Leaderboard

Popular Content

Showing content with the highest reputation on 10/26/21 in all areas

-

This issue is a regular on the forum. I believe what is happening many watch the pro’s on vids and see that they seem to have no issues. BUT unlike us amateurs they have years of experience and have the uncanny feeling/touch gained through working on hundreds of watches. My advice is when releasing a spring always support using either some Rodico or some pegwood as they are springs and under some tension. Fitting a replacement spring is really tricky and covering the watch with some cling film while manipulating to save many hours in a search of the work area.2 points

-

The secret here is the type of tweezers to use. If you use a regular tweezer, the shock spring tends to rotate the moment it touches the wall of the Incabloc and ping off into another dimension. I found that eyebrow tweezers with a tip around 4mm width to be the best tool for this job. Grab the shock spring in the centre, making sure to grip both sides of the lyre. And as JohnR725 says, get one end of the hinge in first, then rotate the other end in. It can be a little stressful at first but with good lighting and magnification, you'll get it in the end. Cheers.2 points

-

This purchase arrived in the post yesterday. I bought it because it looked interesting, the seller suggested it was for fitting jewels in pocket watches but I have my doubts. There are a load of markings around some of the holes in different positions. One of the markings is Venus 10 1/2 so that suggests to me it's been used on a wristwatch. Anyone know what this tool should be used for? It's really well made and seems to have had a lot of use. The maker is ABM (?) and there's a "DEPOSE 72847+" which could be a patent mark? The punch/pusher is spring loaded and can be positioned above any one of the 7 holes. The holes all have collet shaped bottoms and the same outer diameter but the inner dimensions vary slightly (inner hole diameter and depth from the top plate).1 point

-

I wonder if it's for working on balance wheels with roller tables attached. The slots radial to the central hole in each position look as though they might be to accomodate an impulse jewel. It wouldn't be for removing tiny amounts of material from screwless balance rims to poise them I suppose? Although you would normally do that on the under side of the wheel so that it wouldn't be visible.1 point

-

1 point

-

If he's on Ebay there should be a listing for the part you're looking for, fixed price or auction, or you need to contact him for a specific reason? If you're concerned about the reliability of a seller his feedbacks page is the place to start.1 point

-

1 point

-

You need to study that movement. You do not need three trains. A bim bam or if you wish a ting tang movement such as this type the strike side works both the bim bam/ting tang as the hourly strike.1 point

-

Obviously with only one pic from above it's not possible to comment on errors in the flat (it should be flat and parallel to the balance wheel rim when viewed side on) but the most noticeable problem is that the terminal curve appears to be a bit off. It should describe a perfect circle centered on the pivot with a radius equal to the distance between the gap between the curb pins of the regulator and the pivot hole in the balance cock. Yours looks like it is deformed inwards at the stud which will result in the coils being off center when mounted in the cock. This could just be a matter of tweaking the dog leg to correct it. However you may find that the orientation of the stud isn't quite right either. Unless there is supposed to be a second dogleg at the stud (not the case here) the H/S should enter the stud tangentially to the same circle that forms the arc of the regulator. Looking at your pic I don't think yours will do that, although it's hard to be sure. I think that when you tighten the stud screw onto the stud it is going to cause the stud to rotate so that the screw goes into the slot in the stud, which in turn will push your coils even more off center. I could be wrong on this but it would be easier to see with the balance mounted in the cock with the pivot seated in the jewel.1 point

-

A little background... My wife discovered this resale shop in a city we have been visiting a lot lately. The owner had bought some stuff from a watchmaker/jeweler. Most was not displayed. That is where I got my Witschi quartz tester for $20. The guy had this watch that he was going to give to a friend but the watch did not work. So, I said I would fix it for him. What I found was the stem had been replaced incorrectly and instead of placed in the hole, was shoved under the top plate. I further discovered that the crown extension was slightly bent. The watch seemed to work out of the case, but since it was a cheap Ronda, I bought another movement on ebay for under $10. When I installed the movement, the stem would NOT stay in place when setting!! Fortunately the new Ronda movement had a stem with it so I sized it correctly, and the watch is now working properly. I got to thinking...I bet this stem was never sized properly! It probably had come out on multiple occassions...falling on the ground or whatever and the last time it was inserted, it was done incorrectly. That is my theory. Interesting.1 point

-

Yes I didn't want to start us down the path of talking BSF, BSW BA etc, but from my experience it doesn't matter how many spanners you have, you never have the one you need. Besides horology I also like vintage motorcycle and vintage bicycles, or just about anything else old and mechanical and despite having full sets of Imperial, BSW and Metric spanners and a good selection of taps and dies I still regularly come across a nut or bolt I don't have a socket or spanner to fit and have to resort to the 'bodge it' tool and use an adjustable spanner.1 point

-

I quit 5 times and start again 6 times. The ruby underneath the escape wheel kept coming out so I took a main plate from another 2824 that I broke previously and move all the parts over it, I ended at 3 am. Now, in the morning it looks fine, it hasn't stop during night and it keep good time. We'll see. ¡Thank you!1 point

