Leaderboard

Popular Content

Showing content with the highest reputation on 02/03/22 in all areas

-

4 points

-

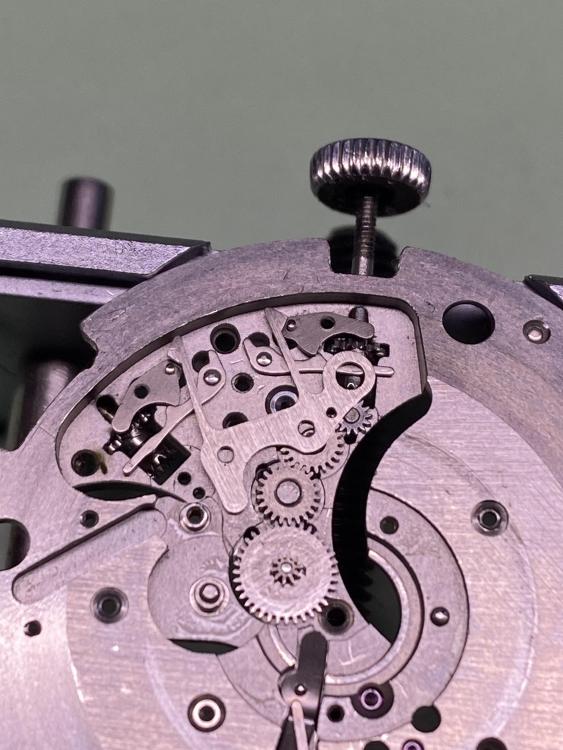

Hello fellow watch repairers, a few days before christmas I scrolled through a website for used stuff and came across an unbelievable offer for a vintage JLC Memovox for just under 1000€. It said that the dial was restored but for this price I just couldn’t say no to it, although I feared that it might be a scam. So on the twenty-third of December I drove four hours to pick it up, still with the feeling that it is to good to be true. But everything worked out well and I bought the watch what makes me the proud owner of my first JLC: And with a new strap it was a really lovely piece: At first everything worked well but after a few days the alarm wasn’t functioning anymore. Diagnosis: broken alarm mainspring. So I had to replace it and give the whole movement a service. The movement itself seemed to be in good condition and marks in the caseback showed that it was at least serviced a couple of times during its lifetime: Here a some impressions from the stripdown: And indeed the alarm mainspring was broken: I cleaned all the parts, replaced the spring and reassembled it. Now the alarm works flawlessly again, it is running nicely and is ready for its next life chapter. I never worked on such a valuable and complicated watch, so I‘m really happy that everything went well and that the watch is working again. I hope you enjoyed this short report!2 points

-

Due to my interest and ownership of four Vulcains, I was poking around on the web to see what Vulcain is selling these days. They still sell the Cricket with various complications. What is inside? Well, here is a youtube video of a partial assembly. It looks virtually identical to the original Cricket. I cannot tell the difference other than shockproofing the balance wheel. I wonder if the parts are back compatible. Might be a moot point due to the Swiss cartel.2 points

-

If it was so simple. There is no way to tell beforehand with Chinese mov.ts, first of all they are graded and sold accordingly without disclosure, they can differ from a batch to another depending on the rush and other elements as in how dirty the air at the assembly place, which oils if any they used, etc. Anyway a couple of things are sure, a totally dry mov.t that is otherwise fine can run very well both on the timegrapher and the wrist. And the single lubrication element that can give a measurable boost to amplitude is using 9415 on the pallets, something best observed after 48h.2 points

-

Here you go. But it's quite involved and needs a lathe and staking set.2 points

-

Maybe some of the longer standing members are transitioning from amateurs into unpaid experts? What doesn't interest them any more might be of vital importance to those just starting out. The walk-through is excellent it will be of great use to many budding watchmakers, maybe some professionals too?! If there are posts that don't interest you, don't read them. No need to diminish others who aren't up to your level.2 points

