Leaderboard

Popular Content

Showing content with the highest reputation on 04/23/20 in Posts

-

Wow. That actually works really well. The old rickety broken bits were really cramping its style, but extending the tubes and fitting the wide field 5x lenses has turned it into a really nice microscope. I did hit a slight 3d printing glitch. That line on the right hand base, caused by the filament catching on the drum which in turn caused a missed step on one axis. I can probably fix it by splitting and gluing along the missed step line, or more likely I will simply reprint the parts. As it stands, the flaw makes aligning the base with the screw holes tricky, so a reprint would probably be a better option. I need to print another set anyway for the other microscope head, so two more prints wont be a major hardship. In the unlikely event that someone else tries to do something similar, the mat black paint on the inside of the parts is essential. Without it there is way to much stray light getting in. This was one of the issues with the broken holders. Light was getting in from the base, and interfering with the sharpness of the images. The new tubes are orders of magnitude better than the old broken ones. Close up watch work with stereo vision. Its a whole new world. It might even help improve my micro soldering skills too. EDIT: The glass stage that the watch holder is resting on is also "upcycled". It is a small tractor quarter light window that I found lying around while clearing out one of the old sheds nearby. I was going to use a ceramic tile but the tempered glass with the curved corners looks way nicer. I stuck self adhesive felt feet on it and now it looks like a bought one.3 points

-

2 points

-

Just finished this 1970's Timex Q quartz divers watch.Surprisingly for Timex in the period this appears to be a genuine attempt to create a watch that could actually be used for diving! It is marked '100 metres' and to back this up has a screw back with 'O' ring seal and a screw down crown, again with a seal. It came to me a few weeks ago in a very sorry state.... The back and bezel appeared to be firmly cemented in place with what looked like a mixture of porridge and plaster of paris. Also I don't think the crown has been screwed down for quite a while as the crown tube threads are under this somewhere!...... The clean up was fairly straight forward and a 2mm thick replacement crystal was easily sourced. The real problem was the bezel insert.... Initially I just removed as many scratches as possible and polished it. The nearest insert, in size, that I could find is the Seiko 4205 mid size diver one, but whereas the inside diameter was near perfect at 28mm, the outside diameter is 34 mm and the original insert is 32.8mm. Also the original insert is convex and the Seiko on is flat. Not to be put off I obtained one and sorting through my nylon crystal press dies I found a combination of concave and convex ones and with them in the press managed to reform the Seiko one to match the concave Timex insert. The next stage was to find two other nylon dies to clamp the two inserts together with an M6 bolt which went in the electric drill to make a lathe of sorts. About an hour or so reducing the outside diameter of the Seiko one down to the original Timex one, finishing of by hand with fine needle files did the job. The final result here:-2 points

-

2 points

-

What terrible engraving. Was it done with a hammer and chisel?2 points

-

I that's a great idea! I have a couple of dedicated comebacks that deserve to be seen2 points

-

I often wonder just how precise time needs to be,I have around 80 watches, and thirty clocks and can say that the old adage is very true if you own a clock you know the time if you own more than one you are never quite sure2 points

-

My favorite 1960s Skindiver - Nivada Grenchen Diver. I have only seen 1 other with the cream yellow dial, and not in person, so I can assume this one a rare one. Additionally, most Nivada Grenchens in this style are labeled 'Taravana' - this one is not. The nice cushion case is quite large for the day and sports a ETA 2472 which not stainless- brass alloy?? And yes, I have replaced the gasket. It also has one of the coolest caseback designs I've seen!2 points

-

Look at the arbour under good magnification. The notch that catches the spring is one directional.2 points

-

If you want to make a useful tool start making Platax tools seeing Bergeon stopped making them, but that in itself says a lot if its not worth their while making them it's probably not worth anyone else's.2 points

