Leaderboard

Popular Content

Showing content with the highest reputation on 10/05/20 in Posts

-

The burnisher removes a small amount of material. But that is not it’s purpose. It’s purpose is two-fold. It folds over the surface grains of metal which makes them smooth and achieve a polish. So this helps to reduce friction. Secondly, the process hardens the surface of the metal which in theory may improve longevity.4 points

-

I always find it interesting with American pocket watches the quantity of answers sometimes seems to be lacking. A lot of your answers will depend upon things that we don't have a lot of control over like you want to do this repair now or 50 years ago? it's hard to tell from the picture whether the jewel is in a setting and whether it comes out. But if you look in one of the Elgin parts books like the 1915 catalog they have descriptions. just in case you out of the parts catalog I snipped out some relative information. so it appears to be it's in a setting but if you attempt to push it out the setting doesn't pop out then you might make the assumption that it's not in a setting. then I have a link below you can enter in your grade number and get the parts list. you'll notice there are two separate fourth wheel jewels and you need the serial number figure out which one you need. now the reference I made of when you should repairing your watch is mainly a reference to if this was 50 or 100 years ago or whatever they made the watch the material house supplier would have the parts or they could just order them from Elgin as Elgin had a really nice spare parts department but it's been closed since the 70s. Then even if was open on not sure if it would still have pocket watch parts. So this mean getting a replacement fourth wheel jewel setting is probably going to be an issue. so that gives you the options of bordering or finding a replacement jewel. Removing the current jewel which is probably burnished in. Ideally you should have a proper shaped jewel to replace and specifically by shape burnished in jewels have rounded outer edges of the burnishing will have some place to go. Modern jewels have smooth shoulders. This means you have to modify the jewel itself so they can be properly burnished in although people will try to burnishing modern jewels with limited degrees of success. Or if there's enough room in the setting you can ream it out and fit in a modern plate jewel. but oftentimes jewels in settings don't really have enough room to get a modern jewel in. http://www.elginwatchparts.com/2 points

-

Well, the case is marked with marks I've seen before; there's some definite gold content. At a guess, at least 14k. But I think more than that. And 15 jewels are nothing to sneeze at. Standard compensating screw balance, but the regulator also has the fine-tuning setup. And it has a very pretty dial also. And you tell us it's running great into the bargain. Yeah, man! You did better than great. That's a steal for $30! Where are these yard sales you go to?!?!? Holy smokes, man! I haven't been that lucky in an age and a half!2 points

-

Adapting the Taig milling slide to gain 5mm travel on the bottom. That will allow milling bigger parts, like 50mm (wow) V-slot blocks for the vise and press drill. To hold it I had to drill and tap the faceplate, which was an easy job as it's made of mild steel. The single pass Chinese set worked well with the help of a micro tapping guide on the press drill. Then for a bit more facing work I beveled some 304 steel nuts. The lathe didn't made a fuss and I got to use the cute compound slide. I have a long list of projects all in line with the above, tools to make tools to make tools.1 point

-

I should be grateful for assistance in identifying a pocket watch movement that I am currently working on. I recovered the movement form a friend's toolbox, it was uncased. The dial has Roman numerals, but no makers name or any other information. The plate over the barrel has the word, BREVET, which I understand is French for patent. It also has a capital M stamped on the same plate. The words AVANCE, RETARD and ANTI MAGNETIQUE, further indicate that it was manufactured in a French speaking country. The dial side of the movement bears the number 6804.1 point

-

Looks good to me. If it keeps good time on the wrist then I’d say job done.1 point

-

Hi! This happens sometimes. You need to reinsert diagonally one leg at a time very carefully. Under magnification works best. I would personally do this with fine tweezers, not actually holding the spring, but working the ends in carefully as it rests on the Incabloc.1 point

