Leaderboard

Popular Content

Showing content with the highest reputation on 04/02/21 in all areas

-

I think this is a misconception perpetuated by one YouTube video on polishing. Nowhere in material science literature have I come across this explanation. Silver melts around 900°C and stainless steel around 1300°C. If the friction is enough to cause the surface to melt, the polishing mop would burn. Burnishing can move material from high spots to low spots by plastic deformation. You have demonstrated that in many of your pivot polishing videos. But the forces involved in burnishing are much higher. The force generated by pressing an object into a buffing mop cannot generate sufficient force to move metal molecules. When polishing thermoplastics like acrylic, if too much pressure is applied until it melts, it never a good thing. The mop would gouge out the softened surface.3 points

-

2 points

-

2 points

-

Coincidentally, after a tip of JohnR725, I just went through the 7750 regulator-pins exercise. Nickelsilver pointed this out also. The movement is a freshly serviced NOS 25-jewels normal grade 7750. Runs in every position with straight lines, lift-angle 49 degrees. I started off with the regulator pins nearly "full-open" and started slowly turning to reduce the gap between them, reducing the freedom of movement of the hairspring between the regulator-pins. Here are the results; 1) DD +4 333 0.0, DU +3 320 0.0, CD -13 296 0.1, CU -16 298 0.1, CL -17 292 0.2, CR -18 292 0.1 Started to turn the pins to close the gap and had to adjust the daily-rate downwards; 2) DD +5 327 0.0, DU +5 315 0.0, CD -5 291 0.0, CU -8 289 0.1, CL -3 295 0.1, CR -10 282 0.1 Closed even further till there was nearly any gap left and had to adjusted daily rate further; 3) DD +8 325 0.0, DU +7 318 0.0, CD -2 291 0.1, CU -5 296 0.0, CL -2 290 0.1, CR -7 287 0.2 4) Closed a tiny bit further, but that turned out to be too much and I had weird readings. I had to open the pins up and to start "squeezing" again. These are the readings with the pins as close together as I could get; 5) DD +1 323 0.0, DU 0 311 0.0, CD -7 287 0.2, CU -10 289 0.1, CL -7 287 0.0, CR -13 281 0.1 As can be seen, closing the gap to the point whereby the hair-spring just "breaths" makes a substantial difference in the positional error. In 1) the biggest difference between the fastest and the slowest daily rate is 4+18 = 24. After adjustment the difference is down to 1+13 = 142 points

-

One thing we may be seeing a methodology problem? Then what kind of regulating system does this watch have? I see several problems with what you're doing when you placed the watch on the timing machine I assume you time dial down only? This would be perfectly acceptable If you can cleverly where your watch always in a dial down position. Now we get an interesting problem when you're wearing the watch I do wrist it's in multiple of positions. When it's on the timing machine most people only time in one position. They never look at the other positions or don't even think about timing and a lot of positions and doing some math in seeing what the average is supposed to be. Because you may find that that's different than what you see in one position only. Then your numbers are wasted time unless you give us a complete picture? In other words every time you give us a number of fast or slow we also need the amplitude. This is because if for instance your regulator pins are a little bit a part or you have the etachrion system not quite adjusted right In other words the regulator pins are too far apart amplitude can have a insane amount of influence on what the watches doing for timekeeping. You should also try winding the watch up timing it in if you are obsessed of like I would be six positions just because minimum of two positions your minimum of two positions on the dial down and the crown down. Otherwise your obsessive your six positions we dial down and up 4 different crown positions like up downright left. Allow at least 30 seconds between rotating the microphone for the watch to stabilize measure about 30 seconds. Then let the watch run on your bench for maybe 12 hours do it again 24 hours again I think your watch run a couple of days may be one more time see what the effect of amplitude is on your timekeeping. Also look at the PDF take the numbers that you got run the math see what it says the average is and at the same time be doing this timing trial cost of physically look at the hands and see how they compare with what you think the timing machine is telling you especially if you do the math to get an average. Oh and I assume your time reference keeps better time than your mechanical watch otherwise that's an added complication to the whole thing. witschi X-D-DVH-Di-Im-N_EN.pdf2 points

