Leaderboard

Popular Content

Showing content with the highest reputation on 05/18/20 in Posts

-

When I was 14 or 15, I applied for a watchmakers apprenticeship with all the local watch shops that offered that program. It was in the suburbs of Chicago, Illinois. No one was offering the program at the time, and life, cars, girls took over. I am now 67, and am following my dream finally. Oh well, better late than never!3 points

-

3 points

-

Well from working on a shabby chic table and using a chest of drawers for storage for the last 6 years I have been hankering a new work space, the garage was first option. All the plans were in place, pricing for lining and insulating etc etc, then the new 2 seater arrived and now lives in garage so watch work shop put on hold. So back to old table again, an Internet search a good while ago I found a site that a tinkerer had made a bench from Ikea products. I saved that site and went back to it and searched Ikea and all components were still available, so whilst on this lockdown I ordered the lot and it arrived. Now I’m fully organised with no more hunching over the bench. total cost £247 including delivery, much cheaper than a bench from cousins/horotec etc.2 points

-

It is just friction tight. Some of the old fusee P/W's are the same. The cannon pinion can be a sod to remove.2 points

-

If beat error does turn out to be the issue then you may find that Timex have been particularly helpful. At some point Timex very helpfully marked some of their balances with a little notch in the rim to assist in positioning the hair spring so that the balance would be in beat. Assuming the hair spring is not distorted then if you line the pinning point up with the notch you should be as close to being in beat as needed for the watch to run. A little fine tuning may help if you have a TimeGrapher to check beat error. I don't know when Timex did this, or on which calibers. I'm pretty certain that it's not on everything though. This balance is from a 1970's M25, and the notch seems to have been there on most of the M24 and M25 movements that I have played with. It is possible that I have got this wrong as I've not seen this written down anywhere, but I have done an awful lot of Timex's and wherever the notch has been present, aligning the h/s as described has had the watch in beat. @JerseyMo may be able to provide a more authoritative comment.2 points

-

Hi Take all the power off the movement and check where the pallet lies. If it constantly lies on one side even after moving it manually its probably off beat, If you had the balance out it may not be pinned back in the on beat position. worth checking out. The pallet should lie central between the banking pins at rest.2 points

