Leaderboard

Popular Content

Showing content with the highest reputation on 05/06/20 in all areas

-

Hello everyone, today I'm showing another watch of my collection : my Lip Chronometer. Brand Lip Model Chronographe Movement 7730 Valjoux Case material Gold plated Year ? I don't know anything else about this watch, so if somebody has some infos I will be glad to hear them ! I can't do a summary of the history of Lip because the story is tooooo long. Idk if the brand Lip is known in other countries in the world, but in France Lip is a symbol. Lip is the french watch that your grand parents had, and gave to your parents etc... Lip exist since 1867, and since that date there has been some issues with the worker, even taking them to block the factory and sell the watches themselves so that it doesnt close during the quartz crisis ! If you want to know more about that brand, I suggest you to go to : https://en.m.wikipedia.org/wiki/LIP_(company) A. Nogues, watchmaking student.4 points

-

your paragraph is confusing? If it's not parallel and touches the plates there is a definite problem. But if it's also flat when you twist it that indicates that it's parallel which conflicts with the first statement you had that it's not parallel? So when restaffing a watch before you put the hairspring on it before you put the roller on you put the balance wheel with its new staff in to make sure it spins nice and that it is running parallel and not wobbling was that something that you did? Then once you verify that it looks right then you can put the rest of the stuff on like the roller table next to verify that it engages with the fork then finally the hairspring. also watches like this specifically pin lever watches are made the price. So even though they have screws and can be disassembled there really really cheap and they're going to have issues. also in your photograph I can see the lower pivot of the balance staff but I can't see the upper because they hairspring is blocking it. So perhaps put the balance wheel back in the watch the bridge back down and a sideways pictures so we can see what that looks like. https://17jewels.info/movements/e/eb/eb-8021-68/3 points

-

3 points

-

Back on 'blue dialled watches', I finished sorting this one out today, day and date change were 12 hours apart . Turned out to be that the day change finger had somehow jumped over its stop on the plastic date change finger..... Anyway once working correctly it deserved a nice new crystal and some wrist time.. Its a 6923-8000 from June 1982, not a quartz calibre that I've come across before, rather surprised to find that the usual bronze 'C' clip that usually is used to hold the day wheel down had been replaced with, a very much more expensive to produce, solid ring with a sort of collet on the bottom, that clips onto the tube when pushed down..........2 points

-

2 points

-

The one in your link is a genuine french carriage clock but the platform escapement is a modern Swiss replacement, many clock makers replace platforms that have been broken or damaged rather than repair, this effects the value and integrity of the clock.2 points

-

Agree with John, I suggest you go back to the basics, remove the mainspring and roller table & check it spins freely without any wobbles.2 points

-

I had a need to safely remove a C clip holding in two pusher buttons and thought I would share my method on the forum. I had a spring bar removal tool with a solid pin on one end and a scalloped forked end on the other. I placed a small bit of rodico on the bottom side of the clip and turned the C <- gap facing up. As you can see in the picture, I simply used the forked end that was the perfect gap to push off the c clips. I installed by getting the clip in place, C gap facing down, and used a #200 flat screwdriver blade and carefully pressed down to lock in place. I used the case wall to keep the c clip and push button slit in line. Don't attempt to push the c clip back on with the button pressed all the way in, use the wall of the case to help keep the clip straight in line. Hope this helps someone.1 point

