Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/20 in Posts

-

What is your definition of a mess? Remember this is not a precision jeweled watch so it may run just fine with what look like crap for pivot holes. Another variation of using solid plugs is for people who don't like premade bushings. So for these a solid plug is used the plate is refinished then a depthing tool Is used. My understanding of these early made watches is that a whole variety of people made the components. Somebody would cut wheels somebody else made the plates conceivably somebody else fit the wheels to the plates. It was a cottage industry of a whole bunch of different people all coming together to make one watch. This unfortunately from a repair point of view means that every single watch is unique.3 points

-

Have you ever taken apart, inspected cleaned in a jar, lubricated, reassembled and tested a (pocket) watch before? Because the gained ability to do that in is much more important than semi-automatizing the cleaning process, something that becomes important only to workshop doing many pieces per day. And you have some many more important tools to worry about before that piece of machinery. FYI we have a dedicated section here where it's considered polite for new members to introduce themselves.2 points

-

2 points

-

Ok. I see. It's an AC brushless motor. Not DC. TThis is probably a single phase AC induction motor with a run capacitor. It sounds like the run capacitor is failing. Look for a cylindrical object. It could be an aluminum can or plastic cylinder. If you can remove the capacitor, look at the rating and capacitance. If you have a multimeter with a capacitance measuring capability, measure it to see if the value is still within specs. A failing capacitor can cause an AC induction motor to seize or hum.2 points

-

The cheap China demagnetizers are ok. But you have to use them correctly. They do not come with a auto power down function like some expensive models. What you have to do is press the red button, feel the object that you are trying to demagnetize vibrating, then slowly lift it away from the demagnetizer perpendicularly to about 6" - 8" away. Then release the red button. If this is done incorrectly, you could end up magnetizing the object instead. You can get a small magnetic compass, even those small compasses attached to watch straps, to check for residual magnetism. There are some phone apps that can measure magnetism also. Practice on your screwdrivers. Magnetize one of them first. Then hold it near the compass, the needle will move. Then demagnetize it. If done correctly, the needle shouldn't move anymore. Best of luck.2 points

-

My understanding was that brass plugs were used of a better quality of brass than the main plates in some cases. You see different grades of brass used for different parts within clocks too. Is there any trace of original scribe marks left on the plates at all?2 points

-

2 points

-

1 point

-

Sorry I have not come across this particular movement but, looking at the movement it is a low grade pin lever with no jewels (apart from the balance). It will be difficult to achieve a top performance due to worn pivots etc but a runnable watch should be achievable.1 point

-

Hi Dave I found this link, It appears they are linked to canada . http://www.rodaniacanada.com/about.html1 point

