Leaderboard

Popular Content

Showing content with the highest reputation on 01/27/20 in all areas

-

There are a lot of formulas, but the most useful one I know of is this one: L= Length of spring R= barrel inside radius r= barrel arbor radius e= thickness L= π (R² - r²)/2e You can add 10-20% to that for high grade pieces. This is for barrels that develop approximately 6.5 turns of wind, which covers 99+% of timepieces. That solves for length. If you are missing a spring totally, or have zero confidence that the spring in place is close to correct, you can get a very close value for thickness by dividing the inside barrel diameter by 87. So for the OP's watch, imagining it has a barrel inner diameter of 16mm, you get 0.18mm for the thickness. Without knowing the arbor diameter, we can imagine it's 1/3 the barrel diameter, so 5.3, Plugging into the above equation that makes for a spring 497mm long, maybe 50mm more or so. To see how close that might be I checked my Generale Ressorts book for an A.Schild movement using a 16mm inside barrel diameter and I see one right off the bat that's 0.185mm thick, 540 long. Another 0.20 thick 460 long. So we're definitely in the ballpark with the calcs. When working from nothing this will get you very close, and many cases be very satisfactory. You can go up or down a little in thickness if you find you are limping along or rebanking.4 points

-

I haven't seen one yet that wasn't repairable. I suspect that they have had a bit of rough treatment. Check the hairspring is sitting true and flat. If so, then move the balance wheel gently in the direction it is free to travel. next gently push the fork in to the same side, then allow the balance pin to rest in the fork, now carefully release the fork and see if everything now works as expected. If the hairspring is distorted, you will need to address that first. If the balance wheel pivots are not sitting in the vconic cups, then you will need to fix that first. I think a few closeup pictures would go a long way towards helping us with any further diagnosis.3 points

-

2 points

-

2 points

-

Hi The problem is known as over banked, what happened was as the balance swung onto the banking pin the watch received a shock this caused the fork/pallet to bounce back leaving the impulse pin on the wrong side of the fork/pallet. Follow Andys instructions and it should pop back in. In theory this should not happen as the guard pin on the fork/pallet should stop it but if the balance "V" conic bearings are not adjusted correctly,too high or too low or are loose it can.2 points

-

2 points

-

Have been giving this one a test drive today after a complete rebuild over the weekend and it's rapidly becoming a favourite. At just 32mm across the all stainless steel case (not including the original signed crown) it's small by today's standards but it feels perfect. The movement is Citizen's 21 jewel "Homer" which according to Sweephand's fantastic Citizen site is part of the 02 movement family with it's origins going back to 1960. The only stampings on the main plate are 00, J, and either M or W, none of which are obvious caliber identifiers. There are no numbers on the case back either that could help with ID or dating, but my gut feeling, given its size and also the Citizen script on the dial, is that this is an early one from the front end of the '60's. If anyone can shed any better light on this then please do. Either way, it's super comfortable and running very nicely indeed.1 point

-

that is true you never know what someone else may have used before, unless you are familiar with manufacturer, caliber and grade there is no way to tell. Which is why i stopped working on swiss trench and pocket watches, way too many movements out there and no resources on them. Thats why I made the switch to American movements. plenty of resources and NOS parts available, and they hold much more value since the craftsmanship of the time was unmatched compared to the swiss.1 point

-

If you kiddos saw some of the "springs" I've seen in barrels.... you'd get yer calculators out. I'll look in the books when I'm in the shop tomorrow, I'm sure we'll find the maker. Can you measure the outside diameter of the movement? 12s is American but that's a Swiss movement.1 point

-

Hi As Andy said move the balance to its free side up to the banking pin and hold there next move the fork/pallet to wards the same side untill the impulse pin on the balance engages the fork/pallet. Use no force at all. If it engages ok without pressure release the balance and now it should work. If you cannot engage the impulse pin with the for/pallet using this method then undo the moveable "V"conic bearing untill you are able to manouvre the impulse pin into position then tighten the "V"conic bearing until the minimum of shake but still free to rotate the balance. Do not over tighten The "V"conic bearing.. I assume that you have the service manual for the watch, If not go to 'google drive' they are all on there cheers1 point

-

1 point

-

Man that's a bonny watch elegant with style. Every body chases the big chunky watches today.1 point