-

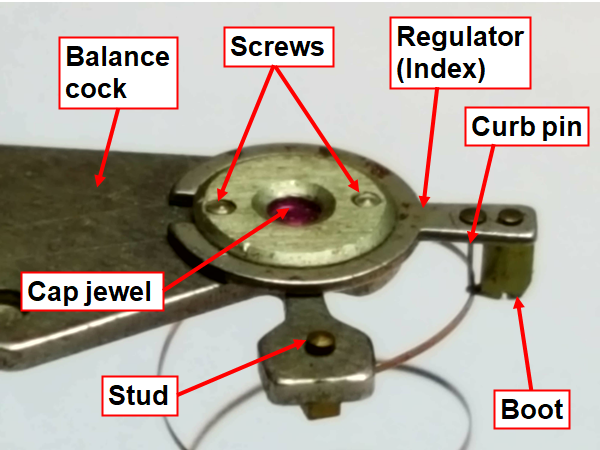

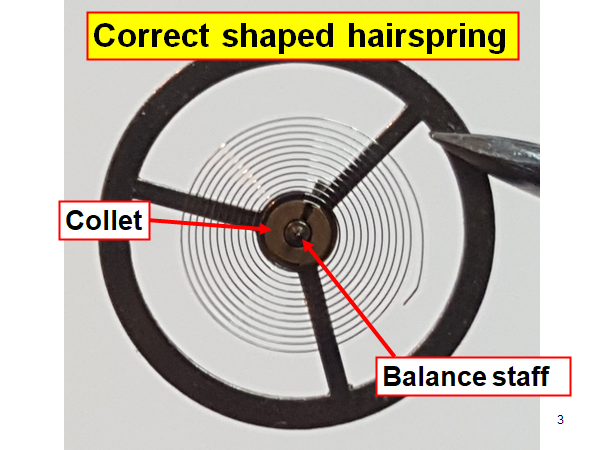

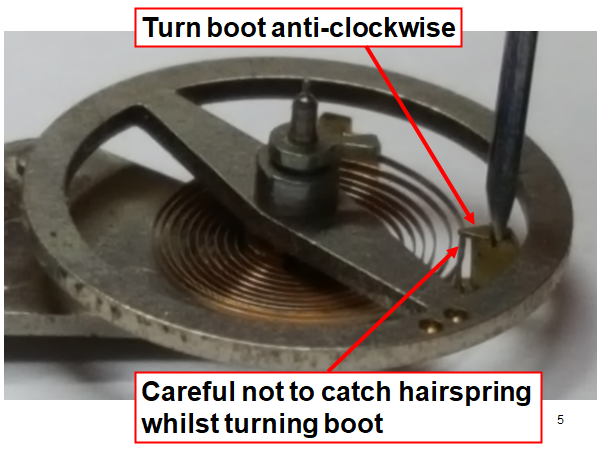

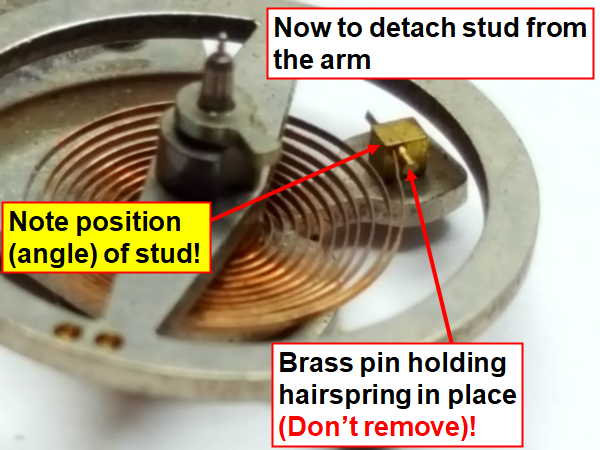

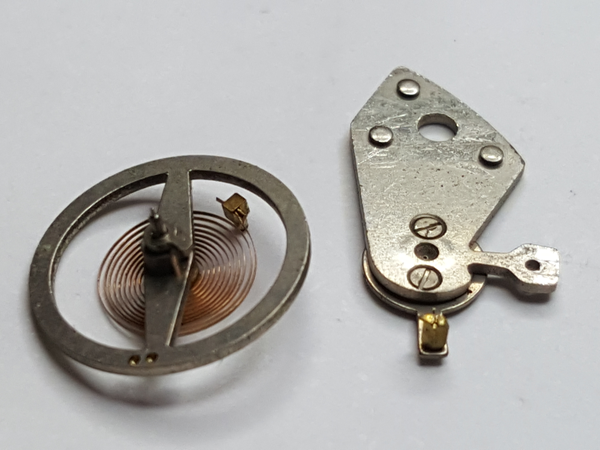

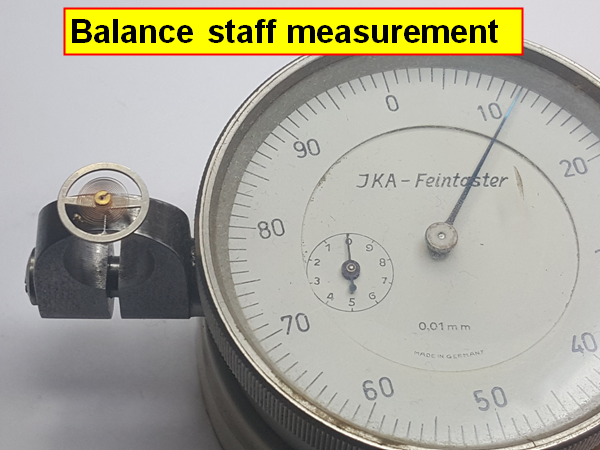

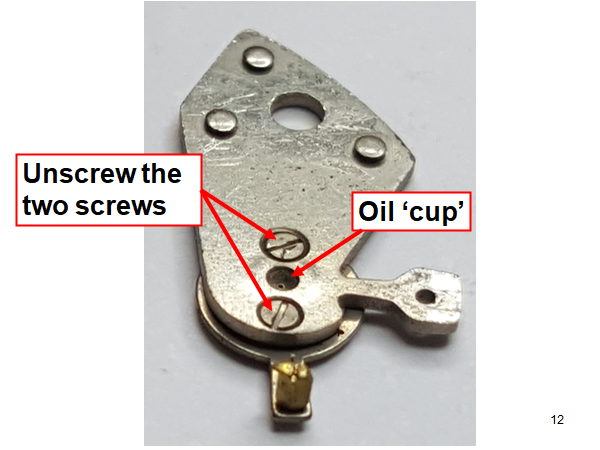

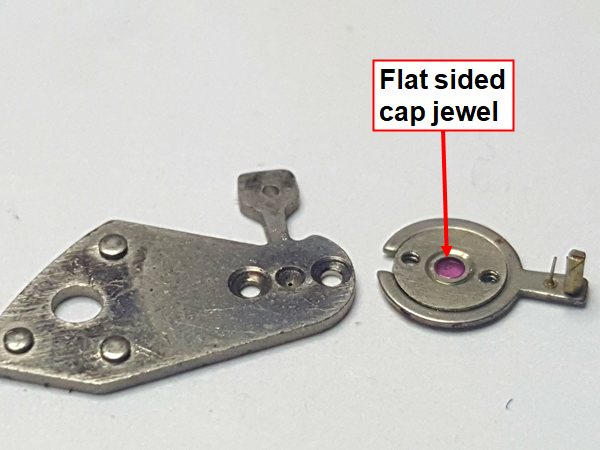

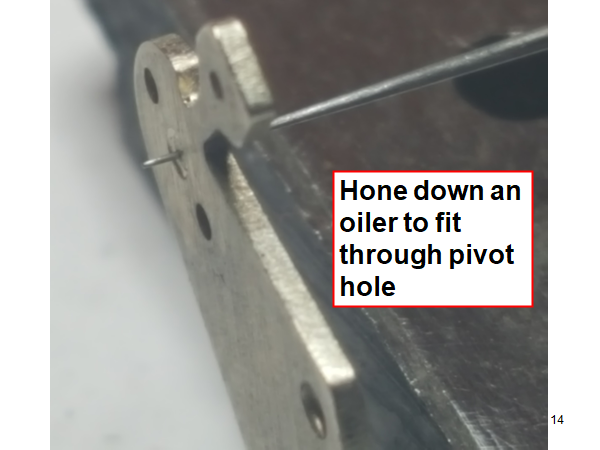

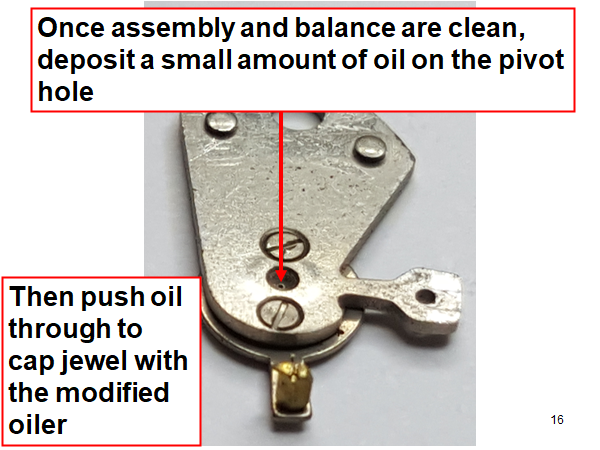

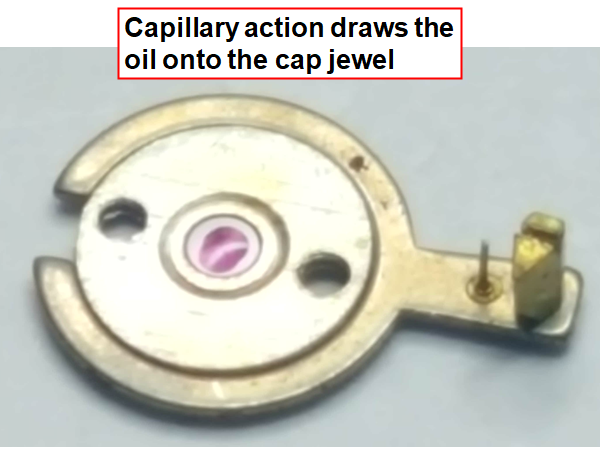

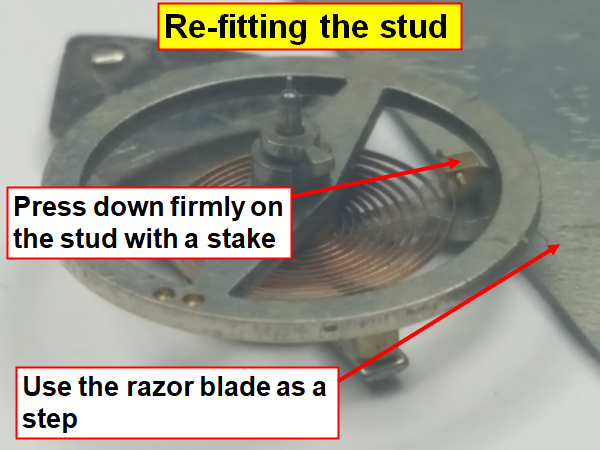

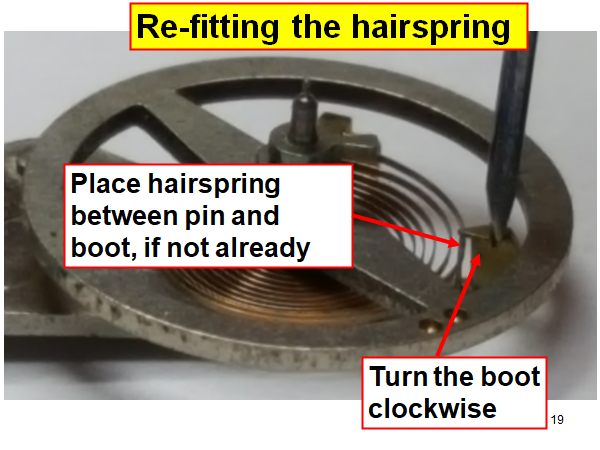

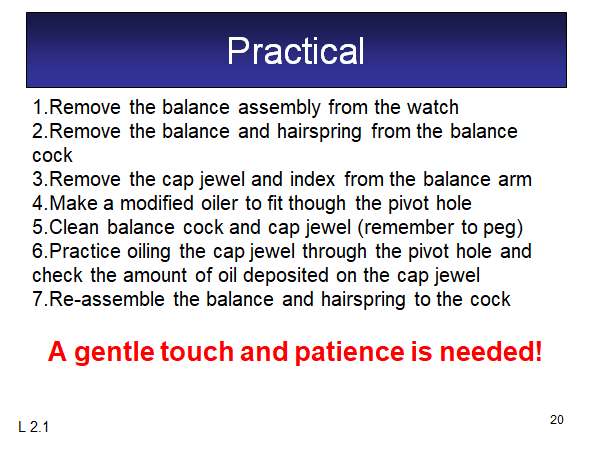

Hi All, I posted a while ago a walk through of the Baumgartner BFG 866 and wanted to add to it, especially as there is little out there to explain how to oil the cap jewels of a non shock proof watch. This is the balance cock of the BFG 866 and as you can see it has a cap jewel held in place with two screws, screwed from underneath. Some