Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/21 in Posts

-

I own a little coin shop. One of my regulars knows I enjoy watches, especially seiko automatics. He finally brought in his watch that he bought new in 1977 (watch is dated early 1977) while he was in the coast guard. Moisture somehow got in the first year he owned it. He took it somewhere to fix the issue and he never wore it again. I think that's possibly why the lume is not great. When I got it, it was not running. He was about to throw it away but when he bought it he had a custom band made for it and he couldn't get it off. The inside of the case back has one marking on it from a service. Either way, it's neat to buy a 40 year old watch from the original owner, especially a watch I've been wanting to stumble upon for a while. The NATO strap on it was the nearest I had to me so just threw it on.2 points

-

2 points

-

If are going to keep track of the number of mistakes you're making watch repair isn't the place you want to be. So your second mistake is you expect us to read your mind? It's a pocket watch and its caliber 534 I don't suppose it was made by a company with a name that we might recognize? Because otherwise trying to find parts for 534 could be challenging without that information. A lot of this depends upon the particular pocket watch. In modern Swiss watches replacing the pallet fork staff is usually relatively simple if you have the right tools it's friction in. I don't think I know of any pallet forks that the staff is riveted in like it is in a balance wheel. Then some of them they actually screw in.2 points

-

2 points

-

According to Jules Borel there is a generic one (415) at approx 21.40 see attached sheet. Jules Borel are a material house in the USA. MATERIAL CGI UTILITY.html2 points

-

2 points

-

Too right They are robust workers and will last, any watch will break if abused even a rolex1 point

-

AMEN to that brother!!! I have been doing that, albeit a little carelessly. Gonna be very detail oriented going forward. In the video posted, the watchmaker noted returning screws to their position after removing respective parts--so as not to get screws and their locations confused. This is very clever, I think. I ordered the part today. Still not certain I will attack it, but at least I will have the part on hand for me, or a skilled watchmaker.1 point

-

Oops! Sorry! I think I should give up posting before breakfast.1 point

-

There are many walk though's , I believe from VWatchie or HLS on the very subject of dissasembly and re assembly. Have a look via the search facility or contact the members via the PM system, I am sure they will be able to point you in the right direction.1 point

-

Hi and welcome, I started about 7 months ago, when you start looking for your tools have a look on the "Cousins" website, they stock everything from the budget range to high end Bergeon could save you buying twice like I did with some crappy eBay movement holders Graham1 point

-

well isn't it interesting to see so much discussion on the watches that so many like to label as "throw away" . ? Here is my latest Timex repair I began on an M25 movement to be used to build a 1970 Marlin with many NOS parts. What I did not notice until putting on the date ring is that two of the four posts were missing. That was a first for me. So I borrowed two from a M32. Notice the one brass colored on in the bottom left? And there she is all happy and shiny new!1 point

-

I absolutely recommend against beginners working on expensive watches, as too often that doesn't end well. Get a cheapest Chinese 7750 that one can find, once you can take it apart, clean, lubricate and have it running same or better than it came, then it will be time to move to an genuine and valuable piece.1 point

-

1 point

-

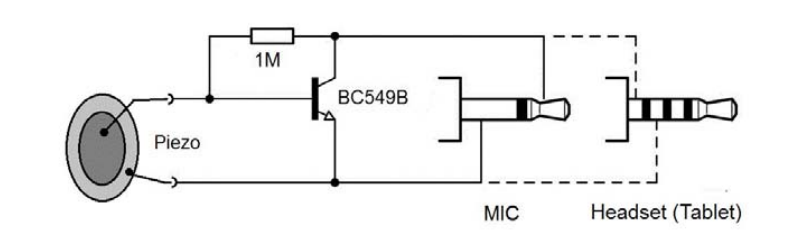

Thanks John for searching the circuit in this loooong thread! Some notes on my simple but proven 1-transistor design: Which transistor depends on your location: BC 549 (a low noise type btw) is more popular in Europe, 2N3904 in US. Generally a transistor produces much less noise than any OP-amplifier. Some mic inputs (4-pole plugs) are quite touchy with switching to the external mic. Though a lower resistor gives slightly higher amplification, it showed that a 1 M resistor gives best performance (switching most inputs). But if you build for your own use, you can try which works best (~ 330 k ... 1 M). Frank Link to PCTM1 point

-

In regards to finding replacement parts in the EU, I have a very good experience with Ernst Westphall(watchparts24.de) and Rudofl Flume( Flume.de)1 point

-

The Valjoux 23 and 72 and their cousins all suffer from weak ratchet wheel teeth. A tooth can break at any time; I am thinking that on the last winding a tooth came off and is now jamming things. The click is just barely visible through a hole to the left of the chrono castle wheel viewed as in the pic if you want to try to let the power down, but it will need full disassembly to get to the ratchet wheel.1 point

