Leaderboard

Popular Content

Showing content with the highest reputation on 12/08/20 in all areas

-

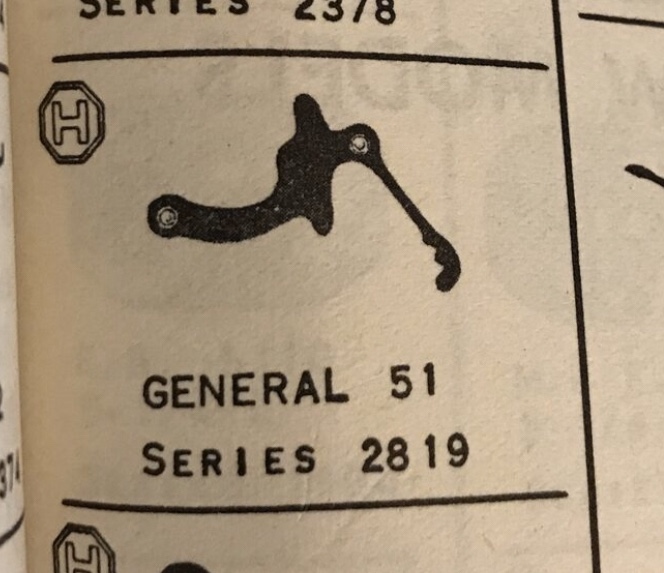

My first step on this process. 1.I tried to draw the best I could the original part to the annealed steel (I used the right thickness from the feeler gauge). To draw the broken part that is missing from the original, I used the drowning from the swartchild watchmaker guide. I actually copy the drawing to the steel. It was quite of challenge to do it but I managed. By posting every step on this process and explaining the best I can to my knowledge, it may benefit someone else on this matter. So I hope you all agree and help on the way with good and constructive advice as you all did here. Once again I would like to thank all for the impressive response to this subject.4 points