pull the hairspring out of the way to oil through the oil sink, but I find it safer to remove the hairspring, but also it is good practice to do so. If the balance and hairspring is removed the shape of the hairspring is seen a lot easier and any manipulation can be done. The hairspring may have to be taken off the balance if it isn't a simple tweak. Removing the balance from the cock is quite simple Measure the balance staff to find out how big it is, so when we make a tool to push the oil through to the cap jewel, we will know the correct size to make We need to unscrew the cap jewel to clean it Now we are going to hone an old oiler to fit through the hole in the oil sink that the balance staff pivot passes through Be careful not to damage the pivot hole Once the balance cock and setting has been cleaned thoroughly, we can then oil the cap jewel through the oil sink with Moebius 9010 If you are not sure you have oiled it enough, or your technique is correct, remove the cap jewel and have a look. Obviously before screwing back the cap jewel it will have to be cleaned properly again This is a safer way than oiling whilst the hairspring is attached to the balance cock. It may take a while longer, but it is a lot safer! It is also good practice in removing the balance and hairspring from the cock, but also checks the state of the hairspring, especially the uniformity of all the coils and how the hairspring is studded onto the collet The other cap jewel in the mainplate would be oiled in exactly the same fashion. Trying to oil the cap jewels and then fixing them onto the setting isn't a good way to oil them, as the oil will probably be smeared when re-fitting them. This is the way I teach my students to oil their non shockproof cap jewels I Hope this helps someone else in the future. More BFG 866 practicals to follow....1 point