-

It's a little hard to describe it. With automatics also it's quite easy to kink the spring just after the bridle too*, but here goes. Get the spring started in the barrel, like the first turn in, as would feel natural (i.e. just do it). From there, you want to manipulate the spring, turning the part out of the barrel around by half turns until that bit will drop in, continuing until the spring is in. The important thing is to not stress the spring. It works with watches because almost inevitably you are working with a low profile barrel, compared to a typical clock for example. So a typical watch barrel might be 11mm inner diameter, spring 1.3 high, a 1:8.5 height to diameter ratio. A clock barrel might be 50mm diameter with a 25mm spring height- 1:2. So with the clock spring to get it out first of all the spring has to twist out of the barrel at an extreme angle, likewise going in, if not using a winder. With a watch spring the angle going out/in is quite small. What some will do, the wrong way, is get it started, and then essentially force the coil in causing it to wrap itself up to the smaller diameter, stressing it. This is when you get a cone shaped spring. * with automatics, the bridle is quite strong compared to the spring. Getting it started in the barrel is tricky, especially getting the last bit of bridle in before it's just mainspring. I would recommend a winder for any automatic if at all possible, or accept that you might put in a bend right after the bridle. Some are worse than others, El Primero springs are a real pain without a winder!1 point

-

Silly old me put the winding ratchet upside down. I checked it with my 12x loupe and the teeth look worn but still acceptable (like the choppers of many of my older patients). I flipped it around and it seems ok now. I didn't take note of the orientation of the wheel when removing it. But when I examined it, I noted that one side had a groove where the rim of the brass washer sits, so I assumed that it must have been caused by wear. So it placed that side facing up. But now when I think about it, it can't be caused by wear because there is no movement between the wheel and the washer. I wonder why Timex put the groove there!1 point

-

Thanks for bailing me out. I had to go do real work for awhile so couldn't look. The diagram I used showed a 1M ohm resistor (Watchuseek link?) and had a wiring diagram for a TRRS plug. Apple swaps the Mic and Ground. The transistor is a BC549b not BC5498. The B looks like an 8 in the grainy pdf. I am an electronics caveman so if I can do it everybody should be able to.1 point

-

1 point

-

1 point

-

1 point

-

Thanks for sharring. I am to a point that I try every solution I get ma hands on. Anything to replace pegging. I feel I die before I can insert anything in so little holes.?1 point

-

You may also want to check your hairspring isn't rubbing on anything. If there is a big overlapping centre wheel (as I think there is on this movement), check that the hairspring isn't hung up on that. Also check the condition of the balance pivots if you didn't before.1 point

-

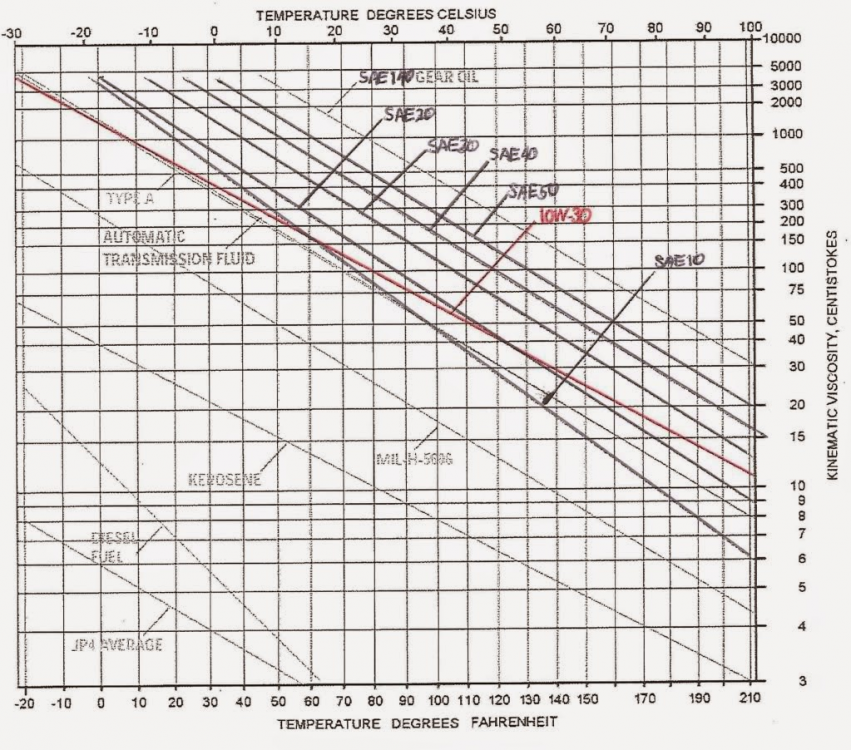

MN-45 oil appears to have characteristics (viscosity) very similar to hydraulic oil (mil-h-5606 for example). https://4.bp.blogspot.com/-mdigmJSSMew/VKGFH6ZJJRI/AAAAAAAAZCQ/phYNso0yLng/s1600/oilviscosity.jpg Another potential supplier of MN-45 oil. https://bora.in.ua/en/ukraine_import/chasovye_masla/mn-45.html1 point