-

2 points

-

The key is usually soft (soft compared to the spindle itself), and can be drilled. The spot you see on the tapered bearing surface is it, you can drill out the old one. Some folks stop there, as the key isn't strictly necessary and if you have a mix of collet brands might hang up on some and be loose on others. I like having a key. To make a new key you will need to turn a plug the correct diameter to fit the hole, with a (tapered) shoulder. It should be a tight fit. Get it in, file flush- a file shouldn't even mark the spindle if the spindle is properly hardened. Then give it a few punches with an automatic center punch. It's very fiddly work. Finally, you can go up inside the spindle with a fine file and fine tune the size. Collets that bind on the key will not turn true, and collets that have burrs raised by the key must have those burrs removed with a stone or perhaps a file and then a stone. Be as careful as you can to not remove more material than the burr itself. On a proper* 8mm lathe, the bore in the headstock is exactly 8mm, -0 +0.005mm; the collets are specced at 7.99 +0 -0.005. With a total window of 0.02mm but most often 0.01mm of freedom in the spindle it doesn't take much of a burr to bind up. *Some cheaper makes of lathe will have the bore loose on size to the large size, and collets loose on the small size, for one because it's easier to manufacture to loose tolerances, and also to make it easier to ensure different makes fit. There is a loss in precision though.2 points

-

Been restoring another cricket and discovered that the pusher stem seems to be damaged, so I decided to turn a new one. Notice that I made the each end a little longer than the reference piece. I can shave it down if necessary. I made the narrow end on the right a little bit larger in diameter than the sample because I noticed that the pusher button was not seating well (still loose).1 point

-

Small success story... not long after my wife and I were married (25 years ago) we were walking through Fordingbridge UK and the small jeweller's shop was closing down. In the window they had a display of new old stock Oris watches including an SA7445 with an exhibition back... later on that year, my wife presented me with the 7445 for my birthday. I wore the watch every day for 10 years, had it regularly serviced. However, about 15 years ago I was giving a lecture (cell biology (yawn)) in Belgium and whilst waving my hands around enthusiastically I felt something go cataclismically "sproing" inside it. The auto-winder span round and it died. The watch has sat in a draw neglected since. I've made half hearted attempts to get it fixed but no watchmender has been interested. Recently have been reading around, watching various videos, acquiring tools and started renovating quartz watches. Last weekend I plucked up the courage, sharpened my screwdrivers, got out rhe tweezers, loupe and rodico and investigated the Oris... I found that the all the screws in the rotor and the automatic mechanism were loose and the click had become disengaged. After a couple of hours I reassembled the auto wind, re engaged the click ratchet but the watch still didn't work. Then I noticed that one of the screws that holds the auto wind mechanism in place was missing. As I'd never had the watch apart before the logical conclusion was that the screw was somewhere inside. So... I carefully disassembled everything again and started to delve deeper into the movement... sure enough... there was the screw, jammed in the gear train. Gentle prodding and coaxing loosened it and I was able to shake it loose. Hey-Presto... the watch immediately started ticking and woke up after 15 years of suspended animation. After reassembly and ensuring everything was screwed tight... I proudly showed my wife the fruits of my labours. Sadly... she can't remember giving me the watch in the first place... oh well....1 point

-

1 point

-

1 point

-

Hey folks, I'd like to share a watch I put together for my Brother's birthday. The movement is a pretty old Unitas 6497 which I picked up from the widow of a watchmaker a year or so back, the plates have been skeletonised and I'm pretty sure this was a once off job by the watchmaker. The mainplate is brass, and the decorated bridge plates appear to have been plated (quite crudely, when inspected under a loupe). The movement is keeping great time now that it is serviced. I made an attempt at a logo using the film-free transfer technique Mark has used in a couple of recent Youtube videos. The logo didn't adhere very well to the dial, not particularly happy with it. In person and to the naked eye it looks pretty good I think. The case is a 41mm case I picked up from Ofrei, who I sourced the dial and hands from also. Hope ye like it!1 point

-

1 point

-

Is it just me or do you guys get weird cases too? This is an ETA 2658 ladies movement. Everything in this watch is tiny. The biggest screw heads, the ratchet wheel and crown wheel screws are only 1.2mm in diameter. Everything else is 0.8mm. The movement had a multitude of problems that I replaced the movement with a NOS movement from cousins. One of the problems is the auto mechanism could only turn in one direction. I dismantled the wheels and found that one of the reverser wheels was stuck. Under the microscope, I found a white hair coiled around the shaft. I tried my best to coax it out but small bits kept breaking off. In the end, I had to use my staking set to loosen the wheels and uncoil the culprit. The auto mechanism is working fine now. Now I have to straighten the hairspring and check the pallet stones.1 point

