Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/21 in all areas

-

Hi, As a new member here to ask for help I thought the least I could do is contribute what I could, so this is my simple collection. The Certina still has it's wrappings as it just arrived. Seiko 5 7S26-3040 Seiko (quartz) V657 8060 Seiko SKX007 Certina DS-1 Powermatic 80 COSC King Seiko 5626 7113 Raymond Weil Tango 5560 Andrew2 points

-

Yes back then as well still now some casers and retailers insisted and maybe paid more to get complety sterile mov.ts. Others paid more to have some modifications made to the bridge layout and then apply their markings. There were no reliable sources of information outside industry circles and perhaps few precious illustrated parts catalogue. Buyers were left either buying big names otherwise hanging to the word of the jeweller telling and selling them whatever he wanted. It was a very competitive and profitable market for a necessary item, the equivalent of a smartphone today.2 points

-

My guess is that since it is going fast rather than slow or stopping the quartz crystal is the most likely source of the issue. Dampness, physical damage or even just becoming loose in the casing will affect the rate of the crystal. If you are up for a bit of micro-soldering then you could try swapping the crystal. They are readily available on ebay and very inexpensive.2 points

-

Based on the AS observation from Nucejoe then you're probably actually looking at an AS (A Schild) 1906 (you've read 1908) which is in the same family as the 2066. Parts missing? Mmm. Wouldn't necessarily be taking that as fact.2 points

-

Hi Have a look here on Ranfft http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Venus_188 it notes that it change to the Valjoux 7730 so with that in mind I have attached some information for you and a bit extra on the 7733.34.etc which may be of help. cheers Venus 188.pdf Valjoux 7730.pdf Valjoux 7733, 7734, 7736 Pages 6-10.pdf Valjoux 7733, 7734, 7736 Pages 1-5.pdf Valjoux 7733, 7734, 7736 Pages 11-15.pdf2 points

-

Looks a AS 2066 to me. You can google AS 2066 out of ranfft's site and compare both images.2 points