-

1 point

-

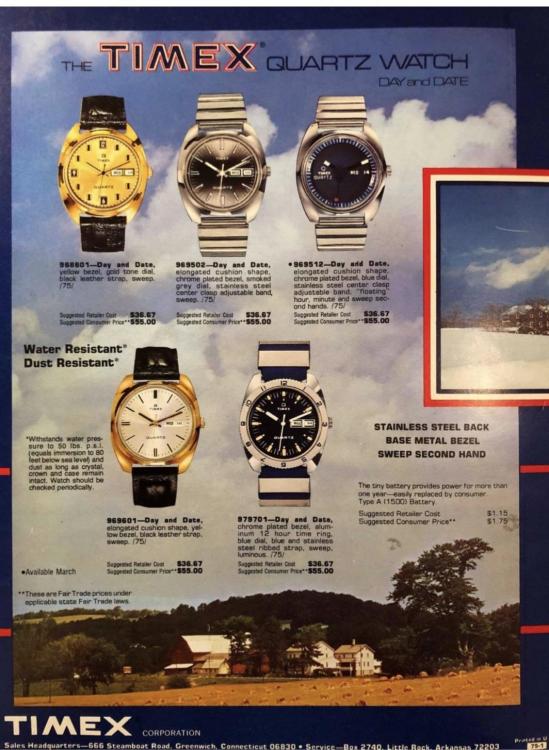

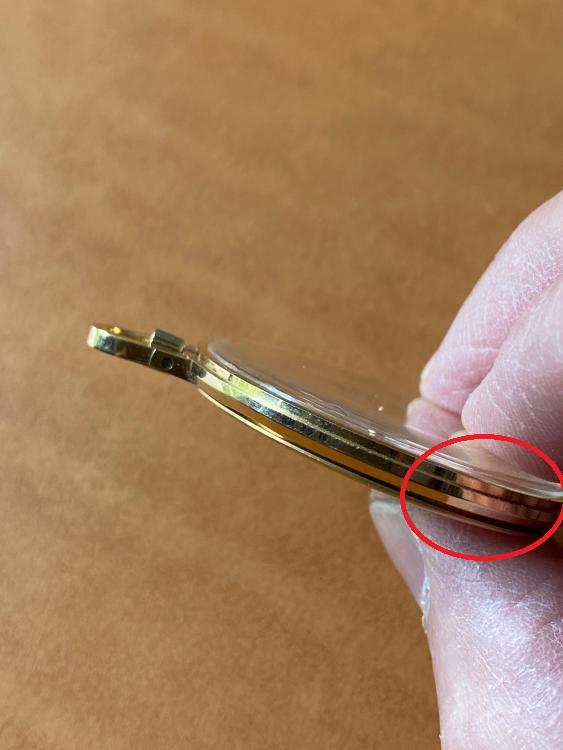

Sporting my newly acquired Timex Q with their version of a mystery dial. Had a scratched crystal but It cleaned up nicely. The replacement bracelet looks like a large heaping pile of steaming rhinoceros poo and the clasp was mangled and wouldn't close. I was able to tweak the clasp into submission though. Seller sold it as not working because they couldn't figure out how to get the battery cover off, lol. My gain, Placed a fresh cell in it and off it went. I do like how the hands seem to be floating in space. The sales catalog suggests this was available in 1975 at a retail price of $55. That's $263.87 adjusted for inflation. Not exactly a cheap watch, but very affordable. Love the midnight blue dial and the "floating" hands.1 point

-

It is OK to open it and clean. You won't do any harm. Years ago you would just replace it with a new unit, the same thing with old Seiko movements, Seiko recommended you to replace the sealed unit I think every 5 years. These days replacements can't be found so you take it apart and clean the whole unit.1 point

-

Hamilton 992 with a salesman case. Sent from my iPhone using Tapatalk Pro1 point

-

Thanks. I I did put on a ring thru finger trick. Just look up jdrichard soft ring or removable fingers. PS: I have a big safe:) Sent from my iPhone using Tapatalk Pro1 point

-

The grandfather clock simply had the weight cables get cross/tangled on their spiral-grooved cylinders during a slight move. Very obvious. At that point, I had no idea how clocks or watches worked!1 point

-

A Tissot gentleman powermatic with a blue face and bracelet. Originally, I was drawn to the Oris pointer-date, but that fell out of budget this year and the Tissot looks like a solid everyday watch. What I've been struck by is the difference between the gorgeous macro photos and videos of watches and how they look to my 55 year old eyes. Just can't appreciate the detail without a loupe, other than knowing it's there. And thank you!1 point

-

You have a good selection of Horology tools there. If I were your neighbour I would have taken up house burglary by now[emoji56]I’m very envious. And please keep up the videos I really enjoy them - especially the card tricks [emoji38] Regards Deggsie Sent from my iPhone using Tapatalk1 point

-

Just like most other drill press of its class mine has 5 steps pulleys. I use some reference tables to set speed based on drill size and material, then augmented by experience and observation. I like to set the correct speed aiming to get a nice swarf like the below. I'm very curious about which effect a new capacitor will have, it might turn it into a beast, LoL.1 point

-

1 point

-

1 point

-

Take a good look at the barrel bridge, this is made of brass and much more likely to wear than the arbour. I have a 215 which had very heavy wear there. It was hard to see at first because the arbour doesn’t protrude all the way through the depth of the plate, so the hole looked perfect from the oil sink side.1 point