-

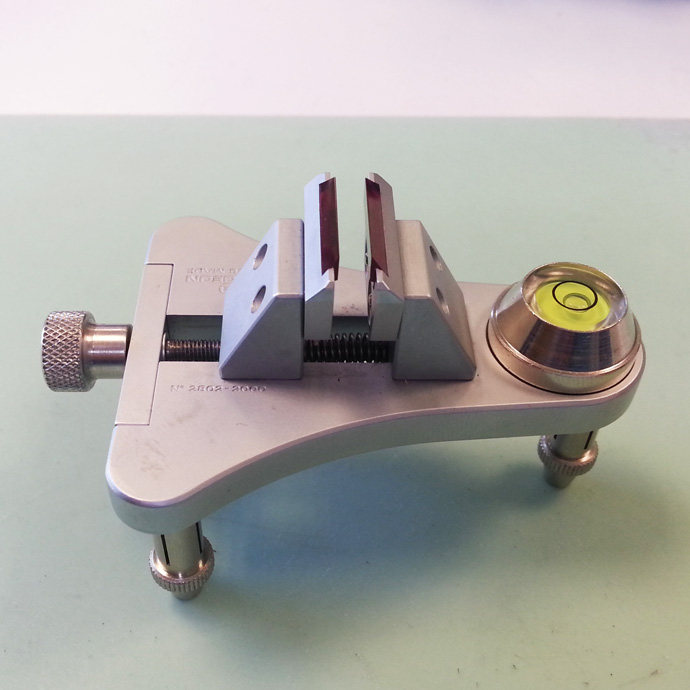

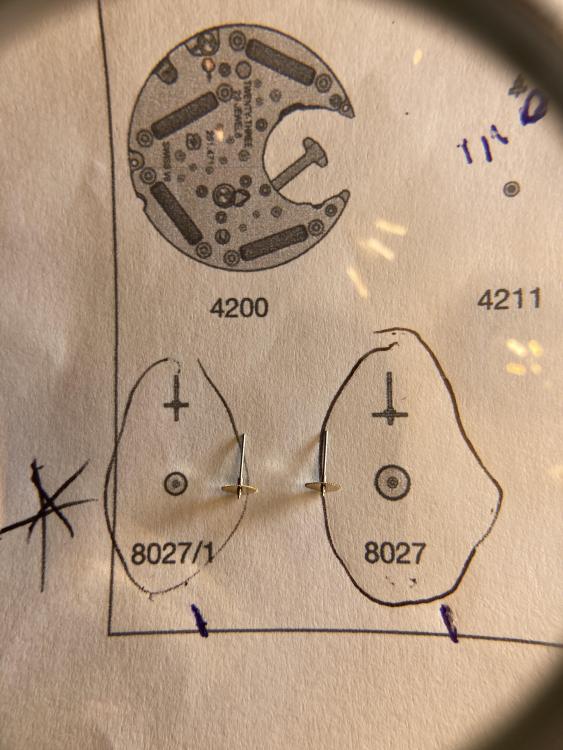

You might remember me literally destroying a Chinese movement on my Loreo Sub homage watch. I also got a Corgeut Seamaster 300 homage with a malfunctioning date complication, with the same movement as the Loreo. So, I contacted Corgeut about the malfunctioning date, and they offered to send me a new movement. I asked for a Miyota 8205, and they agreed. So, great customer support from their part, quite frankly. The movement arrived a few days ago, and I went and replaced it with the Miyota. This time I took all necessary precautions, I got a proper movement holder, new hand setting tools, and a 15x loupe. I also used the dot of rodico on the tip of the hand setter method to set the seconds hand, and it worked like a charm. Now I have a Seamaster 300 homage with a Miyota movement. Success #1. Now, what can I do with the remaining movement? Other than a misaligned date wheel, is a perfectly working and very accurate movement, so I decided to put it on the Loreo. Sadly the dial had a broken hour marker (I applied so much force trying to fit the seconds hand, which was already broken, that the tool slipped and punched the marker away, and fell in the floor, nowhere to be found). So it looks weird, but I was able to put them movement back in, and setting the hands went also very smoothly. So, long story short, both watches are working and ticking very fine. Success #2. The mods are not finalized, though, as the date window on the Loreo is still showing a crooked date for some days of the months, so I purchased a replacement sterile no-date dial with a nice vintage design, kind of a 1958 Rolex. It'll remove the cyclops with a torch and go no-date. It'll have the ghost date position on the crown, but I don't care as I'm looking for the vitage no-date look. You might also notice that the date on the Corgeut is still a bitt off center, and I agree that it might not have been entirely the movement, but the dial itself. They did sent me a new dial and hands, but I decided to reuse the old one, so I might replace the dial and see if that fixes the date issue. In case you are interested, here are some details on the mod:2 points

-

2 points

-

Are they chipped _all over_ ,or just in one area? It takes some effort to chip them, and while I have my gripes with Bergeon their poising tools have always been really nice. You only need a sweet spot of about 5mm to be useful. I have a Levin, humongous ruby jaws, built in level that's spot on. They made a couple of grades, but the german silver ones with ruby jaws are the best I've seen. If you scan Ebay you can find them around 50 bucks, still probably 100 shipped to you, but a seriously nicely made and beautiful tool. Whenever a European watchmaker sees mine they're like "OH MY GOD!".2 points

-

That's a lot of amplitude. I wonder if it has the correct mainspring; the 72 should have a spring 0.14mm thick. I've gotten replacements from suppliers in little packages marked V72 that were 0.15+, and had the watch rebanking. Otherwise, lots of little things can cause a 20 degree difference in amplitude in the horizontal positions. As JDM and Joe say, check your endshakes. If they are excessive you can have things lining up differently enough between the two positions that you get what you're seeing. Another thing that can happen is a microscopic bit of dirt can find its way to the tip of the balance pivot and act like a ball bearing, giving you more amplitude. That is usually a problem with flatter pivots. Then just small variations in pivot shape can have an effect, and cap jewels can look fine until really closely inspected and you find that there is in fact a small bit of wear.2 points

-

Looks like a set of Roller Removal attachments. Very nice to have http://images.yuku.com/image/jpeg/5431665d12db139c18759ea561df2fdc82a6c2d0.jpg https://mb.nawcc.org/threads/first-staking-set-k-d-or-marshall.140672/#lg=post-1092335&slide=0 http://images.yuku.com/image/jpeg/7a61605c1ed9149417f6e2609441787c653136dd.jpg2 points

