Leaderboard

Popular Content

Showing content with the highest reputation on 04/27/22 in all areas

-

Forum policy will not be discussed publicly on the board. If you have suggestions or concerns then kindly contact a member of the volunteer Moderators or Myself via PM. To those who have strong opinions on how Moderators (all of whom volunteer their free time to help support this project), then I would say - you are welcome to put your hat in the ring and volunteer yourself, I have on several occasions in the past invited people to apply and rarely does anybody step up. None of us are getting paid to do this, the website barely breaks even financially (despite people complaining to me about ads) and so its disheartening when people complain. So back to the subject of this post - Suggestions on policy are very welcome, but not publicly as I don't want arguments or divisiveness. Policy suggestions from members will be discussed by the team and decided upon. Thank you.5 points

-

I have been informed by the makers of the software of this board that sign-in with Display Name is very bad from a security perspective and this does seem logical so I have disabled it. Before you could choose to use either your Display Name or your Email Address. From now on, sign-in is only available using your Email Address which you signed up with. Your password is not affected. If you have forgotten your password then you can, of course, use the "Forgot Password" feature to reset it. Further to this, I have disabled the ability to sign in with Social Media apps such as Twitter and Facebook due to the constant battle with their respective changes in policy and requirements, I just don't have time to keep up with them which leads to website errors and a poor experience overall.5 points

-

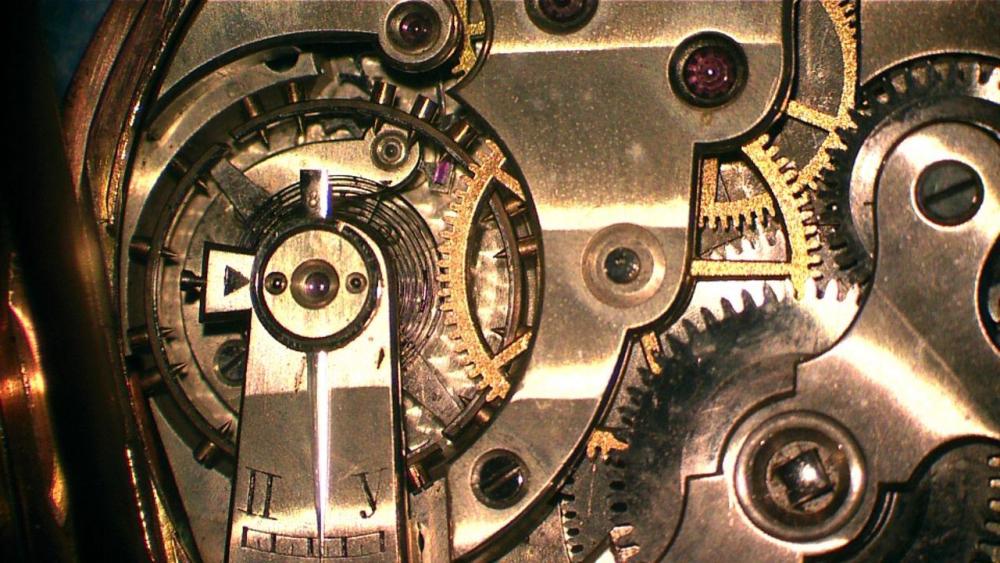

Shim if placed on the outer bound of where the cock mounts will lower the setting and vice versa raises if placed on the inner bound ( raises the setting) . some argue that it will tilt the cock therefore tilits the setting , jewels and the cap jewel. while true you might lose only a few degrees of amplitude or grind a bevel wear on the pivot end. Needless to say shimming both the inner and outer bounds will raise the entire cock. End shake is the axial free play of balance staff when balance is installed and cock screws tightened. Regds Can we see a picture of the setting on balance cock and mainplate? as it might let you adjust for end shake by moving the setting.2 points

-

@LittleWatchShop well it's better than the one I have lol I don't have a stereo scope I do have a usb that I've got a stand coming for by the way that was £20.00 so really I'm made up2 points

-

Open the mainspring end with a pair of round nosed pliers just a little at a time. You can press in the arbor at an angle which will force the end of the mainspring to open even more and it should hook on. That is what I used to do. Others might have different ways.2 points