-

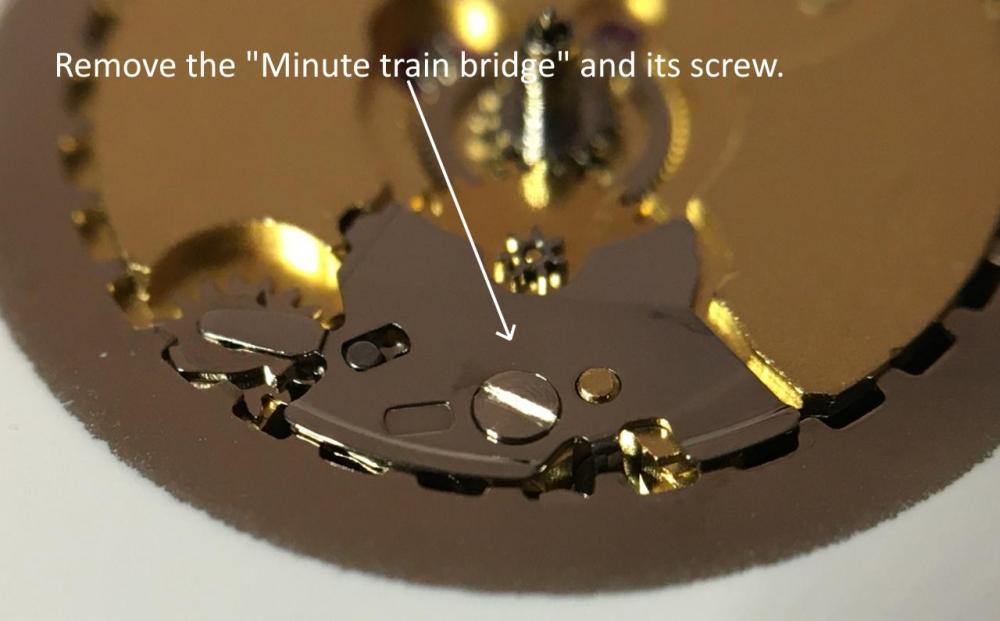

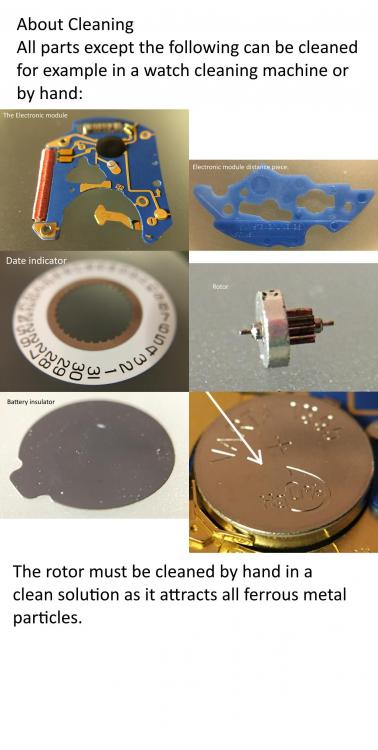

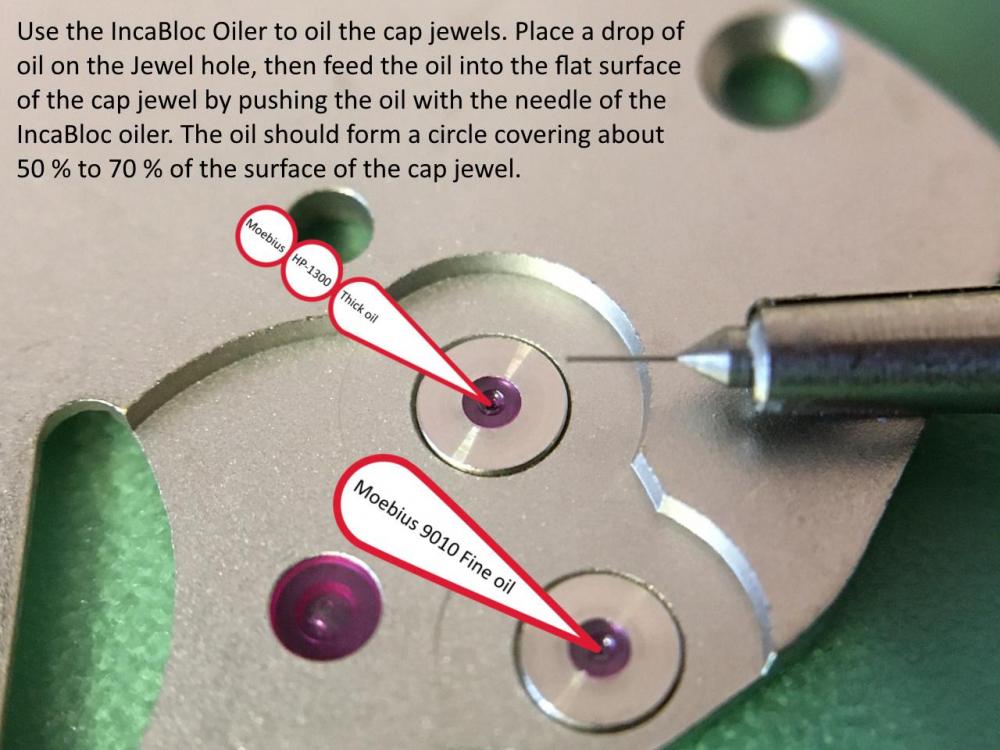

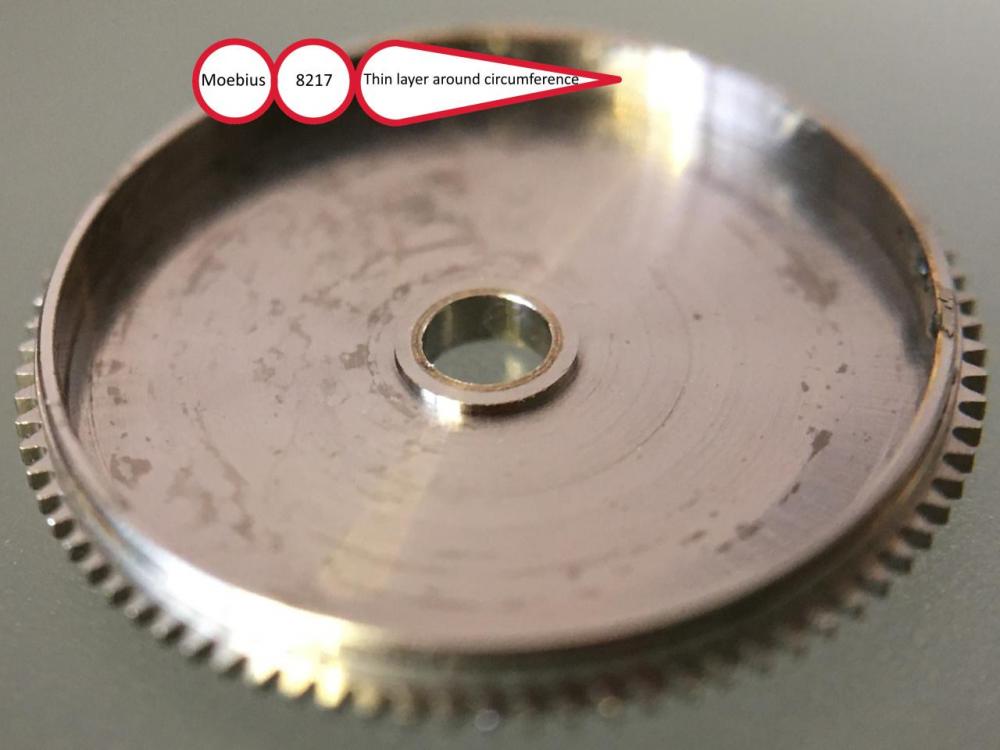

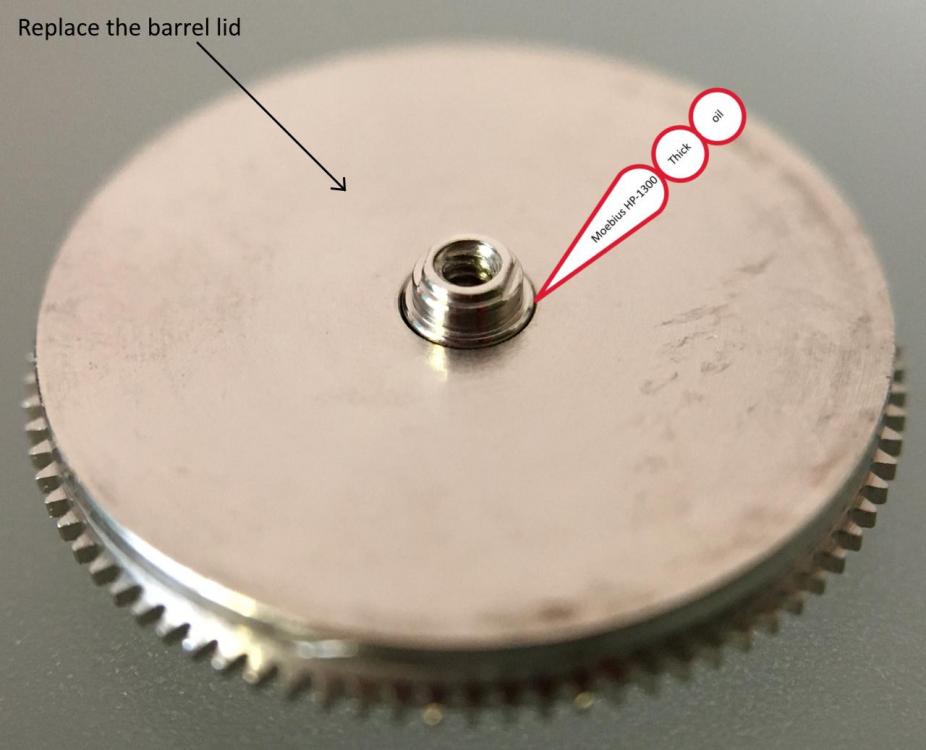

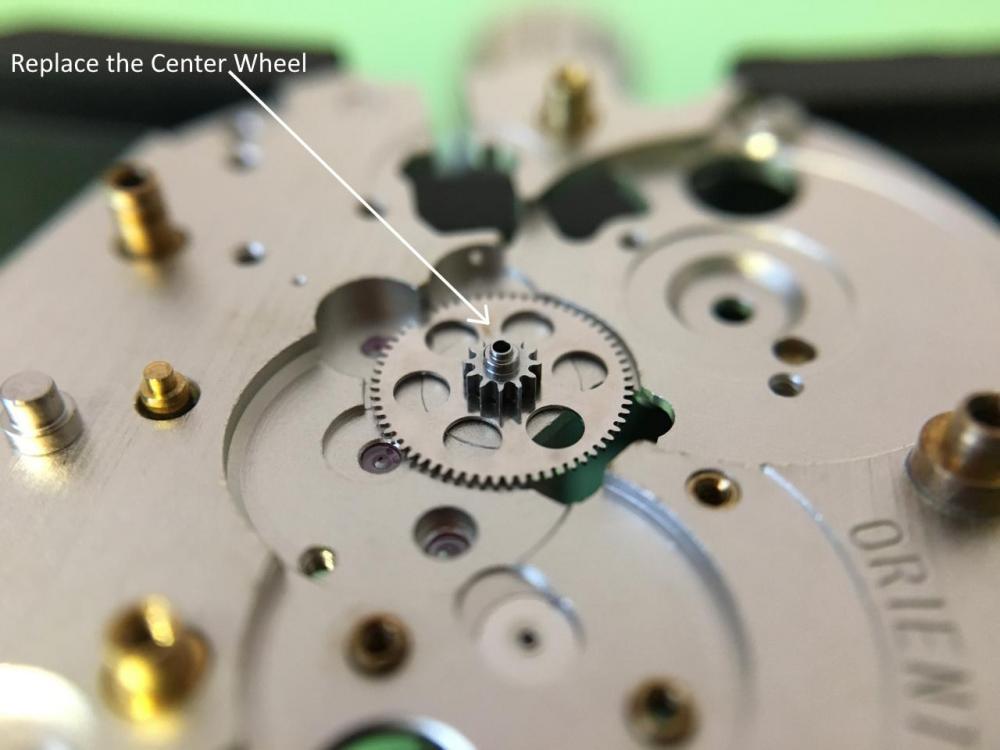

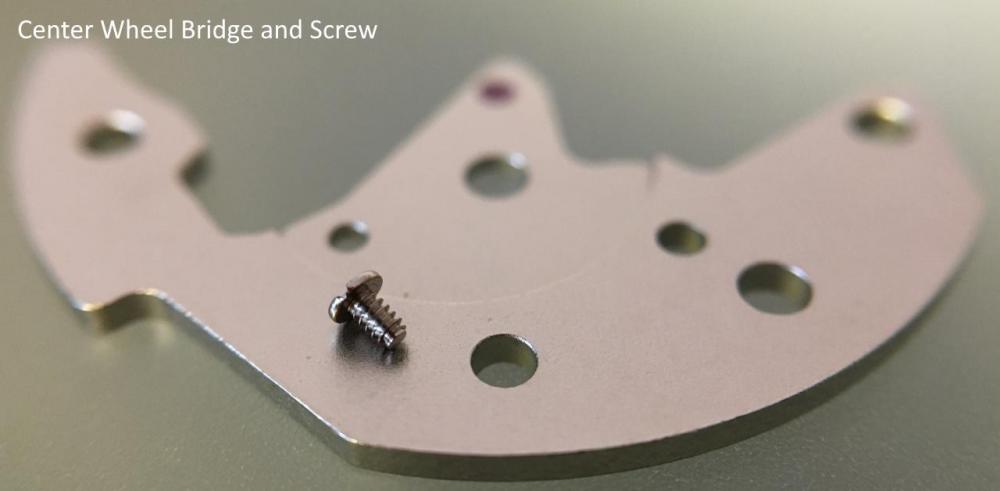

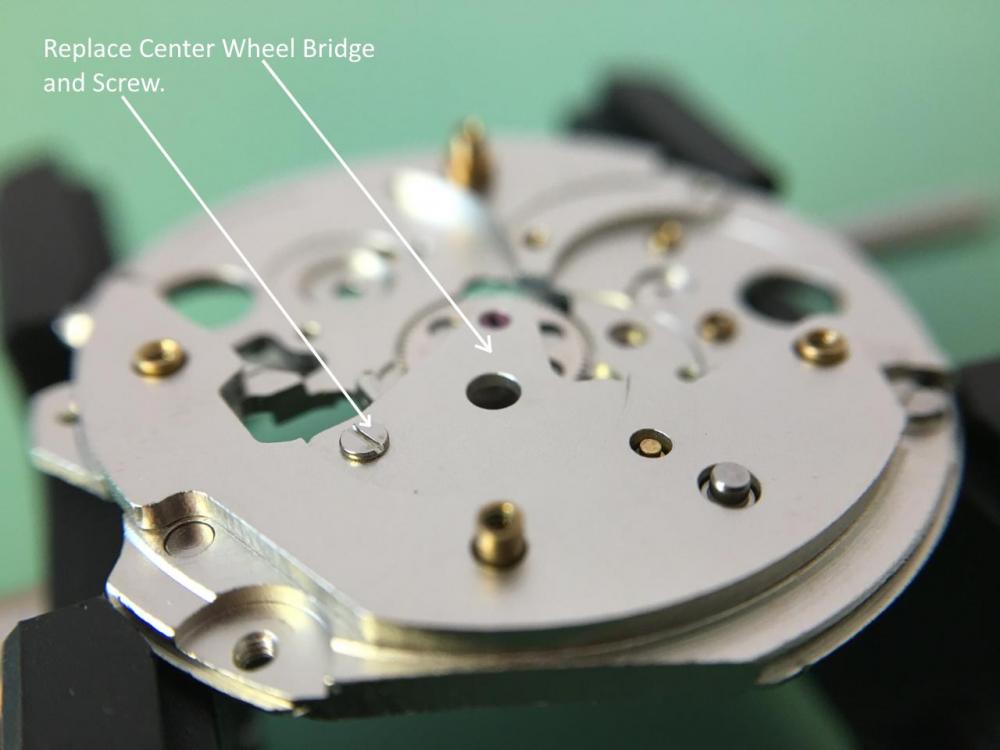

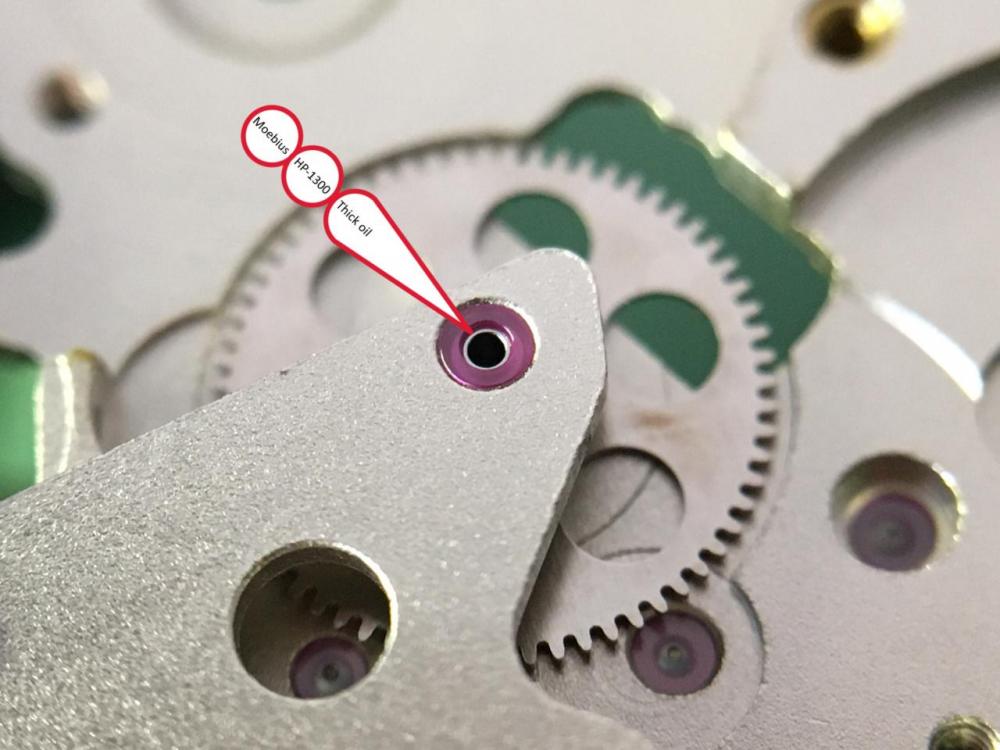

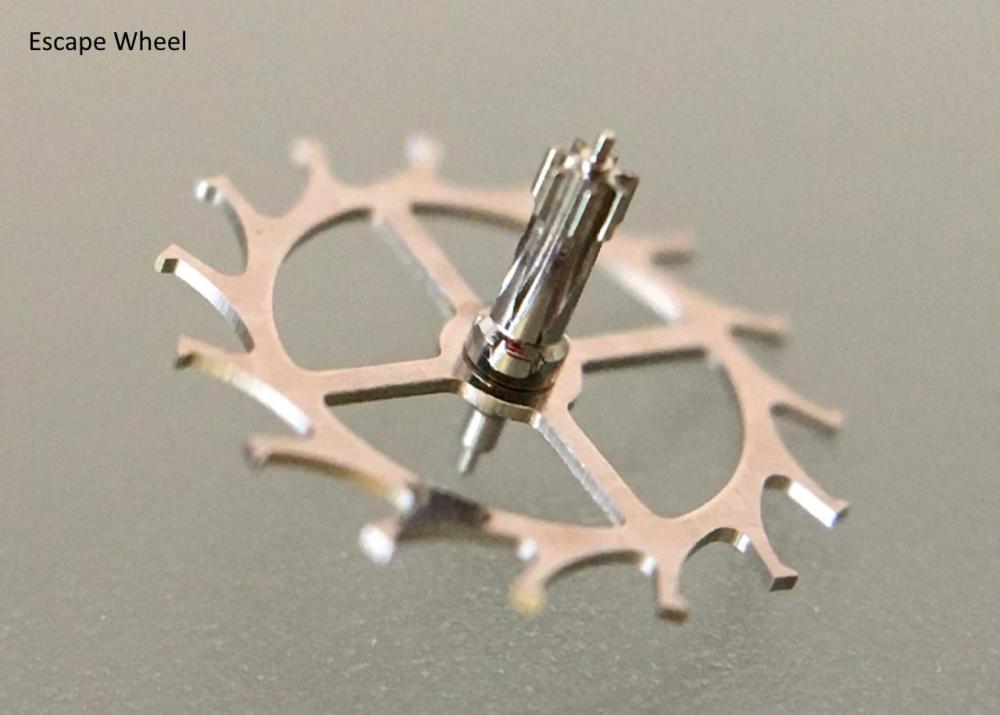

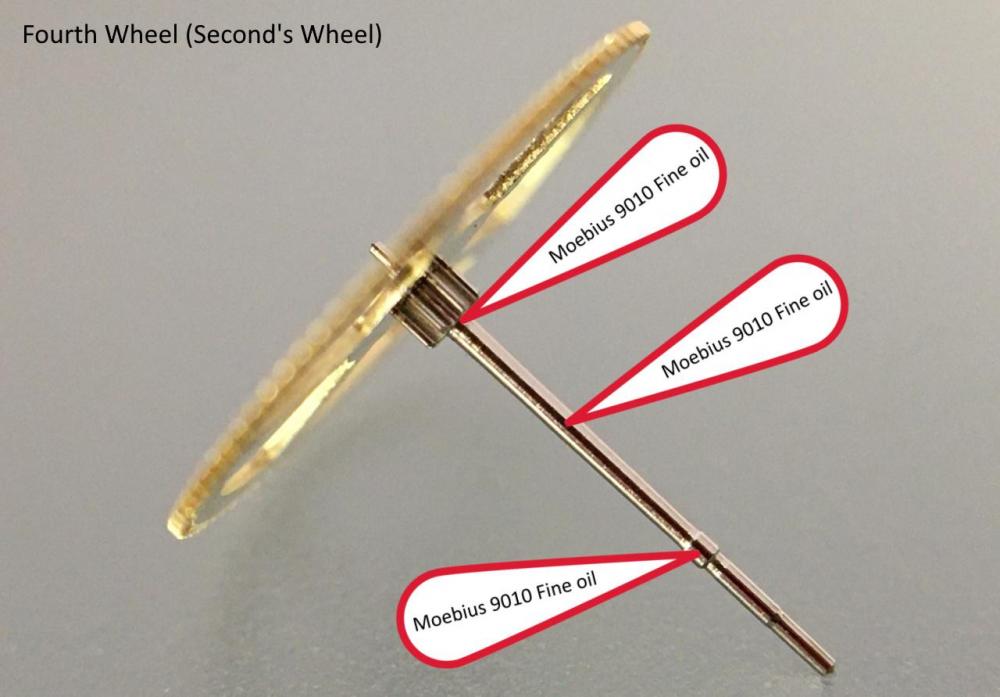

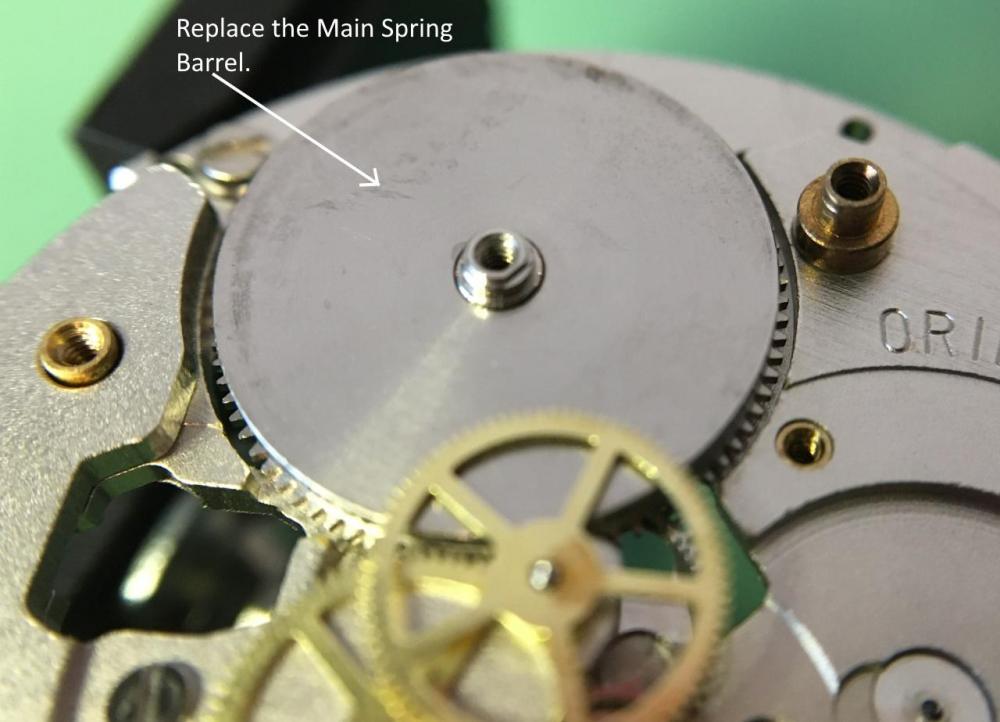

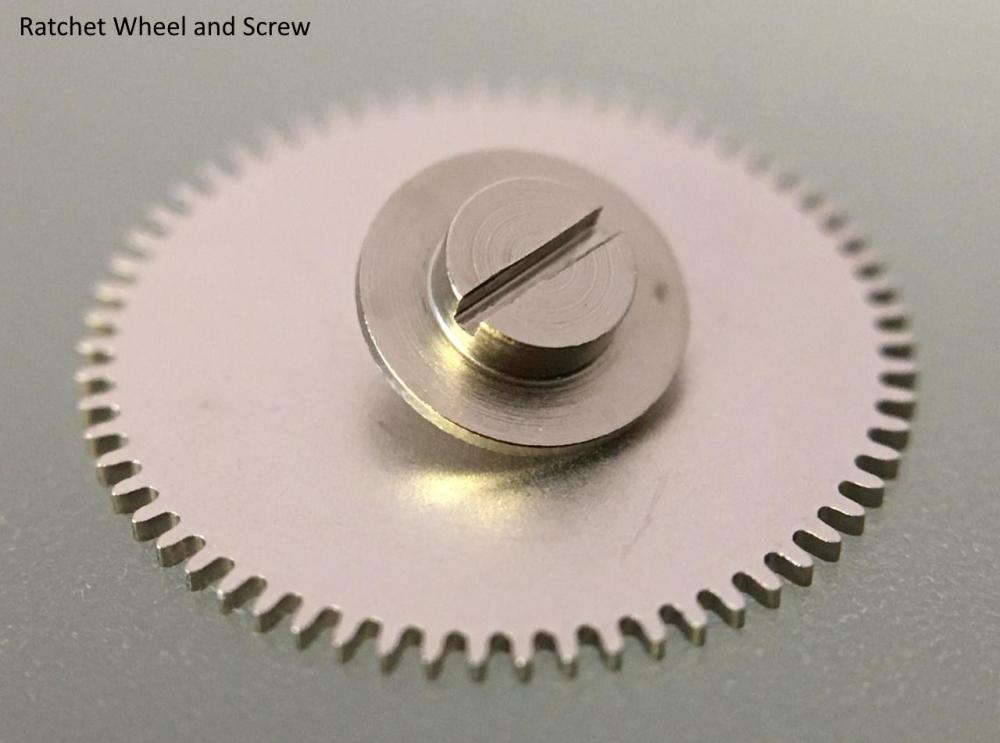

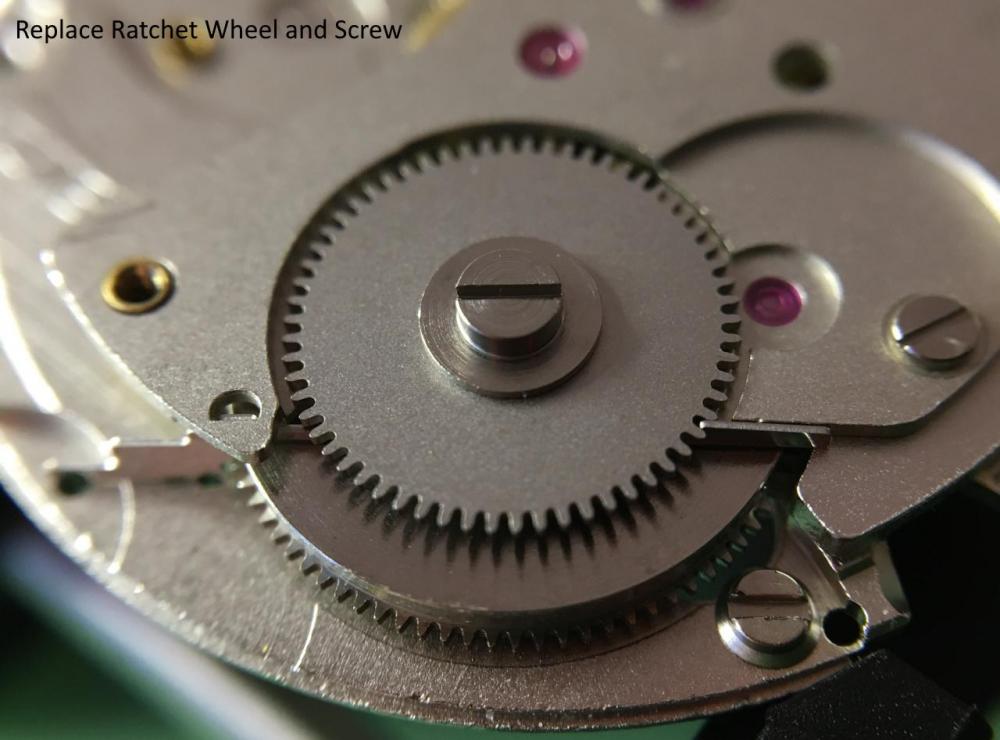

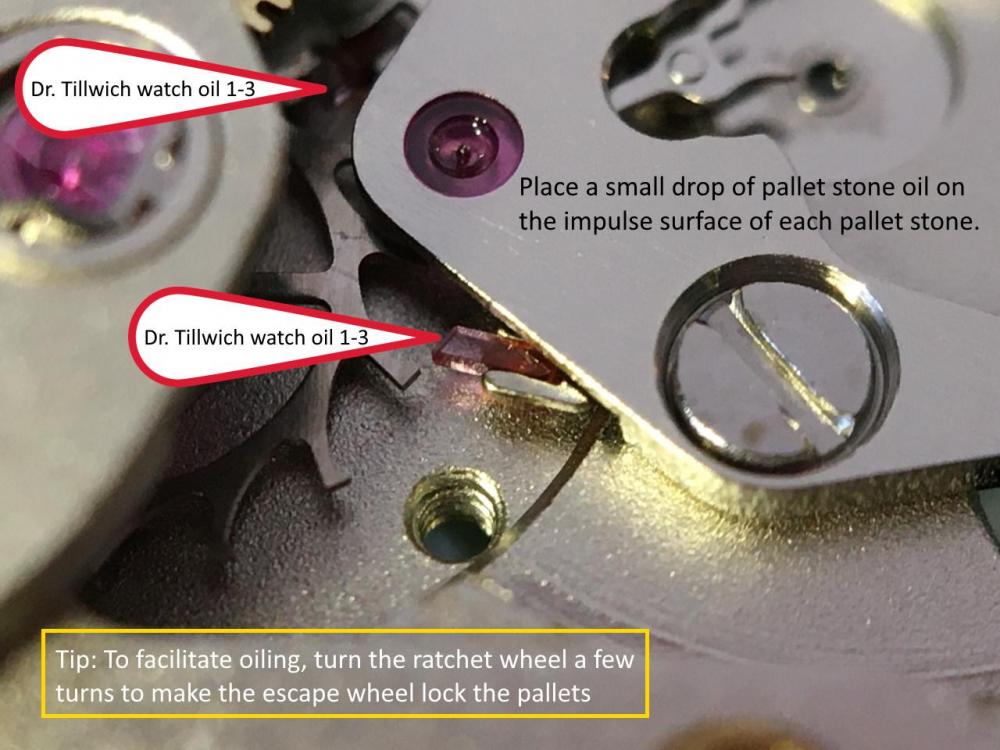

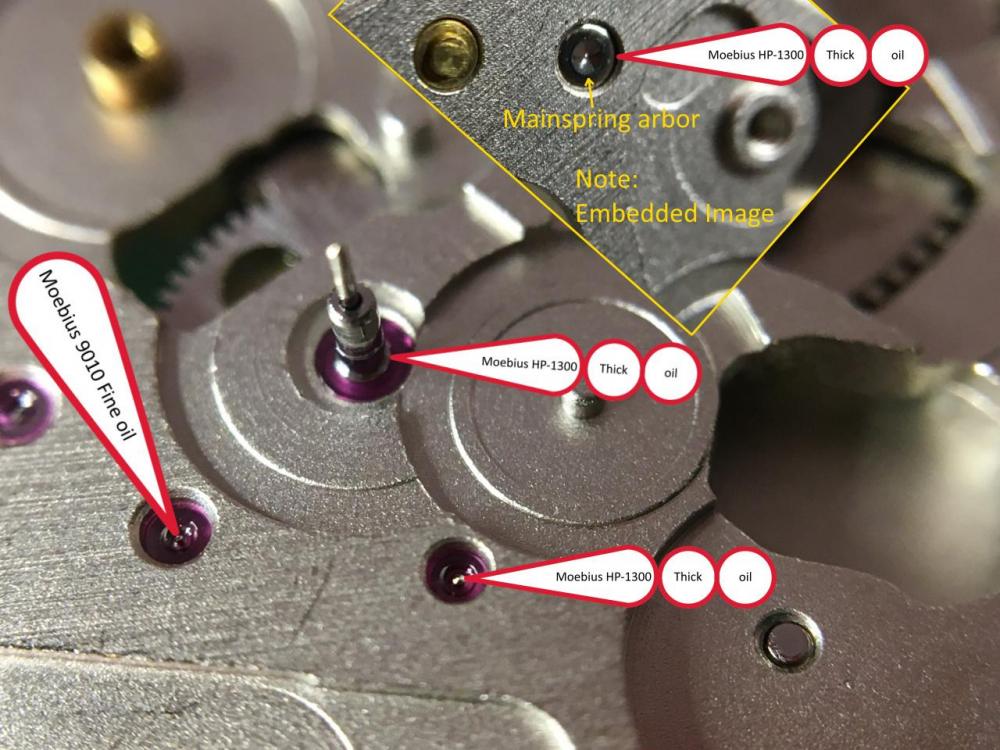

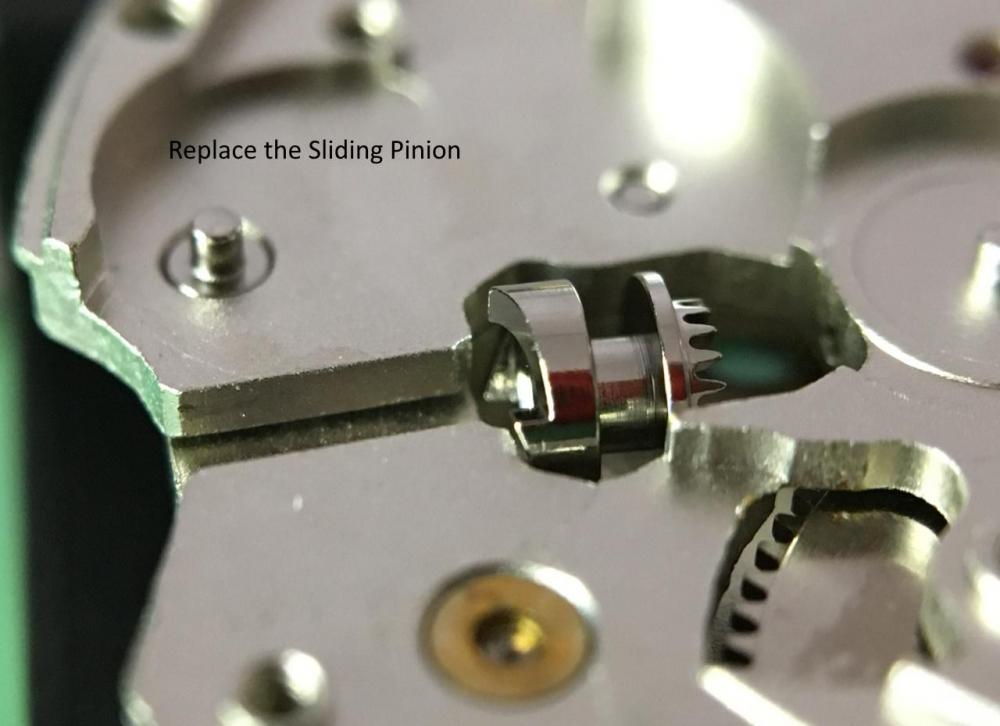

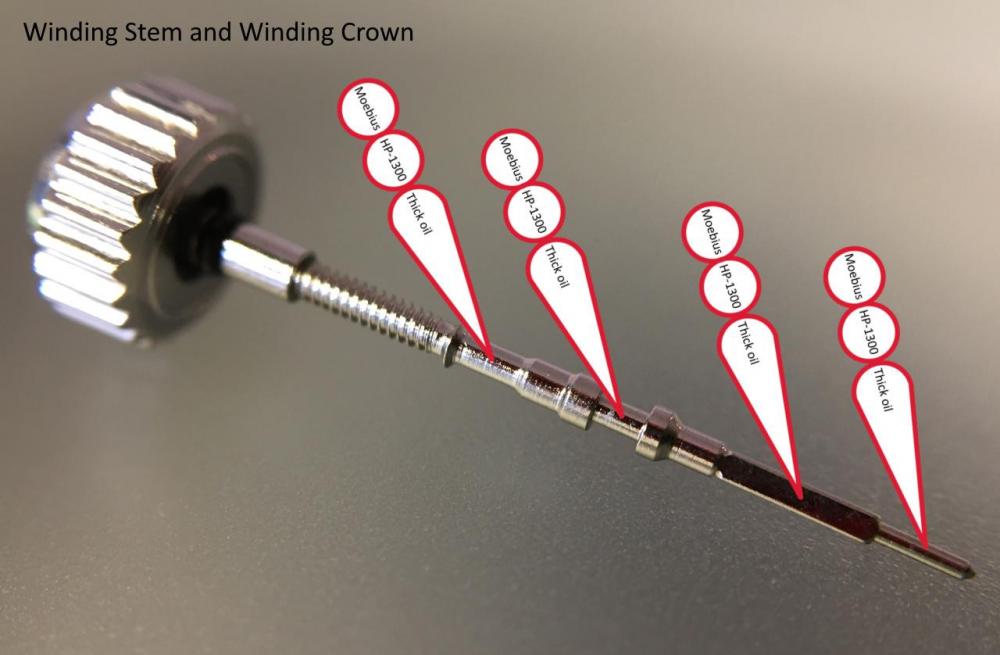

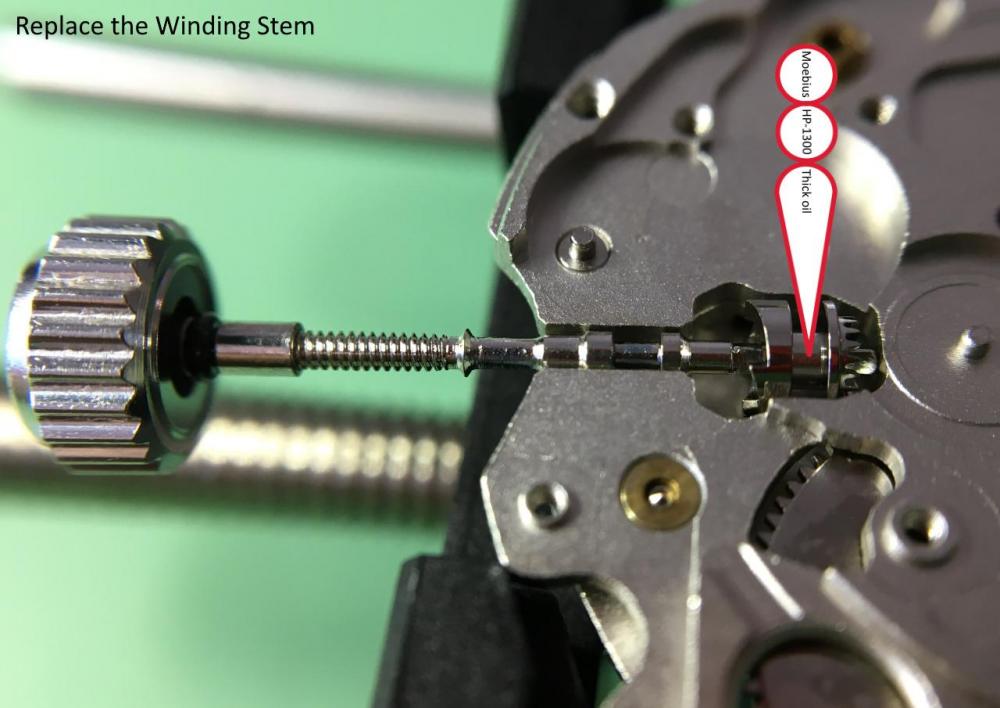

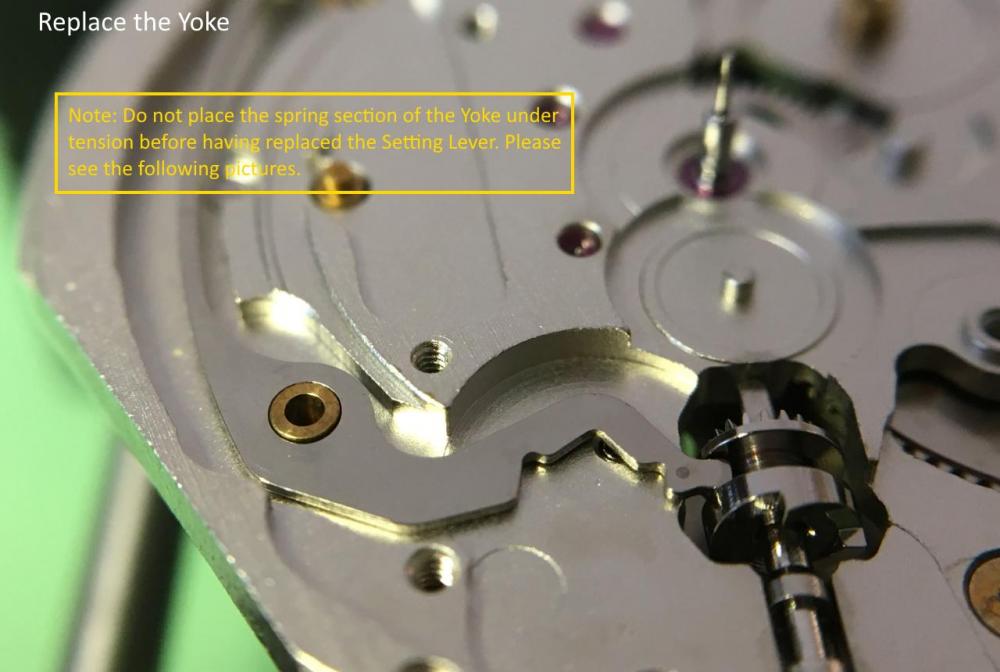

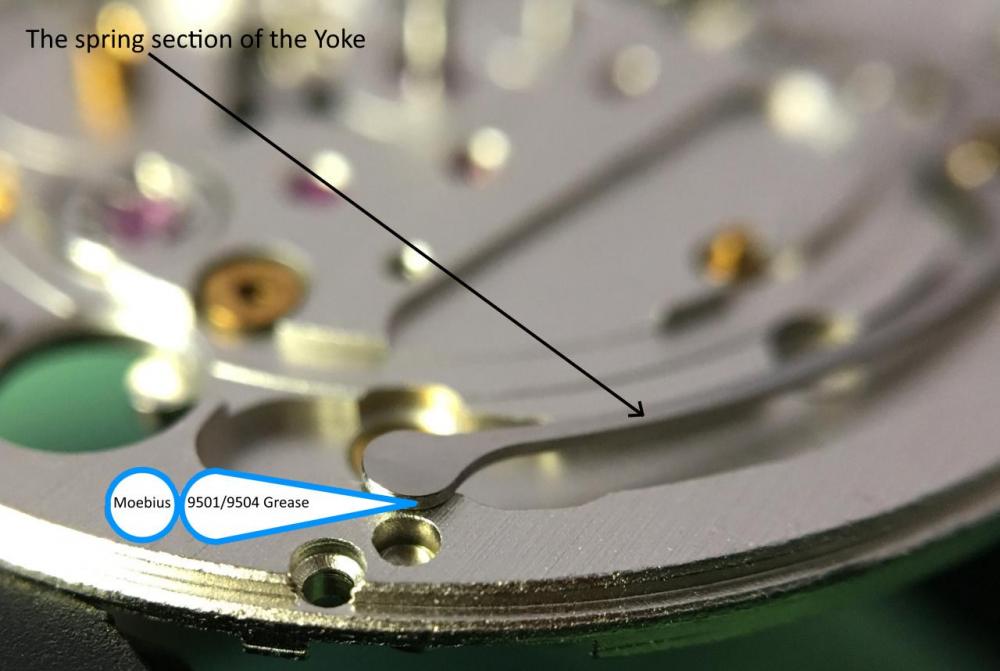

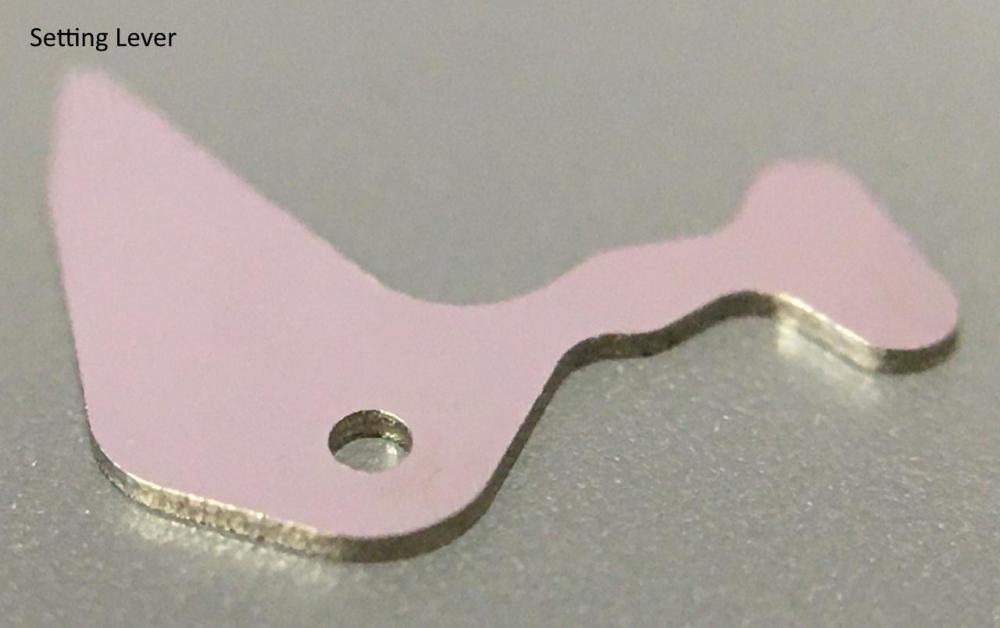

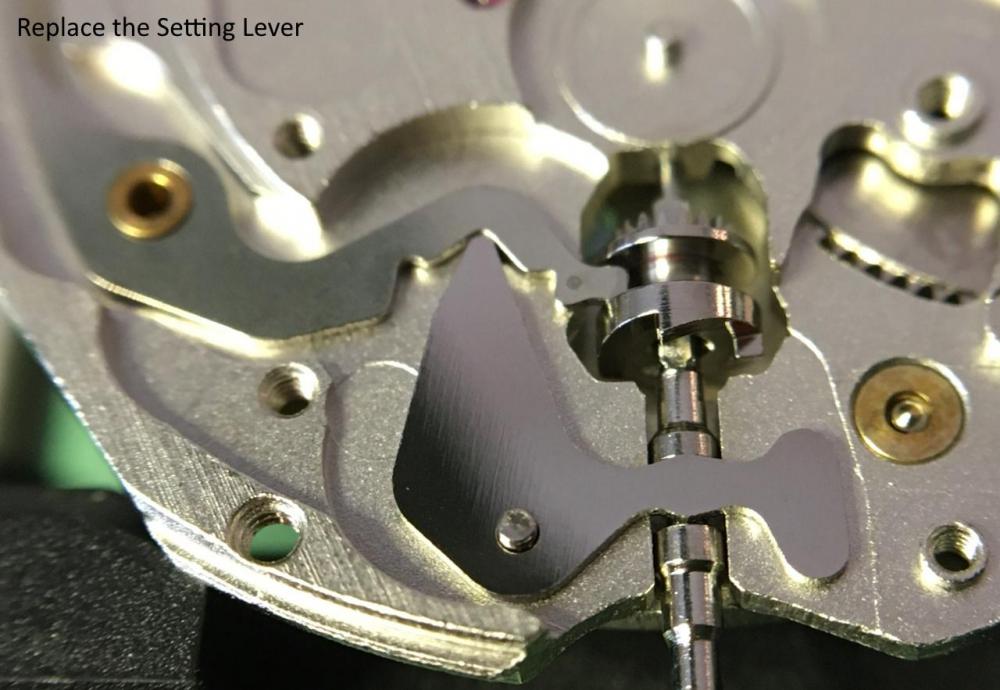

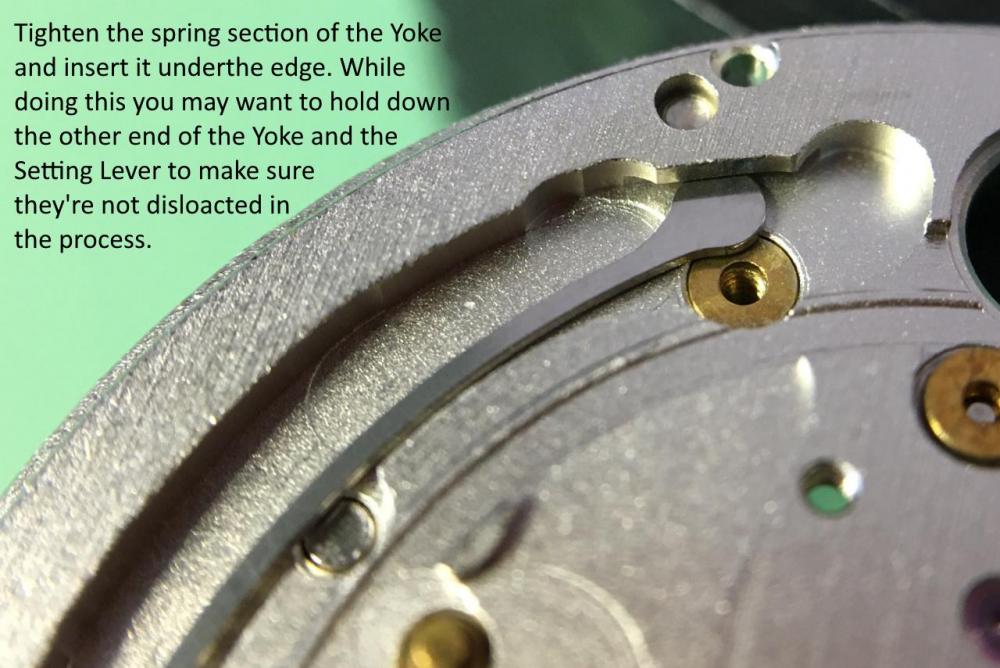

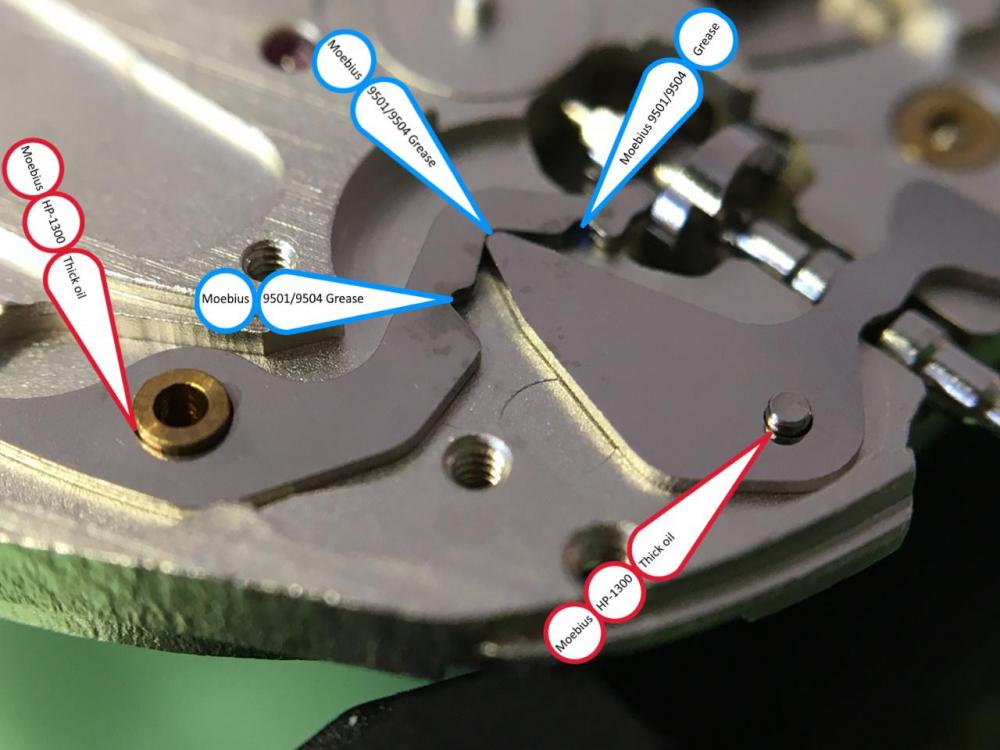

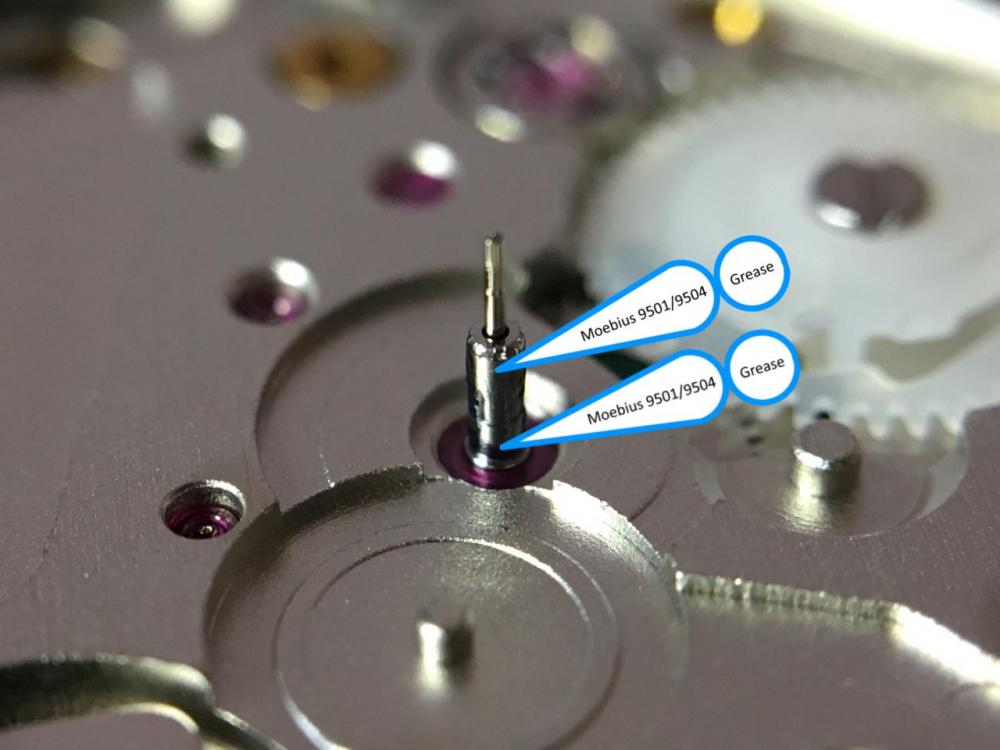

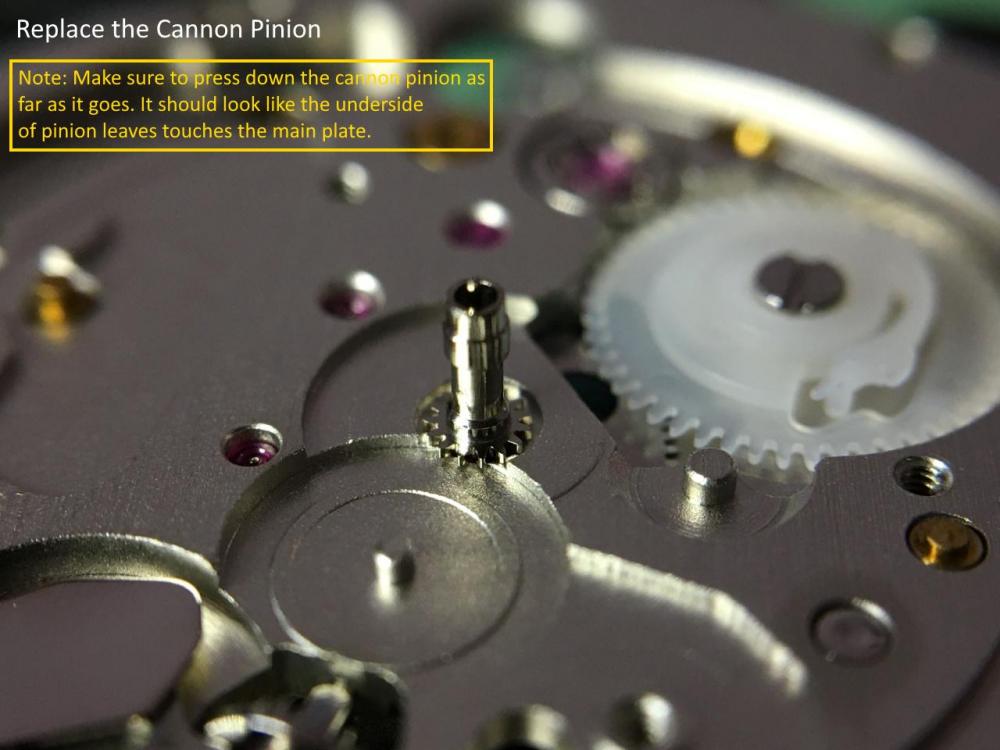

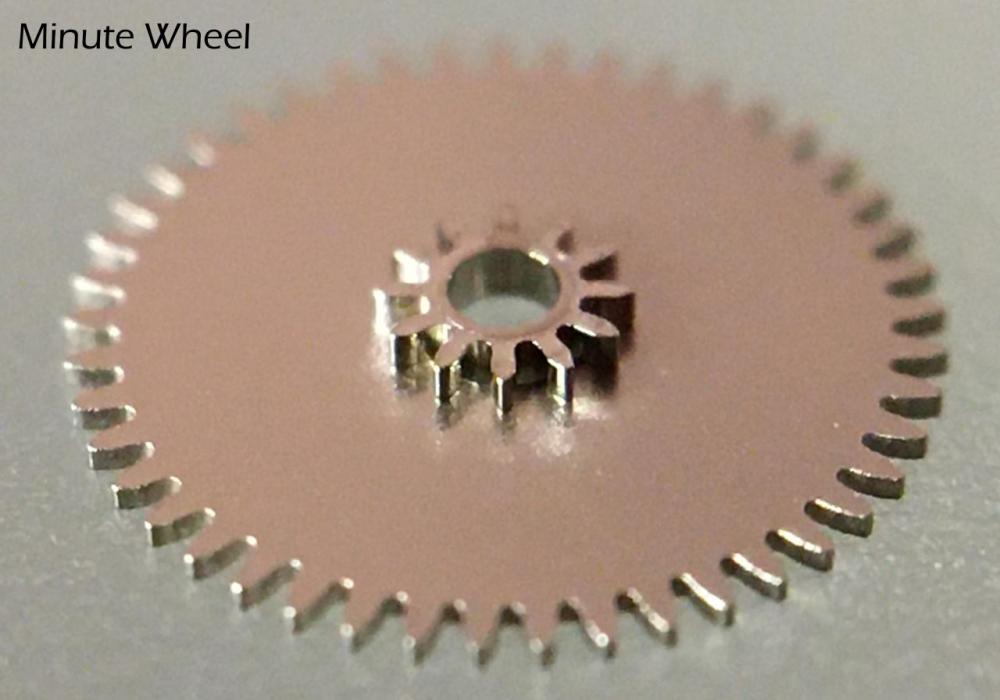

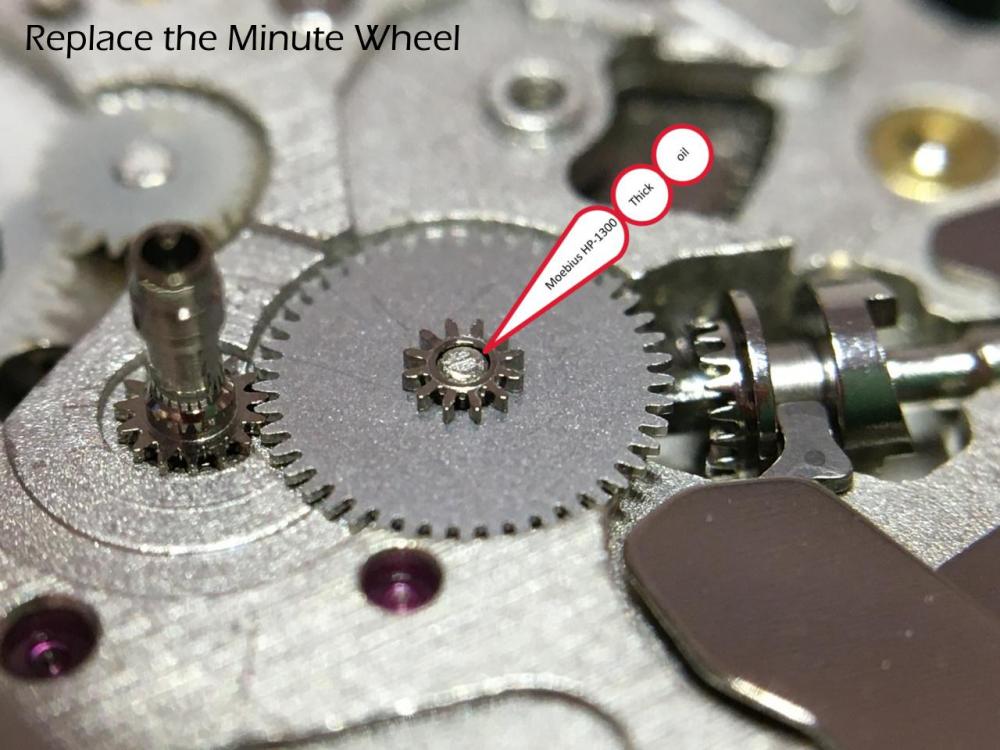

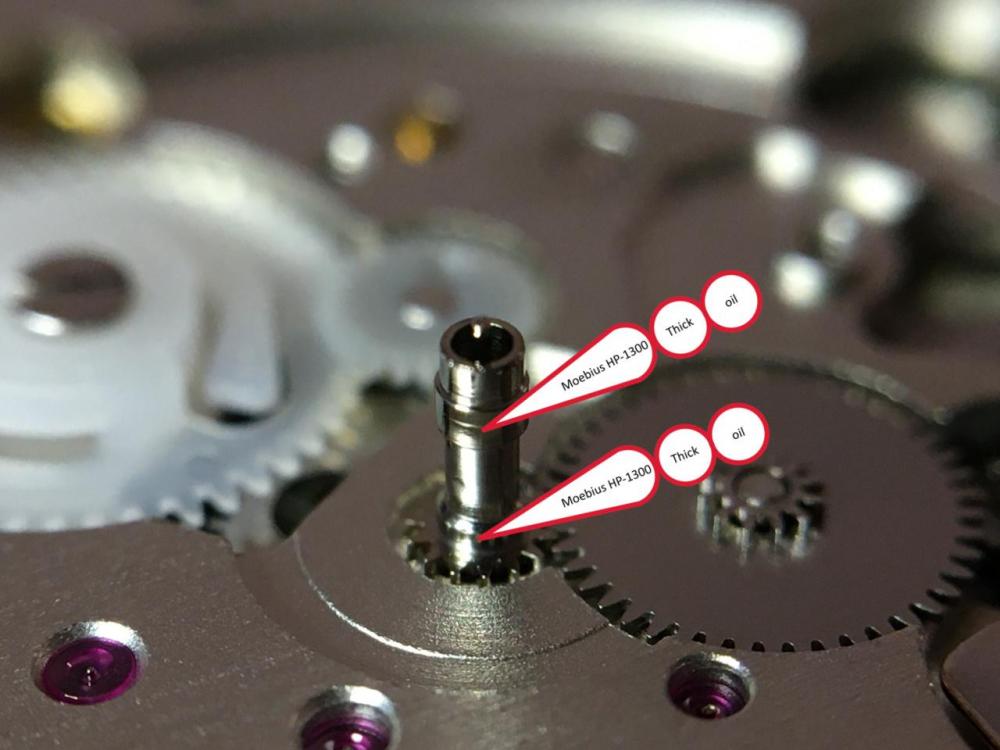

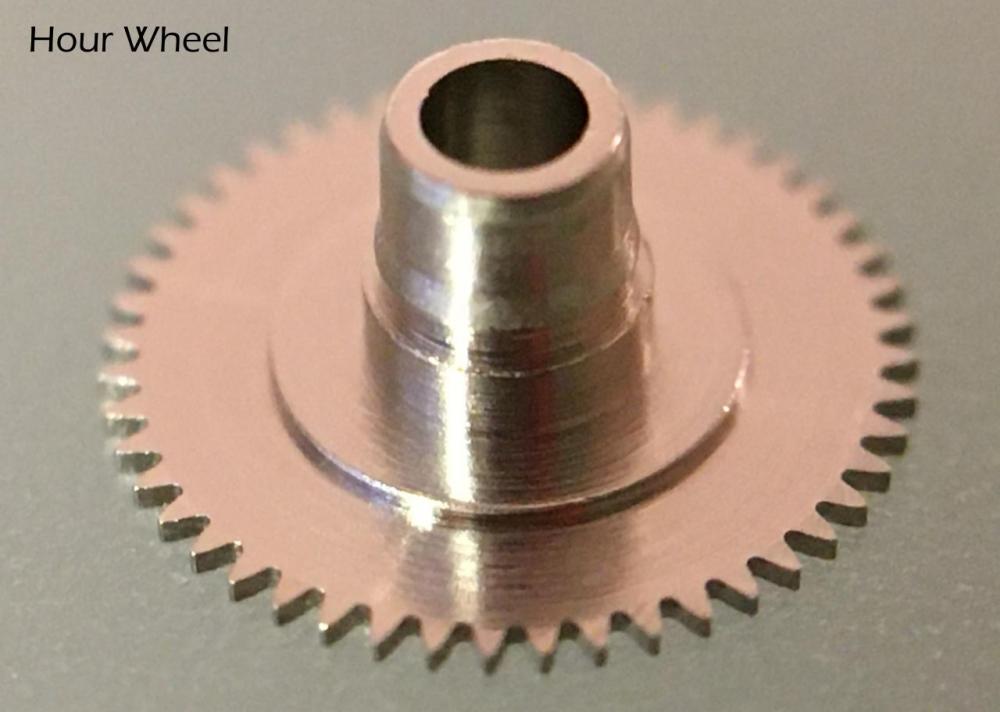

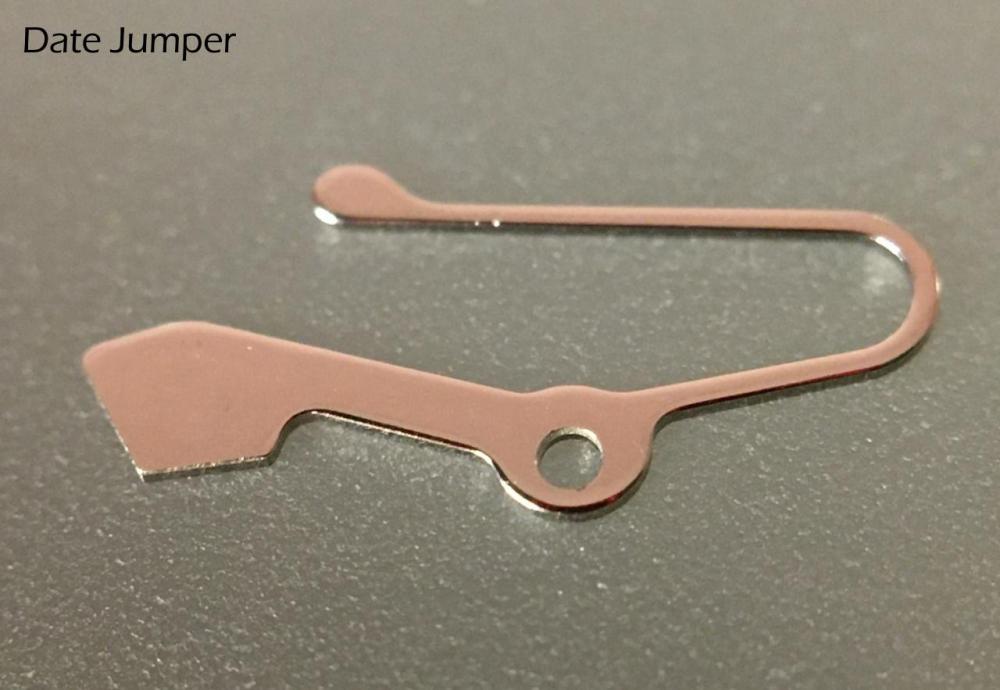

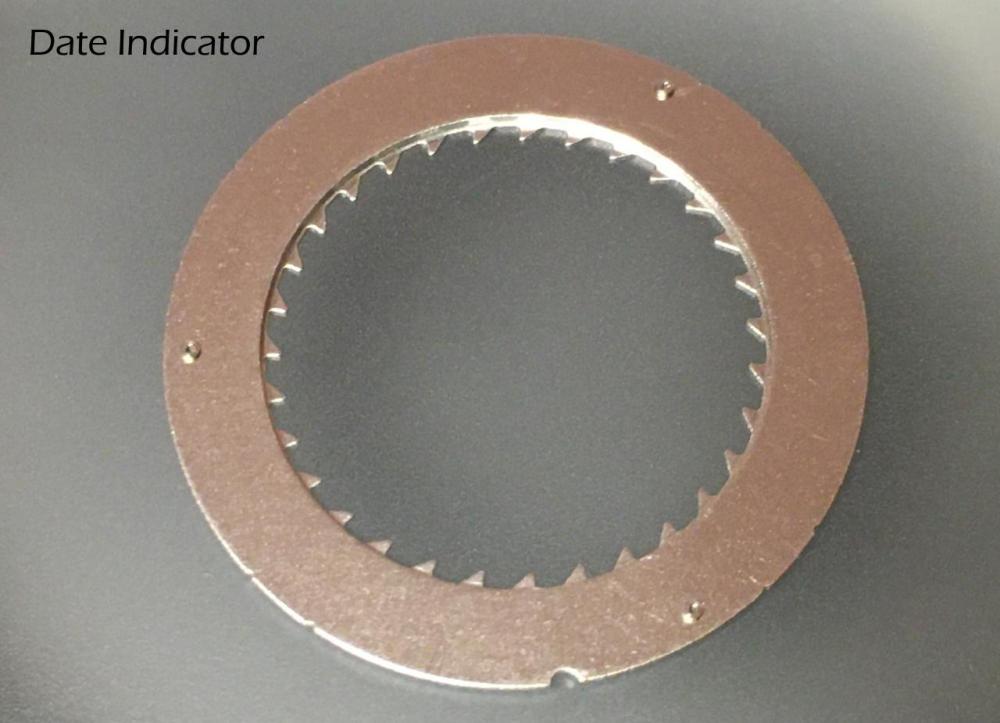

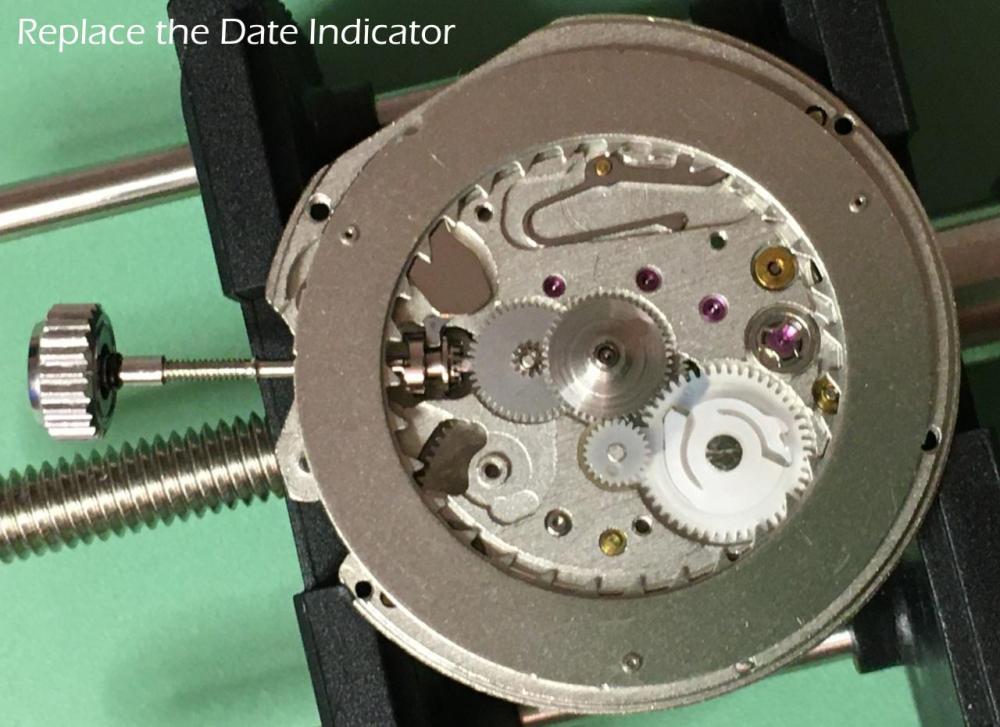

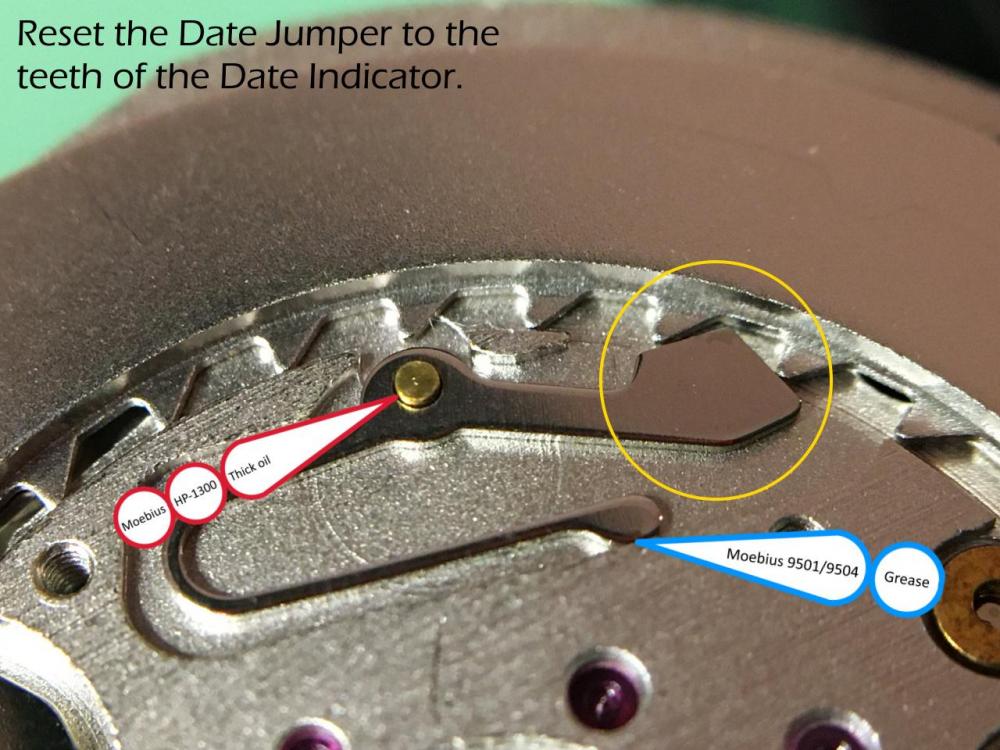

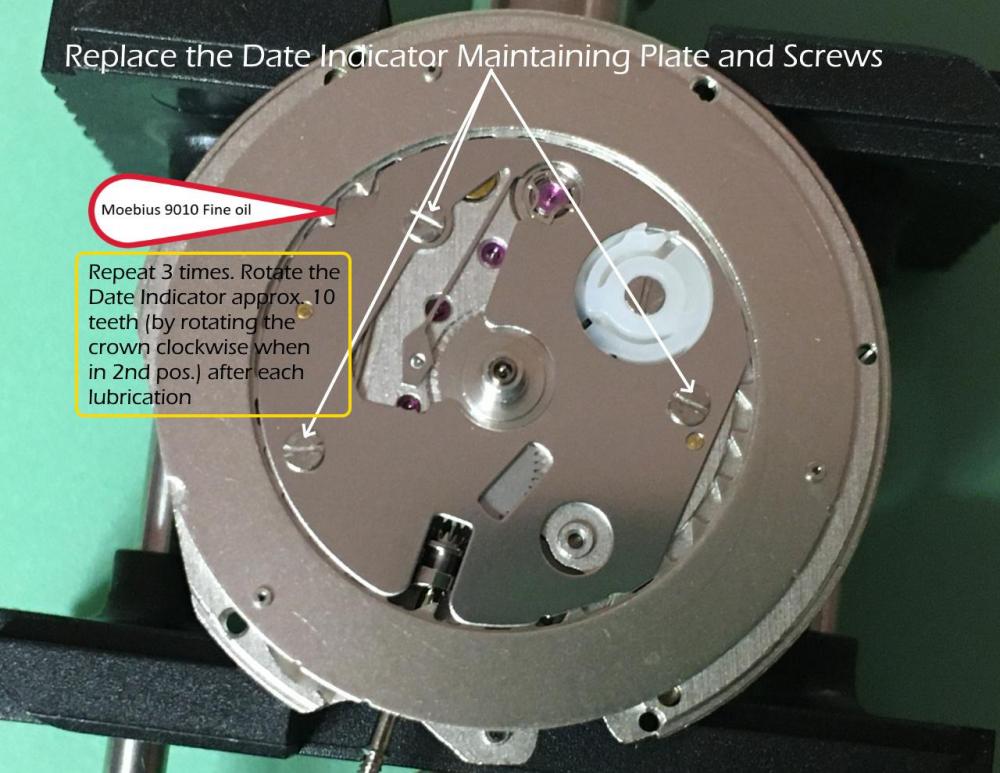

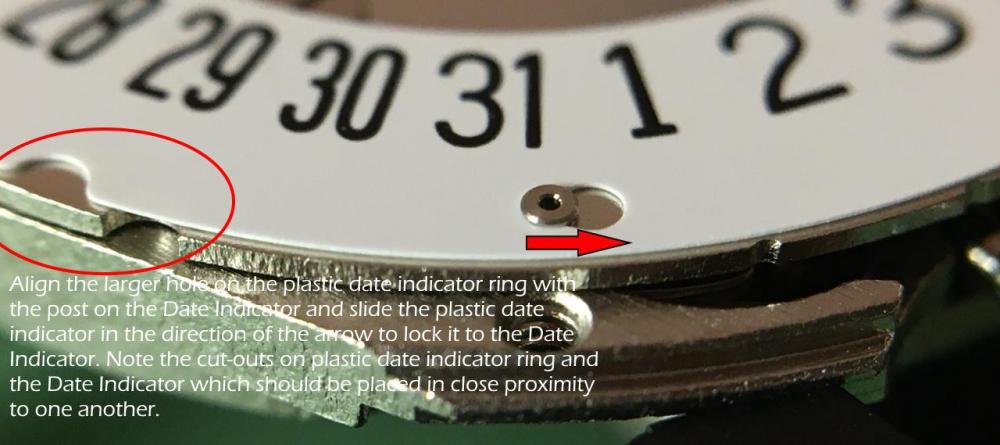

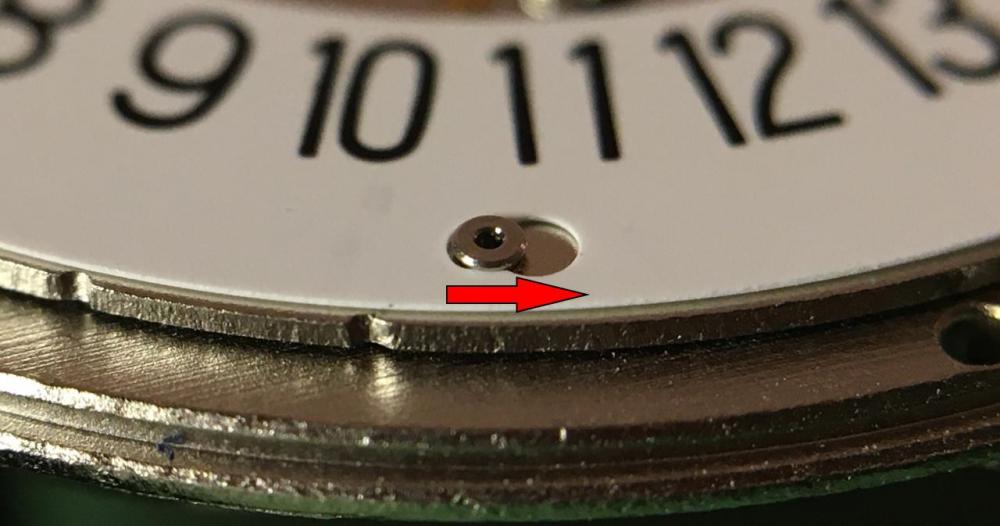

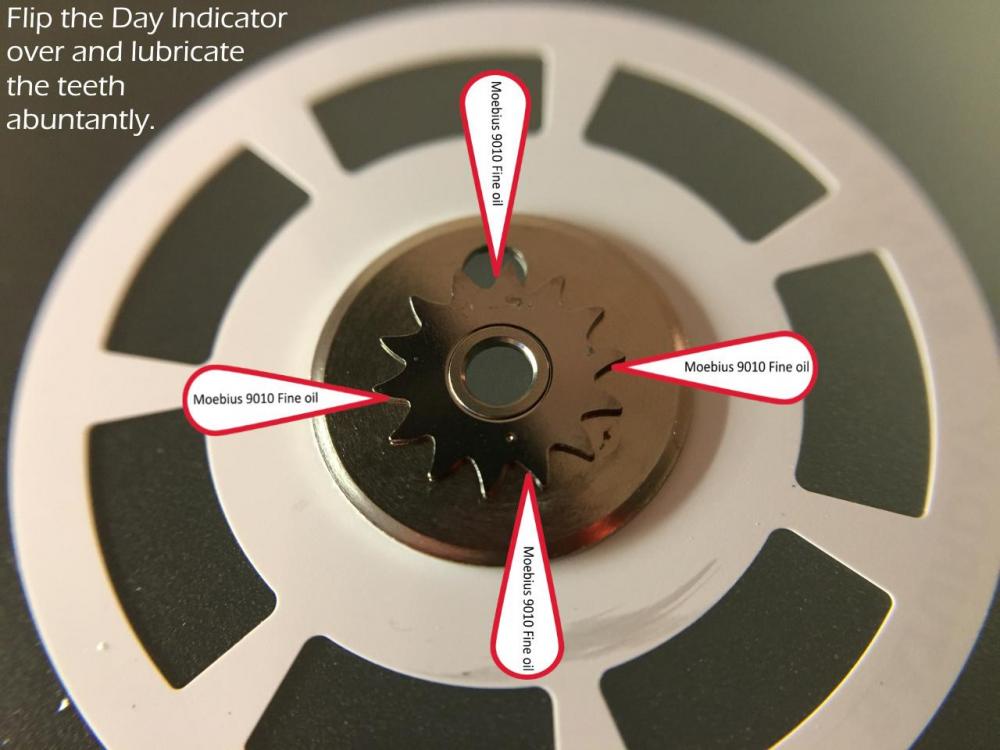

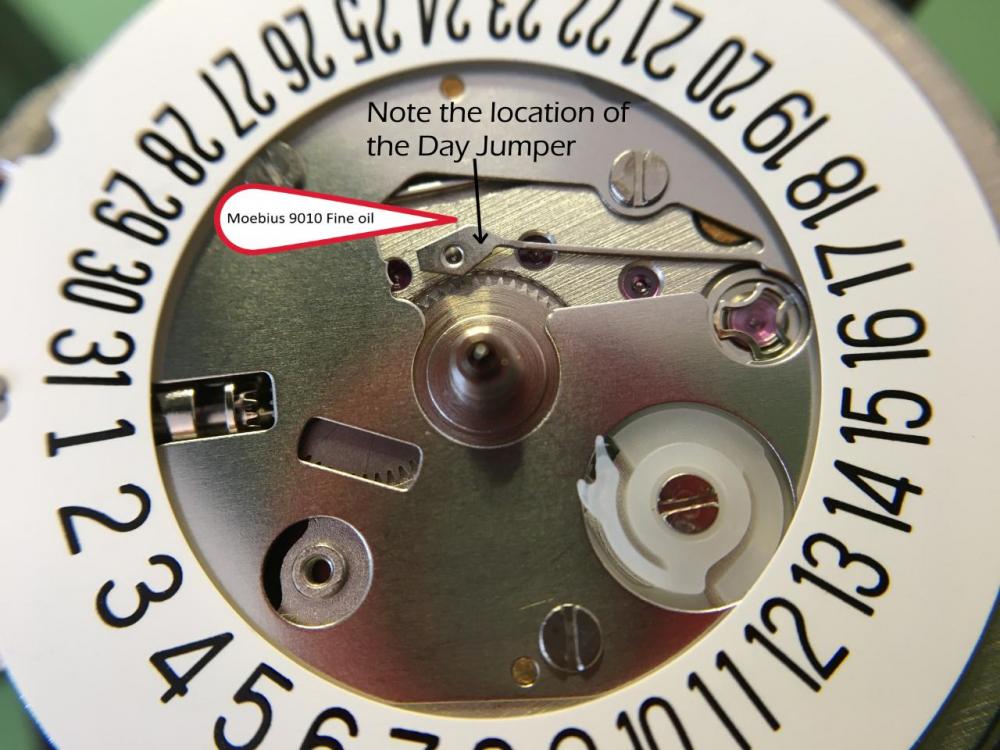

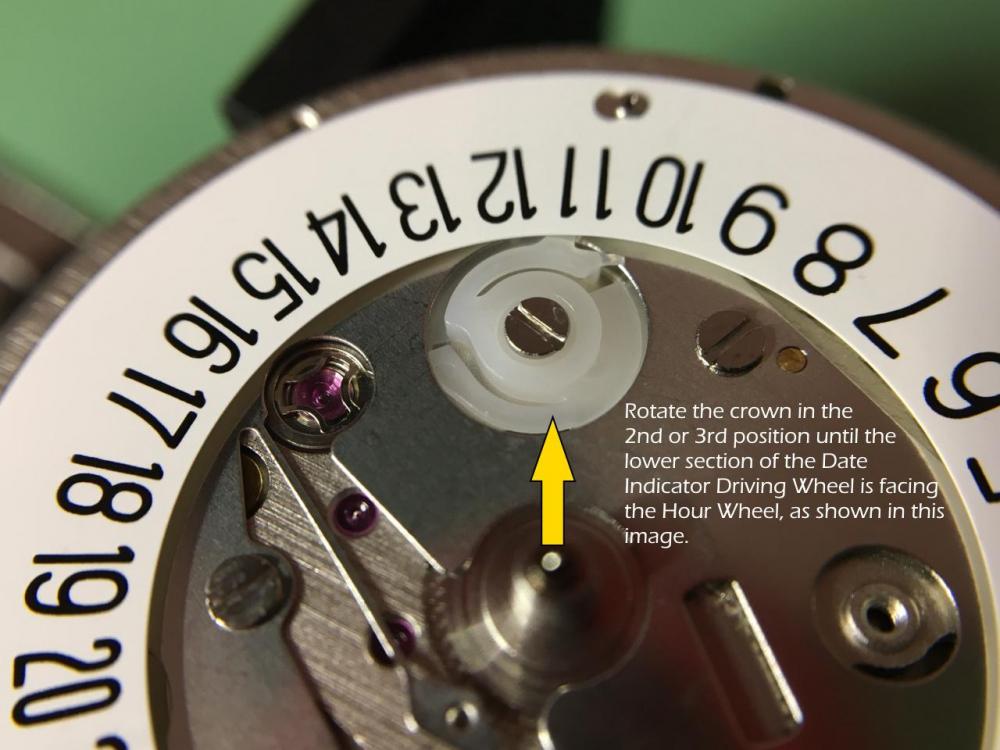

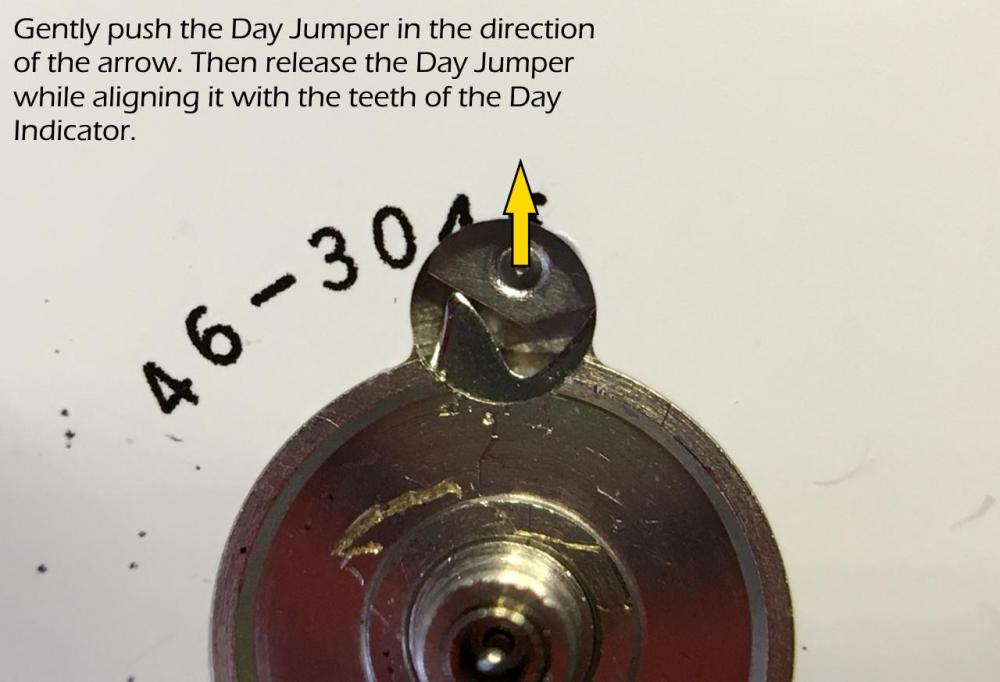

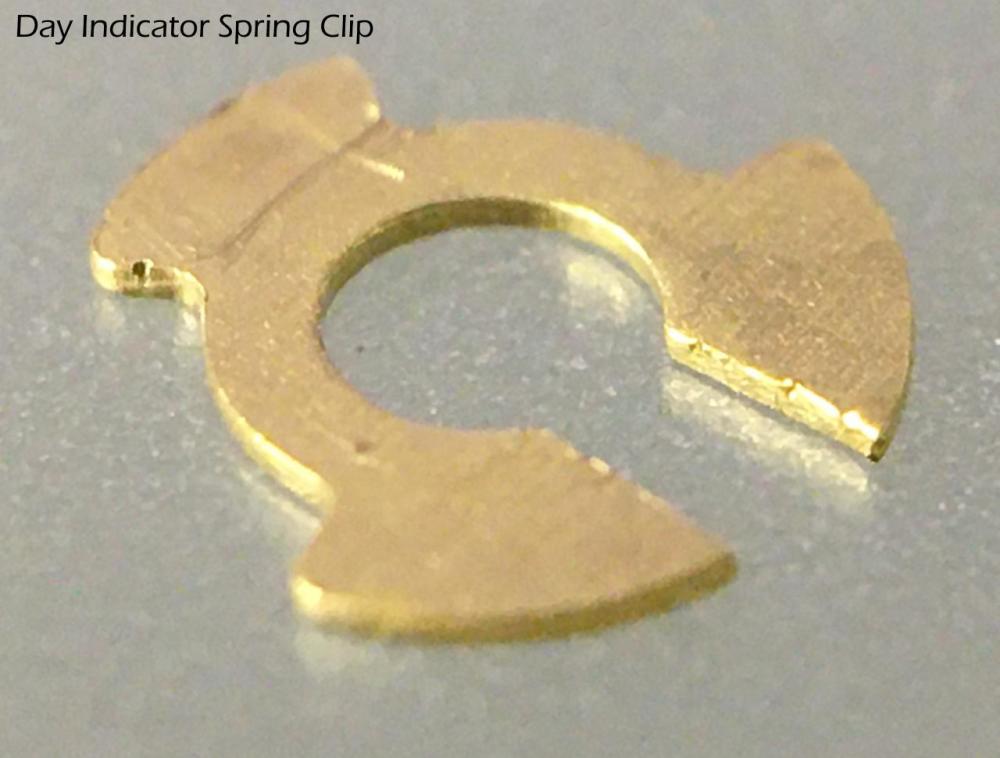

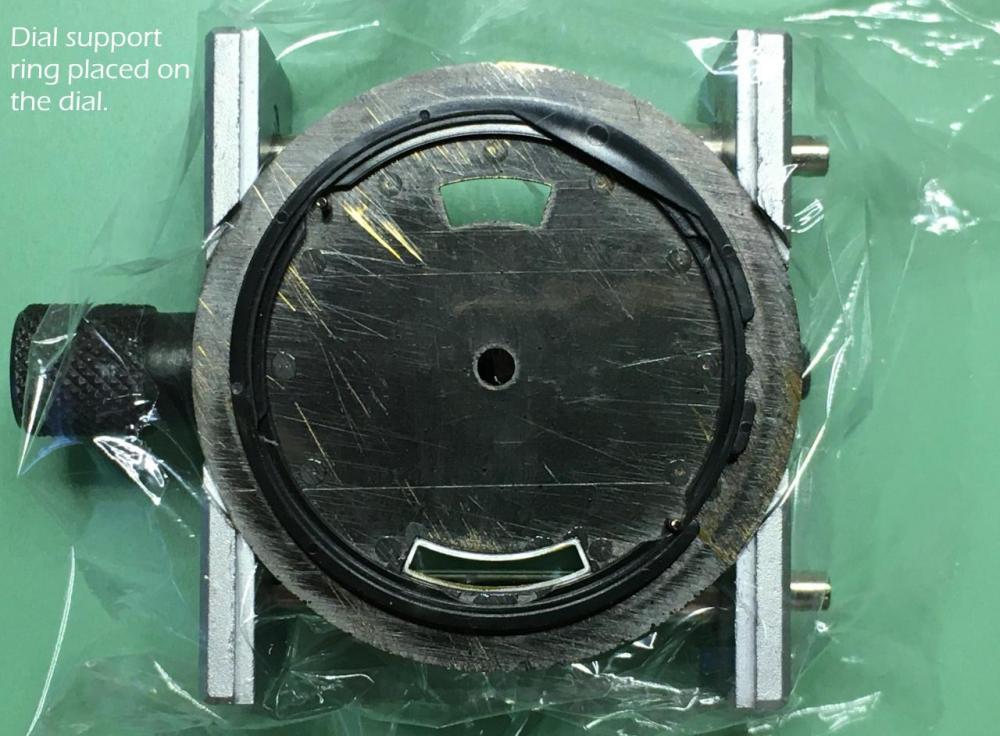

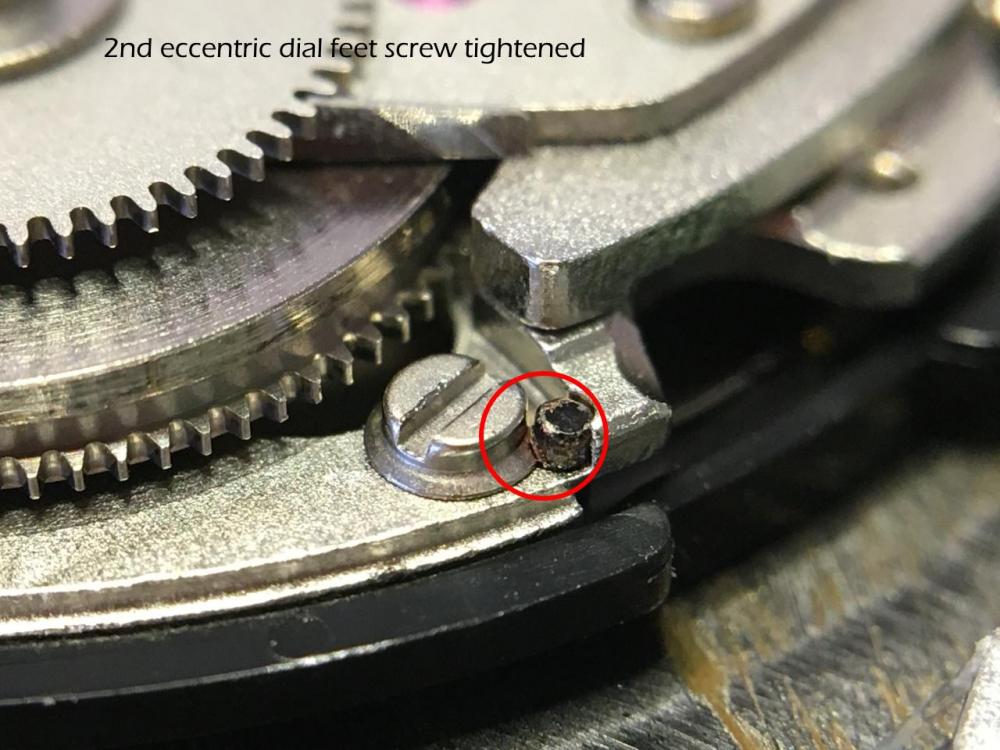

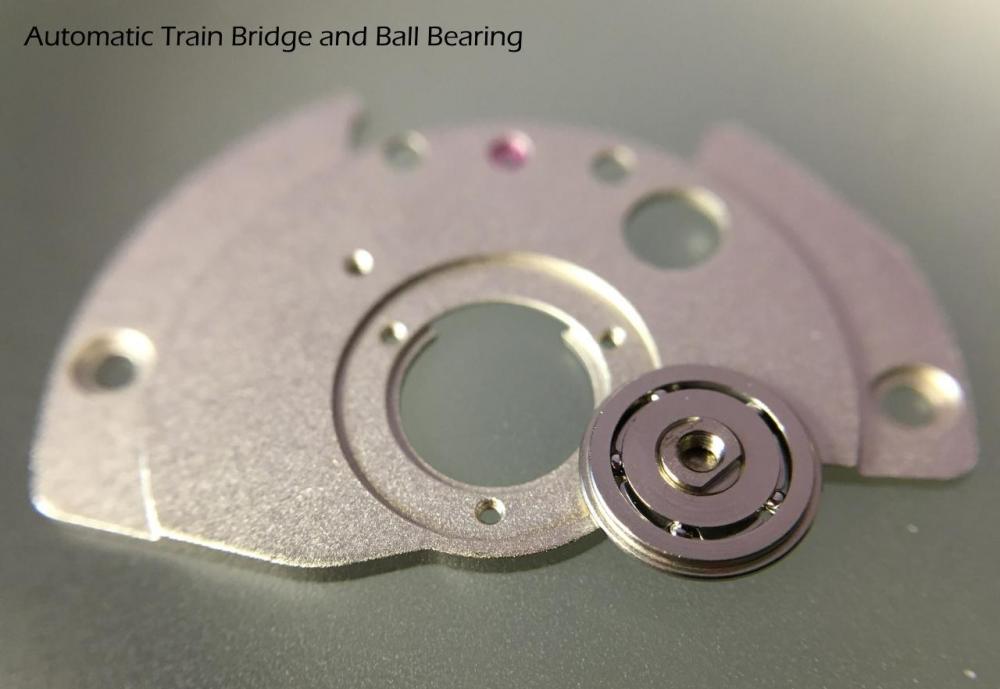

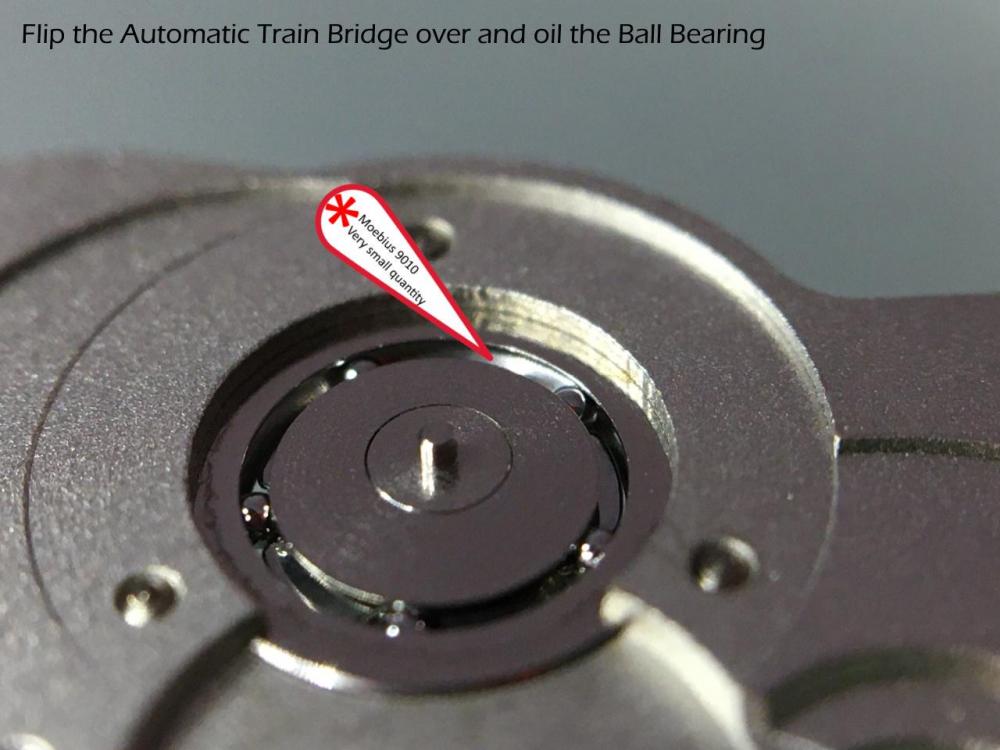

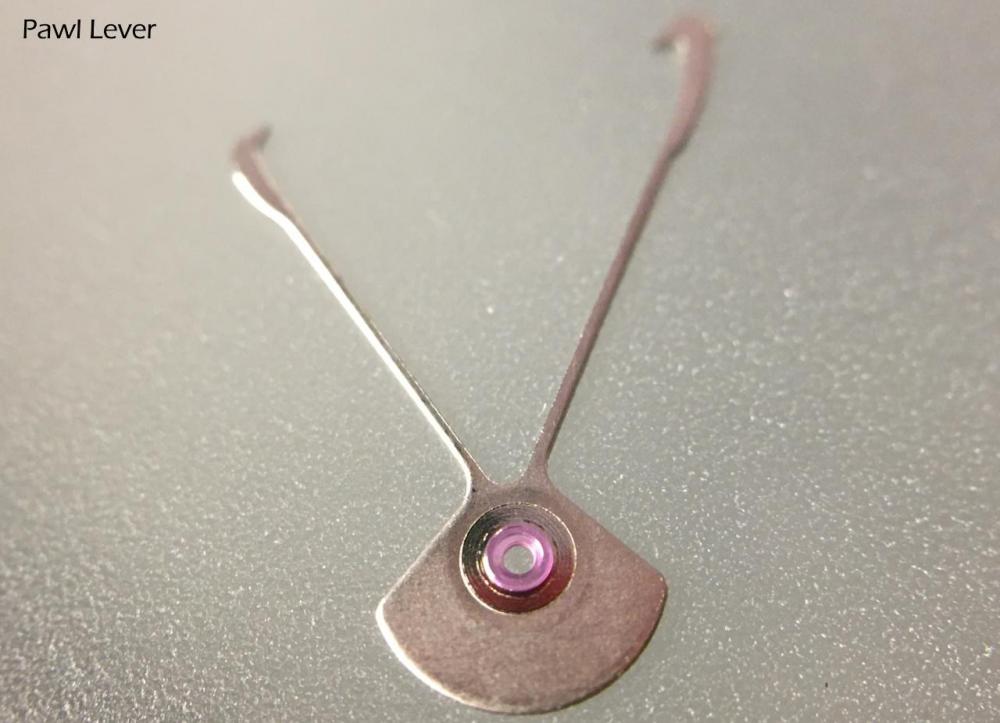

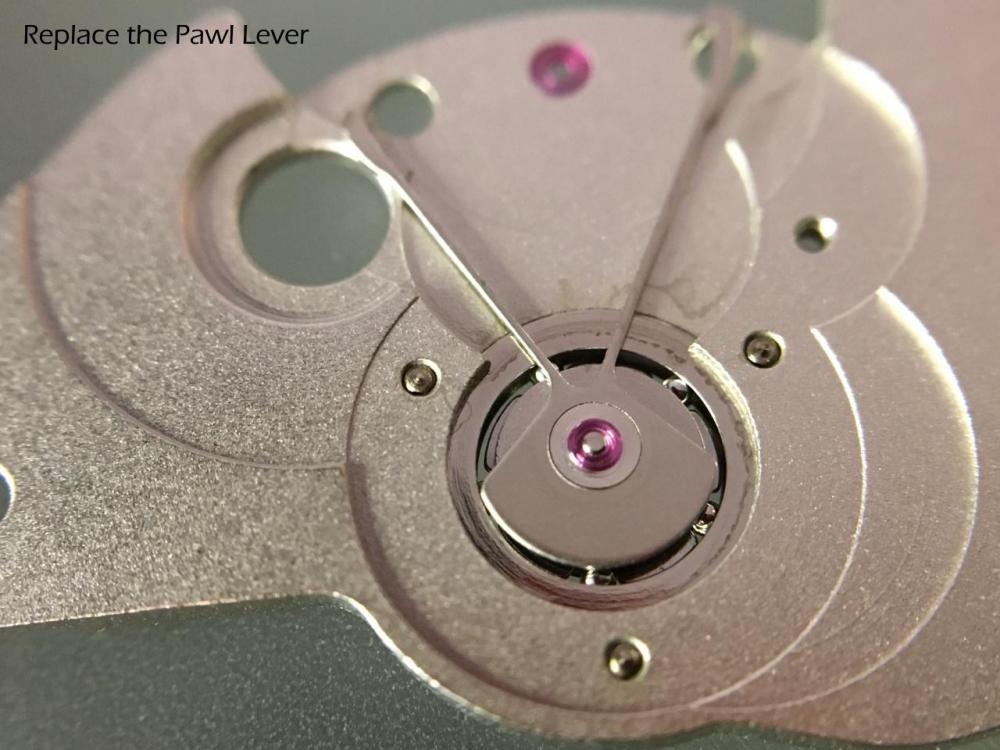

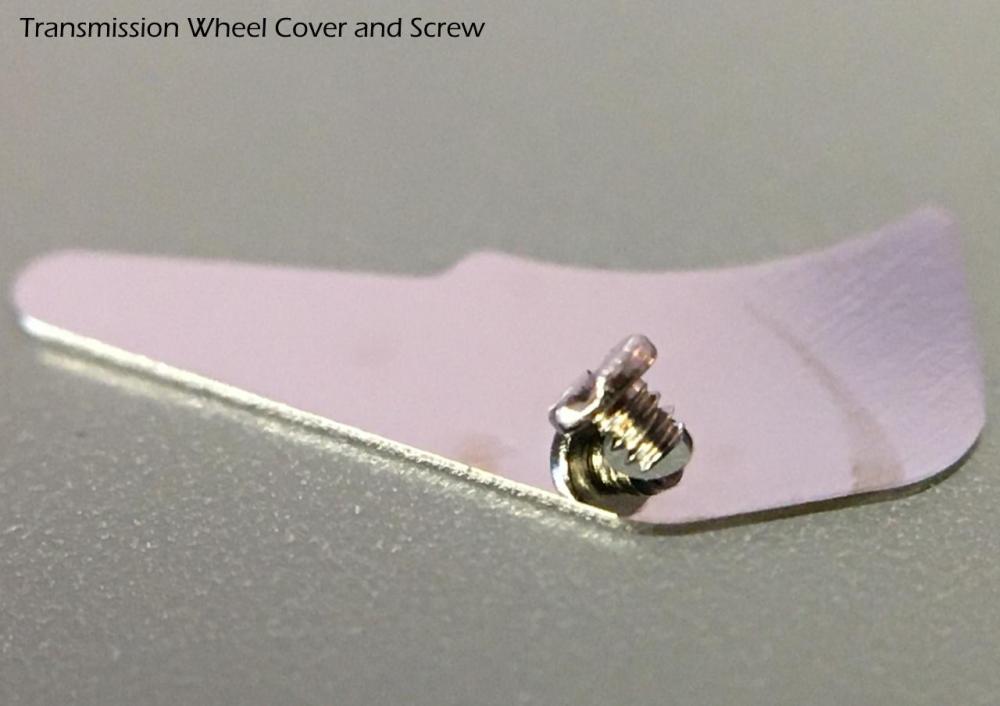

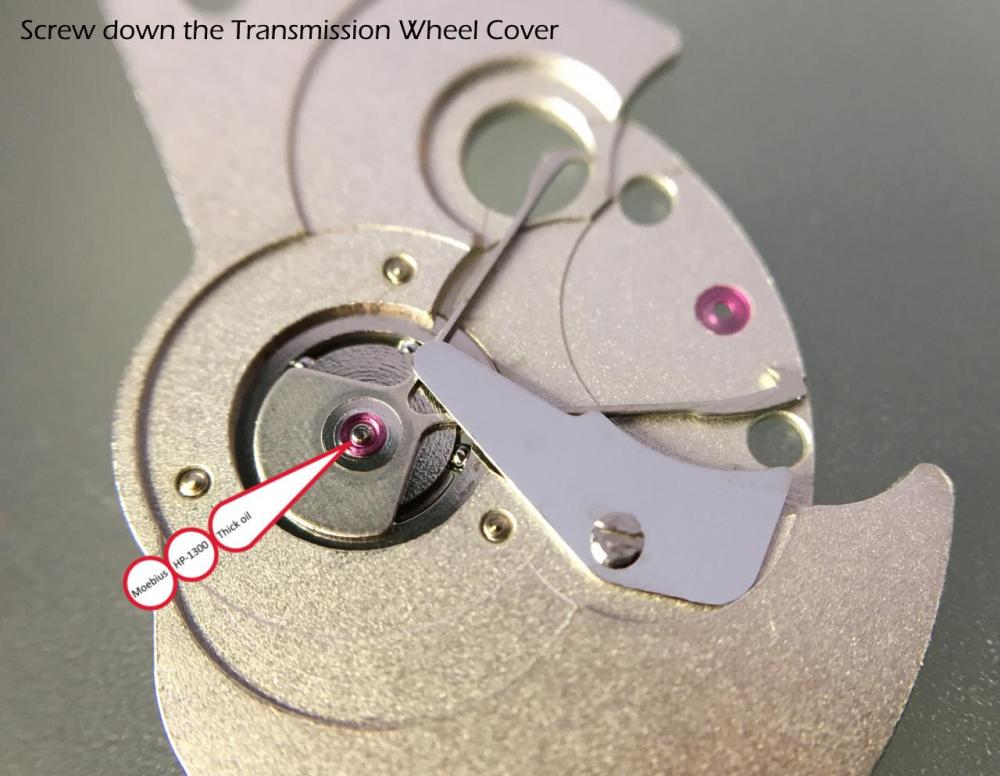

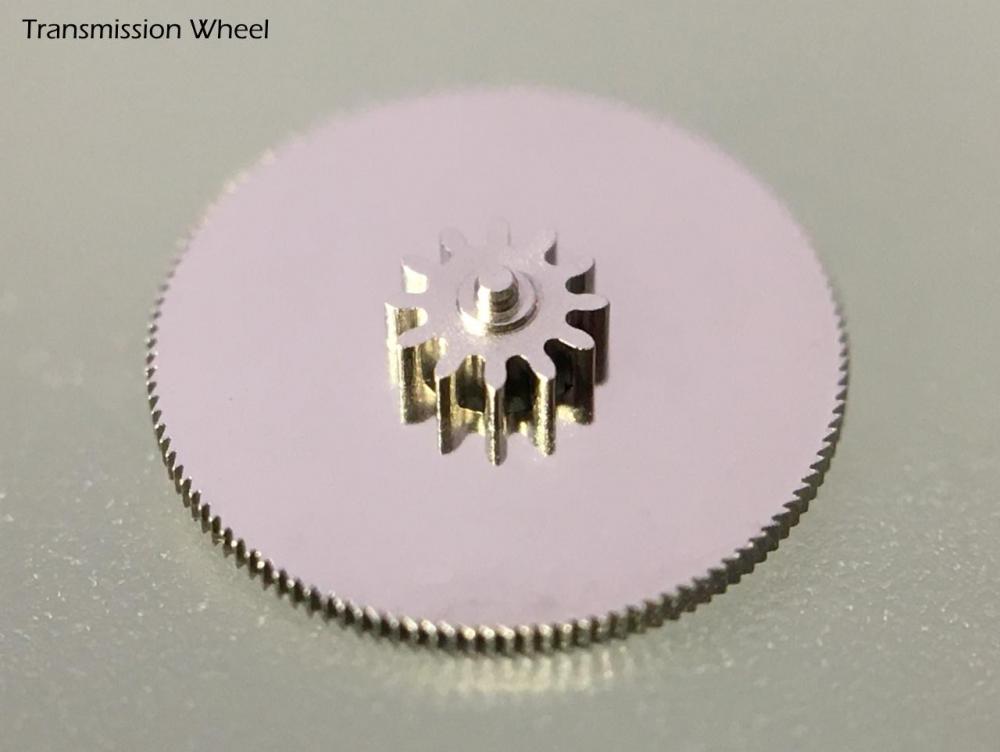

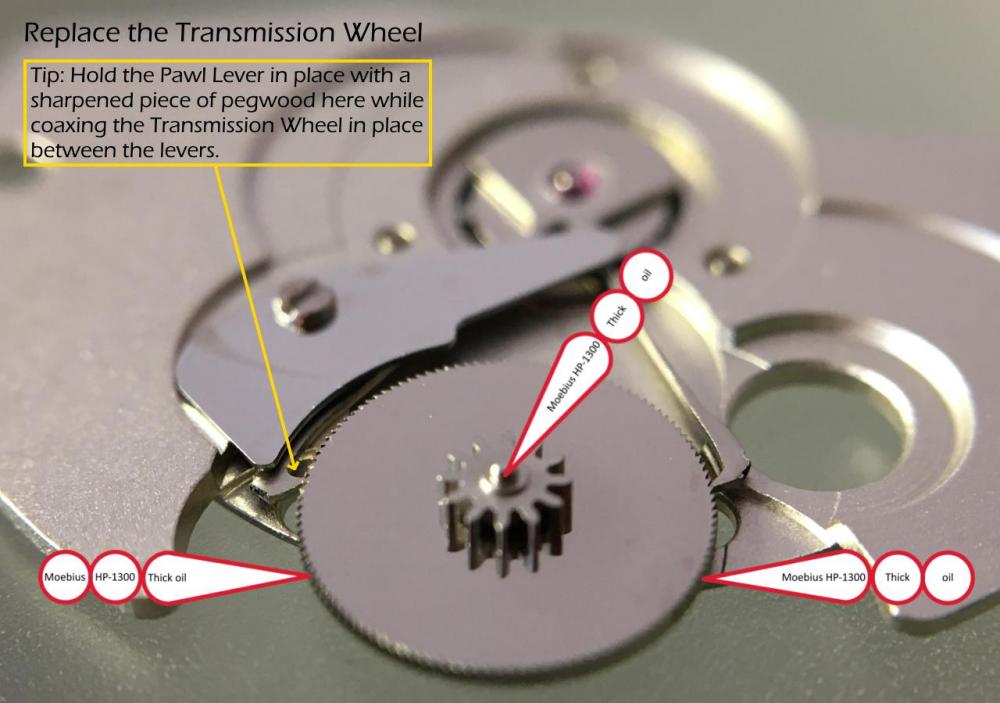

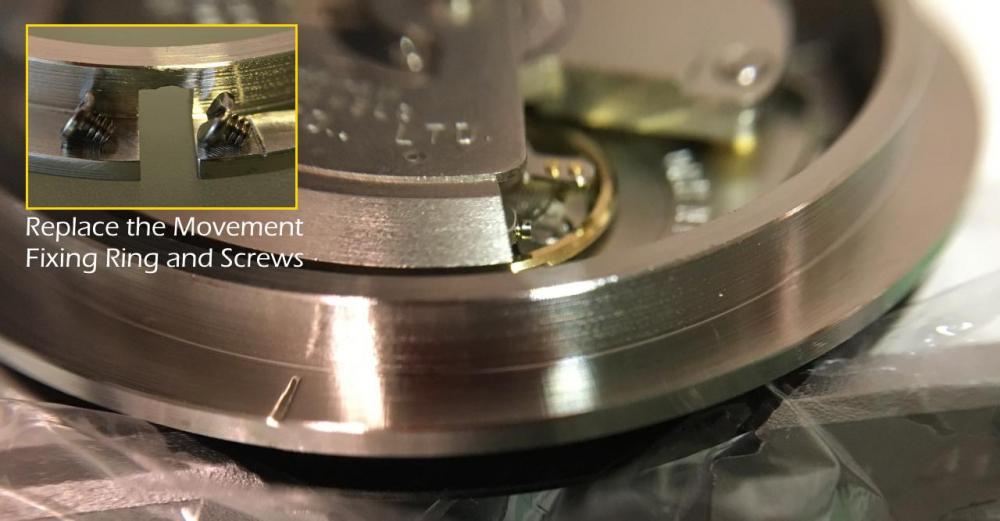

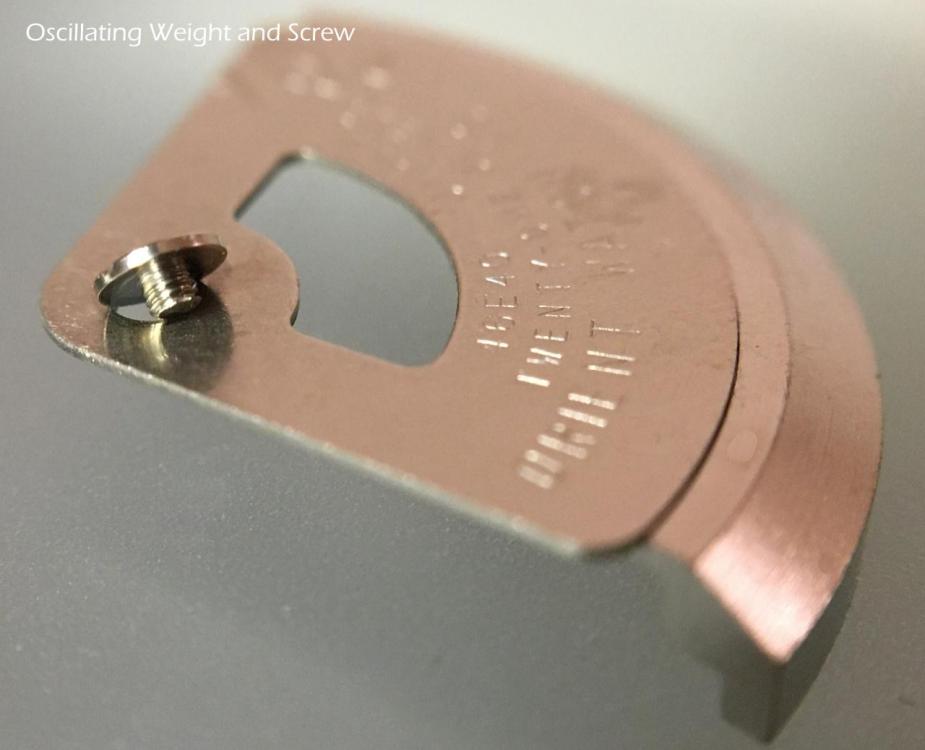