-

I find it quite hard to remove the balance wheel+hairspring from the etachron system without the specialized tools from bergeon. The regulator stud is quite difficult to get a good grip to rotate it just right to allow the hairspring to be removed from the regulator stud. The hairspring stud can be removed from the stud support with a pair of tweezers, but using the tool makes it significantly easier.1 point

-

Here’s some pictures on a movement (ETA 2000-1) I was working on to illustrate: place a tiny piece of rodico in the gap using a sharp tool (tweezers, or a rounded pin in a piece of wood) nudge the middle part of the shock spring slightly until it pops out; repeat the process on the other leg of the shock spring After removing the cap jewel, using tweezers close the shock spring back into the setting. Then remove the rodico. When repeating the process after cleaning to reinsert the balance jewels, it can be significantly harder to open the shock spring legs from an empty shock block. You need really sharp tweezers, using the flat at the end as a blade to “twist” up the shock spring from its catch, because the balance jewels are not there to stop the shock spring legs from downwards movement.1 point

-

You may want to take a look here: Someone has already tried to interchange a genuine incabloc shock spring in there and found that it doesn’t fit quite right. However, the genuine incabloc lower shock spring may work in the top setting. If you do decide to buy a genuine ETA movement to make getting spare parts easier I recommend you to get some bergeon or dumont brass tweezers to handle parts without them flying away or getting scratched. Just a friendly tip from someone who was in the same position as you 5 months ago.1 point

-

The pliers that LWS bought is a bird beak plier. This has a conical beak on one side and a flat beak on the other side. This works well for round wire but if a flat wire is used, it will develop a conical twist in the bend. Spring grade wire is very elastic and to get the radius that you want, you have to use a smaller radius former because it will rebound and open up. It is usually easier to bend the curve to a smaller radius, then use the bird beak plier to squeeze the curve to open it up to the curvature you desire.1 point

-

Sounds like the watch could be a size 18s or maybe even 20s. I know a couple places that might have the springs, but I should ask if you can post pictures please. And the serial number too (you can use a "*" for the last digit if you don't want to post the exact number. I will still be able to look it up and hopefully find parts numbers too. That'll hopefully tell us exactly what we ought to look for.1 point

-

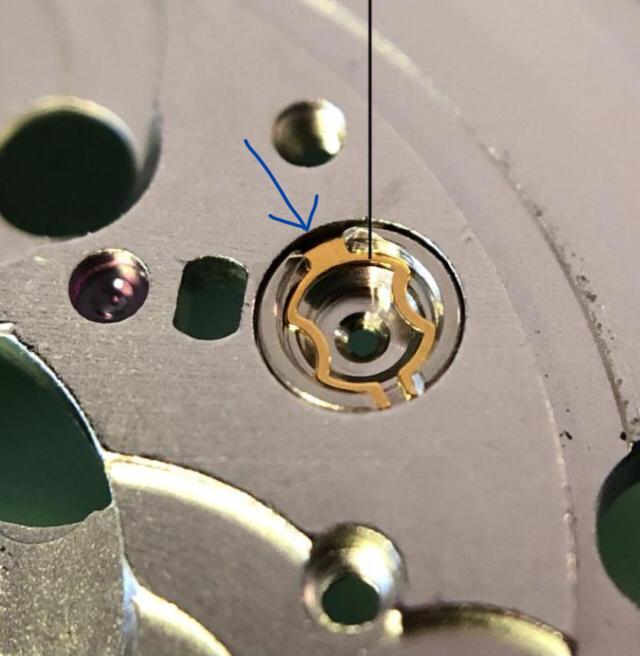

KIF shock springs (not the trior 1-X series) are inserted from the inside of the shock block as you mentioned, making replacement of the KIF shock springs easier. Incabloc type shock springs are hinged in a gap on the exterior of the shock bloc, and have the propensity to fly out when opening the shock spring, even though they are engineered to be non detachable. The Genuine Swiss Incabloc shock springs can only be easily installed by removing the entire shock block, but some have reported that the for the Chinese incabloc clones, the shock springs can be re-inserted carefully without removing the shock block from the plate/bridge. For incabloc type shock springs, I have now taken to placing a small piece of rodico at the gap in the shock block where the incabloc shock spring hinges to prevent it from flying off when opening the shock spring. I have attached a photo indicating the gap from which the incabloc type shock springs tend to fly out. In this case it is t main plate one, but the balance cock one is similar. Try putting a small piece of rodico in the gap whenever opening or closing the shock spring. I am unsure if you can try using genuine Swiss incabloc shock springs in the Chinese clone but you can try.1 point

-

1 point

-

I guess when the market is huge, industry players can afford to go open source. But in a small niche market, manufacturers tend to be more protectionistic. Like in the dental sector, which is really small, manufacturers tend to be rather protective. Our equipment need special tooling to disassemble them or risk damage. And with every new range of equipment, even from the same manufacturer, new tooling is required. Recently I learned that a prominent European dental equipment manufacturer started putting code into their motherboard to cripple their equipment if a routine maintenance service is not performed.1 point