-

Thanks Mark for the info. I stay signed in all the time. I have never used Twitter or Facebook I wouldn't know what to do. I don't even have a mobile phone or a T V.2 points

-

It's not going to change a lot on the timing machine but your lift angle is wrong. Instead of 52° it's supposed to be 49°. Then 214° amplitude for a freshly serviced watch wound up seems a little on the low side? Then that's an interesting way to hold the watch? Doesn't seem to be hurting anything but you want to be careful of insulating the watch from the microphone sometimes you might get bad readings. Then ideally the crown should be facing out word it will pick up a better signal that way when the Watch is cased up. Then usually when you're assembling the watch And you put the Canon pinion on it's always good to check the setting see how it feels. Not always but a lot of times you can tell if it feels really well you just don't feel any friction you know you're going to have an issue and it's a good time to deal with it when you're assembling it. You can't always tell 100% sometimes they'll feel not the tightest of the world with no work fine but it's a good time to check when you're assembling. Then because this is an Omega watch you should bill regulated a little bit better than it is now. Also nice if you give us another position than dial up usually crown down is another good position. This is because when you're resting on the pivot your at the least friction and you usually get the best reading when you go to one of the crown positions friction increases and were more likely to see if there's issues. Like the 214° you'll probably drop below 200 and for freshly serviced watch that's definitely going to be undesirable.2 points

-

As mentioned above - theme chooser at bottom of website - Dark Mode and High Contrast (Light Mode) both still available.2 points