-

They used to make a ton of stuff. I have a Levin machinists square that belonged to my father, is ancient and spot on that I use to this day.1 point

-

МЦ-Н replaced МЦ-3 МН-30 replaced МЗП-6 МН-45 replaced МБП-12 Those in Bold are mineral oils, no longer produced (i believe).1 point

-

Before doing anything proper diagnostics is needed. People are often eager to change things without grasping why things need to be changed. Unfortunately sometimes we don't know why things have occurred because previous watch people have mutilated our watches. To make it easier to understand I'm attaching images snipped out again. Always good when people have decent pictures for diagnostic purposes. This is a bimetallic balance wheel one of the problems with this is if somebody squeezes it the arms are movable. Movable in the term of they get bent. So classically somebody squeezes it the arms are bent in the watch runs fast. Normally need true and calipers and very carefully spinning to look at that but you can usually I ball it and if you grasp what you're doing been the arms back out. You do need to make sure that the little gaps of the both the same size and the both symmetrical otherwise you will have different issues. I suspect the reason why the arm doesn't move is it's been pushed to an extreme and with the hairspring looking the way it does I not sure you want to push it back because your risk damaging the hairspring. The regulating arm is supposed to have friction is not supposed to move effortlessly otherwise it will move all by itself or if the watches bumped gently it may move. I suspect all you need to do is loosen the screws underneath rotated back into the middle tighten the screws back up and it should be fine. Only if it's not fine in the middle in other words it cannot move at all then you can worry about. Or if you want just take it all apart make sure everything is nice and clean no rust for instance but it should work fine without lubrication I think it's just been pushed to the extreme and it's catching on the edge of the bridge.1 point