-

Yes, three of them. The fourth I bought on Ebay in running condition. I am quite comfortable with the Cricket now! One of them had a pretty much destroyed dial, so I had it refinished--it is the watch I wear most often. Oh, and one of them which I am finishing now came to me in pieces and some of those pieces were rusted, so it was an ordeal finding parts (and making parts). I will be happy when it is on my arm...just waiting for a crystal to arrive--maybe today!!!1 point

-

You could always improvise by inserting a fine tapered pin into the jewel until it starts to bind and then measure the taper at that point using calipers or a micrometer. I have seen someone on Youtube using a gauge that worked on this principal, only the tapered pin was mounted in a sliding sleeve. You put the pin into the jewel as far as it would go, then as you continued to push the pin was pushed back into the sleeve until the jewel came up against the front of the sleeve. A pionter on the back end of the pin could then be read against a scale on the sleeve. Probably a terrible description so if I can find the video again I'll post a link. Here it is, about 25 seconds in.1 point

-

JohnR, your speech to text software did not pan out very well in that post in the first paragraph. Can not follow. You should probably also check the escape wheel teeth. If those two components have been working together for a while, the escape wheel will have suffered worse than the pallet jewels. Meanwhile, it's not just the steel on sapphire, it's the steel on sapphire plus whatever contaminants get in there. Silica being the most likely suspect to my mind, which is much harder than steel as well. I'm reminded of automotive engines. Specifically performance oriented engines. The bearings in your passenger car will last hundreds of thousands of miles, but a performance engine will rarely last 50k. The way most people build them, that comes down to air filtration. To get more air, they remove the restrictive filters (or use "gravel catchers" that just keep out the big stuff). The byproduct of this is that silica dust suspended in the air by the tires of other cars gets in, eats up the rings/cylinder walls, gets in the oil and subsequently chews up bearings. Rebuild time. Same deal. The different hardnesses and lubrications SHOULD keep everything copacetic, but external contaminants find a way.1 point

-

Great work, very inspiring… please keep posting your achievements.1 point

-

I chose not to relume. After a bit of bright sun at my window, they still glowed a bit, and I don't have any lume at present anyway. They aren't as bright as they were, but they still glow. Aside from the strap, this watch is entirely original. And it only needed the briefest adjustment to get it keeping really good time. So I am leaving much of the "patina" on it, as a testament to its rugged nature. And I, also, often find it hard to bear, selling any of them off. That's why I have a number of pocket watches and several wrist watches already. But I remind myself that I am also taking some of them in for the purpose of making money, so I try very hard not to get too attached to them. Although sometimes it happens anyway. I found something endearing about this big, noisy Timex. I think I may hang on to this one.1 point

-

Requests are allowed. Advertising items for sales is not. I don't know if you can find a suitable replacement but the parts shows being available at: https://www.spareparts-watches.com/product/1889324/seiko-4006a-27-and-17-jewels1 point