-

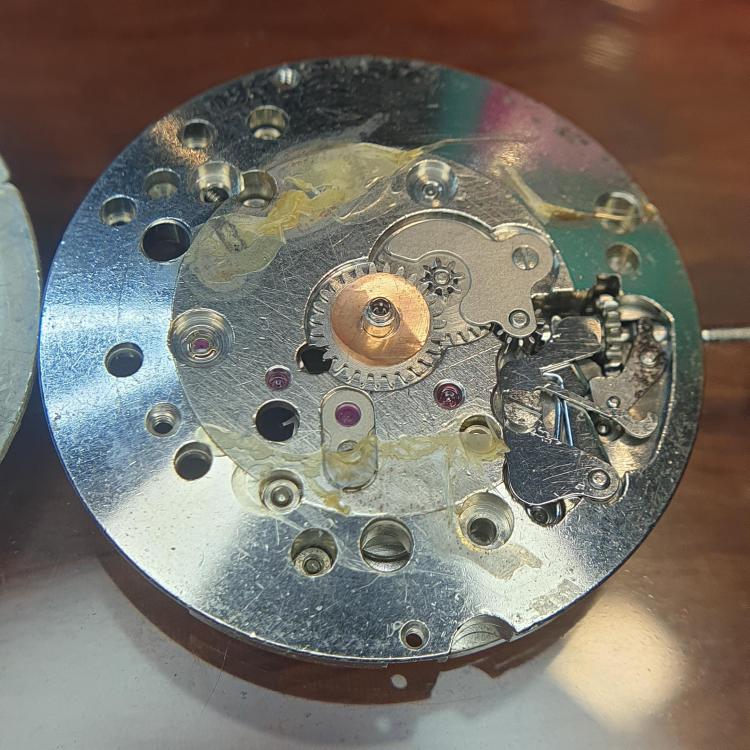

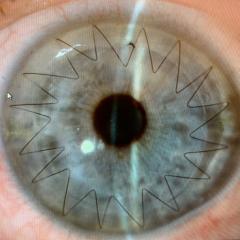

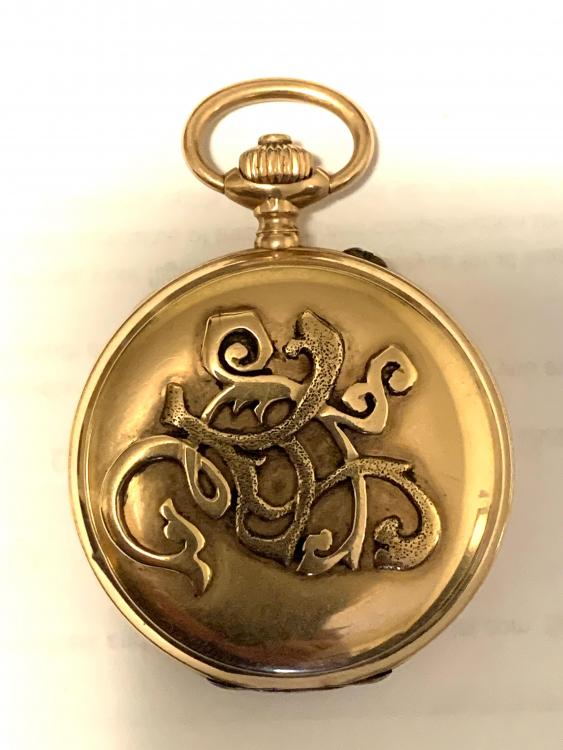

Hello Hector. Thanks for the question and I am certainly happy to try give advice or an opinion. For close to 37 years I have performed eye surgery with operating microscopes - this provides both good and variable magnification and using both eyes allows for good stereoscopic vision (depth perception). Using a loupe with one eye (monocular vision) there is loss of depth perception. Both eyes are required to achieve excellent (or even very basic) depth perception. I would be impossible to perform eye or any delicate surgery without this fine depth perception. Also with a microscope and a work surface that is well positioned one can work in a more natural and upright position as apposed to using a loupe. Personally with my background I would never be able to manage with a loupe and in fact would not pursue the hobby if this was my only option. If you follow the excellent Chronoglide YouTube channel you will notice that they have switched over to stereo microscopes. We used to operate with $200 000 Zeiss microscopes but obviously this is not an option. Unfortunately I sold my very nice Zeiss scope but it was heavy to transport and I also wanted a system with good video/camera so I will be purchasing an Amscope with a 20 megapixel camera. The model I am looking at has a good working distance (200mm/8 inches which is similar to our operating microscopes). Probably the most useful magnification will be in the 2.5 - 10x range. These consumer microscopes are very reasonable cost wise and although there will be a bit of a learning curve your work will be far more comfortable and enjoyable. Finally using the microscope in the attached photo I opened up my grandfathers pocket watch which I inherited - see photos. Anyway looking at it through the microscope I was sold and made the decision to pursue this as a hobby. My grandfather would have likely purchased this watch in Lithuania or Latvia but unfortunately I have not been able to identify it. Regards, Jeffrey2 points

-

Next time a 400 day shows up, I will buy it. AND, I will charge my friend to cover the cost. Right now I am fixing clocks and watches for friends for free. Man, on man, I have so many new friends now!2 points

-

Although I signed up for this forum some time ago, I'm only now returning to watch repair after the lockdowns. Looking forward to getting back into it. Jake O1 point

-

Hello and good morning, Just to say I find the new background a lot easier and not so hard on the eyes. brilliant. And as regards the moving question which Mark quite rightly nipped in the bud, I think Old Hippys suggestion is probaby the right one. One cannot please every one but as said a compromise has to be found and informing the member his post was moved and why is a good compromise. I am sure that we all have faith in our Administrator and moderaters to find the solution and continue to provide a brilliant forum which is open minded and informative. Thank you Gentlemen your work is appreciated.1 point

-

Many frown upon gouging as it destroys the mainplate or cock. Moving the setting is prefered and if thats not possible then shimming. Both ofcourse are only worth considering when you are sure lack of end shake is not due to short pivot. Ain't that right Weasol.1 point

-

1 point

-

Interesting topic...glad you got it to at least start up ! My "favorites" are the sellers that post " recently serviced",..or "Complete COA",..and the photos show a watch that has fingerprints and debris everywhere..even the cases are full of gunk.1 point

-

I'm with Nickelsilver on this one. It bears a lot of the design elements of La Phare. I found this (listed below) on Chrono24. Check the movement photographs. https://www.chrono24.com/all/pocket-watch-le-phare-le-phare--id3446959.htm#gref1 point

-

1 point

-

1 point

-

That's a Lephare, full calendar chonograph repeater; could be quarter repeater or minute.1 point

