 60s and 70s. If these are indeep genuine WAGR watches from the late 60s and 70s its clear they were not worried about railway standard. The second watch can be no earlier than 1976, but if these are genuine the quality of the engraving is just terrible being the railway workshop was still in operation and had atleast 2000 qualified tradesman employed and I'm sure atleast 1 of them could of done a better job than this to engrave the watches. https://www.ebay.com.au/itm/WAGR-RAILWAY-WATCH-c1967/264285680979?hash=item3d88a77553:g:UwgAAOSw5iVctZSw&frcectupt=true https://www.ebay.com.au/itm/WAGR-RAILWAY-WATCH-c1970/264285623691?hash=item3d88a6958b:g:cEgAAOSwG89ctYPz&frcectupt=true If these are indeed genuine 1960s and 1970s WAGR watches I can live without adding them to my collection1 point

-

Hi,That HS is good to practice on. I recommend flying each wheel with new HS. You got to first get them runing before you get a chance to diagnose the fault the led the mangler ruin them in the first place. The Oris movement is a ST caliber. Google ST96 ranfft. Regards1 point

-

The 1236/1238/1239 service manual, if you don't already have it, is here -> https://www.cousinsuk.com/PDF/categories/5544_Ronda 1236.21, 38.21, 39.21.pdf1 point

-

.. or you could try unfankling the current one.. what could possibly go wrong. As to being glued, it is probably shellac and would probaly dissolve in nail polish remover (acetone), or possibly denatured alcohol or perhaps isopropanol. I pretty sure the one I have is held in place with a screw, but it is not to hand, to check.1 point

-

Hi Ted, welcome to the asylum, I think you will fit in well the depth of knowledge here is unfathomable. Everyone here is friendly and helpful. Enjoy the forum.1 point

-

Well.. pretty pricey, but here is one. https://www.ebay.co.uk/itm/RONDA-MATIC-cal-1238-automatic-swiss-Movement-Spares-Parts-Choose-From-List/143133641422?hash=item21536e0ace:m:m_WopSwuG21zF7L8oRXtoMg Seller is in Poland, and the postage is steep, the part is more than you paid for the watch, so you would probably be better keeping an eye out for a better price, or even a whole mechanism with good balance. I suspect you could pick up a beat up, scrap ronda automatic for <£10 if you are prepared to keep checking every few days.1 point

-

I'm sure when I was repairing my old sicura which has an almost identical Rondamatic 1239 movement I came across the balance, mainspring, fork and balance staff as spares on ebay, but as it happened I didn't need any of them. However I've just done a search and can only currently find the staff.1 point

-

Welcome to the group and the wonderful world of fiddling with tiny mechanical marvels. Patience is definitely something you need and developing your dexterity and tweezer skills.1 point

-

Get yourself a Unimat 3. It’s the only one I have and it does everything. Loads of accessories still available. The one I have has the milling attachment. Some good second hand ones on Ebay.1 point

-

First, you're posting the wrong section, if it's about watches there is a section for that. Sorry about you bad experience, but if you read here on in other venues (e.g. Seiko section on WUS) you will find a general appreciation for Seiko mechanical watches, and testimonials numbering in the hundred as opposed to a single piece. Also I'm not aware of a Seiko 809 mov.t, perhaps you're referring to SKX809, an economical watch using the 7S26 mov.t. Could you tell which watch model you've supposedly bought? Because really none of 6R15 look like "light and cheap". Certainly a big difference between dial up and down indicates a problem. BTW, what you call "the error" is actually "beat error", something that doesn't such a big influence on accuracy as you may think. 0.8ms isn't even that much, and is something very easy to regulate. Again, that doesn't describe a Seiko automatic. In fact, thanks to the magic lever mechanism invented more han 50 years, Seiko achieves a very efficient bi-directional winding using a fraction of the parts used by others. Of course the weight spins down effortlessly. Maybe you could post detailed picture of this object to help others recognize what actually is, and avoid falling to fraud. I don't know if you bought it for cash in person but if it was online you should return and if any objection is raised dispute the payment with the card issuer.1 point