-

Thanks. when they were new, and a new batt. voltage 3 the light worked fine. so, i guess the chemicals "evaporated". i have a quarts watch that had 2 1.5 V batts. it just ate batterys.! vin1 point

-

OP, what is the inside diameter of the barrel, the diameter of the arbor, and the inside height? From the two diameters we can figure out the theoretical correct spring.1 point

-

1 point

-

So, it is back to your first diagnosis, wrong jewel with larger hole, in which case the pivot should easily slide out of the larger hole, just gently lift one side of the wheel, I grab one side of the wheel with a pair of tweezers and lift gently. End shake has to do with the distance between the two end stones, you adjust by reducing the distance, ideally end shake is to be set about 0.02 mm. End shake adjustment would reduce amplitude variations in FU and FD positions. A larger jewel hole hardly impedes oscillation to cause poor amplitude. I always adjust shakes before the final clean/ rinse. How sure are we of the pallet's health? You may find it scractched under high magnification.1 point

-

Oh.. I nearly forgot. There was one more..... An Ingersol Sealion, for a whopping 0.05p more than the Aviatime. No jewels, so probably an EB 8800.1 point

-

For me, the single most difficult was a Sicura with the BFG 158 31/7 movement. Finicky damn movement. Also, timex m21 and m22 are maddeningly fiddly with everything under one plate. Quartz movements have to most microscopic of gears add to that the fact the stepper rotors are magnetic and pull everything to them.... all add up top my personal choice to simply swap quartz movements.1 point

-

Does the palate fork Snap back and forth with the balance out? Have you tried running the motion works without the palate fork in to see if the power releases properly. Have you checked the cap stones for damage. The the impulse jewel loose? Sent from my iPhone using Tapatalk Pro1 point

-

Full plate pocket watches. Getting the pivots back into the jewels can be either easy or next to impossible. The game of nudge. Sent from my iPhone using Tapatalk Pro1 point

-

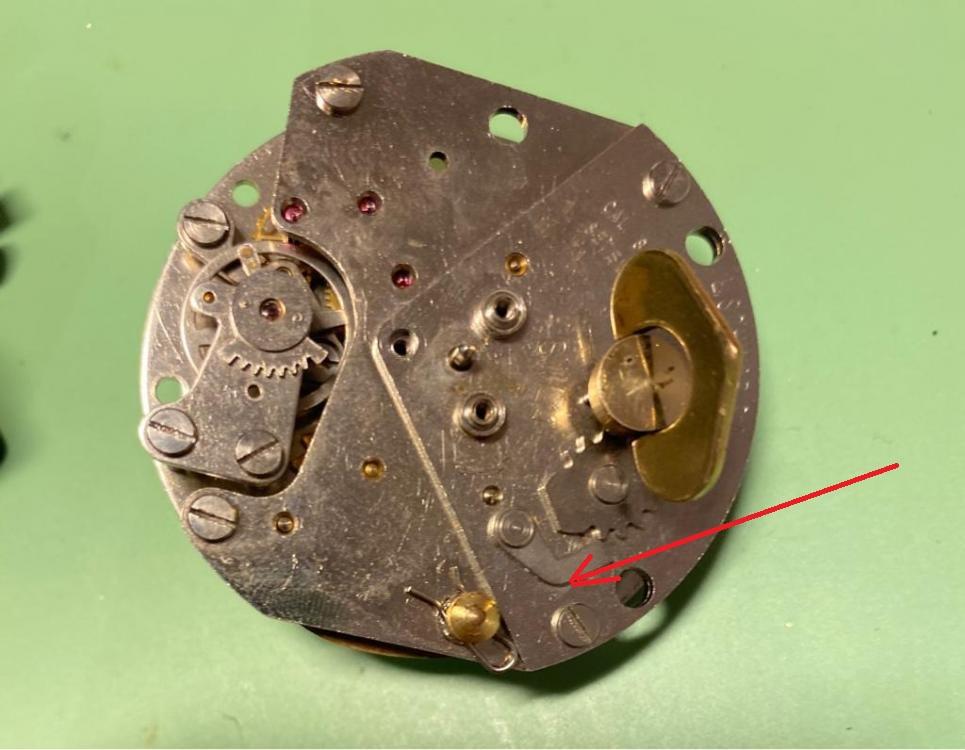

I would call it a stop spring. It is part of the winding that allows the the alarm to work off one spring. Underneath the winding key you have what looks like a star that fits over the arbor, next to another shaped wheel fixed to the top plate. Wind the clock right up. The star is placed with the one part that is longer. Alarm rings and runs down, the star part with the long finger traps so the alarm cannot ring anymore after a little, that broken spring prevents the click from falling out of place.1 point