-

1 point

-

I'd avoid others in the Seiko 70** series and hold out for a 7019, to avoid compatibility issues on the few parts that aren't interchangable. You should do well with a movement from speedtimerkollektion. Unfortunatly, their photos all show the motion side, and it seems like your issues are on the calendar side. The problem is that there are different day stars/discs for different watch models. Crown position in watch case: as you can see in the watch examples on the speedtimerKollektion page, some watches have the crown at 3pm, and some at 4pm. The day/date window is always at 3pm, and the movements are identical apart from the daydisk - the wrong model will result in a totally misaligned day. (Sometimes this happens even with the correct daywheel as it starts slipping on it's star - that can be rectified by re-tightening it, ideally with a staking set, but you can improvise) Colour: most are white, but some are black. Language: All are dual language - English and a choice of Spanish, French, Kanji (japanese), Arabic, and possibly others that I haven't come across. Your issue may be with the day finger, but if I recall those are metal on the 7019, and are protected from users quicksetting close to midnight, so should be ok -- see attached photo. So you may be better of on ebay where you can see the dial. You don't have to wait for a movement - you'll likely come across a tired old (usually gold plated) watch that is ready for scrapping. If the second hand has moved between photos that suggests it's at least ticking. Best, Jake O1 point

-

it would help to have dimensions of the old spring? I snipped out some images one out of the 1923 Illinois parts catalog. Then off a mainspring list I had the other mainspring list I had was confusing because it insists the same part numbers are T brace. But the pictures maybe that would be okay as it's not a T brace with whole I think it's just a T brace and as long as the TV fits into the slot that's okay. Then once I confirm your dimensions are on the right track to look like on one of my list is another company that has a TN spring of the right dimensions but I want to make sure the dimensions are right before I give it to you. Then the problem with the pocketwatch database is it actually less three different springs because of course there's variations. Then of course there's the minor problem of the pocketwatch database isn't always correct.1 point

-

That information just made those bolts look amazing! As I previously mentioned, I just don't care much for aesthetics w/o function. When I become rich I'll get myself a nice Royal Oak or two.1 point

-

1 point

-

Hi You might try "The Watch Site" they are a dedicated japanese forum with a markrt place where spares are swapped and sold.1 point

-

If the hands move easily when setting the time then the canon pinion needs to be tightened or replaced. Anilv1 point

-

It's indeed a Swiss movement, an FHF ST96. At least that was true. The strange thing is after I took the photo of the pallet, I put everything back together for safekeeping and the balance came back to life, in spite of the deep locks on both entry and exit pallets. The TG traces are terrible but that's to be expected.1 point

-

Maybe post a photo of the front and back of the watch? How is it that you know the p/n for the stem and not the p/n for the crown? You ought to be able to measure the OD of the threads and count the number of threads and come up with a reasonable guess on the required threads and then see if you can't find a donor watch.1 point

-

I'm completely new to this but I would: See if running the watch past the point where the date changes WITHOUT the date mechanism engaged also lost time. Inspect the cannon pinion. When you say the watch keeps ticking, I assume you mean that the escapement is behaving as it should? During the period when the date is changing what does the Timegrapher say? I would take a hard look at the date mechanism.1 point

-

1 point

-

It's not just Seiko or the Japanese that sneek plastic parts in, just watched a strip down video of an Omega Seamaster and that also had a couple of plastic parts, if it's good enough for the Japanese it's good enough for the Swiss. Any other Swiss maker using plastic ?1 point

-

Er hello mm . I see you are a man of many words ( not like me then) a bit more information about you perhaps ?1 point

-

1 point

-

1 point

-

Haha yes it's extremely accurate but only twice a day. My guess is the seller was just a little bit shy on the truth. Its kind of nice looking though in a dodgy non genuine wasted some money kind of way. Nice bit of shellac as well, I could french polish two mousemen sideboards with that.1 point

-

They're bolts, the slot is aesthetic, but they do go through the case and are fastened with nuts through the back.1 point

-

1 point

-

1 point

-

Eyup specky.( don't take offence lol. I get called alsort by my missus, water off a ducks back). Is this a fixed jewel in the main plate ? Put a picture up mate so everyone knows what you are dealing with .1 point