-

1 point

-

Yes folks, brought to us from our good friends ebay. Would you pay £400.00 for this? If so you need locking up. https://www.ebay.co.uk/itm/ANTIQUE-STYLE-LARGE-REPEATING-REPEATER-ALARM-ENAMEL-PANEL-CARRIAGE-CLOCK/133396725177?hash=item1f0f107db9:g:QuwAAOSwIWBdmk3O1 point

-

the good news is I can see the pivots and they look straight and they're still there. Something that I can't see is what does the balance staff originally look like? then did you physically compare the original staff with the replacement staff? then there's something is bothering me but looking at the close-up I'm not quite sure? Normally the roller assembly would be tight against the hub and you have a gap? But having not seen the original staff it may be tight against something it may be exactly where it's supposed to be. So the next picture would be put the balance wheel in the watch without they hairspring and see if the balance wheel turns and of it that some weird angle get a picture for us1 point

-

Welcome, Johnny. It's never too late, especially where watches are concerned.1 point

-

1 point

-

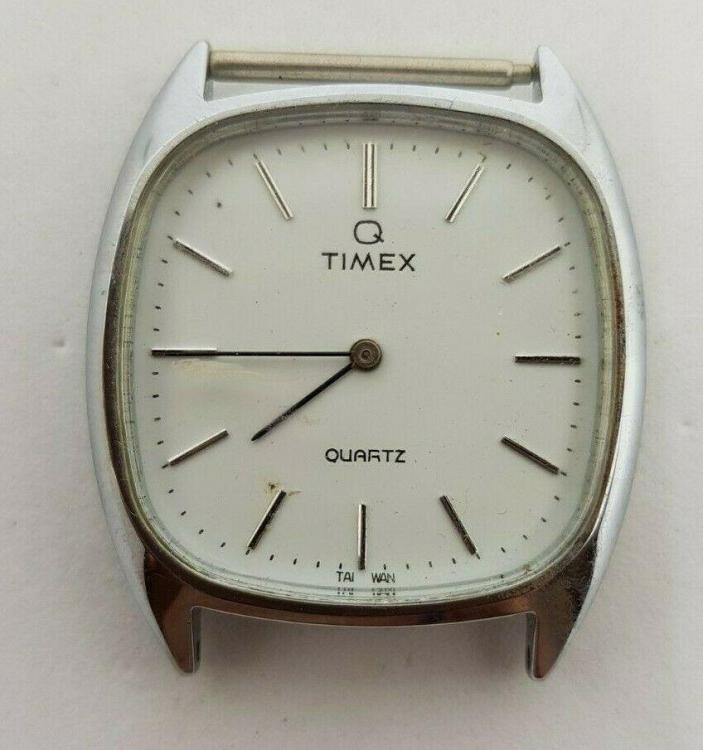

A variation on the one tick per minute Taiwan Timex mechanism. It is missing the crown, but I figure I can probably improvise one, unless someone has a spare of course. Even if the crown proves elusive, I'm only in to it for 0.99p, plus p+p so I'm not going to loose any sleep over it. It would be nice to get it going though.1 point

-

Ok, so this is how it ended: I actually needed two gaskets to get rid of the leak. Here are the places where they should be installed. One of them was missing... It was more difficult to place the new ones than getting out the old ones. Here’s how the old one looked like, well worn: New gaskets for this Bergeon bought from a famous wholesale shop: I also put a new gasket on the post: And as the last step, I put some silicone grease on the post. It moves a lot more difficult now and is more stiff. As a result, it keeps 3atm easily now! Thanks for your advice!1 point

-

That is a real looker! I'm working on a 7730 at the moment, but it has a bent fourth wheel arbor, that to replace would be silly money as far as I'm concerned1 point

-

The crown may be integral to the case. In some old pocket watches, the movement is removed from the case from the front, and you just remove the case screws, pull the crown, and the movement pops out.1 point