-

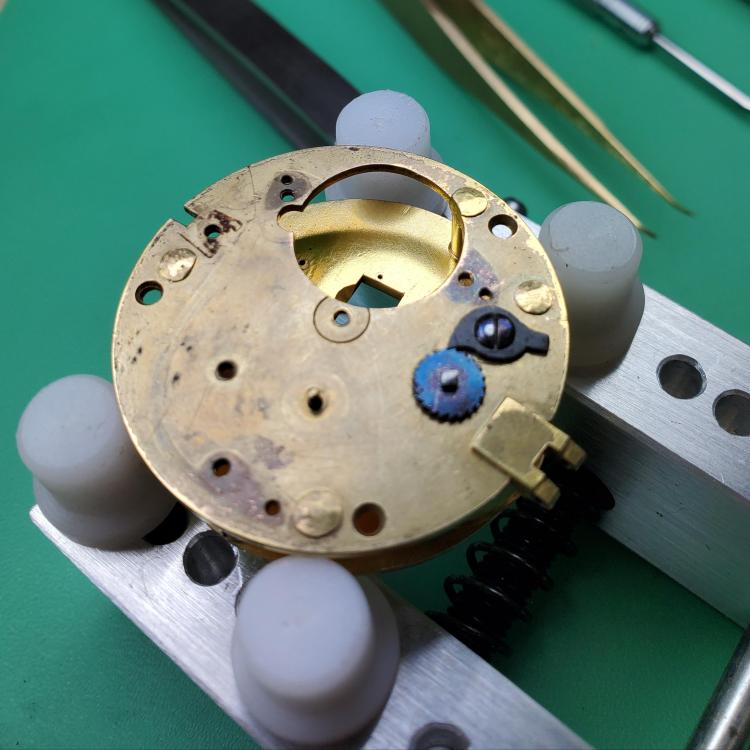

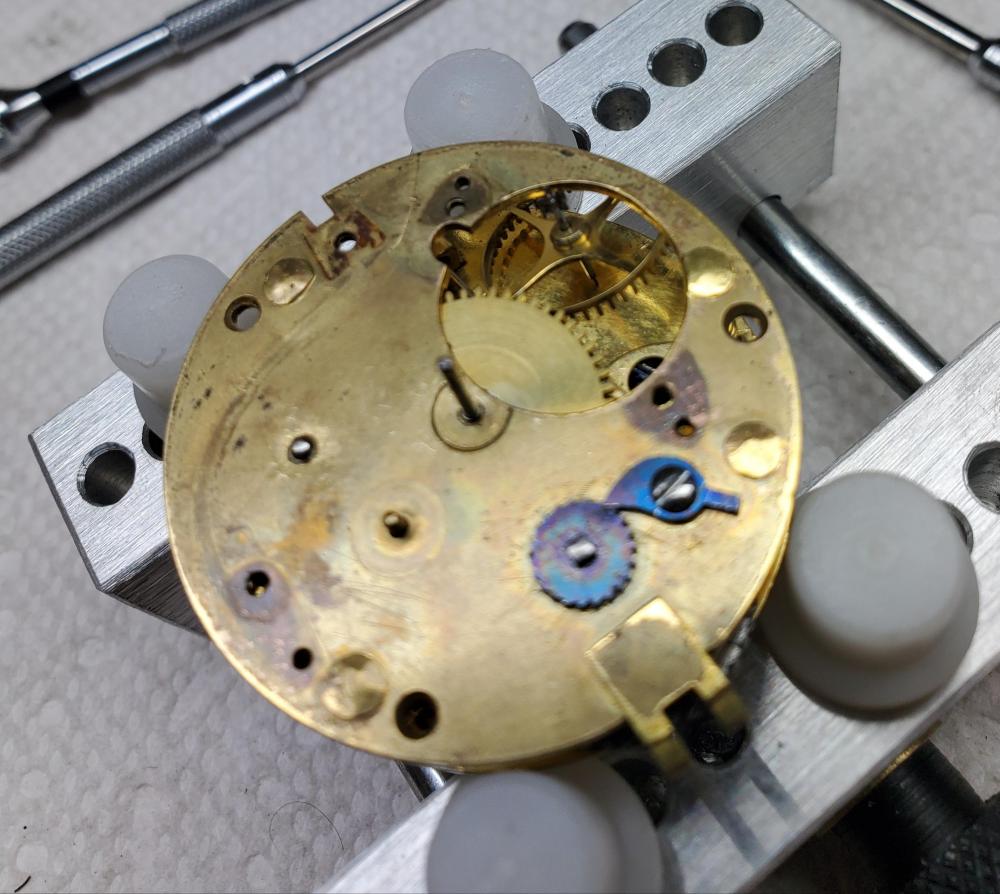

So im unsure watch the correct term for this ratchet is. Its purpose is to hold a certain amount of power on the mainspring in a fusee pocket watch when the fusee is run down. So i go to start working on this movement which i disassembled a few days ago. I had everything neatly organized in small lidded containers. Low and behold this ratchet was missing. Of course i looked everywhere but we all know how that worked out. Haha. So i made another one. I found a piece of steel off a junker gustav becker movement. Filed it to the correct thickness. Used my jewelers saw to cut out the shape. Halfway thru that, i drilled and reamed a hole to the correct diameter for the screw. I then finished cuting it out. I filed the edges to shape. Sanded it and blued it. Mine is the first pic. Not as delicate as the original, but not a bad remake. I dont think A 3 hour mistake. Working on clocks for years i have lost my share of parts. I try to keep everything enclosed and well organized, but it happens. On my first pocket watch too, no less. Haha.1 point

-

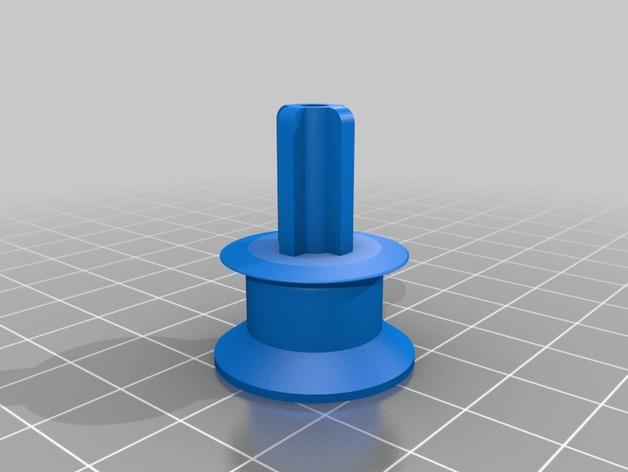

A slight hiatus in the microscope building today, due to a minor breakage in the kitchen, which necessitated a 3D printer part. Braun insist that if you break this flimsy little plastic linkage... You need to buy this... .. which naturally costs almost as much as simply replacing the whole hand blender. However a user on Thingiverse has done the work for me, so instead I printed this. Time