-

It‘s a Miyota FS21 quartz movement. Instructions: https://gleave.london/content/TECH/Miyota FS21 - Operating Instructions.pdf The strap of this watch can be purchased separately and be replaced.1 point

-

What I've done in similar applications is get the broach that's the correct range, then find the spot that it's the right diameter with a micrometer. Mark it somehow; a tiny piece of masking tape for instance, or some graphite pencil lead. For larger format analogs (thinking a set of carburetor jet reams), I use paint pen marks that are semi-permanent, and do the full set in appropriate increments with alternating colors on whole numbers or fives/quarters. Then broach up to, or right before the mark, test fit, and go a up to/past the mark as needed.1 point

-

Too aggressive... I know there are dedicated tools for this but are you guys talking about using tapered broaches by hand? The difference is .01 mm, .0004 in, 10 microns. Potable water filters and automotive oil filters filter out 10 micron particles. Gust thinking about a cutting tool should remove more than that in a softer material. I have had some luck just burnishing small amounts from the back side with a tapered steel pin that I have. I can't say what it was supposed to be or for what purpose it was made but I modified it to fit in my jeweling tool. It has a fine semi satin finish and is held perpendicular to the table. It is a bit slower than cutting but that gives back some extra control over turning a tapered broach by hand to an uncontrolled depth. The jeweling tool gives fine adjustment of the finished depth and diameter achieved. It should also produce a rounder hole than a tapered cutting broach. Just protect the front surface from any damage, put some pressure against it and gently swivel the hand about the pin (if you can't swivel the hand you're pushing to hard). I wouldn't try changing sizes by drastic amounts this way but for small discrepancies or the last little bit after cutting it's fine. Just keep going until it fits. Shane1 point

-

Did you manage to get the mainspring into the arbor in the end? Maybe you should start a new thread to get a specific answer.1 point

-

The piece above the ratchet wheel is a nut. You need a tool to fit the two radial holes to unscrew it while holding the ratchet wheel, usually a stubby pair of tweezers will work but you may need fine round nose pliers. The ratchet then comes off and the rest is as usual.1 point

-

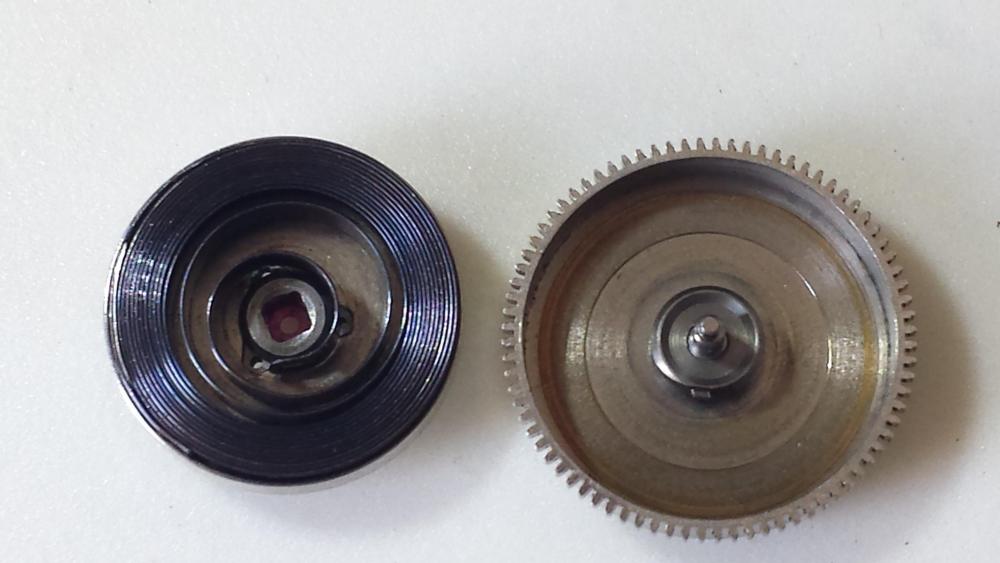

They are 2 separate pieces. It has no screws, the upper wheel is pressed with the arbor of mainspring barrel. I recently found myself in the same situation. Somehow you have to try to separate both wheels. I don't know if there is any specific tool for this task. I'm sure someone with more experience will explain it better. Greetings.1 point