There’s no shortage of service walkthroughs for this and similar ETA quartz calibres on the Internet, and here on WRT. Nevertheless, I thought it would be good fun and educational to create my own walkthrough, and here it is now! Only having experience of servicing mechanical and automatic movements, I truly learnt that a quartz movement is not “just a time telling battery device”, but indeed a mechanical movement, except that the power source isn’t a mainspring but a battery and that the escapement is made up of electronics (no escape wheel, pallet, and balance). So, just like a mechanical movement, a quartz movement has a train of wheels, a setting mechanism, a dial train (motion works), and in this case calendar works. The watch belongs to my father who got it as a gift from my mother at his 40th birthday in 1979 (41 years ago!). He asked me if I could fix the crown which had come loose from the stem. So, I glued the crown back to the stem using Loctite 638. Perhaps not the ideal glue but at least the crown will never come loose again. Anyway, I thought to myself; why not try and give it a complete overhaul!? After all, it had never been serviced and I wanted to learn more about quartz watches and return a perfectly working and clean watch to my much-appreciated dad. One of the things that surprised me while taking this movement apart was that the parts are very small. Smaller than the parts in an averagely sized mechanical movement and that was a bit of an extra challenge. So, before servicing a quartz movement I think it’s a good idea to gain some experience servicing a few averagely sized mechanical movements first. Both the disassembly pictures and the assembly pictures basically mimic and complements @Mark's videos “How to service a quartz movement. ETA 955 412. Watch repair tutorials” and “How to service a quartz movement. Part 2. Assembly. ETA 955.412” which I used for guidance (Thank you!). However, my walkthrough includes lubrication suggestions according to ETA’s technical communication which are intentionally omitted in the videos to save time. For reference I also used the video “Quartz Service ETA 955.112”, @HSL's quartz movement walkthrough, and @Lawson's walkthrough (Thank you!). All part names I’ve taken from ETA’s technical communication. So, without further ado. ETA Calibre 955.112 Disassembly1 point

-

1 point

-

1 point

-

the amusing aspect of this is that no oil is required in the original design but is used with Omega just not for lubrication. page 10 of the attached PDF covers lubrication of this escapement. My understanding is Daniels was not happy about this at all. cousinsuk.com Omega 8645_WI_40_rules for lubrication-4.pdf1 point