-

Don't just rely on the demagnetizer, remove the balance and clean it and oil the pivots. HectorLooi is correct in how to use that type of tool.1 point

-

So I cleaned and re-oiled the mainspring and barrel. This time using 8217 braking grease on the walls and 8141 on the spring itself. I then worked the spring to latch securely onto the arbor - just in case something was slipping there. And it happened again! But I got to observing things as I wound I witnessed the slip. The whole barrel whizzed around without effecting the ratchet wheel or stem. What I’ve discovered is the barrel has quite a bit of wobble when installed. So much that it can wobbles off the teeth of the drive train. Which explains why it releases on an autowinder but was not releasing when wound and set perfectly still. So now I’m on to suspecting either the arbor is worn or the brass jewel is worn (or both). I can readily order a new arbor from Ofrei so I’ll start there.1 point

-

It would be really nice to have a picture to grasp what sort of size were looking at. I was just thinking about my drill press I like my fingers I most definitely would not try to hold the pulley. Although I might be able to hold the drill chuck but I really don't want to think about that. I know that if I was drilling something and carelessly or stupidly didn't use a clamp to attach it to the table and something went spinning it was always in my best interest to keep my fingers away. A lot of this depends upon the size of the drill press.1 point

-

It does better with practice. Trust me. Try not to lose them in the first place. Good tweezers and tweezering technique are essential. Get a good set of tweezers. A fine tip, medium tip and heavy tweezers. When I say good, it doesn't mean $$$$$. My favorite tweezer cost just over $1. A good tweezer must have tips that meet evenly. No crossbite or crooked tips. And tweezers, like screwdrivers, meed regular maintenance. When a part inadvertently flies off your tweezers, don't panic. Try to see the direction it flew off. Listen for any tell tale sounds of where it landed. Did it land on the bench or the floor. Personally, I hate it when it lands on the bench. Tell me, who has a clean, uncluttered benchtop. I prefer that it lands on the floor. I use a flexible magnet strip about 14" long and sweep around where I was sitting. If that doesn't work, expand the search area. It usually doesn't fly more than 6 feet away. Oh yes, check if it landed on your clothing too. I once had a screw drop inside my shoe.1 point

-

Yes, you use the lantern end that has many sized holes where the pivot end protrudes and you can use a pivot file or stone to take off material in a flat manner and round the end by angling the pivot file as the part turns. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

<= Wood/metal worker/drill press owner/restorer. For a the little cheap models (like Harbor Freight and equivalent), there really isn't much torque. They're made for hobbyists to make small holes in soft wood about three times a year, and last about five years. As long as ~90% of them work out of the box (hence the generous return policies), they call it a win. The nicer bench top models also don't make much torque, but they're more precise (you won't be shimming shafts) and last longer. My 1939 floor standing Delta has a 1/3hp or 1/2hp motor (I forget which motor ended up on it), and due to the way the belts are tensioned, it'd probably stall if I was really aggressive in something thick and hard, but that's due to a design issue that was rectified 70 years ago, and there are ways around it... You should probably be able to pull the motor and check it out. I'd be looking at the belt, pulleys, and motor shaft first. I'm not really sure what a brushless DC motor looks like mid-failure though... I'm wracking my brain, and I'm not sure I actually own a single tool with a brushless DC motor, and I'm pretty certain I haven't had one fail on me.1 point

-

There is a another method to do this if you have a watchmaker's lathe it can be found at the Link below https://youtu.be/9K0-DVmZjrg1 point

-

I am a dad and my dad said the same for me, plus I screwed up a few balance staffs by trimming them down too much: lesson learned. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

I have the eTimer escapement analyzer software and do understand the basics. However, I would like Mark, who I know has this software as I saw it in his shop review, to do an instructional video on how to properly use it for diagnostics of watch problems. A big “Please” is in order here. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