-

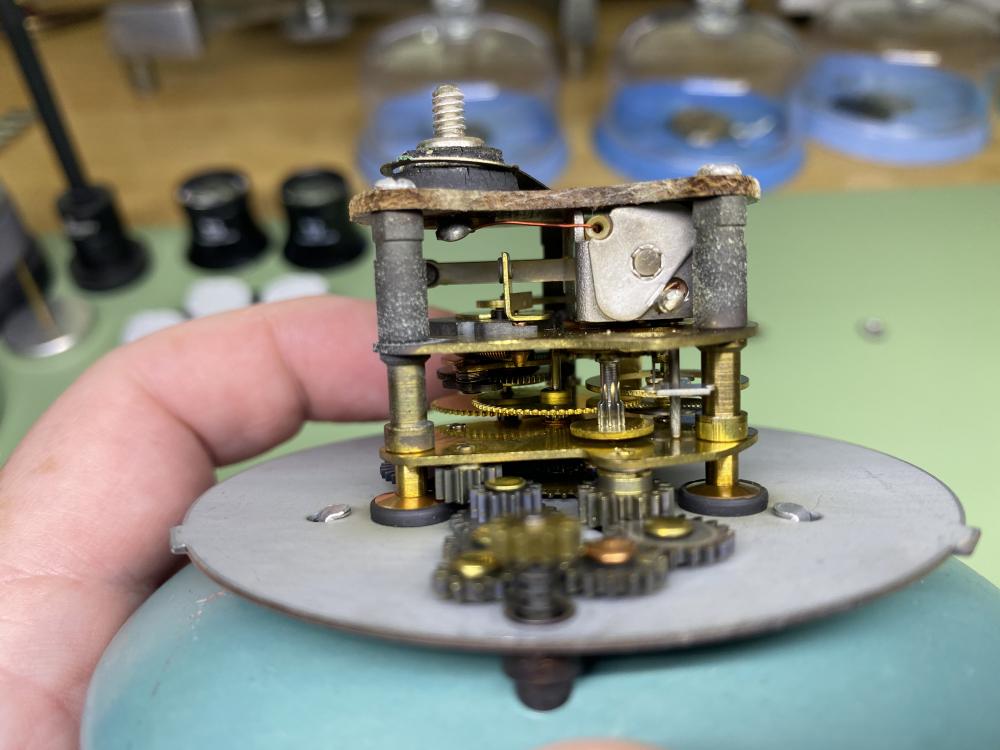

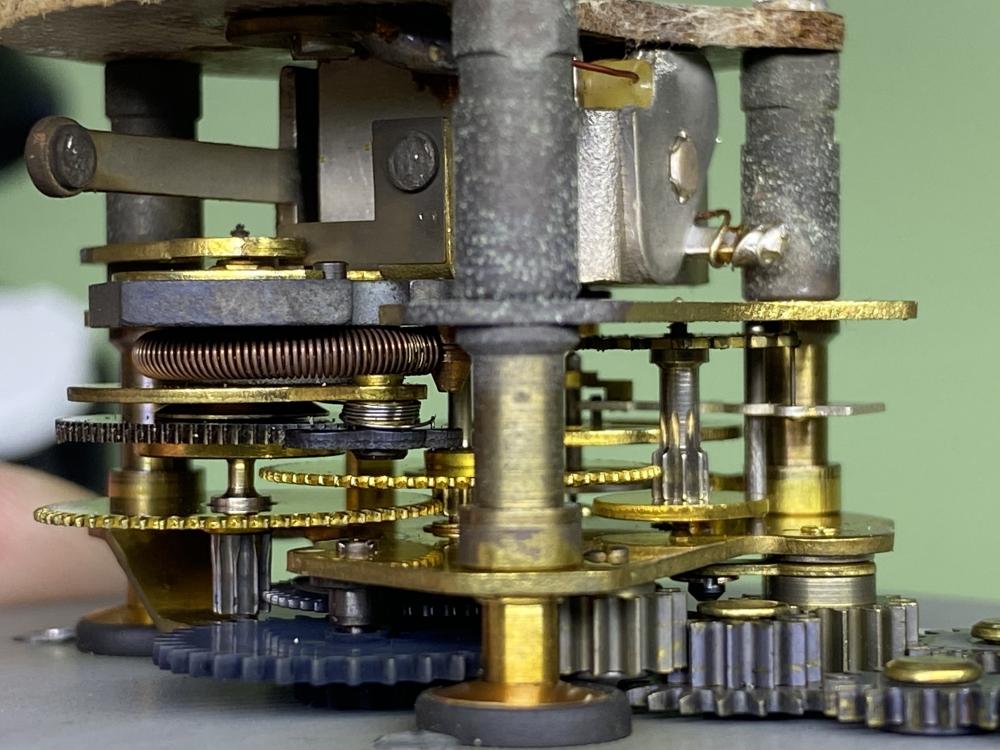

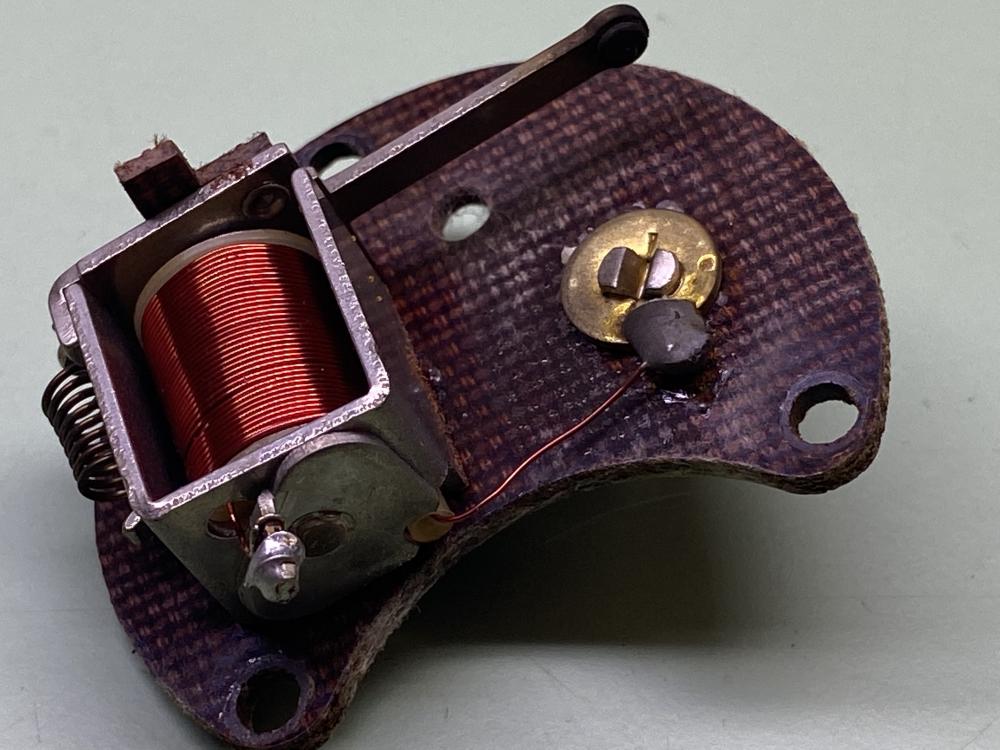

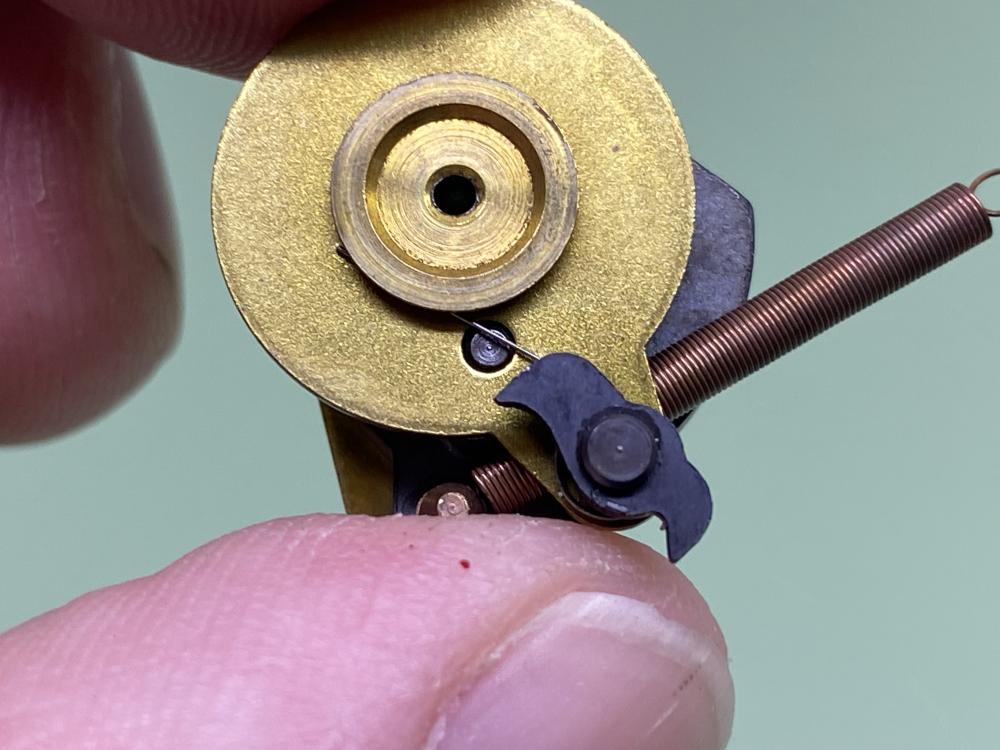

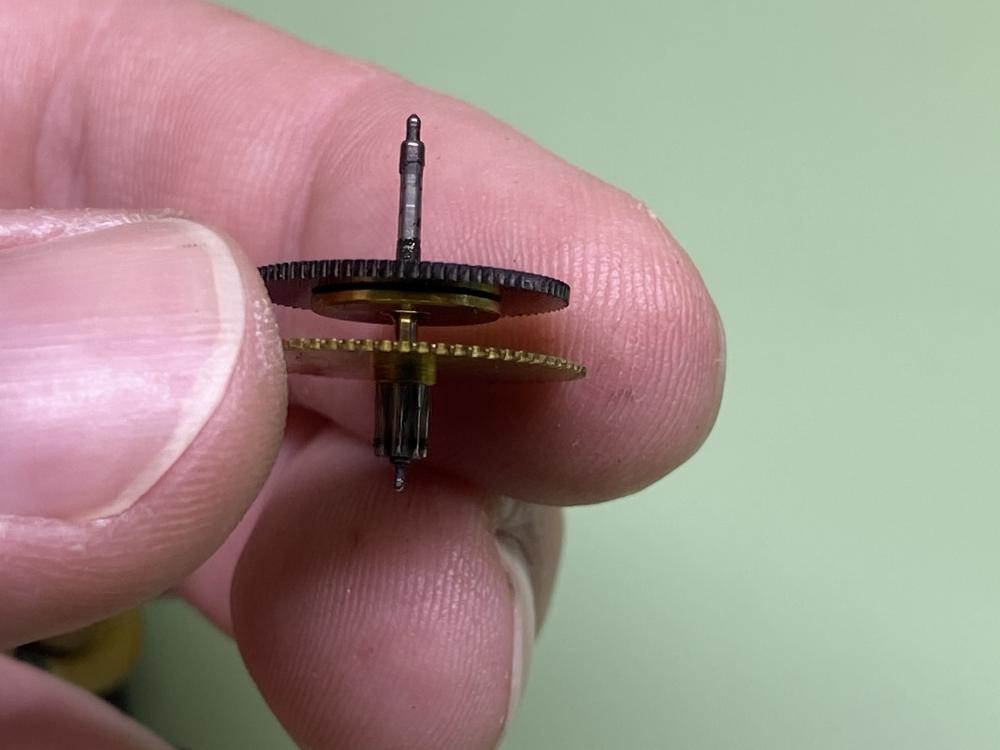

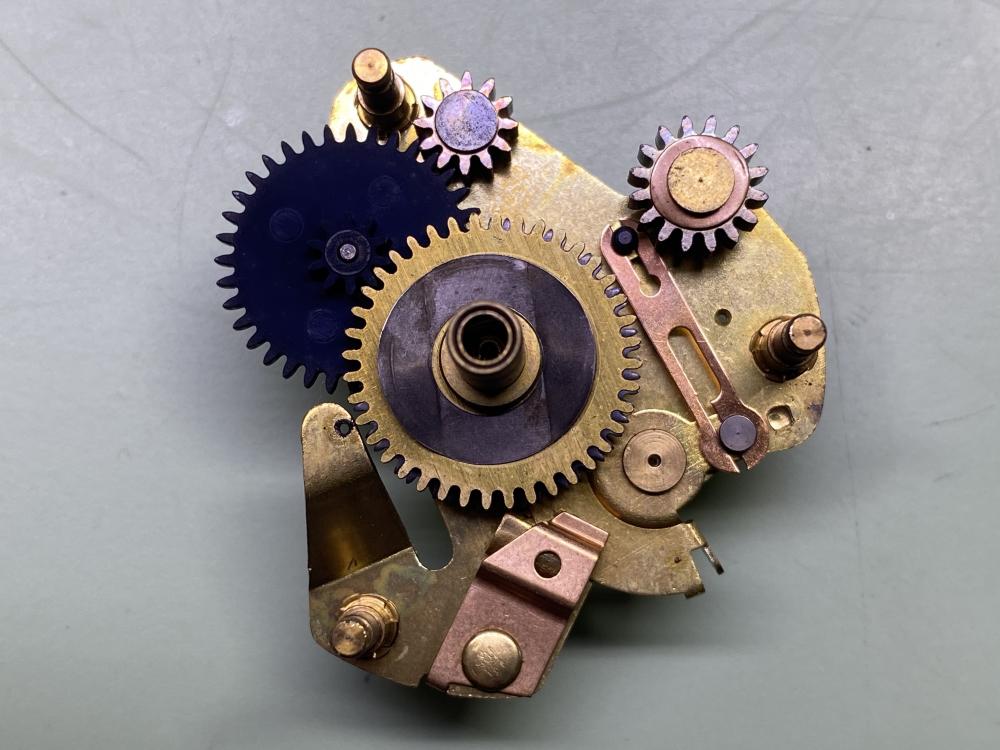

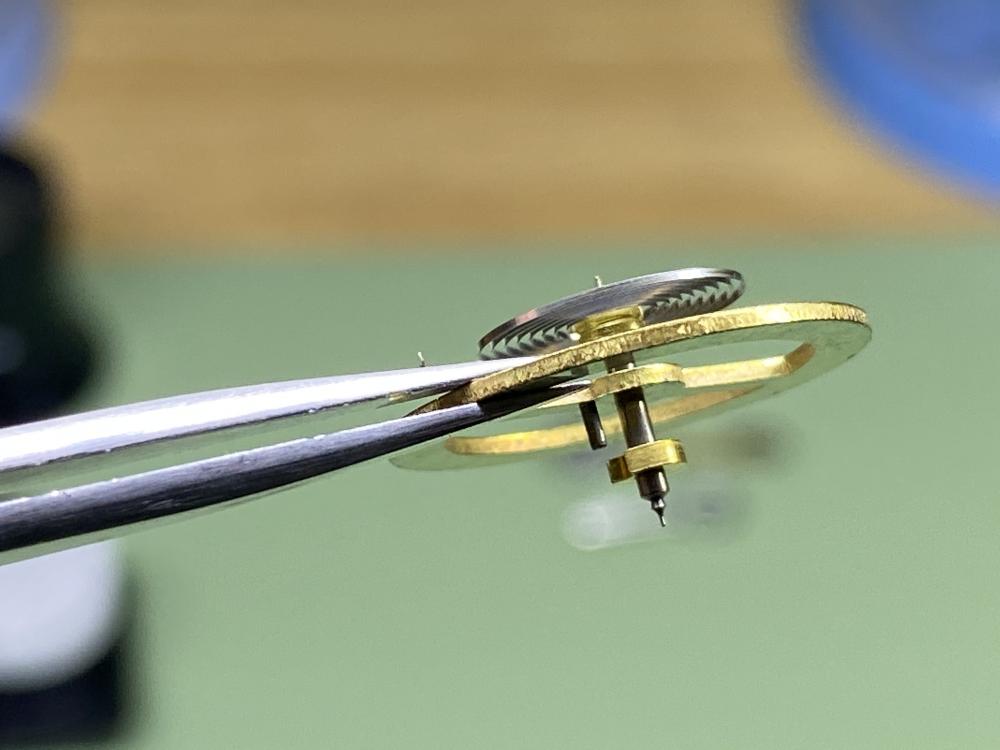

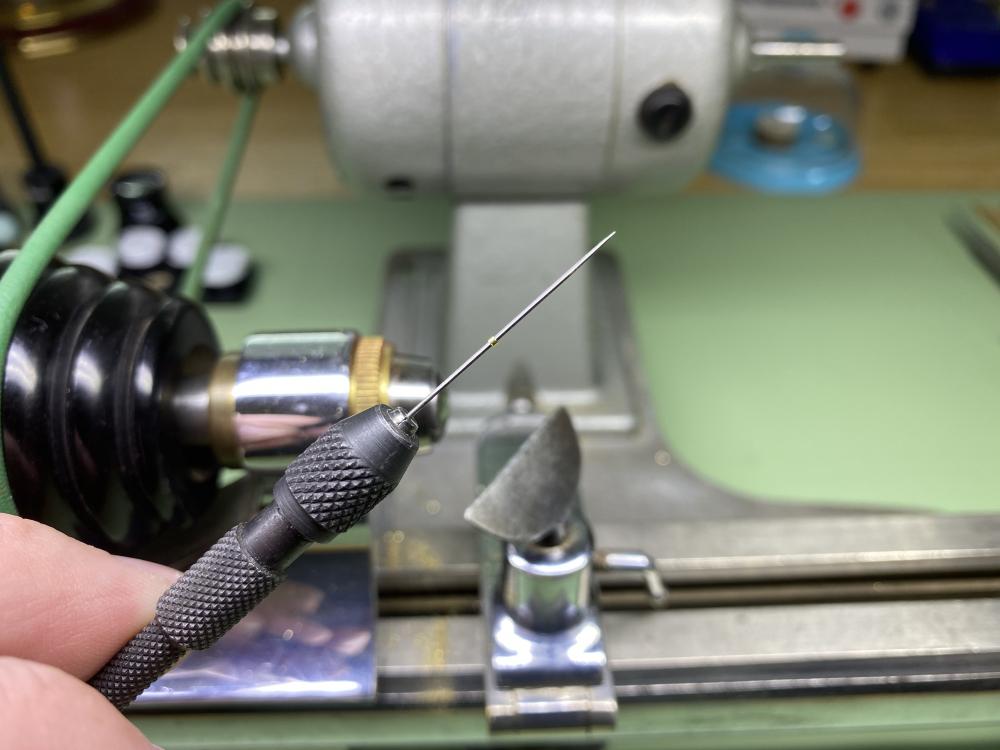

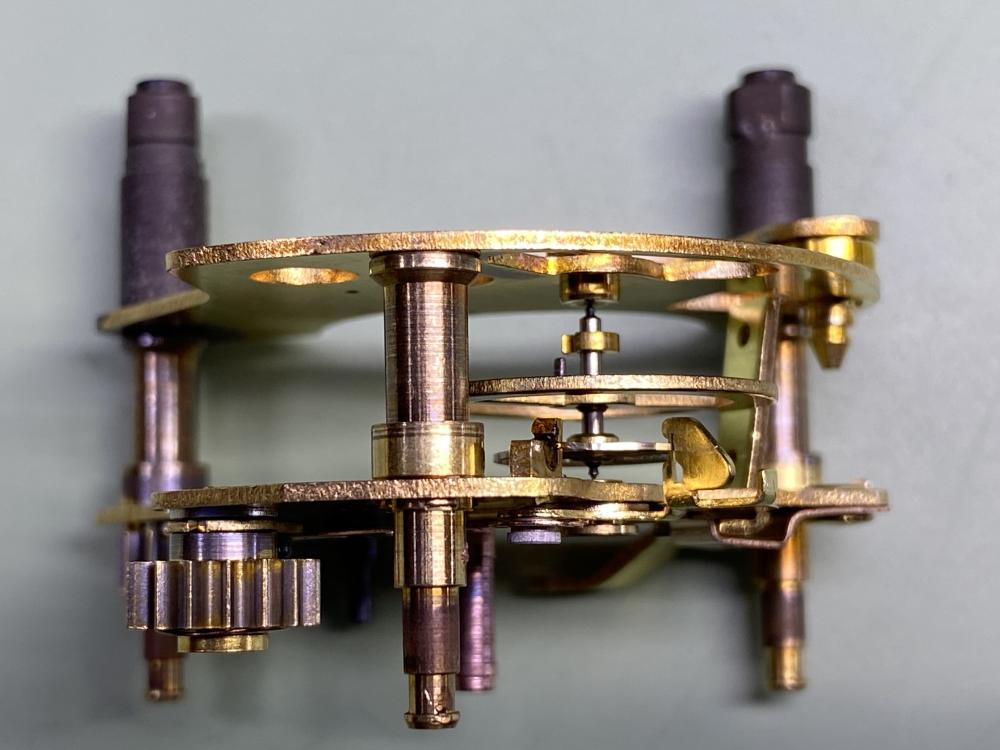

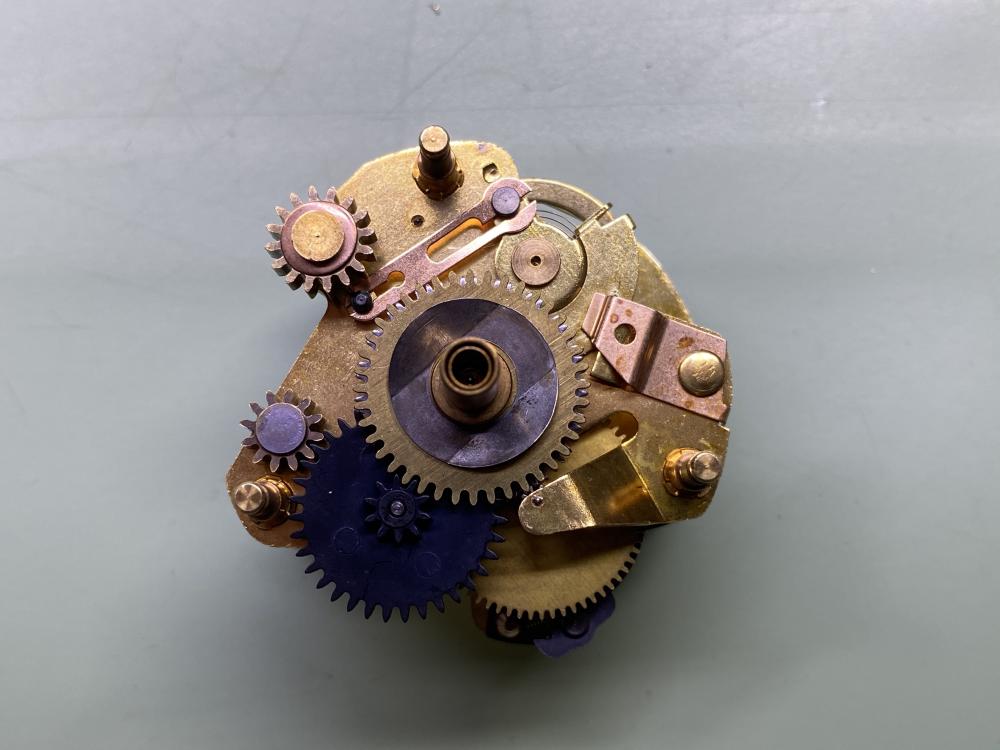

This is the dashboard clock my father pulled from his 1966 Chevrolet El Camino earlier this year. The clock didn't run at all and he asked me to take a look at it. Knowing nothing about automotive clocks I was intrigued and rushed over to pick it up. It's a simple affair with