-

Hi Luiz In the grand scheme of things it all stems back to the Waterbury clock co in the USA and a convulouted history, have a read at the attached history it might fill in a few holes. Waterbury Antique Clocks - Company History.html1 point

-

Hi Yes in there will be the release lever, in some watches you have to pull the stem out to set position and the release lever apears in the hole.1 point

-

1 point

-

In case you don't have the time, it's been a while since I watched these, but IIRC, the stability of the coaxial escapement comes from the pushing/rotating action of the jewels against the escape wheel rather than sliding as in a Swiss lever, and the degradation of oil over time. With a Swiss lever, as the oil becomes stickier over time, the sliding action of the escape wheel teeth across the pallet jewels results in changes in timekeeping characteristics. With the coaxial, the rotating/pushing action slides considerably less, and is thus considerably less affected by oil degradation. Since it's not/less subject to changes over time due to changes in lubricity, it's more stable.1 point

-

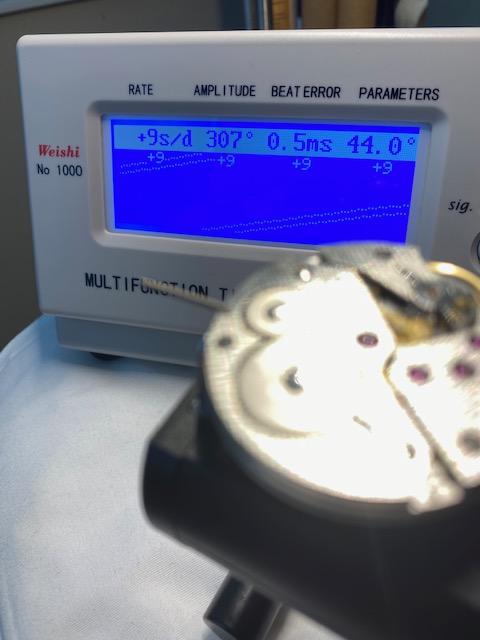

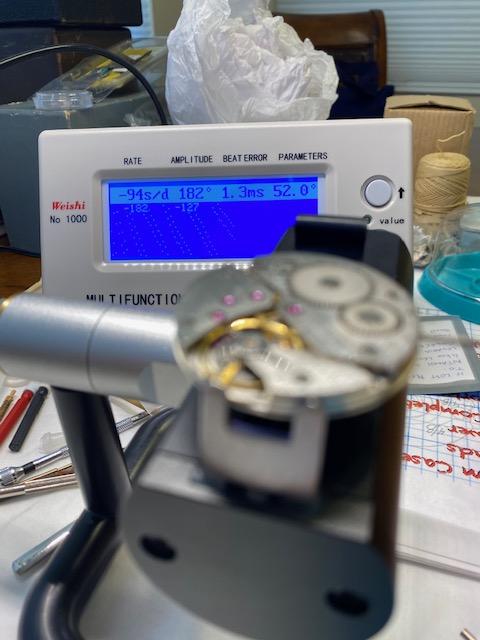

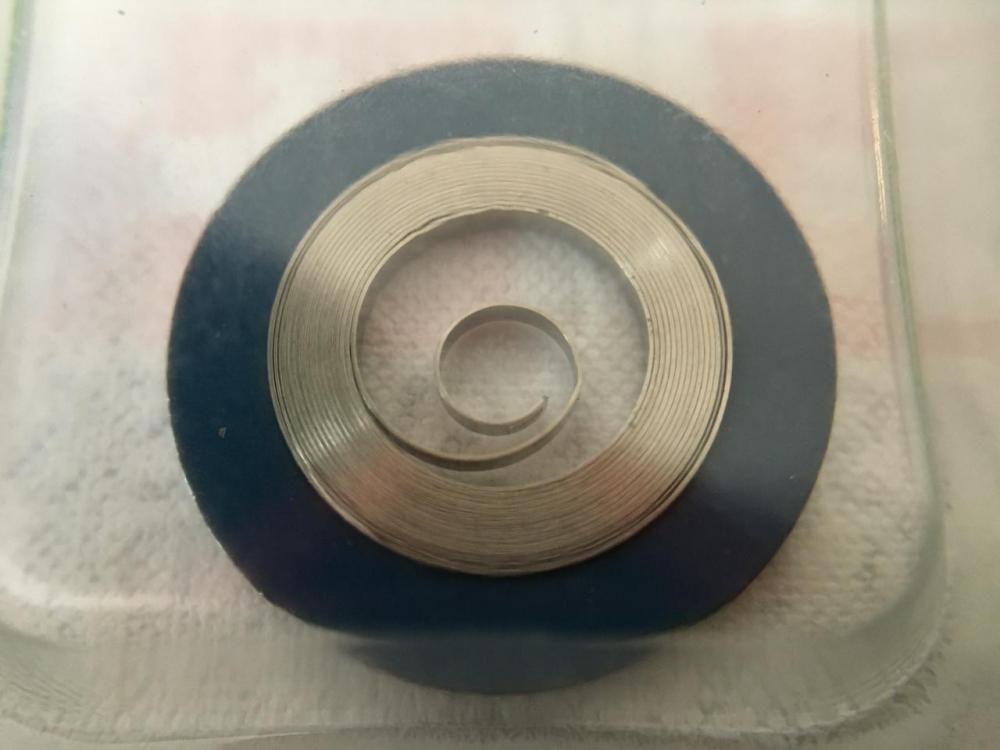

Thank you, John. I changed the position from dial up to crown down and that caused that blip. See below. Thank you. I've reset the lift angle to 44. That certainly changed things. The amplitude went up, predictably, and the movement is closer to accurate. I have an issue where the balance stops in the dial down position. I found several threads with excellent advice, and will begin to identify if it's a bent pivot, poorly oiled end stones, or any other list of many things. I will begin to address that hopefully today. BTW, I purchased the three different sized "jeweler picker uppers" from Cousins. First time buying from across the pond. Thank you, Stuart! Lastly, I should mention I did not disassemble the barrel. After 19 hours, here's the result: I certainly don't have isochronism. I will pull up my britches and do this today. I have a mainspring winder, but I'm reluctant to use it. I've watched Mark's videos on it, and I'm going to do it. I think it's fairly easily replaceable should the unthinkable happen. Fold a tissue paper LIGHTLY grease both sides for the entire length and reinstall. I suppose one has to locate the hole in the end and align it with the hook on the periphery on the inside wall of the barrel. Here goes.1 point