will tell if it is as robust as the original, but since it cost about 20 pence worth of plastic I can print about 150 of them before I come any where near the cost of the Braun approved alternative. Back to printing microscope bits tomorrow I hope.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

The click shows the direction ratchet wheel is suppose to turn, then you have the arbour its notch and catch. Clockboy and this one is no april fool.1 point

-

1 point

-

Not sure who has one to be honest. You can call GS directly and they may be able to help you. I contacted them about my Sicura Satellite. They did't have that info on file, but they may with a Seiko branded watch, especially if you have the manufacturers part number. Their customer service was excellent. They won't sell to you, but they can get you a part number and you can go from there. Their phone number is at the top right on the first page. https://gssupplies.com/crystal-catalogs/?gclid=CjwKCAjw-YT1BRAFEiwAd2WRtqEhwu6RTe6_xsg8ltSEsNJS-eP5As8CQr_HONnDtW3aufNej2cMJBoCnxMQAvD_BwE1 point

-

I think that both references (318N02AN00 and 318N01AN) refers to the same type of crystal, a 31,8 mm non water-resistant with no accesory (like tension ring etc) acrylic crystal. The 01/02 in the middle of the code is just a serial number for production classification, and the 00 at the end, not specified in the first code, means a transparent crystal. Cousins have this crystal out of stock, but they say it's expected by 2 June https://www.cousinsuk.com/search?searchTerm=318N02AN001 point