-

These Tudor Submariners have really shot up in price the past few years. I've had my eye on the 7928 model, as I thought it was the way to get an affordable vintage Submariner (and I liked the rose on the dial), but they're out of my range now. This one has some issues but having the box and papers and whatnot might make up for the oxidized hands and what appears to be a "re-lumed" (luminous paint reapplied) dial. That being said, since it's a heirloom, what potential buyers think may be irrelevant. Here's my observations, and a truckload of opinions: The hands look oxidized- they can probably be cleaned up but if they are replaced I would have the owner hold onto the originals just in case the intent to sell is there. The dial appears fine but the luminous paint looks unusual- it should be brownish red or possibly even black (if moisture got into the case). I think the luminous paint was reapplied at sometime. If that's true I would have the luminous paint redone; it will make a huge difference in the cosmetic appearance. If the paint's original and the plan is to sell the watch then probably better not to touch it. The rest of the dial looks fine. The case and bezel just need a good cleaning (no polishing) and the crystal, well if it's an original Rolex "Tropic" crystal (honestly I don't know how you would tell) it should probably be held onto. If the owner will be wearing the watch then I would definitely replace the crystal a new one but again have him hold onto the original just in case. For the movement, parts availability could be an issue but they usually come up on eBay if parts are not readily available at Cousins, etc. I would expect the cost to be somewhat less than servicing a Rolex Sub from the same era since you won't need Rolex parts. That's a really great watch- thanks for posting on it. I love seeing the stuff from the 40's, 50's and 60's come up as that's the era that really tickles my fancy.2 points

-

1 point

-

Hi, my name is Mike. I have been a collector for over 20 years. I was in the process of teaching myself watchmaking when neuropathy in my hands kind of put a stop to it for the most part. I still try to tinker with my Timex watches as they are not quite as expensive if I goof. (Though that seems to be changing!). I still have a pretty big collection. I like Soviet era watches, and Accutron watches too. I have a running Soviet Slava Transistor (a virtual copy of the Accutron 214) that is one of my prized watches. I find it difficult to type so I wont be posting a bunch. I be happy to answer any questions if I can. Thanks all.1 point

-

Nice clock Roger , Nice repair to the suspension ! Cusins uk, Meadows and Passmore, will have the bits you need for sure.. Yes its a Junghans made in Germany, like Hermle they are nice clocks. cheers1 point

-

Not sure when the first sapphire watch crystals became available, 1925 seems too early as the process for creating synthetic sapphires was first developed after 1910. Rolex didn't start using them for watch crystals until 1970, so if this was factory work it would predate this by 45 years. Otherwise there were watches made with natural sapphire crystals also. Must be quite the watch. Can you post a photo? Do you think the shellac was applied as a thick varnish adhesive, or flowed with heat? Seems like shellac would be a logical adhesive choice for 1925.1 point

-

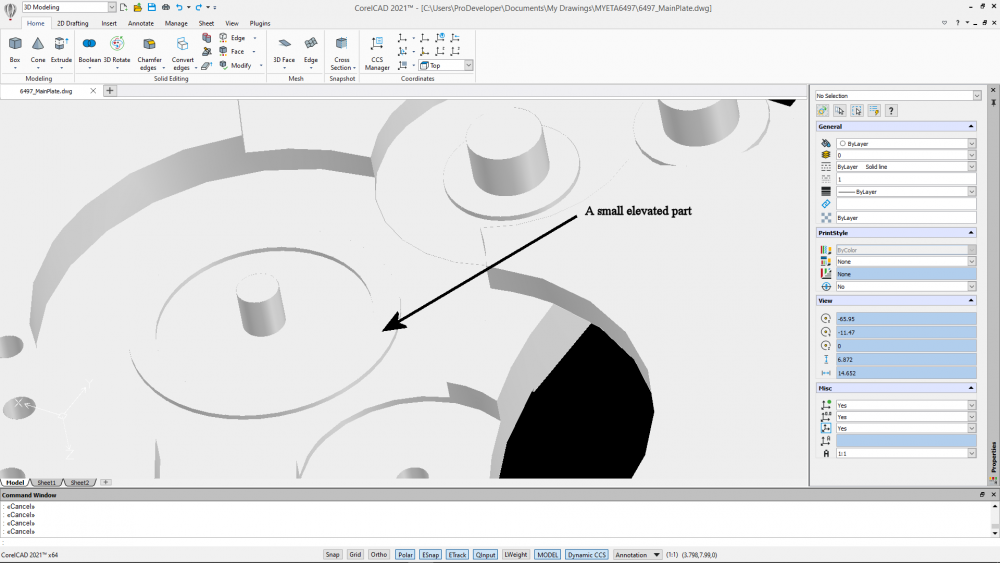

I would think that is quite normal wear on an old watch of not so high grade. To avoid what you see there one usually by design put in a small part which is elevated. This is done since the teeth on the wheel sooner or later will get some burs which are chipping away material and resulting in the damage you see there. One can avoid this by always check the wheel for burs and remove them at service and put just a microscopic dot of grease on the elevated part. If the elevated part is worn away you need to address this issue and put a shim of some kind under the wheel. Otherwise, it will just be continuing to dig in to the material and make it harder to wind up.1 point

