Leaderboard

Popular Content

Showing content with the highest reputation on 08/11/20 in all areas

-

Bicycles are another fixation of mine. I like to work on them almost as much as I do watches. I tend to make my tools and skills available to the neighborhood kids who nedd work done on their bikes. I also always wanted an early motorbike, like from the 'teens to early twenties. Being tremendously expensive though, I had to find another way. So I built one. This here is "Tempus" (because time flies). It has the frame of a 1948 JC Higgins balloon-tire cruiser, to which I bolted a 50 cc two-stroke engine. I fabricated the tank, the headlamp (which is actually electric) the clutch lever, and a number of other little parts. It has a leather saddle and a little leather-covered trunk. It's not very fast, maybe 30 mph tops, but for in-town it does very well. And it's almost theft proof, in that nobody has anything vaguely like it for miles around.2 points

-

Hello everyone, I'm John, new to this group and new to the watch repair hobby. I got into this when I decided to replace my old quartz watch. One YouTube rabbit hole lead to another, and now I'm obsessed. I've taken Mark's course and practiced stripping and reassembling. Made a few mistakes with old Russian movements (hairspring adjustment is tough!) but learning slowly. Currently trying to rehabilitate an Elgin and a Bulova, both from the 40s/50s. I have recently learned the ubiquity of bent and broken balance staff pivots on non-shock-protected watches. Currently trying to seek out some donors, as I'm not yet equipped (with tools or knowledge) to attempt replacing a balance staff. Looking forward to getting advice and learning from everyone's experience. All the best, John1 point

-

1 point

-

This appears to be a similar product : https://www.cousinsuk.com/product/liquid-protection?code=V49991 Or Boley sell this one https://www.boley.de/en/shop/3118.protection-lacquer/1838282485.protective-lacquer1 point

-

If you remove screws they need to be in pairs, directly opposite each other, not here and there. Otherwise you might get close to whatever bbh it should be, but will have a positional error in the hundreds of seconds.1 point

-

Have you looked at the documents posted above? in your picture at least the winding click is missing. You need to fully understand the working of parts and their ensemble, otherwise you won't be able to diagnose faults.1 point

-

The case screws are 1mm thread. Are you putting new threaded holes in different locations or have messed up thread and want to retap them?1 point

-

There's not a lot of information on Sonora out there but it was a brand name registered by Complication S.A. in 1953 in Switzerland. I would say that your watch is more 1970's in design. If it has Incabloc shock protection then it is unlikely to be a pin pallet movement inside. More likely to be a fully jewelled movement, possibly something like an AS1950/51 or similar, however a pic of the movement would help, and better still a close look at the main plate under the balance wheel. As for re-casing it you have two options. 1. Find any case that appeals and is physically large enough to accommodate it, and then make up what ever spacers are needed to make it actually fit. 2. Find a donor watch that has a case you like and uses the same movement and dial size as yours and swap it out. But for that a positive movement ID would help.1 point

-

That's a very confusing model number. FE 255 suggests that it's made by France Ebauche and that it's a Cal.255 (if there is such a thing). However it isn't, which could cause you issues if you need to get parts for it. It is in fact an ETA movement, I think 23xx family. You may find a number on the main plate underneath the balance wheel that would identify it exactly. As @Nucejoe says, it's the screw closest to the stem.1 point

-

good show. there ar a lot of "panel clocks" posts on this forum. check the gallery. vin1 point

-

I have read the ISO 3159 criterion and I must say they are rather lax and probably developed when inferior material was still in wide use. If you look at either extremes of the requirements for temperature they aren't actually that extreme at all. The temperature range basically amounts to a moderately chilly Fall/Autumn day and a hot Summer day here in New York. Most alloys used in modern movements would perform to these standards with very little problems. The actual practical advantages of the different alloys employed by ETA are nebulous at best. Nobody in the public knows the quantifiable value that these bring to the table. Outside of buzzwords ETA won't say by how much these actually help. It might just be marketing gimmick or give them just the slightest of edge when it comes to submitting mass produced movements for COSC certification. In a blind test I doubt anybody can with confidence tell the difference. I have stated elsewhere that you can't call a movement "chronometer" unless it's been submitted for testing by an organization, but if you just want to make a movement that run at "chronometer" specs, it wouldn't take swapping parts and upgrading alloys to achieve in most cases with half decent modern movements.1 point

-

If you're going with the example in the link it does come fully equipped to take a day wheel with exception of the washer that ETA lists as "indicator distance piece". Your LeJour should have it. It's a little silver washer that sits on top of the day wheel so do keep in mind to transfer this part over. 7750 and derivatives should all be the same size with the exception of the Valgranges line (wider diameter) and that alarm-equipped one that Fortis modified that added considerable height.1 point