-

It would be nice if you would could take the dial off so we could look at the setting parts. Then we may be able to perhaps identify the actual caliber and see if the staff is available.1 point

-

That must have been before "China AND CNC" https://www.aliexpress.com/item/4000745105373.html That's just an example, there was another seller with many more types sold (not cheaply) individually, Now that Cousins UK sells unbranded AF for cheap, that is even more correct. Previously I've got the below and very happy with. https://www.aliexpress.com/item/32565947452.html I'm the first being intrigued by screwcutting but I remain a bit skeptical about the utmost importance of having a complicated threading setup on a (small) watchmaker lathe to make small threads. Change gers copiers, etc everytime a new job shows up. Better maybe bite the bullet (steel bar) once and make your own tap or die with the hope of reusing it the future1 point

-

If the cap is on top of the barrel when looking down at the movement then it is wound in right hand, the barrel arbor will turn clockwise from that view to wind the spring. I think that is the case on this movement, as the center wheel goes below the barrel and the barrel teeth are thus very low compared to "normal" barrels.1 point

-

I don't think they donor movement you show is the same caliber. If somehow it is, or is the same family, it appears the Gubelin has a flat hairspring and the donor an overcoil. Out of curiosity who did you contact for the staff? 200 is a very good price.1 point

-

Here is the parts list Seiko 66A - Parts List.pdf Seiko 66B - Parts List.pdf1 point

-

Every pivot straightening can potentially end with a broken pivot. For one like that, I like to stick the pivot out of a lantern in a Jacot tool, then use stout nickel (or brass) tweezers that have been warmed in an alcohol lamp flame until almost to hot to handle. Turn the wheel by hand and locate the direction the pivot need to go and coax it with the hot tweezers. Keep going until it's straight. The hot tweezers really really help; they aren't hot enough to affect the temper (not even close) but the heat is key.1 point

-

Making a Platax would allow one to see that the rare used ones that come up are well worth the price at several hundred bucks or more! On that note, I have made tools in the past, but really only when there either wasn't something commercially available, or making it actually is cheaper than buying. If one is a professional, then you have to count your time as you would working on paying work and see if it's worth it. I made a quick change toolpost for my watchmaker lathe, at that time I was in school and the day or two spent was far less painful than shelling out hundreds of dollars. I made a pentagonal female driver to remove the back screws on an Audemars Piguet, no chance of buying one. For basic tools like screwdrivers there are so many choices not including the Aliexpress stuff that it just doesn't make sense. For something like a staking tool which is painfully expensive new, there are dozens available at any moment secondhand for very cheap. Tweezers would be incredibly hard to make and be even close to what cheap ones are quality wise. Then there are things that might be useful enough, rare enough used and no longer made, to warrant making. In the Louis Levin book Practical Benchwork for Horologists there actually are blueprints for a screwcutting attachment that can be adapted to almost any watchmaker's lathe equipped with a cross slide. One of my old students did make one a few years back and does use it frequently; but he does primarily component making for restoration work, and encounters many odd threads that would be tricky to impossible to make without it. A few of the lathe makers offered these in the past but they were rarely bought and thus very very hard to find second hand. Something I do make quite often is special pushers and stumps to be used in a jeweling tool. Pushers with short blind holes to help push small steady pins in straight, pushers or stumps with relief grooves or holes machined in to clear obstacles, all sorts. I have hundreds and still make them once a month or so. It's handy to have some steel in staking punch diameter too, even with a large set you might find that you really want/need something special.1 point

-

In general, it is so. But what the OP wrote above is absolutely correct, it's easy to understand that a V shaped tip will be more robust than a parallel one of the same size and material. And that a parallel one will grip better, for example, on a rounded profile head as commonly found in vintage parts, not limited to watch and clocks.1 point