-

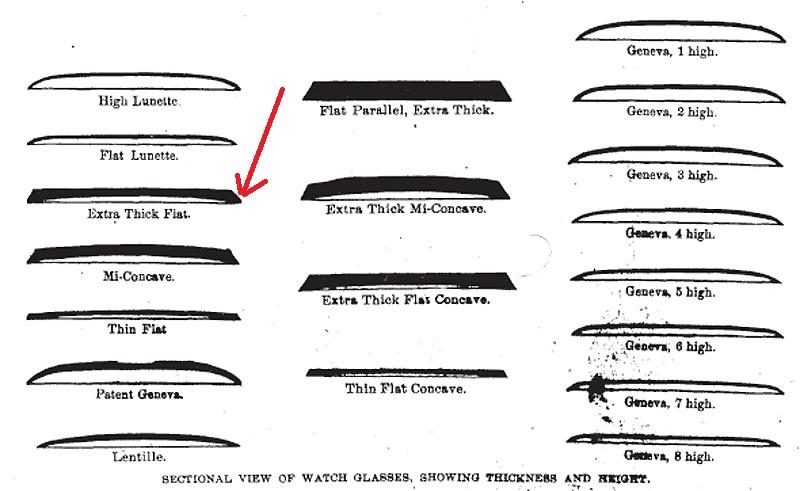

That is a five bar movement with a cylinder escapement, also it is open face so the glass would be quite thick. This is the type you need and it should be glass not plastic that is if you want it to be like its original. Here is what you need. Make sure all dirt is cleaned from the bezel where the glass fits. Measure from 12 to 6 or 9 to 3 for the diameter, if you can't get the exact size you go for the size down you will need to get the proper cement to hold it in. The red arrow one is the type to get.1 point

-

You're confusing petroleoum-based solutions (as in benzine, engine fuel, lighter fuel , naphta, etc) with alcohol, the first does not dissolve shellac at all, while the second may soften it however it takes a relatively long time.1 point

-

Have a look to the thread below, it shows good case holders and the Japanese type caseback knives. Not expensive and a must have to do this work in total safety.1 point

-

1 point

-

Thanks for the video, very interesting. I only used a hand drill and a set of needle files for the hour and minute hands, so this would be quite a big step forward. I think I’ll try to make another set from stainless steel and see what happens. I’ll keep you posted.1 point

-

1 point

-

Fluttering might happen due to bent fork, excessinve side shake on fork arbour, banking pin issues, can't it. @JohnR Is proper escapement possible here? what do you expect to see with balance installed. I worked on a case like this, oscialtion seemed normal, but would flutter once I removed the balance. TIA for your advice1 point

-

This should help you. https://www.quicktest.co.uk/blogs/jewellery-and-horology/conversions-clock-and-watch-key-winders#section_11 point

-

Just for the fun of it what happens if you put the balance wheel in Will the watch run?1 point

-

Quote: "I really enjoyed working on this watch and even though I sometimes feel that contributing to this current WRT-forum has sadly become a bit of wasted time, I do hope that my write-up, perhaps found via Google or some other search machine, will be of some use to somebody, at some point in time" I have been following WRT since its inception, but only recently contributing. Unfortunatly you have seen, as I have noticed, the lowering standard of many posts. But I have thoroughly enjoyed and profited from your excellent walkthrough - as good as it was in the old days. Incidentally another loss is the full set of Mark's early Youtube smoothly spoken and presented watch walkthroughs such as the Breitling Bentley. This may be the fault of Youtube ... or my finger truble?1 point

-

This is normally a sign that the stones or at least one stone is seated too far into the fork. Rather than an escape tooth falling on the locking face of the fork it falls on the impulse face, then the other impulse face and you have this result.1 point

-

1 point

-

That unfortunately is standard operating practice for most watch schools in the US. Personally I always find it amusing that you have to take it entrance test that shows that you have watchmaking skills so that you can go to a school to get watchmaking skills. It's a shame you didn't have a time machine You can travel back in time and go to the Bulova school it was in New York somewhere. Was a really excellent school but it's gone like most of the schools in the US. There aren't that many decent schools left unfortunately. If you want to grasp the US school situation for watch repair look at this link https://www.awci.com/educationcareers/research-and-education-council-rec-schools-u-s/ This is an interesting school I don't think driving is going to be a problem at all. They even have a website with testimonial information and I wouldn't waste my time here at all. The description of the master watchmaking class is interesting and I think interesting is probably the nicest thing I can say about it. https://ohe.ct.gov/heweb/PosaInfo.asp?F=1757 http://jwrschool.com/ Too many choices too many problems? If you can get in the Patek-Philippe school You would really be set for life. For those that don't grasp the school I have a link it talks about the school. The biggest problem is getting in and really would be nice if you had prior knowledge? But as there's a phone number and you know where they're located It's worth giving them a call talking to them. Who knows maybe they have an opening right now maybe have a waiting list of the end of time. The only way to find out is give them a call. https://mailinwatchrepair.com/sample-article-1/ As you don't want to leave home your choices become extremely limited. Maybe you should listen to your mother? Start the college get something practical get something Practical that you can make money with but don't give up watch repair? Here's a nice suggestion that I've quoted The nice thing about Mark's course is you don't have to physically go anywhere. It's recognized and well respected by everyone on this group. It's being taught by somebody who actually knows what watch repair is. Take the first course find out if you like watch repair.1 point