-

It seems I accidentally won this pocket watch. i had my eye on this open balance pocket watch with a mother of pearl case back. I set up a bid snipe on my app for it and then a couple days later I removed it from my watch list because I changed my mind. However, I forgot about the snipe and a day later I got an alert that I had won. hopefully there is nothing broken on the inside. It's being sold as non running, fingers crossed it just needs a cleaning.The mother of pearl case back has a large chunk missing near the crown, not sure what I can do to repair that. I'll keep everyone in the loop as I go through it. It was cheap enough that if I get it running, I may repair the original with epoxy putty, make a mold of it and the cast a new one with a mother of pearl epoxy. May be a fun project.1 point

-

1 point

-

Almost right the Omega co-axial is inspired from the Daniels design, there is a quite good illustration of the Omega one on the tube. Even if the escapement looks fantastic I belive in the device of minimizing the amount of components to make the solution more robust (like the swiss lever).1 point

-

Hi there to you all I hope you are all keeping safe and well, Can anyone help me with a small problem I have with an Illinois 18S Grade 2 Pocket Watch.Does anyone know how to remove the cannon pinion from the center wheel arbor.It looks like the square that is for hand setting is larger than the dia of the center wheel arbor so I cannot remove the cannon pinion as normal?? Also the center wheel arbor has quite a bit of endshake so is it possible to tighten this by using my staking set or is there some special way of removing the cannon pinion.Any help would be gratefully received,Many thanks keep safe,Regards,Seth.1 point

-

@AndyHull pics as promised. There is a brass clip that snaps onto the plastic spacer to almost bridge between the movement and the pusher. Pushing the pusher completes the bridge, presumably shorting the contact out to the case. When I opened mine up there was a second brass clip just rattling around loose which I am struggling to find an appropriate location for. It looks as though it may be to provide a better contact between the case and the pusher outer, or it may be that pusher presses it against the other brass clip, but I can't see how it fits at all.1 point

-