-

2 points

-

How much endplay there is at the pallet and escape wheel? Between DD and DU even a small change in the area the pallet stones present to the escape teeth can introduce variances.2 points

-

In earlier days, it was often used to help orientate the barrel lid in the same location as parts were hand-finished. But yes, it allows you to pry the cap off. Some barrels are less suitable for pressing the barrel arbor to push the cap off. But that’s still my preferred method.2 points

-

For a long time, I’ve been in the process of learning about poising and considering whether I should try dynamic poising or static posing first. From a practical standpoint each method has advantages and disadvantages. In the end I decide to try static poising first as I wouldn’t have to measure the rate between each adjustment of the balance wheel, and because it felt like it would be safer to drill on the underside of the rim of the balance wheel without the cock, collet, and hairspring in place. So, I got myself a used poising tool privately (no eBay money back guarantee) and the seller assured me the agate stones were flawless. I paid about £100 for the tool which felt like a bargain considering buying this tool from CousinsUK would have costed me approx. £530 including tax and shipping. Once the poising tool arrived, I was thrilled and indeed it looked flawless. So, I cleaned and polished the pivots of my balance spotless and checked that the pivots were perfectly straight and round. If the pivots are bent, oval shaped, have flats, or the wheel itself isn’t true the poising tool basically becomes useless. I then placed the balance on the tool and made sure only the cylindrical sections of the pivots were resting on the edges of the agate stones. However, and without going into detail, the balance didn’t behave like I expected. For example, depending on the rotational speed the wheel could suddenly stop unexpectedly on certain sections of the agate stones. As I said, I perceived the agate stones as being flawless, so I didn’t suspect anything being wrong with the tool, and it really made me scratch my head. To make a long story short I eventually studied the edges of agate stones under my stereo microscope and at 40X magnification and with light coming from the right direction I could ascertain that the edges were indeed chipped. Near impossible to see at 10X magnification and still difficult to see at 40X magnification, but there they were. No wonder the balance would behave completely unpredictably. So, a word of warning; if you buy a poising tool, do not settle for the seller promising that the tool is error free and that the agate stones look flawless. The stones may indeed look flawless even at 10X magnification but could still be chipped. Make sure an acceptable return policy and/or money back guarantee is in place. £100 is quite a bit of money but at least I learned something in the process. BTW, here's a nice article about static poising, and Henry B. Fried has an extensive chapter about "How to poise a balance wheel" in his book "The Watch Repairer's Manual" (2nd edition).1 point

-

Hi All, A not so quick intro, i’ve always loved watches, and anything mechanical really, but normally on a much larger scale, cars, boats, anything R/C, I studied mechanical engineering with automotive design, but never really put it into any practice, but i’ve always got some projects i’m working on, restoring something, an old car, bike, motorcycle etc etc.... never even considered watches as something i could work on... then at the beginning of this second lockdown I found an old Tissot that I bought when I was about 15... (42 now with 3 kids) i loved this watch a wore it for years and it had always been great, very stylish with its square face and leather strap with clasp... i felt really guilty i hadn’t worn it for so long, it had long been put aside for a Rolex i got a bit later and have since grown to love and use all the time, (35mm SS Mechanical Precision Datejust) I felt like I just have to get this Tissot working again, so I put a new battery in it, It worked for a bit then stopped, so i though it needs a service, got a quote of +£300 to sort it and couldn’t believe that, so i thought i’ll do it myself, and my online endeavours brought me to Marks lessons, i’m currently half way through the 3rd course, the Tissot (i find out has got a ETA Quarts Movement 251.471) its currently in a million bits, cleaned it now, lost a few parts, when dismantling ???, but managed to work out what parts and reordered the parts... like a mad jigsaw puzzle, so now im nearly ready to re assemble it, just seems like it was very dirty, i think dirt right down in the motors, pinion within stator i believe, love this watch almost as much as the Rolex... so one way or another i’ll get it running, even if i have to buy a new movement (last resort, and would be cheating, i think) enjoying the silence of being at the desk, parts in front of me and a mechanical challenge... i find it so relaxing, i must be mad really, looking forward to seeing members others projects too, and would love to be able to service my Rolex too, but woun’t attempt that until the Tissot sorted... i recon the Rolex would probably be easy in comparison to what i’ve started, anyhow, my intro has dragged on a bit, i’d love some fundamental lessons on quartz, have been surprised about the lack of info on quartz movements, if anyone could point me in direction of basic info on them/lessons etc that would be fab... Looking forward to working on a few other watches i have, (Post Tissot) and looking at other members projects too... thanks Clark ill try a post a few pics of the tissot and its parts for you to see... i hope you agree it’s a nice looking watch, worthless but of big sentimental value to me...1 point