-

Hello from Florence & Tourin! I started watchmaking as hobby a few months ago, as I am commuting weekly between Florence and Tourin, I have made this my Tourin hobby and I am filling up my apartment with more and more tools... you know how it goes I spent nights watching videos and I just had to register to the forum! See you around. Cheers.1 point

-

Again I will take your advice, the Rondamatic is twisted badly and as they are available I will go down that route. The Oris, I will try to sort out, have looked at Mark's YouTube video on sorting hair springs so will give it a go, nothing ventured nothing gained. Many thanks.1 point

-

Hi Andy, the previous owner of all the above watches has had a go at them all ! He said, " the Rondamatic was running fast and the Oris was slow, so got his mate to adjust them and they both stopped" ! Can't imagine why lol. I will try your suggestion about the stem removal. They were cheap and ideal for me to practice on, and the bonus is I know out there there is someone worse than me ! Thanks Andy for your time and advice.1 point

-

One I restored for a lume-rot. I will be reluming it at some point to mount in this restored model as my eyes can't easily make out the hands on the gold dial.1 point

-

I've still not finished with the various bits of building maintenance round here, so not much in the way of actual watch repairs going on, but I gave another of the freebie junk lot generic quartzes a quick polish and a new battery. I'm not fan of fabric nato straps, but this was what it came with, so it got a clean too. It has no brand name, but is reasonably well constructed, all be it with a pot metal body. Mineral glass and a two hander Chinese movement, and not much else to report.1 point

-

Oh and you might want to reconsider your title..... we could end up with fetish weirdos finding your post through dodgy search engines1 point

-

Blue steel can't be cut with a jeweler's saw but can be filed. That used to be how they checked the repivoting exam for clocks back in the day- saw bites, fail, file doesn't bite, fail. The commercially available blue steel bars watch and clockmakers typically use is very hit or miss. The nomial size is often way off (not such a big problem), and the heat treatment can vary between too soft, uneven, or sometimes actually ok. I have some and use it for pins and such. For staffs, stems, pinions- anything from steel- I use oil hardening steel in its annealed state. The standard in Switzerland is Sandvik 20AP, probably not so easy to find in small quantities elsewhere. In the U.S. O1 would be the closest thing (and is a fine steel for watch parts). Parts get hardened and tempered after machining, with generally the last 0.01mm or removed in finishing for bearing surfaces. For a staff I cut everything right to size except the pivots which are a good 0.10mm oversized, and I leave the taper for the roller table straight and oversized. After heat treatment, holding on the now straight roller diameter the top pivot is brought to 0.01mm over final size, the surfaces polished, rivet formed. Flip around and do lower pivot, roller taper, polish. Finally finish pivots in jacot. Heat treatment is a little different than most books or schools teach. I use an iron tube welded to a long thin bar. These are actually CO2 or N2O cartridges from selzer or whipped cream bottles with the neck cut off (about the size of the first two digits of an index finger). This gets filled about 1/3 with fine wood charcoal powder, parts go in, filled the rest of the way. The whole thing is torch heated until glowing orange, then the contents dumped in oil. The parts fished out with a magnet, and they are a nice grey color and very clean. After cleaning off the oil they are blued in a pan of fine brass filings over an alcohol lamp. With the above method there is rarely any deformation of even long thin parts, and no pitting.1 point