-

Hi attached is the tech sheets for the 7750. cheers 3653_ValJoux 7750 Pages 1-3.pdf 3654_ValJoux 7750 Pages 4-7.pdf 3655_ValJoux 7750 Pages 8-13.pdf 3656_ValJoux 7750 Pages 14-18.pdf1 point

-

1 point

-

Impressive artistic impression in your presentation already. Should not underestimate your aptitute handling tasks as you do, no doubt on your way to acheiving masterhood. Best wishes.1 point

-

That's awesome! I'm going to try that on some of my scrap bin parts and so how it goes. I've already got everything on hand except for the denatured alcohol. I'll have to pick some up on my next run to town. All of what we have now is "good natured alcohol".1 point

-

Not strictly correct. It is indeed the impulse jewel that knocks the pallet out of lock, however once the escape wheel tooth is sliding down the impulse face of the pallet stone it is the pallet that is accelerating the impulse jewel. So both pallet and impulse jewel take it in turns to make each other move.1 point

-

The roller table looks to be out of position, the roller jewel is normally at 90 degrees to the arms. Add to that the hairspring is likely not correctly positioned I agree that you are way out of beat.1 point

-

The simpler explanation is that you're installing with the impulse pin outside of the horns. Depending on the mov't you can actually see if that is the case. When it happens like that, leave the cock screw lose, and lift the balance so slightly that it can fell within the horns. Assuming there is at least some power it will start beating right away. Just a passing note, it is said impulse jewel that makes the pallet move, not vice-versa.1 point

-

Mark has a video on youtube teaching this, Google; How to align a hairspring so the watch is in beat. Good luck.1 point

-

I suspect it is a mile out of beat. I sugest you remove the balance & the pallet folk & re-install the balance & check where the impulse jewel is in relation to the banking pins. It should settle in the middle when it stops oscillating.1 point

-

You need a copy of the tech manual for the 7750. There are many floating around. This will tell you what you are missing and how to put the assembly in. I have added several day comps to 7750s......its quite easy. As far as swapping movements it probably comes down to the fitment ie the watch movement ring. From what youve described it may be a fairy 1 to 1 swap. If im understanding you correctly youre gonna have a dial with a missing slot or vice versa. If you pm me your email I will send you the tech manuals. The 7750 is the one I specialize in......or rather its the one I started out working on and have spent the most time with. Sent from my SM-G950U using Tapatalk1 point

-

Here again 9ne of the most recurrent Seiko questions How do you know with certainty that movt' wont be acceptable without replacing the mainspring? Facts are, first these are quality mainspring and can easily last 50 or more years, and then a brand new NH36 with manual winding and hacking is like 5 or 10 euro more than a complete barrel, or an (imperfect) replacement GR mainspring.1 point

-

1 point

-

To answer the original question - the ring is to put the handle into to protect it so you don't press the plunger accidentally while fooling with the spring. You can sit the handle into it so you can work on the with the handle upright and the plunger protected.1 point

-

The bezel ring and the crown looks like they been gold plated but the rest of the case looks suspiciously like an alloy, maybe brass. You probably can see what the case are made of by popping the case back off and there Longines usually have the data stamped, must say I never seen that case style on an 817 before either. Anyhow think the polishing cloth @Rocket suggests is the way to go with softer metals.1 point