-

1 point

-

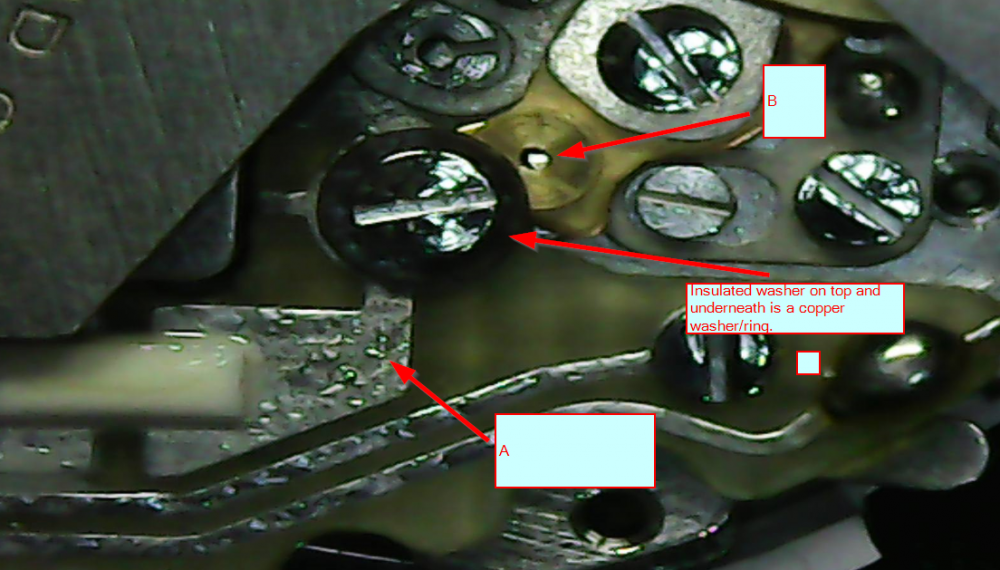

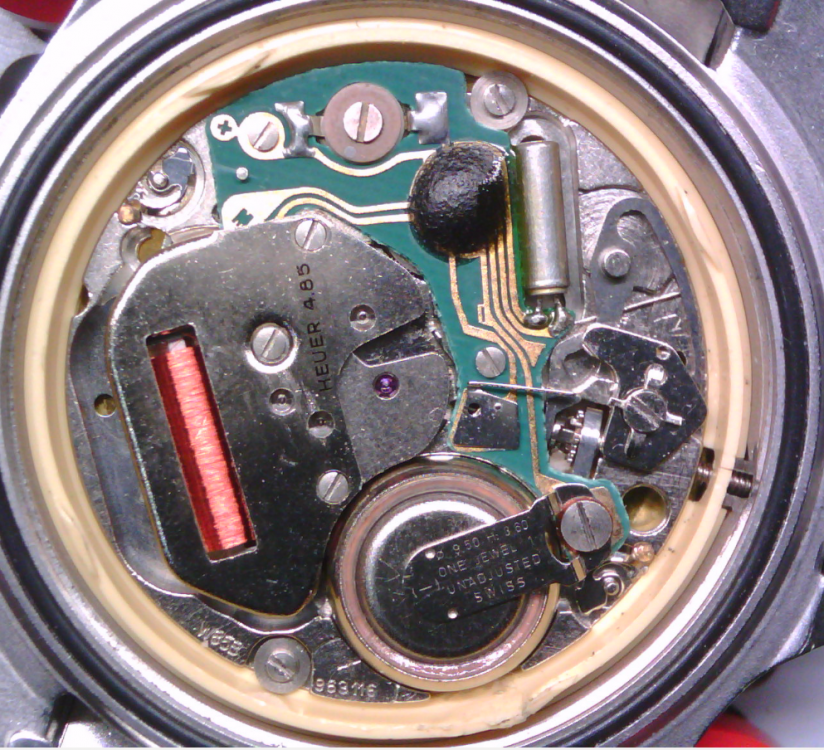

At this point, I walked away for an hour or so. I came back with the theory that there was a break in the circuit somewhere and my speculation was that it was along the contact point spring and associated interconnections. So, here is where I focused. I did not take a picture of the insulating washer on the bottom. Interesting feature. Insulation on top keeps the screw out of the electrical path. The copper ring underneath connects point A to point B. I removed it. It appeared to have some slight discoloration (oxidation on the PCB trace). I just reinstalled and cranked it down nice and tight (not over tight!). Then I connected a battery and VOILA...the balance wheel takes off. In retrospect, I think a different order of tests were in order. 1) testing the coil first was right on. 2) running a curve tracer on the components should not have been the second step...too involved...required building a testing platform...yadayada 3) checking continuity along all paths should have been #21 point

-

I have three different crystal cutters, an Austrian, an English and a Hungarian one but I have never used any of them to actually cut a crystal. I just love them. I quickly checked eBay and there seem to be Little Gem cutters from the US too. Woah. ? If you ever decide to sell your crystal warmer let me know, I will consider to buy it.1 point

-

If it's not the oscillator are you suggesting a mechanical issues? Then an easy way to figure out if it's a electrical problem or a mechanical problem would be to just replace the entire circuit. Then convince the original poster to mail you the old circuit and then you can verify that it's not an oscillator issue.1 point

-

1 point

-

It's not a mechanical issue. Typically on quartz watches if there is slow beyond a few seconds per month it's a mechanical issue in other words there's some reason why the gear train can't rotate. Like the watches never been cleaned lubrication went bad dust is amazing how little dust and upset a quartz watch. But typically fast is something in the electronics. Because the electronics on a watch even though we visually can see it is basically considered a black box you just replace the whole thing.1 point

-

I Think it would be better if you just replace the entire circuit board. You don't actually know what the circuit itself is doing and this would solve the integrated circuit having a problem and the quartz crystal everything it in one package. Then these watches were made quite a while ago I would think about cleaning it. Contrary to popular belief quartz watches actually need to be cleaned like a mechanical watch from time to time.1 point

-

Should be able to i d it by the keyless work under the dial. We need to see a photo of the complete keyless work.1 point