-

Sorry, I just checked. India might still be using the old British colour code, which is Red - Live Black - Neutral Green - Ground1 point

-

I suspect we've covered it before some place the problem is trying to figure out what we called it what it was titled to find the discussion? I'm attaching an image that hopefully isn't too confusing. In the Swiss version when you lift up the spring or release it ,it stops at the red line. It basically just pivots here the block that outlined in pink doesn't exist in the Chinese version. This is why when you release the spring it just slides out there's nothing to hold it in place. putting it back is easy if you understand how and if you're really careful on how you hold the spring. The tabs that hinge are wider than the slot. You need to place the spring at a angle like the blue line shows then gently rotated into place then the tabs will be under where there supposed to be.1 point

-

Do you mean cock side shock spring? To stand on the safe side, I seperate the balance complete then lay the cock on an anvik to get the spring installed using one prong of fine tweezers. so if tweezer slips then, sensative balance/ hairspring is not underneath it to get damaged, hardly any part can gets damaged. Remove the regulator arm as well. Detaching and safe removal/ reinstallation of balance complete is a must to master task. Trying to instal a shock spring with balance complete underneath it is RRRisky.1 point

-

I just now purchased the pliers I show above. Under twenty bucks with tax title and license!1 point

-

SG$ 22.62 | Dental Lab Orthodontic Plier Loop Forming Plier Nance plier Archwire Loop Bending Plier Step forming plier Special Adam plier https://a.aliexpress.com/_mMtyGzu1 point

-

Well, this plier-like tool was in with the other tools I inherited. Not sure how my Dad used it, but I think it was used for mainsprings. That is how I have used it. It could be used for click springs, although the diameter of the smallest jaw seems a bit too bit. I show a click spring in the photo for relative size. I have never seen these for sale on ebay. They may be found on jewelry making vendor sites...dunno.1 point

-

Hey I am attempting to rewire a brenray cleaner exactly the same model as below in pic. I have done my due diligence and looked around the internet for help and low and behold we have one on our own forum. The problem i am having concerns the power lead, Both the one from the motor and the one leaving for the plug seem not to have all the wires. In one lead you have a blue wire and a earth and in the other lead there seems only to be the blue wire. This is surely not correct?? Or is this correct or can i not see in the picture were the other wires go???? cheers gary1 point

-

Not all watches with flat spring have the distinctive "dog leg" from the terminal curve to the hair spring body. This one looks OK to me, maybe needs a little bit of centering, but I think it's otherwise original and correct.1 point

-

You want the pins straight, and parallel, with a gap approximately equal to two spring thicknesses. The gap is a guide, you might want it closer, for example an overcoil would like a very small gap (just free) as OH said. Depending on how the pins are installed and their spacing. One some older pieces they are spaced a bit, so you have to bend them toward each other, then straighten. I just use fine tweezers for this, like #5. Sometimes to widen the gap a little those are still too big, then I will use a broken oiler that has been stoned to a very fine wedge shape (like a microscopic screwdriver). That will fit in the smallest gap and allow some tweaking.1 point

-

1 point

-

HI JohnC, on a pocket watch with 2 pins, remove the balance cock but with the hairpin stud intact. Turn the balance wheel together with the cock over; hold the cock & the balance up & use a thin sharp pointed blade [ similar to a scalpel ] to slightly open the pins enough to clear the hairspring thickness. The reason for the pins set towards one another is to prevent the hairspring from being dislodged. If a watch has two regulating pins they should be parallel, not bent towards each other. Generally the spacing between them is about 1.5 to 2 times the thickness of the hairspring. The spring is not "captured" but should be centered between the pins with no power to the watch. At normal amplitude the spring will bounce from one pin to the other. This is true also with the single pin and guard, the spring should be bouncing between the two when amplitude is "normal" On wrist watches what I do is if the single pin is bent I use flat tweezers and ever so gently straighten the pin but I don't move in any direction. Chances are it will snap. Once the pin is straight as in no bends in it, I then proceed to nudge it in the direction needed, from about the middle of the pin. You really only have one shot at this on a wristwatch as the pin snaps at the base very easily. Anyway that's what I do. I haven't seen any tools specifically for the job but I use hairspring manipulating tools to push the pin. Hope this helps Graziano1 point

-

Hello and welcome to the forum. What you could try is putting it on a line release tool. (available online, Ebay, this is essentially a coil and as current is passed through it it creates an electrical field and spins the watch at speed and frees any particals jamming the train. If this fails to restart the watch It wtll need further action, dismantling and repair (if possible or replacement). Best to post some pictures of the back of the movement with the cover offo determine its make and caliber.1 point

-

There is plenty of donor movements on Ebay. Only problem is that it takes weeks to arrive from ukraine.1 point