-

1 point

-

1 point

-

Yep you bet. Had already verified it is a #2720. Already got it and I mic'ed it out and have the correct jewels coming. Hopefully today.1 point

-

Please be careful when ordering Staff or Balance Assy for your Hampden 16S. You need to verify the actual caliber of your Hampden 16S and only then select the proper Staff as you have three options (different length, dia). Otherwise, your new Staff could be too high or too low. https://www.balancestaffs.com/hampden.php1 point

-

1 point

-

1 point

-

With manual wind, you stand a good chance, if you get a decent power reserve, which you can measure with a bench test, you might be happy with 35hrs reserve, the nominal is 41hrs. It can keep accurate time, but expected to fail precision( expected precision is within seconds per day) which is what you have paid for( since Landeron48 is a chrono grade). Precision has to do with good amplitude. The watch is worth a new mainspring. Good luck.1 point

-

There will be no hope, as you do not like the correct answers ... Frank1 point

-

I am with oldhippy's method. But now I know where all the bowl shaped caps come from ? Frank1 point

-

1 point

-

I'm with most above, for clock barrels I'll give a quick smack with a plastic faced hammer on the arbor to pop the cap. Most of the time on watches similar, pressing down on the arbor to pop the cap. But in some cases you really need the slot; on a lot of older high end calibers like JLC 122 you have a situation where the ratchet wheel is part of the barrel arbor, with the hook threaded on to the ratchet. In these cases the slot is usually particularly well designed and a properly fitting screwdriver will get it off with no damage.1 point

-

I would understand if the recommendation was to use an L shaped hook and pull up vertically. But with prying the force is off the axis, makes the lid bind and the most immediate result is dings and frustration. Exactly.1 point

-

1 point

-

1 point

-

one of the things puzzling me with this question is I had seen within the last year explaining what the notch was for. So looking at the usual books there is no mention? But I looked in one more source that's the Chicago school of watchmaking you can get the PDFs off of eBay. Sure enough in the mainspring barrel section it says the notch is for prying with a screwdriver. That's not normally the method I would use and any time I tried its definitely not the method I recommend. I'm the skip over how I know this one perhaps it's really for the opposite? If you get carried away with your mainspring lubrication it leaks out the hole and gets all over everyplace.1 point

-

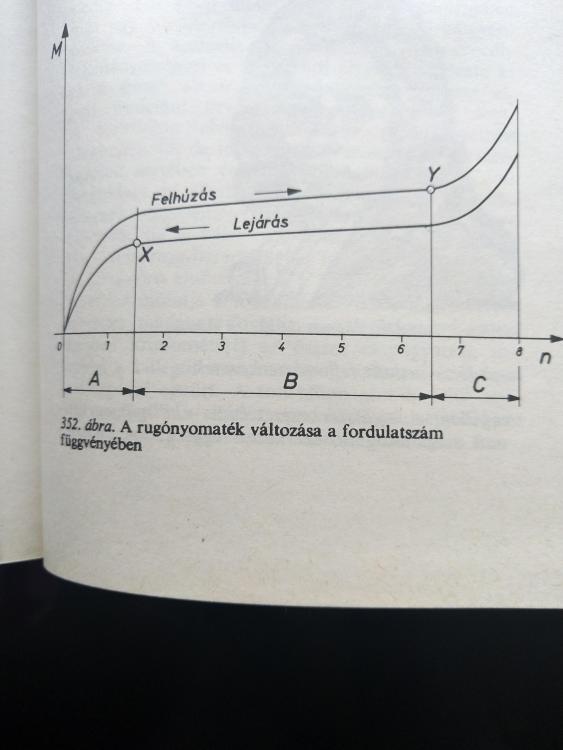

That Maltese cross helps to keep the torque in the section B. (i took the picture from one of my book written in Hungarian). This cross is also used in music boxes to help the tune so it would be not too fast and not too slow. Mine is obviously not adjusted well, because it is too fast at the beginning and stops before the cross could stop it.1 point