-

1 point

-

1 point

-

1 point

-

Returning the original topic now... I have an ISA 389 movement in a watch that I gave to my wife years ago. Also years ago, it quit working. I recently took it apart to see what I could learn and started looking for a replacement movement. Today, I decided (in the spirit of this thread) to troubleshoot it and attempt a repair. I discovered that the coil was an open circuit. This is due most likely to a battery leaking and the acid eating away at the wire on one end. I could see the green sludge on the wire. As soon as I touched it, it disintegrated. However, there was still enough pigtail that I could carefully grab it and unwind it by one turn. All of this done using a stereo microscope at 40x magnification. I did unwind it and laid it over the PC board where it need to be soldered. Moving to the electronics workbench, I used a relatively large (by these geometries) tip and super fine solder and soldered the other end of the coil. A quick measurement indicated that I should be back in business. Installed the battery and VOILA!!! I wish I could have taken pictures of this, but I do not have the right gear for that. At the end of the day...you can repair these quartz movements!!!1 point

-

1 point

-

1 point

-

Have you tried the two approaches invariably mentioned in answering this kind of question? Look under the balance for markings Search "ranfft database" online1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Me and spiders have a mutual agreement: they don't come into my 3 ft. personal space, and I won't burn the house down trying to smoke em.1 point

-

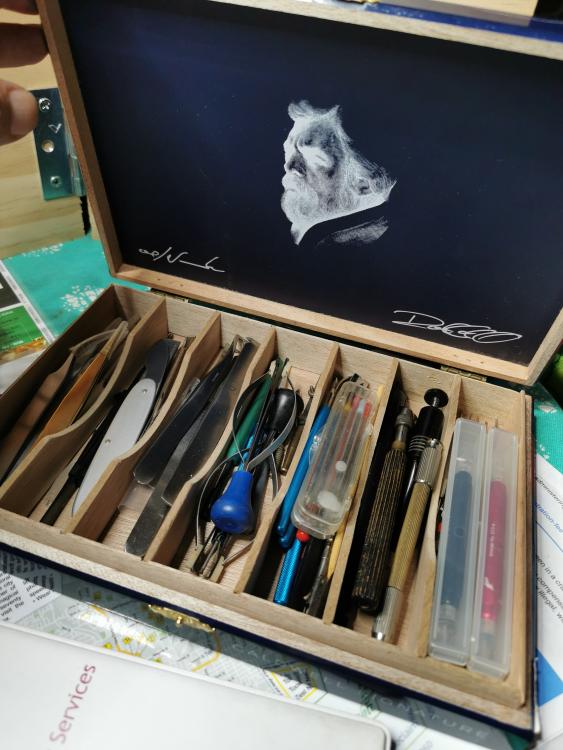

Do not automatically assume that the old 70's capacitors are bad. I restore old dental equipment and hifi amplifiers. I frequently come across 40 year old capacitors that are still up to specs. Somehow things were built to a higher standard in those days. The "skin drawer" is also seen in jeweller's workbenches and dental laboratory workbenches. It was to catch the gold dust from sawing and drilling gold pieces.1 point