-

1 point

-

It will be interesting to see if I can get it running when it arrives. I've had successful repairs on plenty of Timex electric/electronic movements, salvaged a non running ESA9158 with a replacement electronic module and fixed the date change problem on an electronic ESA9157 a couple of days ago. I also currently have a Seiko 3703 electronic on the bench, awaiting a replacement third wheel, which should see it running again, so as long as the coil on this one is not damaged it may well be salvageable.... Just realised that this movement, because of the date complication, is a LIP R184 not R148 as previously stated....1 point

-

1 point

-

You need to be careful, not all cases are brass, some are bronze. Polishing and lacquering brass cases will not effect the value of the clock. You are just restoring it to how it was in its original way. wls1971, is perfectly correct a replacement platform deprecates the value of the clock. If for some reason you have to replace the platform, normally the balance staff or the cylinder has broken, then the original platform should be kept with the clock. Most repairers say it is not cost effective to make a staff, I shouldn't think there are many around who would undertake making a cylinder. One other thing with carriage clocks when it comes to re-bushing, if the clock has been repaired correctly you shouldn't be able to see the new work it is called invisible re-bushing.1 point

-

The clock in your link is typical of French production of between 1890 and 1920, this was the period of peak production for the french carriage clock makers, some cases are plated and some are made with a gold ormolu finish but the vast majority are just polished brass so polishing them up and re lacquering would be the best way of cleaning the clock and preventing tarnish. You can usually spot ormolu cases by the very rich gold colour that has a slight satin sheen these cases should not be polished because it will ruin the finish of the clock. Another thing to watch for when buying carriage clocks is the glass although some attempt was made by the French to standardise glass sizes it was not very successful it is important that the glass is tight fitting and free from damage because it protects the clock movement from dust, broken glass is very expensive to replace because ideally each piece has to be cut for the individual clock, so if you have a couple of broken pieces of glass it can make the clock all but worthless and uneconomical to repair.1 point

-

1 point

-

1 point

-

@JerseyMo has it right, from a distance and at a glance these two are incredibly simiUn Unlike the Movie "Twins" with Danny Devito and Arnold Schwarzenegger, both these are handsome, stylish, healthy and strong, one is sensible and affordable there other is a status symbol and has held it's value Omega on the left, Timex on the right... They look like eyes, starting at me, following me!1 point

-

Classic 60s. Great example from that era. I run in to Lip on occasion but I also dont know much about them. Thanks for sharing!1 point

-

The movement stamped 'Britain', I've been looking for a while and I have never seen another Black dial Marlin with the gold block indices. The silver case may be an over the pond thing, I'll ck the 'bay' Thanks GOM1 point

-

The one I posted is indeed listed for sale. You can find it over on the bay. But, did you know the one you show is not original. the case should be gold toned. The chromed case was used on the one I show and another with a multi color dial and white hands. If I recall correctly the case style is a homage to an Omega that was also marketed in the early 70's just as these were.1 point

-

No... It was a gift from my favorite local Watch Finder. Are you saying that one is on the block? Bob1 point

-

1 point

-

Hi I would consider JD's advice . they are a dry fit but be sure you get it all square and seated correctly before applying pressure the last thing you need is a bent/crushed gasket.1 point

-

1 point

-

I would push it in dry as lubrication could allow it to slip out. If there is a bezel ring to hold in the crystal, then i would apply some silicone on the gasket.1 point

-

usually it's best if you can dissolve it out but? I don't suppose you give us a picture of what the crown and stem are supposed to look like? when I started to do the answer I stopped it but because I agreed it look like dissolving would be bad except? Look at the picture carefully we seem to be missing the square? We still have the rest of the stem there I think so that should unscrew. This is where having a picture of the crown and stem separate would be helpful. But otherwise I think you can just unscrew that part that sticking out. Otherwise there is another way just not on this crown. On a lot of these the brass tube extend considerably out away from the crown. If you're really careful with a watchmaker's lathe you can trim the tube down just a little bit then grab what's left of the stem sticking out and unscrew it usually with a helping of penetrating oil helps.1 point

-

Hi The usual method of removing broken stubs in crowns is to soak them in Alum (warm) which dissolves steel and leaves the brass intact, from your picture it looks as if the stem is screwed into a steel shaft fitted to the actual crown, so I dont think that method would work, One could use a screw extractor which cuts left handed into the screw therfore turning the screw out , the problem being there maybe thread lock or lock tite on the stem . Heating the stem core will destroy any gaskets in the crown. Best bet is a new stem and crown1 point

-

there's probably nothing visible online because if you have to ask they don't want to talk to you.1 point

-

1 point

-

Yes...a small piece of the interior woodwork. Only offered on this reference I believe...2006. GB1 point

-

1 point