-

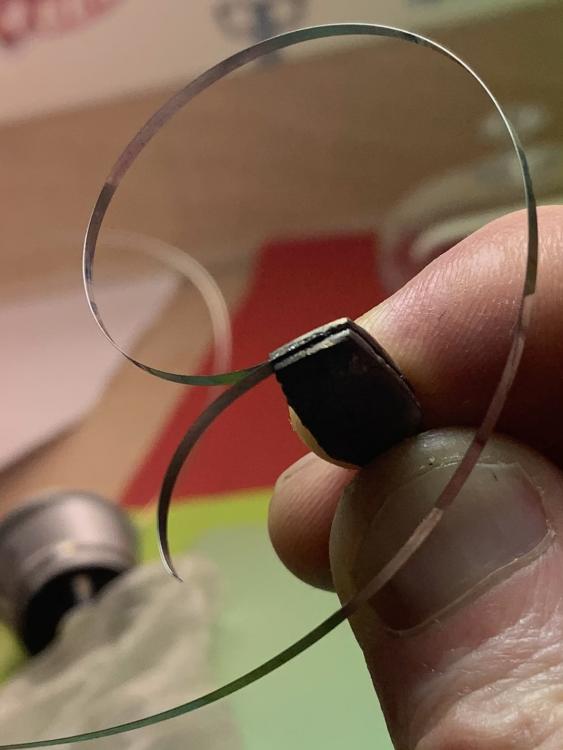

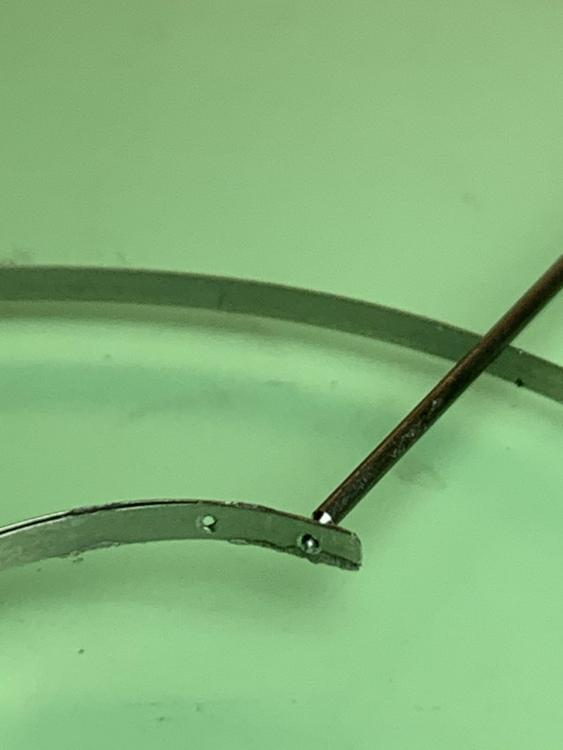

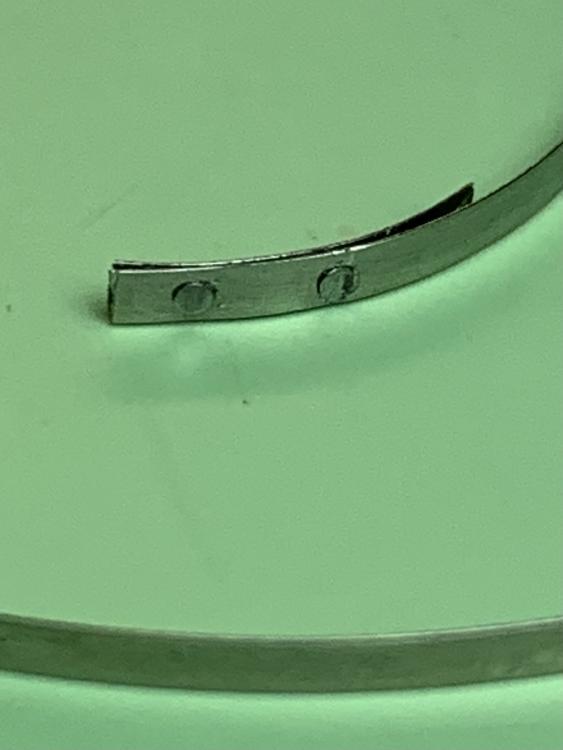

Purchased an automatic mainspring instead of a manual from Cousins. A bit pee’ed off at my mistake, so tried the repair. Any tips or advice from the experts will be gladly received on how to improve the process (if there will be a next time) The photos are pretty self explanatory to the process I tried. I used superglue to hold the 2 pieces in place before drilling and riveting, then will acetone it all away at the end. (For some reason the last photo should be the first photo)1 point

-

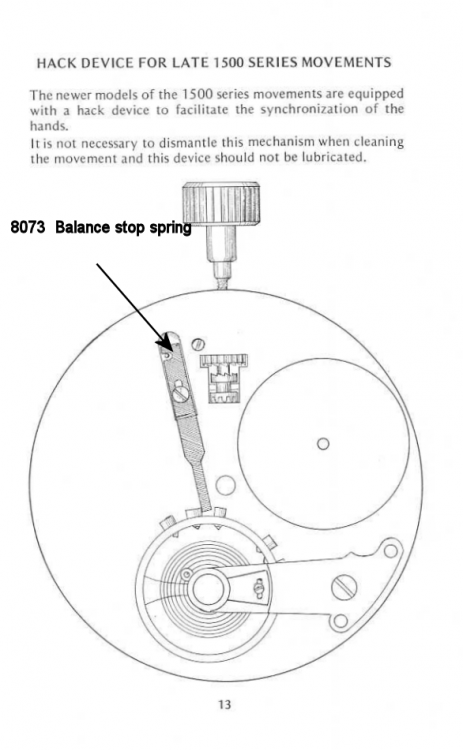

Correct. I usually work on the older versions, which do not hack. be sure it is clean and dry, and installed right-side up. It should slide in and out with the stem. Test that before assembling further.1 point

-

1 point

-

1 point

-

Industry standard of end-shake is between 0.02 mm to 0.06 mm, so I believe1 point

-

thanks to all.there are actually SIX different stems on cousins if you put in eb 8800 and search all! eg.male inner /outer female inner/outer one at tap 120 (12?) and the one i now know i need. Very confusing!B.1 point

-

I have a link below that you might find helpful. Scroll down until you get to Joseph School of Watch Making. Then you want to download unit four. at the bottom of PDF page 7 you going to find something of interest. notice there is a reference to the shape because the shape of the curvature of the burnisher has to correspond the shape of your pivot. Then notice and they follow up with a reference to refinishing. Unfortunately just because something is called a burnisher doesn't mean there is a universal standard of what the finish should be. I've noticed they range from being very course to basically shiny smooth. Elgin watch company made a sapphire burnisher one and was slightly frosted and the other was really really smooth and shiny. then with your nifty new tool at find something to practice with before jumping in with a good watch. It's an interesting tool to learn how to use and requires a lot of practice if you want to be good with it. But if you know what you're doing you can produce some incredibly beautiful finish on the pivot. https://mybulova.com/vintage-bulova-catalogs1 point

-

It depends how much metal is taken off. The more taken off, the more side-shake you will have. 5 degrees of play from vertical is optimal side-shake. Much more than 5 degrees and you will need to think about another jewel with a hole to suit the new sized pivot.1 point

-

Hi https://www.cousinsuk.com/category/poljot-movement-parts....... http://moscowwatch.com/index.php?categoryID=585 Probably Jules Borel Esslingers Timesavers in the states.1 point

-

If you want clean pivots then clean the pivots. If you have pivots that have wear, then removing metal is the only way to restore them*, and the very best way to do that is the Jacot tool. *to the point of removing the whole pivot i.e. repivotiong, but that's another subject1 point

