Leaderboard

Popular Content

Showing content with the highest reputation on 05/29/20 in all areas

-

This. But there is an easy solution, buy a a similar watch or mov't, that could cost 15 pounds maybe. Practice on it until you can take it apart and reassemble almost blindfolded. Accumulate a modicum of tools and materials in the meanwhile, less than 100 pound say. You be then ready to work on the original, and many others.2 points

-

2 points

-

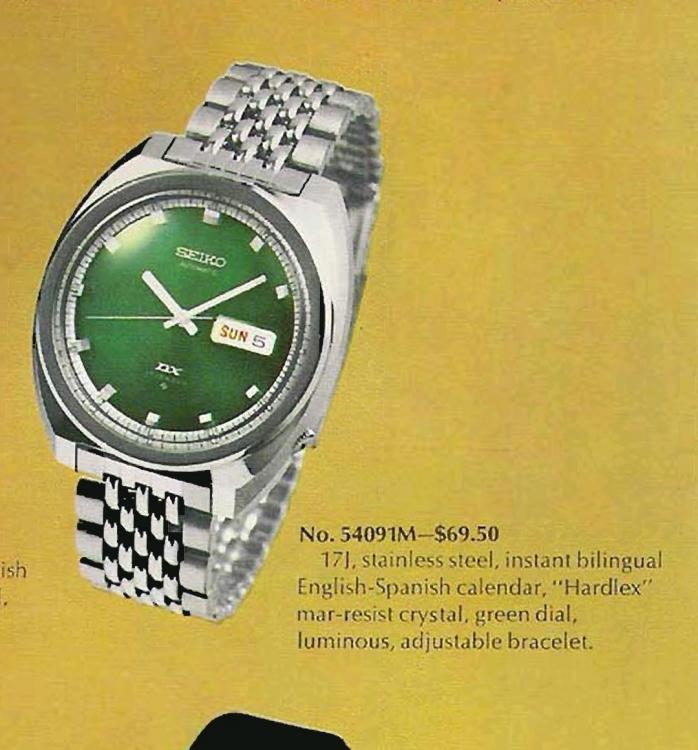

Today I'm feeling a bit green, so I wore my 1969 Seiko DX automatic 6106-8209. I got it last November at an antique show for a $1. It has the reliable in house 6106 movement. I do like the feature of pushing the crown in to advance the date. They certainly don't make watches like this anymore. As you can see, the watch retailed for $69.50 which is about $485 in today's money. You can get a handsome new Seiko Presage for about the same money. It looks as if my bracelet may not be original to the watch. Honestly, I'm happy that it does seem to be period correct. Eventually I'll need to replace the Crystal as it's pretty well scratched up. All in all, not to shabby for $12 points

-

Alam takes time that is the downfall, but I had loads of other repairs to do so it didn't bother me. Good old Bergeon always ready to take your money.2 points

-

Bergeon tool must be nice to have, penetrating oil before any physical approach helps. Alum disloves the screw and wont hurt the base metal.2 points

-

As we all know, our world has been deeply shaken. Lifestyles, routines and every partXa,a of our lives have been effected in some way. This is equally true for our children. Their academic and social life's have also been upended. As a father of 4 who range in age from 15 to 24 this new reality is all too acute. My youngest two are still in high school with one a freshman and one a sophomore. They have been pretty much on their own with getting their online classes up to date and completed. My daughter, who is also my youngest, has been on task the entire time, she had finished her work last week. My 17 year old son has procrastinated much of the entire time. 4 weeks ago he was in danger of flunking. So, as an incentive, I offered to get him his favorite watch which is a duplicate of mine if he finished with at least a C average in each class. In this case, it's a 1978 Timex Falcon Eye. Thankfully I had found one for an absolutely fantastic price, a steal to be honest. When it arrived, it was pristine! Tonight was his final night. The final assignments were due. He plugged away and by 9:45pm, he crossed the finish line! And as required, no class was below a C grade point average. In fact, only one was a C, the rest were comfortably within B and A averages. I'm very proud of him and it was a Thrill and an honor to present his watch to him. For fun, I had him put on his new watch but told him he was trying on my watch to see how victory feels. He was all smiles and kept saying how awesome the watch is. Then I held up mine on my wrist and put it next to his and said, yep, it's almost as cool as mine! He was like, What!? Is this mine? No way! He was so excited! Totally worth the wait. Here they are, two of the finest original 1978 Timex Falcon Eye's you'll likely ever see!2 points

