Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/22 in all areas

-

Random thought I assume you demagnetized it? The nice thing about the graphical display is the meaning hasn't changed since the first machine spit out paper. Although some of the timing machine manuals you wonder about the mental state of the people who Were interpreting the results. The one I'm attaching is pretty straightforward. Then I snipped out an image of what it probably is. Then unless you verified the lift angle your lift angle is probably wrong. But that's not going to change the graphical display output only the amplitude. Timing-Machine-Charts.PDF3 points

-

I strongly agree with the above statements about working on cheaper watches first. Pocket watches are bigger and easier to start on. I serviced about 15 before moving on to wristwatches - I felt quite confident, but suddenly the parts seemed so small ! Buy some cheap Swiss movements, - I recommend doing at least 5 before having a go at your precious Omega. Or do the same one 5 times, practicing handling the balance/hairspring, oiling the balance jewels. I know from experience there is a high probability of trashing the first movements3 points

-

2 points

-

The tin foil trick to test that your ultrasonic bath is working can be quite spectacular and is often used to demonstrate the perils of using ultrasonic cleaners for delicate items, however, I think that a sense of perspective is required to keep things in context. The video above shows how damaging ultrasonic cleaners can be when cleaning aluminium foil, something that I haven't yet needed to do as part of my watch making endeavours. I decided to see how thick aluminium foil is so I measured two sources, one from a chocolate bar wrapper, and the other a piece of heavy duty kitched foil. The chocolate bar wrapper was just 18 microns thick, and the heavy duty stuff just 20 microns, so virtually no bulk or mass to absorb the cavitation energy from the U/S bath (it's cavitation that actually produces the scouring effect, not just simple vibration). Also this is aluminium which is pretty soft in the grand scheme of things; it's not really surprising that the foil comes out looking a bit rough. By comparison balance staff pivots may go down to 50 microns, at least 2.5 times thicker than the foil, and they are made of steel which has a higher density than aluminium, and is considerably harder, and that's just balance staff pivots, virtually every other component in a watch is bigger and heavier and better able to survive the trauma unscathed. So just how useful is the foil test as a means of assessing the suitability of ultrasonics for cleaning watch parts? And has anyone ever done the test with a piece of 20 micron steel or brass for comparison? I may have to try that. The other point to consider is if ultrasonic cleaning is so bad for movement parts, why have so many dedicated watch movement cleaning machines incorporated it over the years? I do have a small U/S bath, but I only use it for cleaning case and bracelet parts which it is very good at. Movements get cleaned using an old Elma cleaning machine that doesn't have a U/S capability, and that also does a very good job. If it did have a U/S capability though I would have no qualms at all about using it. I suspect that the use or otherwise of ultrasonic baths for movement parts is one of those subjects (like oiling, or polishing v buffing) that people will always have differing opinions on but at the end of the day it's a case of "the right approach is whatever works for you".2 points

-

Beginners often ask about where to find this or that crystal, as it happens replacing is cheap and easy as long they are just flat round ones. But the crystal may not be found as generic, or can be expensive, or hard to find. So good old polishing is needed. Here again my technique key points: Crystal mounted on case, that will make it so much easier and safe to handle. Caseback removed, check below why. Jeweller's motor or other rotary tool with a fixed stand. You really want a screen like a carton box. Plastic roundel from a credit card as big as its size allows. 600 grit wet paper. No other grit is needed, as it will lose abrasiveness already after 20 seconds of use and become comparable to finer grades. Try to got directly over the deepest scratches, but without insisting too long (as in 5 seconds max) so to not dig valleys. Find the right compromise regarding the work angle, going flatly is good, but isn't even reasonable to try to sand the entire surface even. Look at the white streaks from inside the glass while working. You will see if you're getting right at the scratch or nick because if so the defect will show up in contrast Be patient with the paper stage. After a while it becomes hard to see if all scratches are gone, but you must remove them all before going to the next step. You should have made a mental note or drawing of where the defects are, rinse it up and observe at different angles. In difficult cases you may need to replace paper once or twice. Crystal will look now very foggy, that is normal Once happy refit caseback and crown, or rodico in the tube. The diamond paste is much more messy and you don't want that inside the case. Mount an hard felt wheel like 7 or even 10 cm dia, 2cm thick, place 1 cm of diamond paste (No. 10 or 14 good, but others work too) on the section toward you while keeping the crystal horizontal. Let the wheel grab the compound one bit a time, keep well pressed up and go over until all paste is used and you can present the entire surface to the wheel, rotate the watch and collect the past on the other side, place it on the crystal again on the other side. You can't do more than 30 - 40 seconds of work before adding fresh paste. Usually I do 4 or 5 passes like that. When working with paste is almost impossible to see the result with cleaning up. Clean with dishwasher detergent, dry it and observe well. Very likely you will notice some small defects, up to you if you want to go back to paper, concentrating on the spot only. Final polishing can be done switching to another wheel and finer paste, no less that 10 as these have no practical effect. Cerium oxide is another option but I didn't try it extensively so far. Below what I did today in about 20 minutes. The central scratch was quite deep. No final polishing or cleaning yet. After:1 point