Just asked my Japanese friend about Seiko amplitude. He says "low amplitude" means around 270, 280, but not below 270. Nothing to do with a weaker mainspring, more to do with having fairly heavy locks on the escapement, which provides extra safety in the even of shocks, which can shift the roller table away from the fork.1 point

-

the problem with American pocket watches without pictures is too many variations. That's why a picture would be helpful. or we could find their own pictures so it looks like your standard key wind keys set. then unhelpful sort of parts book that's because in the early days the center wheel could be ordered separate without the arbor. Or you could buy it with the arbor and you'll note it's missing of the pinion as I'm guessing this is one that can unscrew. But the center wheel looks standard which means the Canon pinion should pull off but it still be nice to have a picture. Then I don't quite understand the end shake issue which is why picture would be needed. https://pocketwatchdatabase.com/guide/company/illinois/images?filterSize=18&filterJewels=all&filterMovementSetting=all&filterModels=21 point

-

Oiling pallet pins directly is not recommended, oil escape teeth, If it didn't run then the fault is something else. Bent pivot, out of beat, no endshake on balance staff or escape wheel or fork arbour, something rubbing .. are the suspects line up. Haha Normally out of beat balance dose a few swings, that it ALWAYS sticks hard on the trailing pin, points out to the pin itself. I would take out the ( balance cock) assembly and nudge the fork to do its jumps, if the trailing pivot keeps on sticking, you have located the fault. Balance pivot, impulse pin and escape pivot should fall on a straight line, otherwise impulse pin is out of beat.1 point

-

1 point

-

1 point

-

Superb presentation and I wish your father wears it in good health.1 point

-

With this superb walk-through you should be on top of the score board. Excellent job and this one is a treat for anyone ever to strip / service one of these movements ! Very well done and I'm sure your father will be happy & proud of his son !!1 point

-

This was only $20 and was new. Had a nice ss bracelet with solid end links but someone had removed many links and I had to replace it with this strap. Sent from my SM-N975U using Tapatalk1 point

-

Been finding a few deals on the poshmark app. Just got this pulsar along with two other accutrons for 15.00 threw a nato strap on and a new battery and was in business. Sent from my SM-N975U using Tapatalk1 point