-

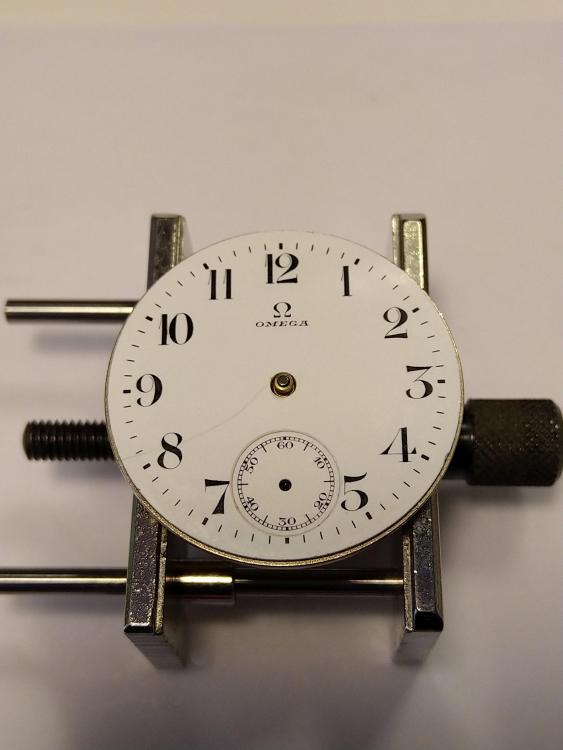

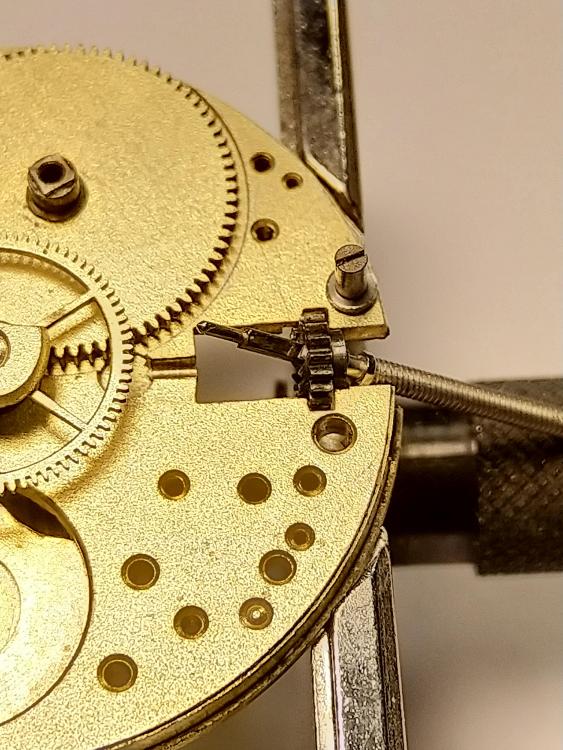

Last night I didn't really feel like watching some Netflix series so I silently returned to the watch workshop. Blind folded from some previous activities I stretched my arm into the box containing not so urgent fix watches/movements. Today the lucky turn had come to a nice little ladies Omega 13”’ movement, it passed its 100 year anniversary so I think it is time for a nice bath and service. Guess we just have to dive into it and see what we can do to it. Just to save space on this server I compiled everything in a web optimized PDF file. Omega 13 ligne.pdf And here are some snapps from the content. Enjoy! The finished result Freestyle assembly I still have a brainfart of this part name1 point

-

I forgot a contribution to this club. Got a bunch of watches in a lot I bought a while ago, think the average price was about 3£ a piece, sometimes one just need one part and end up with a bunch of classic watches, like this which I’m quite sure is the pride of some eastern country watchmaking. Let me introduce the 39-Day calendar watch! With this one all your vacations becomes a little bit longer1 point

-

When I buy/help buy cars for people, a lot of time they come to me thinking they want such and such a car, and just want validation. I would never buy a Prius, but if someone is dead set on it, the best case scenario is that I hurt their feelings telling them how the brakes are inconsistent and vague, the steering sucks, there's obviously no performance of any sort, and the same fuel economy can be had in myriad other, better cars. If they just want validation, the best I can do is validate them. If you're seeking validation, it's a solid workhorse movement in an attractive case from a storied brand. Like others posting, I also feel there's a lot of the price tied up in marketing. While there can certainly be value in that that some may find hard to validate, it is value. I forget the exactitudes of the economic theory, but there's value in having a coveted good. If the value proposition for money works out to you, then it's a great watch for you, and you should pull the trigger if it makes you happy to do so (while also not pissing off any significant others maybe?). What is it about the watch that you like exactly? Mayhap the same attributes exist in something without the brand premium. I've got a 2824-2 on my wrist right now in a case that I think is unique, has historic ties, from a (once) storied brand, and looks awesome with awesome functionality beyond what you typically find in a 2824-2 powered watch. I paid about a quarter the price of the Breitling new.1 point

-

Forgive me for my ignorance and Please allow me to introduce myself . My name is George and iam from Greece . Iam 40 years old and iam professional watchmaker 22 years My knowledge in watchmaking : Diploma in Watch making at the University of Athens Diploma from ETA 1993 WOSTEP Refresher Course Thanks very much for your time and forgive me if i offend you ( that wasn't my purpose )1 point

-

I beleive u will get many answers from that video Now ! from your timegrapher i see that watch amplitude its low but decent . From the 2nd picture i see that the escapment system has problem and especially the pallet fork , anyway the watch has some serius problems and it will not work properly. You have done service on watch ? demagnetisers the watch before you check it on timegrapher ? u check all the watch systems carefully before the assembling ? and 1 lust question plz . You are a professional watchmaker or a hobbyist ?1 point