-

I have noticed this on auction sites such as eBay high end watches being sold for staggering prices way above their actual RRP,s. In this months BHI mag there is an article that maybe reveals what is happening. The reasons for this is complex and deserve their own discussion, but one can include pandemic-induced Swiss manpower and materials shortages, a steep rise in the number of buyers with excess discretionary income, and the self-reinforcing effect of strong prices. So as always, these watches are consistently proving to be reliable stores of value and incredibly good investments. Two particular brands being Patek Philippe and Rolex who are now subject to these mega-price increases. Watches by Rolex now command phenomenal prices in the peer-to-peer market. For example the Rolex GMT-Master I easily commands £20,000-odd, against its RRP of £8,600. The stainless steel Cosmograph Daytona commanded some £20,000 (double the RRP) before the pandemic, but now cannot be had for much under £30,000, and every variant of the green bezel will set you back between around £20,000 and £ 40,000, against pre-pandemic figures of roughly half that. This should be good news for watch owners, and good publicity for horology generally. However it also presents a problem though for manufacturers. With prices buoyant, many people who purchase watches from ADs (Authorised Dealers)find the onward-prices tempting, and so elect to sell them straight away, called ‘Flipping’. One peculiar side-effect has been that some ADs have been attempting to stem the flow of watches from their clients wrists onto the open market. One strategy is by withholding of the Warranty Certificates by refusing to release warranty documents to buyers of certain Rolex and Patek Philippe models, instead issuing a promise to hand them over after one year if the customer would relent to allow his property to be examined at that time to ensure he had not sold it. A watch without its original certificate is worth less than one with. However, this seems to be having little lasting effect, because people are simply waiting the year before selling. If I had a spare £10k/£20k I could be tempted to take a chance.1 point

-

Maybe a picture would help If you look carefully at the pictures on the eBay site especially the side view does that really look like a pocket watch case? Yes casually from the front it looks like a pocket watch but from the side it's not a pocket watch. Look at the description it's big and heavy that's a peculiar description for pocket watch isn't it? I snipped out a few things for you I still think it's a Waltham eight day clock as they call it. I have some pictures of the movement. The parts list for the supplemental spot indicator as they call it. I even highlighted the disc itself.Then they list this is a 37 size movement which would make it big and heavy. Then the eight-day clock was found in all kinds of things. Car clock like the image I have attached. Aircraft clocks just Google Waltham eight day clock and see what you find online found a lot of things. Including apparently something that looks like a pocket watch. Seeing as how currently 19 bids and it's up to $66 not goes they it 20 and it's definitely going over hundred dollars for an interesting very large pocket watch.1 point

-

1 point

-

1 point

-

Well, I was wondering what I was gonna do today. I have six of these in my box-o-watches. I will try my hand it bringing one to life.1 point

-

And I found this video, which better explains a lot of what I encountered when I was dismantling. I had a hunch about how it did what it did, and taking pictures helped quite a bit, but there's nothing like watching one of these in motion to appreciate the utterly simple yet effective way they came with an electric drive.1 point

-

1 point

-

Holiday present to myself. I ordered an ETA 2824-2 elabore movement, PVD coated stainless case with sapphire crystals, dial and hands from a watch materials supplier in Switzerland. None of this stuff was cheap, but the seller guarantees that all the parts are Swiss made and I don't have any reason to believe the items are not genuine. The strap is made in China, but I don't believe in spending big money on 'designer' leather straps. So what do you folks think?1 point

-

Nice work, especially creating your own dial logo. How have you found the ofrei case? I was considering one for my own project and would have paid the extra for the case (compared to the ones straight out of China), but Ofrei's international postage is criminal (around $80US if I remember rightly). Here's mine, also built out of an old pocket watch. Sent from my iPhone using Tapatalk1 point