-

Ha Ha Ha I'm quite sure. My two kittens Freddie & Buster might like as a toy.1 point

-

If there are no micro cracks in the acrylic, then polishing the crystal using Duraglit wadding usually restores them to near perfect condition......1 point

-

You can probably find the exact Sternkreuz crystal you need searching by the Seiko model number in this page: https://www.cousinsuk.com/category/filter/seiko-case-parts I will probably be a XAC crystal (XAC for steel ring, XAG for golden ring)1 point

-

I have a nice Marshall set. But no staff remover. Something to keep my eye out for. Thanks for the info. Appreciate it. I have some new balance staff jewels coming in for a Hampden job I'm doing. I'll probably email you about it tomorrow.1 point

-

and in case you need some parts for Seiko 7009A: https://www.cousinsuk.com/category/filter/seiko-movement-parts https://www.cousinsuk.com/category/seiko1 point

-

1 point

-

I could be wrong, but all you need is Tension (Armoured) Ring - Standard Ring - Chrome Colour - Sternkreuz ATC https://www.cousinsuk.com/product/standard-chrome-ringed-glass-atc1 point

-

Ok, found it here: great demonstration: https://adjustingvintagewatches.com/how-to-replace-a-balance-staff-part-2/1 point

-

Once the roller is supported you take appropriate punch to force the staff out. Let me search for Roller Removal video, but the thing is that Staff Removal is the next step, right? I recommend getting K&D staking tool set #18 with Roller Removal and Staff Remover attachments.1 point

-

Some Seiko movements that I serviced were just under 2mm in height in very slim watch cases. Thus, I would not get any similar movements if they were even slightly thicker. Those movements did not have Sec Hand, just an Hour & Minute. 1.10mm & 0.65mm sounds about right, but I don't remember.1 point

-

Made one of my own. My remaining pieces of 1/4 inch brass were narrow so I had to adjust the measurements a tad. But it functions very nicely. I like that it supports the wheel at a predetermined distance and does not allow the hairspring to hyper-extend. A nice tool in theory, and I plan to put it into practice and judge how often I use it and how it performs. Thanks for all these replies to my query, folks. You have given me the more thorough discussions I was seeking.1 point

-

How about shakes on staff, fork and escape arbours? Are there any end stones on escape arbour?1 point

-

1 point

-

According to my mentor, it's to remove the barrel lid - I suppose by prying in some way. But the only time I tried that on a desk clock, both for the mainspring and alarm barrel, it was clear that would have not worked and just ruined the lid. So I simply pressed on the arbor and removed the lid without any problem. Another possibility is that it's for lubrication?1 point

-

Yes that tool just needs a little oil to work. Abrasives would only damage it.1 point

-

1 point

-

I suppose it's time to add our little Reeces into the mix here. Reeces was once an unwilling outdoor cat who was left behind by former owners. We took her in, and took care of her vaccinations and her ear mites and fleas, and helped her wounds heal from what was dealt her by other cats. Her favorite place to nap is on our down-filled velvet comforter on our bed. She's a little "nurse cat", in that if she perceives you are unwell she will lead you to the bedroom and meow at you until you climb in bed, then she will curl up upon you and purr until you fall asleep. Or if you get sick in the bathroom, she'll lead another person to you to check on you. You can't be secretly sick here. She has never climbed onto my work bench. One time I saw her considering it, so I gently turned her towards me and looked her in the eye and said in my most serious voice "You must NOT!" She looked back with wide eyes, and seemed to actually understand. And never went up there, even to this day. (That, and she finds the windowsill more interesting anyway.) I've cleaned a lot of odd stuff out of old watches, but so far I've never had to remove one of her hairs. She's a good little cat.1 point