-

Welcome to the forum Kaan, I have attached the tech sheet for the omega 552, might give you a clue as to where the screw came from, By the way i would leave the rotor on the watch it was designed to work that way and if you should decide to sell it at some point its some what de valued with bits missing. cheers 365_Omega 552 NewLR (1).pdf1 point

-

1 point

-

The fact that you have a problem releasing power from the mainspring, there must be an issue so untill that is resolved and the barrel will wind up and release through the click every thing else is on hold. we have to solve that little problem, then introduce the train wheels into the equasion and check for power transmission through the gear work, then add the pallet/fork and check its action is snappy between the bankings. When we have achieved all that then its time to fit the balance. It all sounds long winded but its a case of taking bite size chunks and establishing the desired result at each stage. It is all standard diagnostic practice. all the best1 point

-

Likely just bound up with dirt, etc. IF I had to guess, the third wheel has a bind. It clearly needs a service as well.. The center wheel you can see a huge piece of gunk clinging. I would be very careful with working on a sentimental piece. The last thing you want to do is damage it.1 point

-

Good that these are cheap for you, because it is not so here. Since a mechanical men's Omega is always a minimum of a couple hundreds Euro no matter what model and conditions, and parts may be difficult and expensive to find and import, I trongly recommend that you start learning on sothing really cheap, like some Russian, Japanese or even Swiss that you can find locally for 15 Euro each and are almost working. I know well that as a beginner you are eager to start working on the same pieces that yuo also like to collect and wear, but the chances that you will get everything right at the first attempt are very low.1 point

-

1 point

-

1 point

-

I think when it comes to being able to positively identify how parts fits and which screw goes where the best approach is to take pics or even video, AND store parts in labelled sectors. Because some mov't are really unusual with all screws being different, or there maybe a long gap time before re-assembly, and in any case one needs to move on expeditiously before "practice kicks in".1 point

-

That's 99.999% sure a left hand thread, I've found that screws are often rather loose in their threaded hole once the head breaks off, see if you can get a grip on it with strong tweezers and go righty-loosey. You can mimic the Bergeon tool somewhat using a staking tool to capture the screw by each end and turn the bridge to unscrew.1 point

-

And as stainless steel has a lower tensile strength than the corresponding carbon steel equivalent, makes it more likely to shear off......and while the stainless won't rust, damp can cause galvanic action where the brass plate it is screwed into can start to corrode....1 point

-

works ok here....I guess it is as said, practise over and over again...I am just a very moderate amateur and I notice that due to work I sometimes can't work on watches for months. When i then start again, I have to look at Mark's video's again ...I find these a great help. A good friend of mine is working as a professional watchmaker which shows his daily experience when I visit him...In a glance he sees what is wrong with a movement and knows exactly how to interprete readings on a witschi.....so a lot of practise1 point

-

1 point

-

That is the only bergeon tool I ever bought as I thought it is a life saver. I used it twice so far, both times I brutally damaged the main plate. I still have nightmares. However knowing about myself probably I was not careful enough and I had no experience or has no experience yet as how to use it properly. I seem to have difficulties to understand that you have to take your time when you deal with watch movements. The crown shaped end of the tool could not get a good grip on the broken screw by the way and I made also a mistake not to use the proper sized tool originally and when I used the right size? it was already too late. Was too hasty etc. The watch i prepared as an xmass present for Mrs still has the broken screw and this thing never goes away... i must fix it sooner or later as it will haunt me forever.1 point

-

As long as you remove all of the other steel component so you only have the plate then you can use alum mixed in water and that will dissolve out the screw. If you're in a rush you can warm up the solution It will dissolve it out faster.1 point

-

It all depends upon whose procedures you going to follow? Let's see if I can figure out how to word so not confusing? So there is probably more than two methods but originally when I was in school I was taught to evaluate the watch make your repairs once the watch is functional then it's Disassembled and cleaned and we go off with assembly lubrication rating etc. The reason for this is once the watch is nice and clean and properly lubricated other than minor regulation if you have to be disassembling the watch or taking the balance wheel out multiple times you will screw up the lubrication. That means if you screw it up you basically have to clean it again and start over. In modern shops and the modern schools there now teaching pre-cleaning. They do not like to work on dirty watches they like clean watches because they feel they can see things better. So movement assembled is run through a special machine They usually has a shorter cleaning cycle. The other reason it's a separate machine is to keep the cleaning fluid in the final cleaning machine much cleaner. Now you can evaluate the watch do the repairs on a clean watch then it's taken all apart Clean and lubricated minor regulation same as above then.1 point