-

Sounds dodgy. There were websites that advertise real items but send fakes. My friend suggested a website to me years ago selling The North Face clothing slightly cheaper than the high street (only by 10 or 20%) but I did a little digging and found that it was a front for counterfeit goods. The website didn't feel right to me but I using a pc, many people these days only use their phone or tablet to buy things making it much easier to be fooled... unless google et al have clamped down on these sort of sites? Unless it's a company I trust I only use PayPal. Had my fingers burnt on AliExpress too, I'll never trust that company again.1 point

-

1 point

-

1 point

-

Thanks Mike I did order a lot of 4 automatic watches from ebay that are listed as not running to junk if I do that These are only $50 so I don't care what I do but I really want to see if I can detect what is wrong as some training. As far as my omega I must say that I don't intend to destroy it and saying I love this watch is putting it mildly. I watch at least 15 on ebay go out of my reach over about 4 years This omega I will not wear, just around the house so I don't mark it . I do have a idea for a lighted display case for all my collection to be seen so I can admire.1 point

-

What a nice watch, but the real star is the beautiful bracelet. I see mother of pearl, black onyx, carnelian or maybe red agate, and of course turquoise. A work of art!1 point

-

Is your interpretation based on period of occurance only? Could this be indicating a wobbling escape wheel? Educate me gents, please1 point

-

1 point

-

Don't be fooled by the word grease, 9415 is a very clever grease, it is what is called thixotropic, which means that under normal contitions it behaves like a grease, but when it is hit by a pallet stone it momentarily becomes a super slippery liquid before reverting to a grease again. The result is a lubricant that is thick enough to stay in place when it's not lubricating anything, but which becomes fluid enough at just the right moment to do its job.1 point