-

lubrication in horology is such a interesting subject. If you do not oil at all at least for a little while the watch runs pretty decent because oil does have a dampening effect. Of course with time without lubrication it will wear out especially if its metal on metal bearings. So the theory on pallet fork lubrication being bad is the dampening effect. Then if the oil gets or goes bad with time like the old organic oils than the effect would be very dramatic. I think the more interesting thing to try would be I think it's 9000 the oil for quartz watches. Because quartz watch oil has to allow the quartz watch to step really fast or it's a problem. The pallet have to move really fast or it's a problem so it stands to reason the oil for quartz watches would work fine. the other reason they don't lubricate the fork is it's considered a non-rotating part it doesn't need lubrication. I think the last time I played with lubricating pallet fork pivots you have to go really really heavy or a lot before you'll start seeing a problem.1 point

-

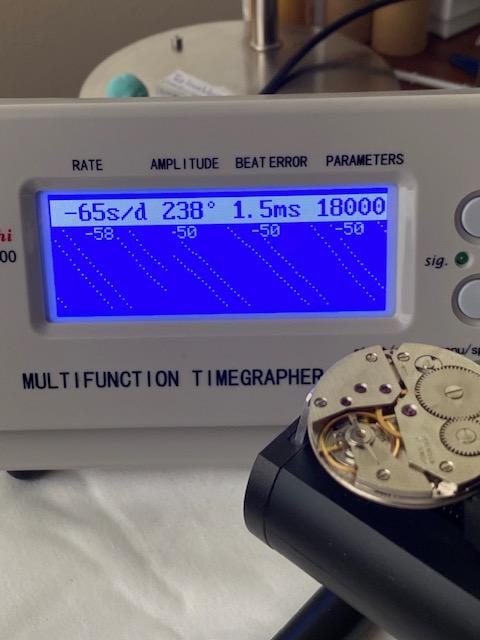

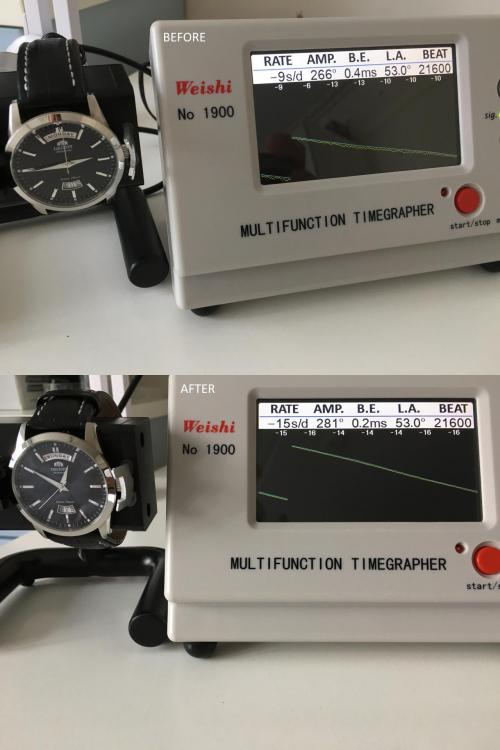

sometimes dictation software sucks for doing anything as it changes how things are worded. so the before image definitely has a problem doesn't it? I've seen the Chinese pocket watch movements and they look pretty decent at least the ones I've looked at so your before definitely has an issue. a minor problem with aggressive cleaning of the end stones. Originally they were surface treated and aggressively cleaning removes that. On the other hand if the watches been serviced multiple of times that also takes off the surface treatment. then for using the timing machine you really need a procedure. so typically wind the watch up let it run about 30 minutes place it on the timing machine. Allow about 30 seconds between changing positions and at least 30 seconds in whatever position your timing in. Multiple position timekeeping is best at the minimum dial up or dial down and this is basically a wristwatch crown down. Then the real test is wait 24 hours and redo the timing procedure but of course don't wind the watch up see how it runs 24 hours later. then I'm attaching an image I circled something that shouldn't be there. You should be able to speed the watch up a little bit and put the watch in beat.1 point