-

@Maxppp If you have never serviced a watch before I do recommend you practice on something else first, for example a Vostok 2409. It's a stunning timepiece you have there and there's a real risk you'll damage something or lose a part which might become very difficult to replace. There's always a risk, even when you're experienced but with experience you'll learn to minimize the risks. Best of luck!1 point

-

1 point

-

Hi The cheap way is to superglue a large nut to the back and use a spanner, Then fill the nut with acetone which will release the glue. Job done. used it a few times and it works.1 point

-

Here's my very humble setup as it sits... My office turned into a baby's room just before xmas, and I've been couch surfing with my laptop since. That's fine as long as I'm just coding, but the hardware work is about to begin. Initially, everything was unceremoniously dumped onto the bare dining room table, but with my couch surfing coming to an end, it's time to resurrect something akin to a proper work space. What you see is my wife's sewing mat at the end of the table (to be replaced if and when my shipment from China ever arrives), with tools and supplies arranged around it for accessibility. There's a Seiko 5 in the cover tray, and a shock springless Tongji "art" watch adjacent. To the left are occasional use tools and/or boxes/containers/packaging. Under the camera tripod are jars of cleaning solution and oils/greases. To the right (I'm right handed) are the frequent use tools, anything that needs power (closest outlet), and a "third hand" for soldering I recently unearthed and deposited in an open space because thought it might be useful (haven't tried it yet). My computer monitor is back left because that's where it landed during the office exodus, and I don't have anything like a desk yet. Back right is camera accoutrement, some leatherwork stuff, and some more even less frequently used watchmaking materiel and boxes. I put a white vinyl/flannel table cloth down on the dark "wood" floor to keep things from bouncing and make them easier to find. The stool is something my BIL made us for Xmas a few years back based on a Japanese design. Annotated tech sheet for the 7S26 is sitting on the stool. It's really low, so it's got me at a reasonable height. Magnetic sweeper leaning against the wall, and to the left of it behind the table are the jugs of clean/rinse solutions. Ultrasonic lives in the basement bathroom because that noise... Very ad hoc and half assed. I'm just getting started, but I'm about to commandeer an area to actually set up a work space in. I'd like to make accommodations for watchmaking, but also need to be able to use my computer and work with electronics hardware. Hopefully, I'll get some inspiration from you guys' shops!1 point

-

I had my eye out for either a 200 foot or 600 foot diver and I finally found a 1970 200 foot in my budget within a large Lot of Timex's. I snapped it up and was sorely disappointed when the seller had forgotten to ship it with the lot. Thankfully they sent it out when I pointed it out. Still waiting on a period correct Tropic rubber strap. Looks great though.1 point

-

Wow, great collections! I just have the one, that I got some while back. Non-running, the balance wheel has come loose from the balance staff, and with its design I'm not sure how to stake it so I'm just looking for another one instead. It's an M75 so should be fairly easy to pick one up from the bay, I just need to pull my finger out. And I've found the stem bridge assembly so fiddly! Give me a Japanese chrono to reassemble any day rather than another one of those!1 point

-

I just grabbed this 1971 vintage Seiko Lord-Matic. It was being sold as a non-runner, hopefully nothing is actually broken. I'd like to replace the Crystal, but it looks like there isn't a direct replacement currently available on the internet. At the very least the dial needs some attention with some kind of stain around the day window. Updates will follow as soon as it arrives.1 point

-

Forgot to add when I clean the parts I use mesh compartment trays. But in the beginning I used mini glass vials filled with cleaning fluid and each one was numbered and I also numbered the compartments of the tray. So each tray section would correspond with the glass vial. I still use this method today when dealing with an unfamiliar movement. But if you have disassembled and reassembled enough movements you kinda start to just know where everything goes, kinda like when you move to a new town you don’t know where everything is, you use gps a few times get to know your area and grid, then you just know.1 point

-

With me it was practice. Never took notes and never used a camera.1 point

-

Canon pinion is too tight, if you did take apart, first oil the canon, refit and advance the hands couple of turns around the clock to spread the oil, it should loosen up, if it didn't you may have to broach the canon.0 points