-

1 point

-

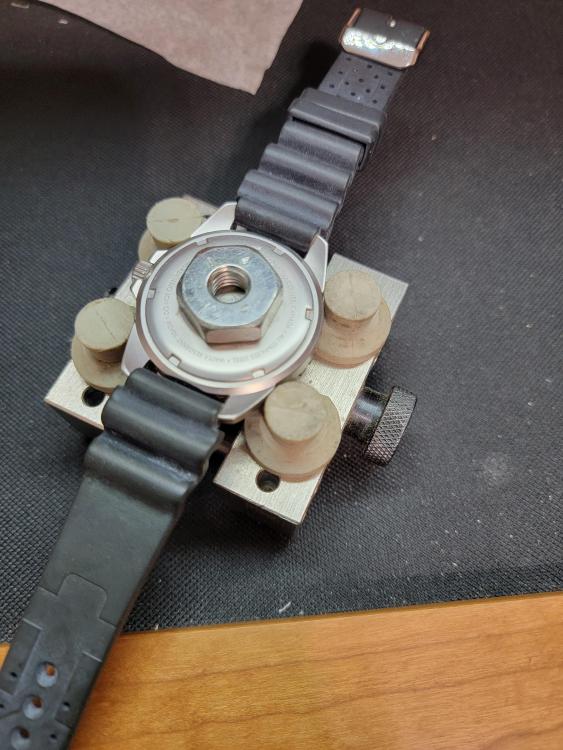

I haven't yet had to do that (*crosses fingers*) since I got one of these: https://www.esslinger.com/watch-opener-brass-handle-case-opener-square-pins/ It doesn't engage with ALL screwbacks, but so far the only ones I've had that were badly stuck have been the kind I could use this upon. (Now I've gone and jinxed myself.) I just put the holder in a vice and take the time to make sure the pins are well-seated into the slots, then turn. Lots of leverage. Somebody on this forum told me about this kind of opener, but I can't recall who. They are somewhat difficult to use correctly, in that they can wobble off the back if you don't maintain a very firm grip. You must clench your wrist tight, and turn straight, on a horizontal plain with the watch back. If you do it exactly right, it can take off the toughest watch backs. Kind of like a breaker bar for watches.1 point

-

I got the one from Cousins, just finished the watch today. Thanks, Steve.1 point

-

Never had it fail and the removal of the nut is straight forward too.1 point

-

That's not the recommended oil for pallet jewels... although I don't know the science behind why. Probably OK to test the running of the movement but I wouldn't leave it on there.1 point

-

I have seen vids of the dangers of ultrasonic cleaners where a piece of tinfoil is destroyed. However when I used to use a ultrasonic cleaner for watch parts I never encountered any issues but as a precaution I always cleaned the balance/ hairspring in a de- greaser not in the ultrasonic cleaner. There is a guy on YouTube Richard Perrett” who services hi end watches and he always uses a ultrasonic cleaner. I did write to him asking if he has ever has considered purchasing a dedicated watch cleaning machine and his reply was that he gets good results in the ultrasonic.1 point

-

Welcome Phil. If you post some pictures of your grandfather's watch, there are plenty of people here to identify what you are dealing with. Although Pocket watches are a good place to start because of their size, spares for the older ones are hard to find. It's always best to practise on something else before tackling a watch of (sentimental) value.1 point

-

This is a very common problem faced by newbies. The Chinese shock springs tend to unhinge very easily. This is because the hinge bar is shorter than the distance between the anchor points. If you slide one side of the hinge bar into place first, then rotate the other side in, it will go in with some persuasion. ( Like putting a AA battery into it's holder.) But you'll need a broad tipped tweezer to hold both tines of the shock spring securely to accomplish this. An eyebrow tweezer works great for this job.1 point

-

That will need a pre-amp to work good with a PC. The articulated mic of the timegrapher has a pre-amp in the black casing.1 point

-

There's not too much to fret over if you've done a regular 7750 before. There are two wire click springs on the calendar plate that can jump, and 4 jumpers. Two use springs mounted on the plate, and two the wire springs shared with the moonphase advance lever and corrector. The jumpers for the date and year look identical, and they are, in spite of the manual showing different part numbers, so don't worry about mixing them up. If you've done a 7750 then you are already familiar with the spring for the hour counter hammer and zero lever, that one is always fun to put in place. There is a flat wire spring for the day corrector here, which is easy to overlook or think that it's secured in the plate, but it comes right out. The manual makes it clear how to orient it when reinstalling. The date advance wheel doesn't need to be oriented like the pair of wheels in a regular 7750 day-date, it advances everything in order without any fuss. Pay attention to the minute wheel- it has a little cap on the pinion which needs to go over the hour wheel teeth. This is easy to miss and will lock things up if not installed correctly. Normal 7750 doesn't have this. Otherwise just follow the (very good) manual for lubrication and assembly. They say not to service the barrel but of course you can and should if not replacing it. On a watch this old it might be a good idea to replace it along with the cannon pinion and reverser for the automatic and possibly the rotor bearing. Do the adjustments for the moonphase corrector (again well explained in the manual), the difference between locking up and not working at all is a very small adjustment.1 point

-

1 point

-

Perhaps you should think in terms of relation to value, as luxury doesn't come cheap. Checking Chrono24 the asking price for a watch like your is about 2,700 EUR. If you like to wear it, servicing is necessary to prevent wear and damage. Two data points which can be useful are the listed service cost by Omega, 690 Euro https://www.omegawatches.com/customer-service/interventions-and-prices/price-information And what a reputable watchmaker charges, 280 GBP https://watchguy.co.uk/price-list/1 point

-

1 point

-

1 point