-

1 point

-

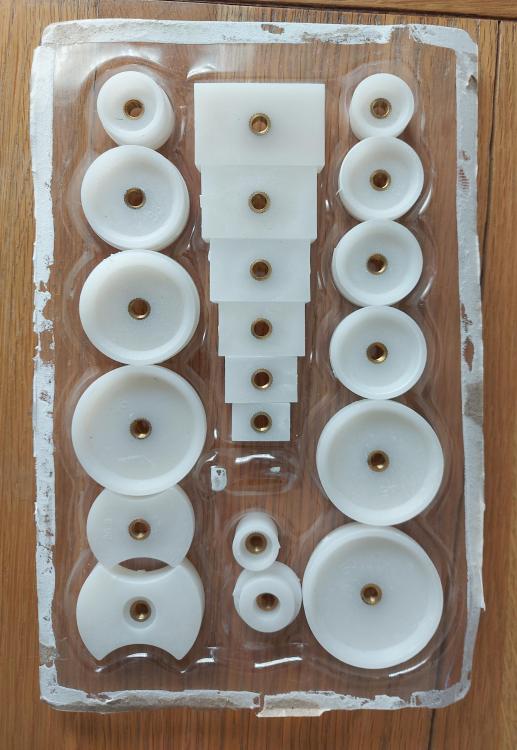

Next up is a cheap but still quality tool A Crystal Press found at the link below for only £38 https://www.aliexpress.com/item/32974408612.html?spm=a2g0o.productlist.0.0.666c5b22pOlc91&algo_pvid=89ce2c17-ff1a-437d-9412-8c071e9cdb4d&algo_exp_id=89ce2c17-ff1a-437d-9412-8c071e9cdb4d-1&pdp_ext_f={"sku_id"%3A"66707322604"}&pdp_pi=-1%3B38.01%3B-1%3B-1%40salePrice%3BGBP%3Bsearch-mainSearch A very well made tool especially given the price, comes with a good selection of plastic (Dies/Dyes) and is of a very solid construction, offering a two speed screw system which quickly opens or closes the press until pressue is applied it then switches to the finer tread to applie the required pressure. My copy is in full allignment and because the vertical polls are so thick at approx 20mm there is zero flex when pressure is applied. All Chromes Steel or Red Anodised Alluminium. A quality product that is well worth the asking price and actually worth a lot more.1 point

-

After seeing this I was inspired to make myself a 5606 star wheel. Made from 0.7mm brass plate, sanded down to 0.5mm with 600 grit paper as last step. Marked out with a sharp sewing needle in a pin vice. Shaped with a Dremel cut off type abrasive disc (was approx 0.8mm thick). Hole was 1mm and then carefully broached to be a friction fit on the gear wheel. After getting the flat shape correct I transferred the star to a cocktail stick and then brought the abrasive disc down vertically inside of the 4 corners (to make the raised teeth and lower central part). Finished the central lower part using a sharpened screwdriver as a chisel. Finished with fine abrasive paper 2000 grit. Took me three attempts to get something I was happy with (lost one when the Dremel spun it off the cocktail stick never to be seen again). Star wheel works really well.1 point

-

I would imaging the sudden release of power is what has destroyed the wheel, unfortunatly from my research information and parts are hard to come by for the ricoh watches. Probably best to trawl ebay or others, speedetimekollection, in europe, welwynwatchparts.co.uk, obsoletewatchandclockparts.com (UK) then there are Jules Borel, esslingers, Timesavers in the USA are probably worth a look , I wish you well, good luck.1 point

-

When removing springs and parts with the likely hood of them disappearing into the ether work inside a large clear plastic bag, one big enough to cut the end off and work from both ends, That way should parts take off they are encapsulated in the bag for retrieval. Or alternativly use a piece of rodico to hold the part while removing or fitting, being tacky it will assist in holding the part. As to finding a new part try Cousins uk watch parts, wether you will be able to get one specific to the ricoh i think that will be difficult buy you may be able to purchase an assortment and get lucky. Cheers1 point

.jpg.ccdd11844bd19872dd170c7da7406e18.jpg)