1 point

-

Some month ago Johnnie here gave an Ingersoll Sealion that needed some care and had no bezel anymore ... It took me some time but today it's on my wrist ... Envoyé de mon moto g(7) power en utilisant Tapatalk1 point

-

Good evening everyone, hope we are all managing quarantine fever reasonably well. Today I'm going to briefly cover my 1938 Westfield Art Deco watch I recently completed. It began with an urge to acquire a nice Deco watch. I won a handsome Hamilton, but sadly the seller had lost the watch. Thankfully they refunded my money and the hunt continued. I finally came across this Westfield powered by a Bulova 10aw. The price was perfect because it was sold without a crown. I tracked down a donor movement with a crown that didn't look too ratty and purchased it as well to serve as a parts donor, wise choice as you'll see. The parts donor arrived first. It only needed a clean and lube to get it ticking away Parts donor... After a delay, the watch arrived. It looked thousand times better in hand than it did online, thankfully. It was fitted with a truly pristine Crystal that surely must be a recent replacement. The case doesn't seem to have any base metal showing through. I promptly opened the watch and lifted the dial and movement from the case. The Westfield as it arrived... A close-up of the barrel bridge showing the little crescent moon date code signifying the watch was made in 1938... Looking closely, I found that the crown and stem weren't just missing, it was broken, snapped off at the winding pinion. I removed some of the keyless works to get at the stem remnant. After fishing the piece out, I pulled the crown and stem from the donor. Winding stem switcheroo... I then attempted to give the mainspring a wind and see how the watch performed. After barely 2 turns I heard a crunching noise indicative of a broken mainspring. Thankfully the donor's was perfect. I swapped out the barrels put it back together and gave it another wind. Off the balance went and the mainspring wound smoothly and stopped at the end. Sprung spring... I put the dial and hands back on, gave the dial a light wash down to remove any excess grime. I put it all back together, added a new leather strap and here she is. Very excited to be wearing an 82 year old watch that looks this good!1 point

-

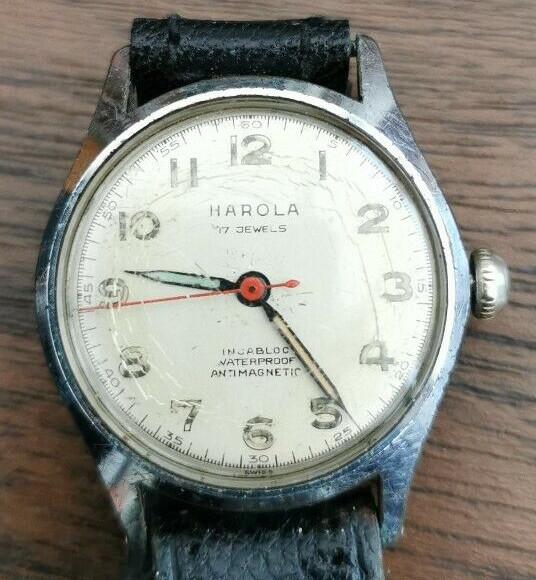

I can't find much information about "Harola", but the watch is obviously in need of a crystal, and undoubtedly a service. It looks most likely to have been produced some time between the late 1930s and the 1950s. Based on a listing for a couple of almost identical watch, it probably had this movement inside, but the listing for this watch only shows the dial and case back. Whatever it contains, at 0.99p no other bidders you can't really go wrong.1 point

-

I recently went through the same exercise. I haven't received the drivers yet, but I opted to pass on the generic French drivers. I read variously that they're made BY A&F, and that they just look like A&F and are made nearby (I believe the latter). Everywhere I looked, I saw "good for what you pay", "good for the price", and other variations on the theme. Given drivers are your most used tool, it's one where cheaping out can be a curse that visits you constantly. I opted to pass in favor of the Bergeon standard set. I see them all the time (and almost exclusively) in photos of watchmaking schools. Since students tend to be less than flush with cash, and the schools want to be teaching how to work with movements and not around the shortcomings of tools, I figure that's a good starting point for a value conscious yet thoroughly effective option.0 points