-

Right on jdm In times like these improvisation is the key, When all the bits and pieces arrive then use it untill then make do and mend and start the learning process, If you can master using improvised tools you will be all the better with the correct ones.1 point

-

Hi Staightening pivots is not for the faint hearted , They can be straightened using a pulling /stroking action along the length of the pivot. It all depends on the hardness of the pivot in question some are pot hard and brittle aka french clocks and others not so bad. There is a tool by Seitz for doing the job bt they are expensive.1 point

-

1 point

-

As already mentioned commercial watch cleaning products do not dissolve shellac. Then why are you using water for the last rinse? One of the problems with water and clean steel parts is the likelihood of rust. Then because of being puzzled by what you are doing and not familiar with the cleaner I looked it up it's the first link below. Then I see your problem you're using a water base cleaner. Then you got things a little bit backwards. So You're using water-based cleaner you would follow with a water-based rinse or basically water. But it's extremely important that the very last rinse not be water. I've experienced this cleaning a clock once and I did not enjoy removing all of the surface rust on all the steel components. The second link is for the rinse which has this line of interest "Elma Suprol Pro is also suitable for rinsing and water replacement before the drying in the course of an aqueous cleaning and rinsing process for metallic precision parts." So what they're telling you is that as the final rinse this will remove the water so it can safely dry without rusting or other complications of having water on the parts. Then personally I would prefer a cleaning solution with out water. A better choice would be the third link Elma WF pro For the cleaner. Then a minimum of two jars of the rinse that you already have. https://www.hswalsh.com/product/watch-cleaning-solution-1-litre-elma-clean-19-hf6093 https://www.hswalsh.com/product/watch-rinsing-fluid-25-litre-elma-suprol-pro-special-hf6092 https://www.hswalsh.com/product/watch-cleaning-fluid-25-litre-elma-wf-pro-hf60911 point

-

I would avoid mixing waterless and water based solutions. It’s asking for trouble. You can just rinse with water if you are using a water-based cleaner. I think the Elma is probably the same as the soap I use from Greiner which is also red. It is a degreaser, but contains amines which will brighten metals.1 point

-

Watch cleaning solutions made for cleaning watches shouldnt dissolve shellac. As for the water it may not react well with your solutions. Also other than the most pure of water it will leave deposits and streak. Why not use another jar of the rinsing solution for your second rinse?1 point

-

1 point

-

For me, it depends on whether the hands have an actual collet to grip the wheel/pinion as sometimes they will split if you try to broach them open. I usually close them down with a jewelling set. If you don’t have a jewelling set then I’d just try broaching smaller ones open though.1 point

-

My advise would be go smaller. Better to open the hole then try closing it, You don't have much thickness when it comes to closing. Just be very careful when opening the hole, the most difficult I found was holding the hand, even with proper hand holding tweezers it is hard, a little lube on the broach will help.1 point

-

If you don't know this movement, take care with the click spring and with this washer:1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum.1 point

-

Welcome Paul Have fun with the rolex should keep you amused for a while1 point

-

Welcome Paul. I must admit I'm a vintage Rolex fan and looking forward to follow your project here.1 point

-

Welcome Paul, Enjoy the forum. As you have found information on Rolex movements is sparse to say the least.1 point

-

I have been collecting the tiny little Wilkin and Sons jam jars you get in some cafés, I can fit 3 in my ultrasonic cleaner and it means I can have a different fluid in each one if I wish. The brass fine mesh balls are useful sometimes as well for the really small bits. Like Bob and George I clean just about everything bar the dial and pointers. The only thing I would say is dont use any solvent cleaner type substance that could dissolve the shellac/glue holding the jewels in place. Since seeing Mark do it, I have started putting the balance back on the plate and it seems to be perfectly ok that way, it does not take long plus the plate gets a clean as well. Cheers, Vic1 point

-

I've cleaned quite balances ultrasonically over the years without any problem. If in doubt, try it on an old movement first to see how you get on. The only thing I will not ultrasonically clean I'd the dial. I tried it early on and it destroyed the finish.1 point