-

1 point

-

1 point

-

1 point

-

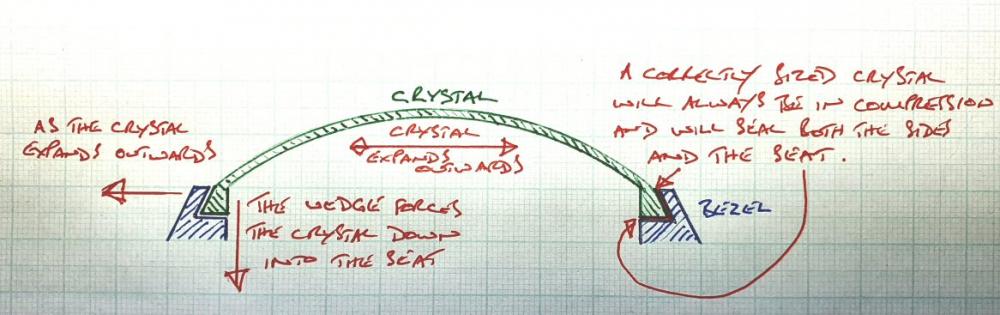

The BB Crystal Company set that you have got on the left is for installing armoured or tension ring crystals. These have a metal ring on the inside of the crystal to keep the sides of the crystal rigid, so using a crystal lift like the Electro-Vise or the Bregeon would be very difficult. The sides of the crystal, and the sides of the rebate into which the crystal fits are parallel, and the crystal is fractionally larger than the rebate, such that when it is installed it is a tight interference fit. The flat dies go on the bottom to support the case, and the inside rim on the upper dies are bevelled, and you select a die that fits over the crystal such that the bevel is in contact with the edge of the crystal dome. The shape of the bevel coupled with the amount of force that the press applies is sufficient to bow the very bottom of the crystal inwards to get it into the top of the rebate, then push it all the way home. The rigidity afforded to the crystal side courtesey of the tension ring allows the crystal to make a very tight, water reisitant seal against the sides of the rebate. The crystal lift is ok for installing standard acrylics but in my opinion it's not the best method. I use one of these.. You have a felt covered lower die that is significantly smaller than the crystal, and a concave upper die that is only slightly smaller than the crystal. The case or bezel is placed over the lower die, the crystal sits on top of the lower die. The upper die is then brought down on top of the crystal and pressure applied causing the lower die to push the middle of the crystal up into the upper die, making it more domed which at the same time reduces the diameter of the crystal skirt. The bezel or the case is then brought up so that the crystal skirt sits inside the rebate, and the upper die is raised, releasing the pressure, and the crystal resumes its proper shape with a flatter dome and wider skirt which grips into the rebate. The sides of a standard acrylic are actually slightly conical, not parallel, and the rebate has a similar conical section, such that as the crystal sides expand in the rebate the sides of the crystal also force the crystal down onto the seat. This creates a contact seal against both the sides and the seat of the rebate and stops the crystal falling out. The set of dies on the right in your pic is for installing glass crystals which are usually pressed into an "I" or "L" shaped gasket.1 point

-

1 point

-

Now it was time to fit the shape of the new clamp to the movement and then bend it so it would perform the intended function and then do the final fitting. You can see the range of colors that result form the heating and quenching in one of the photos. Ever more careful and fine filing and continual testing against the movement until the tip of the clamp fit into the movement. Then simple bending and adjusting of length and trial fitting again until voila! A new clamp that holds nice and solid. This was a fun bit of adaptation and using the know qualities and behaviors of the materials to accomplish the job. This is a useful skill to have until I collect more tools and eventually containers of "donor movements" and collections of little screws and bits. But I currently have none of that. So there it all is. I hope this inspires others to try making some things they do not have at hand. This was done with basic needles files and tools most people probably already have around.1 point

-

.There are many solutions to the problem and this is yet another, How its done is irrelavant its more the fact that you overcame a problem. Thinking out side the box (PC Parlance).1 point

-

1 point

-

It’s actually a process that requires certain steps to be take in a certain order. All this I learned by trial and a lot of error. I am not sure what I can do with this new found way of making dials. Redial watches, dial new cases. If you notice the case is from my Longines Bigeye but will not be putting the Bigeye dial back in because this one looks so muck better. Longines has the best case with the oversized pushers perfect for a cool pilot.1 point

-

Thats impressive to say the least. I know this is not a build along thread, but do you have any intermediate photos or information on how you did the dial printing?1 point

-

That reminded me of the show "Whose line is it anyway?" I caught a few segments of it on TikTok. Brought back some old memories. Anyone remembers "The Benny Hill Show"? I'm sure the members from UK would!1 point

-

Thank you very much for your help guys. I have managed to get the case out of the movement, removing the bezel with a razor blade and then with my case knife. I do really appreciate your help! Now I have already learnt something new ? Thanks a lot, Sincerely, thebosston1 point

-

That red coil is actually a small hydrogen bomb. “it has a very loud alarm.”1 point

-

Or Swatch?! https://www.maxim.com/style/swatch-no-time-to-die-q-watch-2020-2 Although it is stretching the bounds of credibility somewhat that 'Q' would wear a watch that was 'welded shut' by the manufacturer, and accept the notion of 'no user serviceable parts inside'. C'mon this is the ubergeek 'Q' we are talking about. If he can't take it apart and retrofit a micro neutron bomb and a set of nose hair tweezers inside it, then what is the point in wearing the thing? ?1 point

-

1 point

-

1 point

.thumb.jpg.cb6ddfb7bdaa48c5569b12b1edb563c6.jpg)