-

I was able to find Piezo mic elements that work well with my preamp and fit in the Vibrograf pickup. Very difficult to find. Had to make a mounting plate to use in Vibrograf pickup. I tried several different piezos in several configurations before I found one that worked. I will be creating a document on what I used and how to mount. This setup is sensitive and has very little background noise.1 point

-

1 point

-

Before getting even minimally anxious, not even knowing what you have on hand, have a read of our pinned topic. There is a tendency to vastly exaggerate on the subject.1 point

-

The difference between a genuine Rolex crystal and a aftermarket crystal is on many Rolex calibers there is a hologram of the Rolex crown at 6 O,Clock that can be seen using a LED light. The latest calibers now have laser etched crown at the 6 O,clock position.1 point

-

Bought the tool, I will post some pictures when it arrived. Thanks for all the answers. ?1 point

-

1 point

-

Make your own observation, add oil to pallete-escape of a stable watch and you see a curve before it re-stablises. Regs1 point

-

In professional work it's quite normal to let a watch run number of days before final regulation. 7750 is usually quite stable from the start, what would be interesting is to know the true state of wind of yours over this period; it seems you were observing the time not the displayed rate on a timing machine. If the regulator pins are not close enough you can have a quite large difference in rate between relatively normal amplitudes. Overall I would expect a 7750 to be more stable than this.1 point

-

The hole jewel should be of a size that allows the pivot to pass through freely, with perhaps 0.005 to 0.01mm of freedom. The balance pivot end should absolutely touch the cap jewel. If your hole jewel is too small then the pivot is resting on the outside of the hole; this can be the case and the balance still spin as in your vid. Then it will bind when tightened. American watches typically had a range of pivot sizes and corresponding jewel sizes. Take it all back apart and try the hole jewel on the pivot, see that it fits.1 point

-

Here is the title to the original thread in which I purposely showed a SMALL ZIPLOC BAG. " Tips on removal , cleaning and reinstalation of fiddly cab jewels " The bag Idea occured to me over thirty years ago and has never failed. The story has undergone many changes eversince, cutest version was someone made a plastic tent to carry out the task under, run short on oxygen under the tent a got dizzy. ? Regs1 point

-

@motorclassic. Is that any indication of the car you drive?1 point

-

Hi there all, thought I would share this with you. Some time ago, or should I say once upon a time, I got this Longines pocket watch in a box of parts that I bought off a fellow who just wanted to get rid of it all. Most of it was just old movements and wheels and old tools and bits and pieces. There was a few complete watches amongst the box. Anyway I have been at the bench off and on for months between other things, stripping this watch down and checking out why it was not working. Firstly I found one of the screws on the click spring was broken in the plate so it would not wind. Then I noticed the hairspring was not connected to the stud. The brass stud pin was non existent. I could not find any other reason why it wouldn't work. I did not service it as this would have been a waste of time at this stage. So I removed the broken screw from the plate and fitted the huge click spring back on, then the cover plate and bingo it wound. Next thing I removed the balance and filed down by hand a brass stud pin and after using my hairspring vibrating tool to find where to stud it, I put it back together and low and behold it worked. I contacted Longines for information about the Watch and they sent this, The original serial number 480'958 identifies a hunter pocket watch in metal. It is fitted with a Longines manually wound mechanical movement, caliber 18LS and was invoiced on 10 November 1888 to the company Zivy, which was at that time our agent for Mexico.Zivy was a Paris and Mexico boutique of watch and jewellery merchant Hauser, Zivy & Cie. I did not take photos of the work because I didn't think this old jigger would ever work again. But I will when I service it. Just thought I would share this with you. VID_20210330_230238.mp41 point

-

There are a few issues; your replacement pin likely has an "odd" thread that may or may not match something on the old Martin screwplates, and may or may not be close enough to work with a modern metric thread, but you will quite likely have a hard time finding a tap to match. If it matches a Martin plate you can make a tap. If the new pin's threaded portion is close in size to this one you will need to open the hole significantly to get a decent plug in to rethread, which would be unsightly. The easiest route would be to retap the hole with the closest metric size that will get some threads in there, then make a new pin. To make the pin you can hold some barstock in an oversize collet and insert a bit of copper or other thin metal on one side to get the eccentric. Turn the pin, then holding it normally in a collet cut the thread, part off, then slot. When you tap the hole just go a little at a time, as the tap will be tapered at the tip, you can check with the new eccentric and find the amount of thread that lets you screw it in but have some friction when its at the right depth.1 point

-

1 point