just two hands and a knob to adjust the time. No winding is necessary. On the back of the clock housing is a single 12 volt connection- the housing itself must ground the clock when installed in the dash. Stamped on the rear housing are the words Borg Instruments, Delavan Wis. The housing is removed by bending the three sheet metal tabs that run the circumference of the clock. Inside is a delicious stack of gears and a solenoid which winds the clock. A coil spring serves as the mainspring in this clock and it holds just about two minutes of power in it. When the coil spring is completely relaxed the two electrical contact points come together and are energized via the 12v connection. This causes the solenoid to act snapping the contacts away from each other and putting energy back into the spring. This action repeats itself every two minutes until the car battery is dead. Judging from the YouTube videos I watched before tackling this project- the typical failure point is the electrical contacts which wear out over time and fail to connect when the mainspring winds down. This wasn't the problem in my father's clock though. Most of the bearings in his clock had worn pear shaped and needed to be replaced. I broke down the clock for a good cleaning before turning new bearing on the lathe. The movement only has two jewels (for the balance wheel) so it's not surprising that the bearings would give out eventually. Some of the pivots were worn too and needed cleaning up as well. One of the cool things about this clock is that adjusting the time also regulates the speed of the clock. The setting knob is geared to make adjustment to the regulator and in this way whenever you make an adjustment 9adding or removing time) you are also adjusting the speed of the escapement. Everything was giving a nice scrub before reassembly. I removed the balance wheel in order to clean the plates and the hairspring is attached using shellac. This worried me a little bit but I found a narrow tip on the soldering iron was just perfect for softening the shellac and re-securing the hairspring. In the end I think I replaced five bushings in all. My father and I tested the clock by attaching it to the battery and letting it run for twenty-four hours; we found it to be a couple minutes slow the next day. I made an adjustment to the regulator before final installation in the dash and it seemed to be a bit better. Time will tell if it was a proper repair though. It was a fun little side project. I always assumed those dashboard clocks were entirely electrical but never bothered to considered how they worked. Now I know. ?1 point

.thumb.jpg.d53ce0f3c4d5c8df066632aa41df5585.jpg)

.thumb.jpg.8452edd78767b7b65422e41a8ec3ea5c.jpg)

.thumb.jpg.0a65717d152f927b7fc66447c65487ed.jpg)