-

I appreciate very much all the insight. I've done some, and I have a reasonable sense of bearing set ups with AC's - a spindle I designed is below. I did not realize though that the AC for this were the same size - that's an uncommon treat as they usually are not. Provided I can figure out how to accurately measure the outer spacer, I have a surface grinder so can make the inner race spacer to suit the needed preload (or just make it the same). I have not tried to take the outer race spacer out of the headstock - is it removable or is a machined feature of the casting? AC P4's are available everywhere, but deep groove P4's are tougher to find, i.e. SKF or NSK have the former but not the later....so this makes sourcing easier. Now I need you to coach me through bearings for the F1 lol (what a nightmare). Since the theme is home made tools, and we're talking spindles.... here's some photos of a spindle I'm currently working on. Its a new Z carriage and ER spindle for a BCA jib/borer mill. The BCA is a British version of the Boley jig borer/mill. The idea with the T slots is to make it a bit of universal platform for different things, EDM sinker will be the next addition, maybe a slotting head, etc. As the spindle base can tilt, I plan on putting an encoder on the head for an electronic gear hobber as well....so many plans, so little time. I haven't put it together yet, still trying to finish balancing the shaft assembly, which means finishing the homemade dynamic soft bearing balancer1 point

-

That ought to be great! I don't have a reversing switch on my motor so I just flip the belt. For the odd times I need reverse it's fine. Meant to post of photo of the cute thing before- here it is. Have you done bearings like this before? The original setup Leinen used was with normal deep groove (but P4 class). When I did mine I talked to an engineer at Barden and he said that's A-OK for this size and speed, but that angular contacts would be best. Luckily they are the same size. One thing- I asked him about preloading, and he very strongly advised against doing it without a spacer. The Leinen design is similar to the modern Schaublin, no spacer. But the Schaublin, even the 70, is large enough that you can reliably snug up the spindle nut just to zero clearance, then advance according to the manual precisely to obtain correct preload. It's very difficult on the little Leinen, or I should say very easy to overdo it. After an expensive learning set of bearings (they made it about 3 weeks) I made an inner spacer tube the same length as the outer and go with the built in preload of the universal grind bearings. The model I used is FAG B7002.T.P4S.UL. Those have at least 10 years on them now.1 point

-

I see a Levin slide rest on a Boley Leinen WW82 or 83? I just got a WW83 that I'm redoing - the switch plate is a give away What motor arrangement do you have? Is it one of them with the repulsion motor? Mine appears factory but has a large rheostat before a universal motor and a second large wire wound resistor for high/low. Nicely balanced and all, but lousy speed control. I painted it today, been having a hard time getting the right colour (mixing the paint myself) but its getting close. I may play with more green less yellow tomorrow1 point

-

We made quite a few tools in school but here's some more recent and useful ones I've made. A puller for strike cams on typical german clocks, a simple turret for 3 tools on the lathe (I often have small series of parts that need drilling and tapping: center drill, drill, tap), a collet holder for the polishing tripod as I have a good assortment of these little collets and they make polishing screws a breeze, and a dividing head for my mill. The latter is mostly modification; the mill is a Sixis 101, the spindle is a w20 model from a hydraulic automatic machine, the dividing head from a Schaublin 13 mill. Managed to strip the hydraulic spindle down and find a conventional drawbar, a bit of fanagling to get the head fitted, and now it's used mostly to make direct dividing plates for another gear cutting machine.1 point

-

SOME GOOD NEWS !!! today I will receive the Seiko diver case First thing I'll do is to check if : - the date window doesn't comme across the rehaut and is not too much right positionned - the movement inner ring can be shaved enough to fit the quartz movement that came with the dial If everything is OK I'll make the dial plate blank again, shave it to the right diameter (should be about 26mm) and build my new pistacchio green dial. I'll open a new thread for that build but I'll put a link here.1 point

-

Nice work CDJ. There's nothing like customizing your tweezers so they are just the way you like them. Yes, it takes a little time to develop the skills to dress your tweezers; but the rewards for you effort are well worth it IMHO. This is the video I used to begin to learn how to dress my tweezers ... his instructions and tips for dress are most excellent. https://www.youtube.com/watch?v=injDQHraiLI1 point

.thumb.jpg.b2d9433f9d45d2e4414929af0fb4f950.jpg)