-

Got this coming. Sent from my SM-N975U using Tapatalk1 point

-

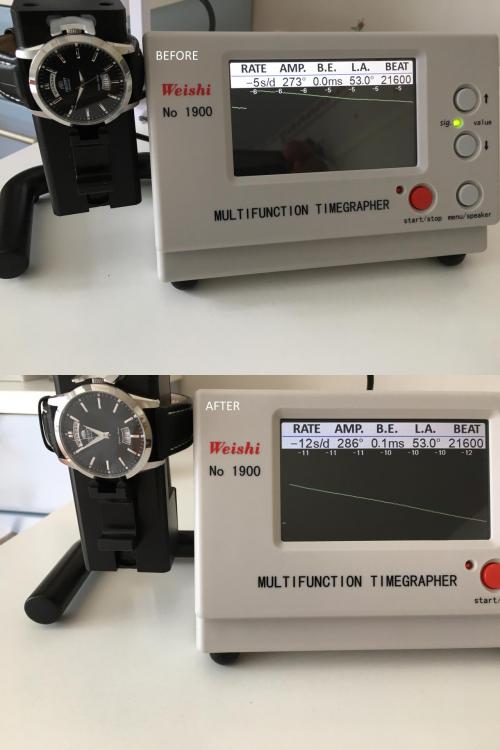

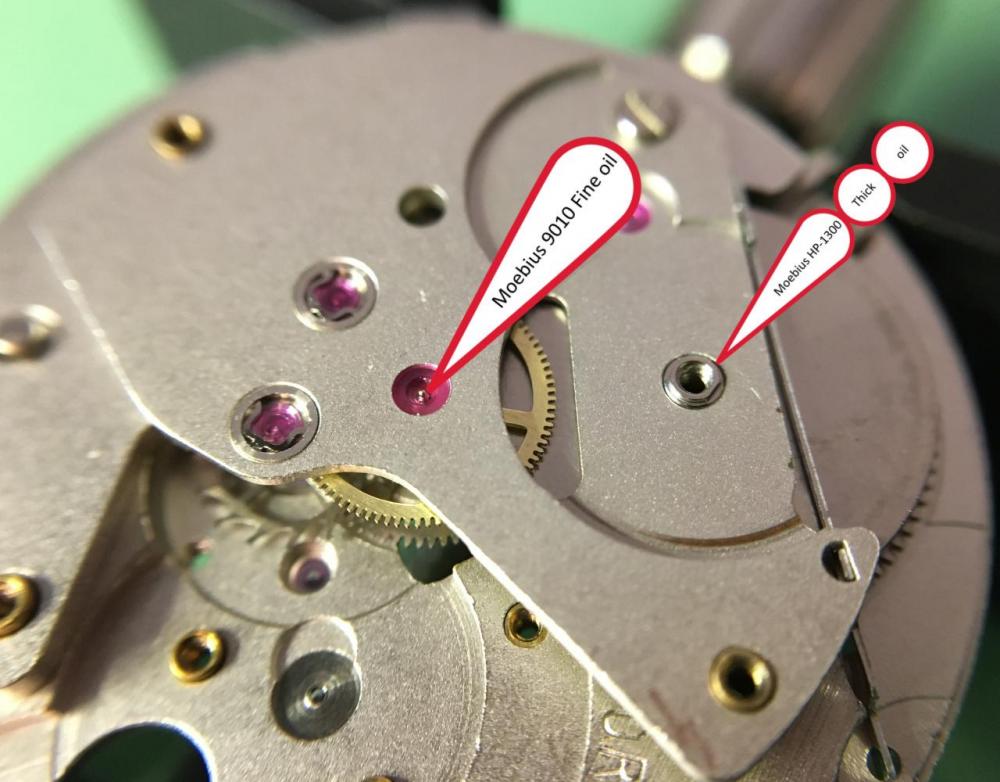

So, I have now oiled the pallet staff pivots. Below are the before and after pictures. I used an exceedingly small amount of Moebius 9010 on both jewels, not more than what would look like a ring around finger. I know it is near impossible, but it still feels like I might have underoiled. Doing the oiling I used my 40X stereo microscope which is truly a massive help. (This type of oiling reminds me of target shooting which I used to do, where you need to be able to breathe deeply and calmly, hold your breath, relax and be extremely focused on the target) I do not know what conclusions to draw. In some positions it looks like a slight improvement. I was surprised to see that it did not affect amplitude. If anything, the average amplitude even increased with 5 degrees. I guess a thicker oil, perhaps Moebius 9104 HP-1300, would have been a better option for creating a bit of drag. Not sure I want to re oil the pivots again, but if I do, I will let you know the result. Anyway, let me know your reflections! EDIT: I guess most of you already know, but to be sure, you will need to click on the images a couple of times to enlarge them.1 point

-

Complete. At risk of setting too low a bar, I didn't make things worse. Before: After: I found success with the bit of rodico at the end of the screwdriver. I found I could rest the bottoms of my fists on the table and manipulate the end stone on the screwdriver and the oiler in the other hand. Under the rodico-laden screwdriver is the little implement I turned on the lathe from dowel rod to install the fiddly Novodiac springs. I'm certain I over-oiled the movement. I'll tear it down again and rebuild (but NOT the Incabloc assy's), lubricating less and see if that gets this 6497.1 closer to accurate. Before the teardown, dial-down would cause the watch to stop. Not much improvement there. The watch doesn't stop, but timographer goes back and forth to "detecting beat" and an amplitude of 160°. I have not checked endshake before. I will check it next time. I have a lot to practice. You guys are a tremendous help.1 point

-

1 point

-

But have you ever seen one with a rotor reluctant to wind?1 point

-

1 point

-

1 point

-

Alwyn Day Date. Listings says automatic. Gut feeling says maybe not. Picture says seller was probably stoned, or maybe they need to speak to their optician. Price says what the heck, its worth a gamble.1 point

-

It means the same timekeeping at high and low amplitude (and in between). There are many many factors that come into play; how well the escapement is adjusted, how well the hairspring is adjusted, if it has an overcoil, if it is free sprung, what type of hairspring collet it used, the alloy of the hairspring/ alloy of balance, the size and finishing of the balance pivots. Ideally a watch will have the same or almost same rate in all positions at full wind and after 24 hours of running. On a flat hairspring watch, with everything already optimized, the main adjustment point is the gap between the regulator pins. On an overcoil watch, everything optimized, the regulator pins can be manipulated but in some cases to get it really good the overcoil is adjusted. Very basically, to make it gain at lower amplitude the overcoil is adjusted closer to the balance center. To make it lose it is adjusted further away.1 point

-

1 point

-

Just asked my Japanese watchmaker friend. He said the old style of lubrication there was to lightly oil the pallet pivots, the reason being better isochronal rate and more stable over time between servicing, with a sacrifice in amplitude. The current thought is not oil. His personal approach is no oil on the pivots. As is mine, and the Swiss industry's.1 point

-

Just won an auction for this sexy beast, another Art Deco watch. It's a Gotham, probably from the mid 30's but I still have yet to identify the movement. I thought at first glance it was an FHF movement, but I'm beginning to think it's an in-house movement. If anyone knows, please let me know. Love the 2 tone case with enamel inlay and the swinging "Drivers" lugs. Only thing it seems to need is a seconds hand. Flawless otherwise.1 point

-

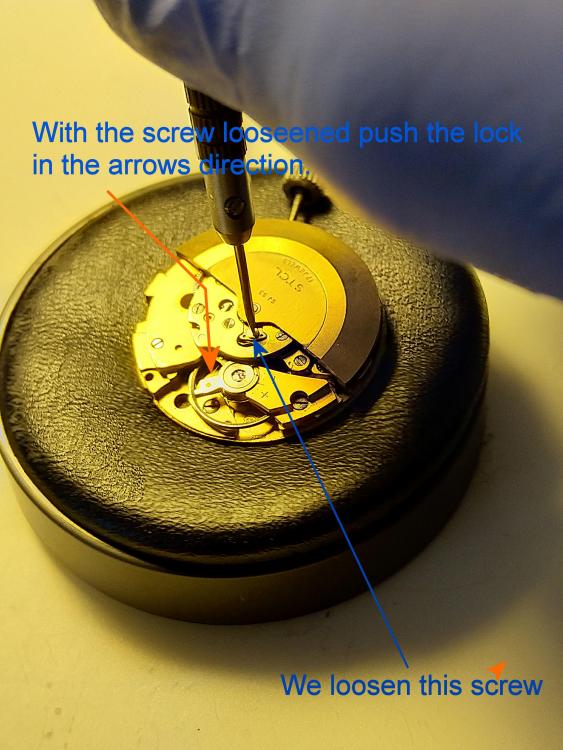

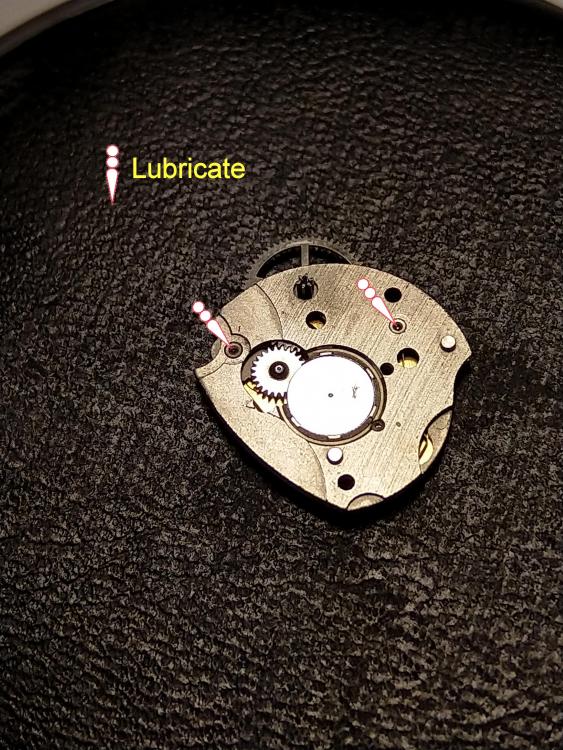

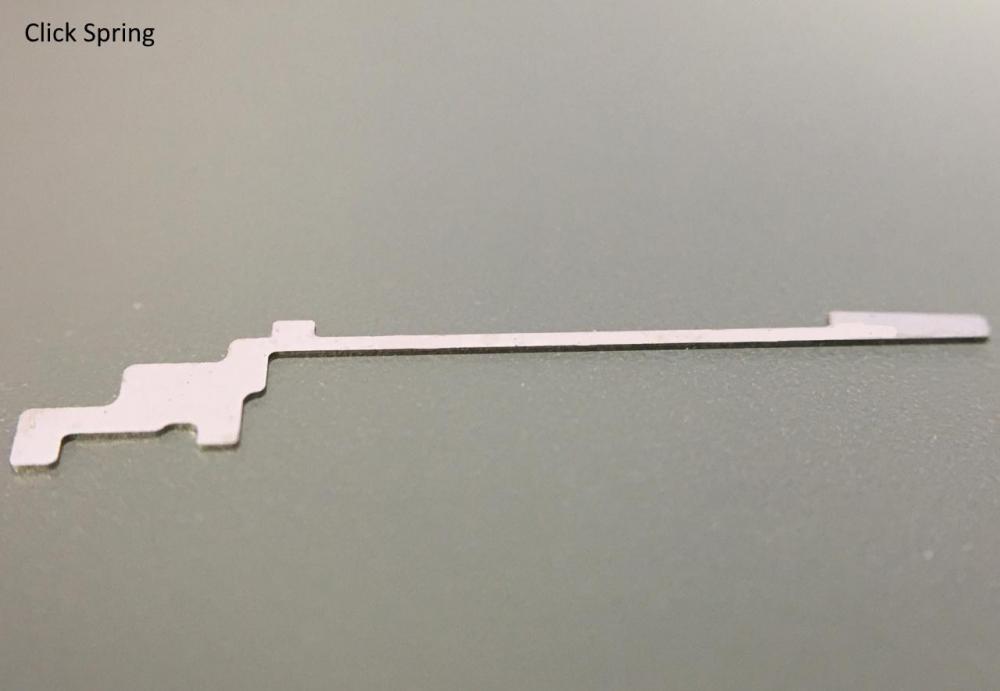

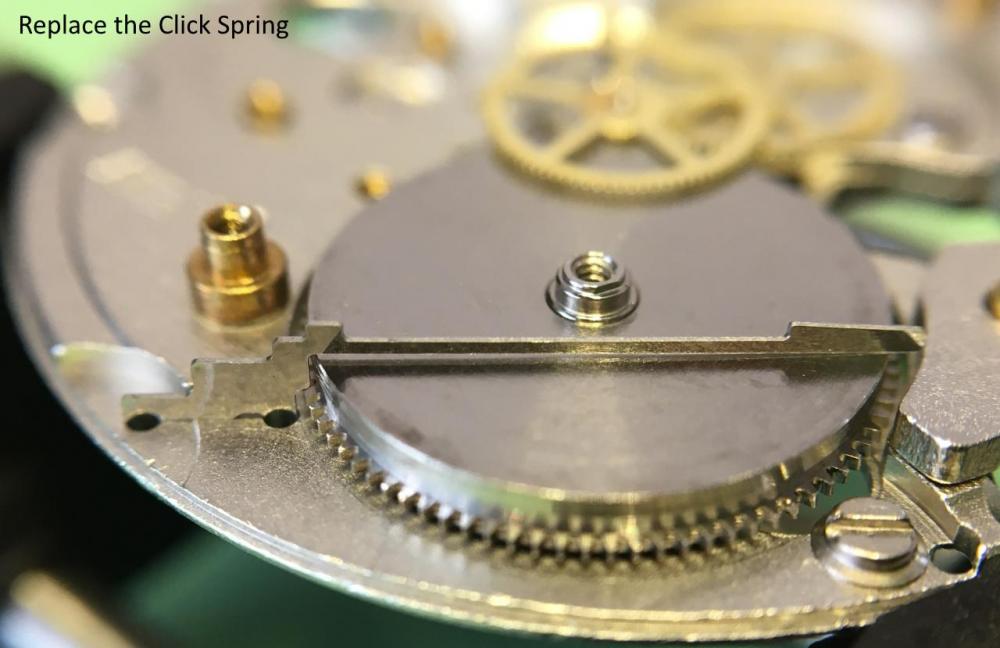

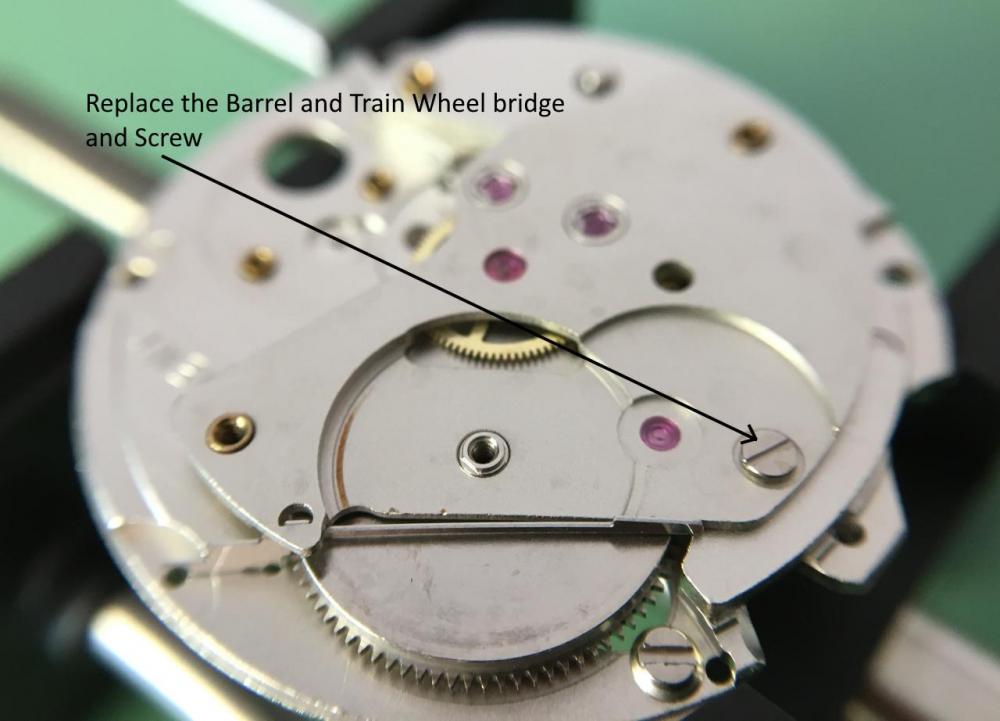

I guess one always can break all kind off springs and by different reasons. I still mostly use manual oilers even if I got a bunch of automatic ones. When looking at your winder assembly I hope you flipped the click so you haven't tried to fit it as it is in your picture. I would invest in Lubricants and practice cleaning of the watch movement as a first step since that will be the most important steps regardless of what you do in the feature in Horology. So even if you got only Moebius 8000 you could always practice lubricate your movement and later on improve the status of it. But now let's se how you could do for now. I taken pictures from the teardown too so you can put it together just by reversing th sequence. First we have to get the oscillating weight off by loosening the lock. Just loosen the screw so you can move the lock to the side. With the lock bolt loose lift the oscillating weight away. To get the autowinder away first screw off the three screws it is fastened with. You could put a extremly small drop in the hole shown in the picture or on the pinion of the gear. Later on when you put the winder back together lubricate at theese two spots. Just a small drop. There are nice pictures shoving the amount you should use in those documents you were presented earlier in this thread . The same goes here lubricate in these three spots, but not when you take the winding assemly apart, just when you cleaned it and put it all together. Always lubricate the surfaces where metal goes against metal. The lever you call "Clutch" actually is like the click by the crown wheel, since you don't have any reversing wheel in this winder this click will prevent the oscillator to wind the mainspring the wrong way. So it is more like a break. In your picture it is flipped the wrong way again. After lubricating where metal parts meet eatch other just put the bridge back and go the reverse way in this picture series. Now you can lubricate in phe previously shown positions. Always try to document by photographing everything before and after you make an egagement on the movement. Hope this helps..1 point

.thumb.jpg.62c9597ea416456873d23c486308f3a9.jpg)

.thumb.jpg.4f263f09121092e489b8efe7553b3bc3.jpg)

.thumb.jpg.3770bf13effde59e7913beabd0ab1abc.jpg)

.thumb.jpg.0c53553d8f623a95aa7ff359b1615c95.jpg)

.thumb.jpg.125b5a8ea93f8292404766808219a1e6.jpg)

.thumb.jpg.0f529bd1699cddd055a3f18bd7aa62ca.jpg)

.jpg.4e9a54c2ef8efccc14b7617545d06fca.jpg)