-

The Vallorbe tool is good but for watch work I'd stick with the Bergeon. The Bergeon is tungsten carbide vs hard steel on the Vallorbe, and the Vallorbe has a larger radius for conical pivots that doesn't work well on small watch sizes. With all commercially made burnishers to be used on a Jacot tool you want a "left hand" tool for holding with your right hand. This is because they are often used with the part in the lathe and the burnisher held under the part, which inverts it.1 point

-

The Bergeon you linked is the standard tool. It has a grained surface which acts as a micro file. Oddly if you hold it in your right hand you want the "G" model (gauche or left). One side is for conical pivots the other for straight shouldered pivots. Like Rodabod said it does remove metal, slowly, while compressing it. For example I tend to leave balance pivots 0.01 or 0.02mm oversize before going in the jacot, a 0.09mm pivot will reduce to 0.07 in about 30 seconds. A larger pivot, say 0.30mm, would take more time to reduce in size.1 point

-

I have seen a method in an old book where the end of the spring is annealed then folded over and hammered flat. I tried it on a broken spring that I had but it snapped everytime. Maybe my spring was already fatigued or the steel in the old days was different.1 point

-

Sorry not solid gold, but 'gold filled', see HERE for more information....1 point

-

It's the tap size that's different as @Stuart2says. You probably want the normal tap 9. I can tell you the Ronda number for the stem is 1296. What's interesting is that if you look up via this number on Cousins it's three pounds more for a pack of three!1 point

-

Use to do both. I use the more coarse one to bring the pivot close to size and the more fine one to complete the pivot as was noted by the other comment. Watch this video of mine. I used the double sided burnisher. Making a Complete Pocket Watch Balance Staff - Video Mirrored, Sorry Sent from my iPhone using Tapatalk Pro1 point

-

Hi Bernie Dr Ranfft quotes the stem for the EB 8800 as W2975. If you haven't got the tech sheet I have attached it. Stem P/no 401 2849_EB 8800etc (2).pdf1 point

-

Hi, i went on cousins and only found 2 for that movement, it maybe that they have different tap sizes for the crown or they are different lengths you could try emailing them to see if they can help.1 point

-

1 point

-

There is an advantage In larger multi meters. They tend to stay where you put them,and their larger parts tend to break less.Once upon a time I used a Simpson 260. It was tough and accurate and did not move with every wiggle of the leads.I was a young marine at the time,and from experience I can tell you the Simpson is as jarhead proof as it gets.1 point

-

For Seiko with a ready tool I recommend Anchor drivers, cheap as chips, good blades with spares, they served me well for years. The "upgraded" to some Chinese with a thinner body, which one may like or not. In fact one needs a minimum of two sets anway.1 point

-

1 point

-

This is specially problematic when you come across a real small and somewhat rusted screw with worn slit, usually screw head pops off or one side of the slit breaks. I got a cheap set with replacable flat blade driver, and collect broken sewing machine needles( real strong) dress a bunch of needles to different sizes. I also soak old pieces in coca-cola for 48 hrs, which eliminate the chance of breaking screws. Safe removal of old screws is rewarding and worth all the work, certainly beats having to extract broken screws.1 point

-

Thank you for the walkthru. It will help me too. It is an amazingly beautiful movement. I was fortunate to have a colleague entrust me with one for service. You can really see and feel the quality and thought that has gone into making this movement. I, like John I think, would be really grateful if you could post servicethe service docs should you have them. Thanks.1 point

-

1 point

-

I've got a stupid question. Has anybody tried using Loctite? I've used a staking tool to drift metal to close a loose hand on a pocketwatch before. But that left a lot of dimples in the metal. Luckily it was the hour hand and the minute hand hides the defect.1 point

-

1 point

-

1 point

.thumb.jpg.8933b2cd35cd912c18deac136c16c5e4.jpg)