-

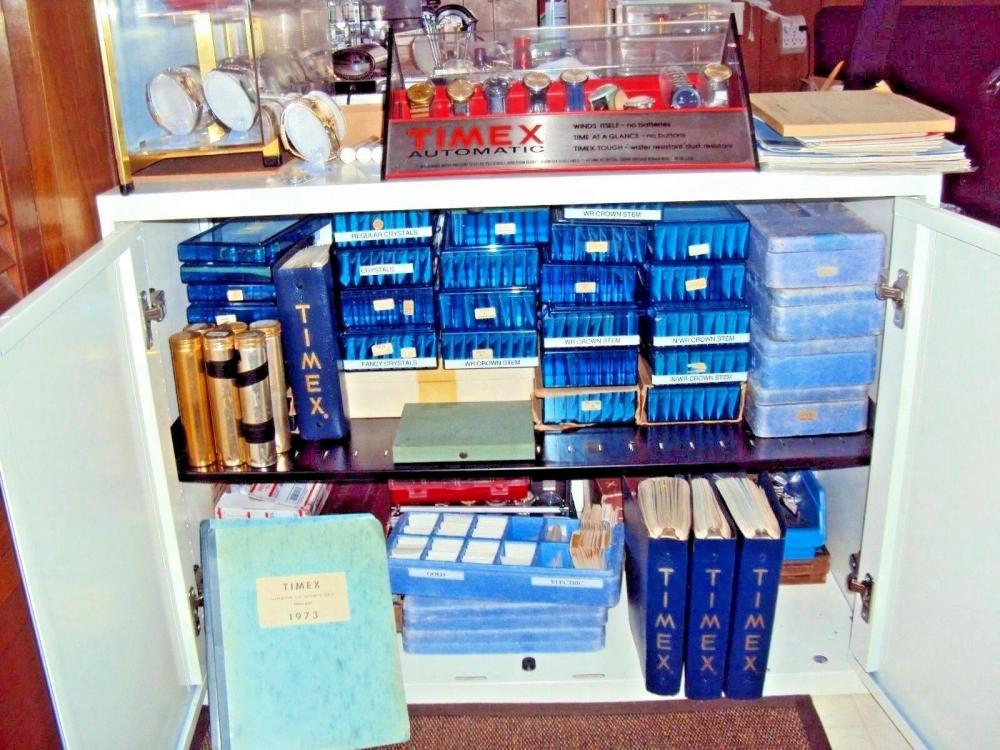

The Timex movment pdf files were compiled by the a few members of the "Vintage Timex Watch Forum" once hosted on Network 54. A great idea to 'keep em tickin' as the site admin would often say. I scanned and provided many of those manuals as away to give back to those who helped me when I first began. How much these manuals helped each other didn't really matter. Rather the benifit was the effort of finding and sharing the information and commuiincating the success and failure. Commuincation and interaction with others is the true benifit. That is what needs to be past on to the those who follow no matter what hobby or interest they have.1 point

-

I am trying to find a possible cause for excess side shake. Daily rate is Ok. The Shakes and positional variations should be improved. Is mainspring new? amplitude on such good grade movement should be more.1 point

-

1 point

-

1 point

-

Actually mineral glass is more resistent to impact than sapphire. That's why is still fitted to some true diver's watches, a choice that raisises criticism by some.1 point

-

I have read several threads talking about using super glue for the repair watches. Whether or not I think it is the right way or the wrong way to fix something isn't my intention. I would gust like caution everyone that cyanoacrylate adhesives release vapors that can be very irritating to the eyes, damage the surfaces of some materials, as well as, negatively affecting electronic circuits, especially if allowed to set up in a confined space. The words of experience. Shane1 point

-

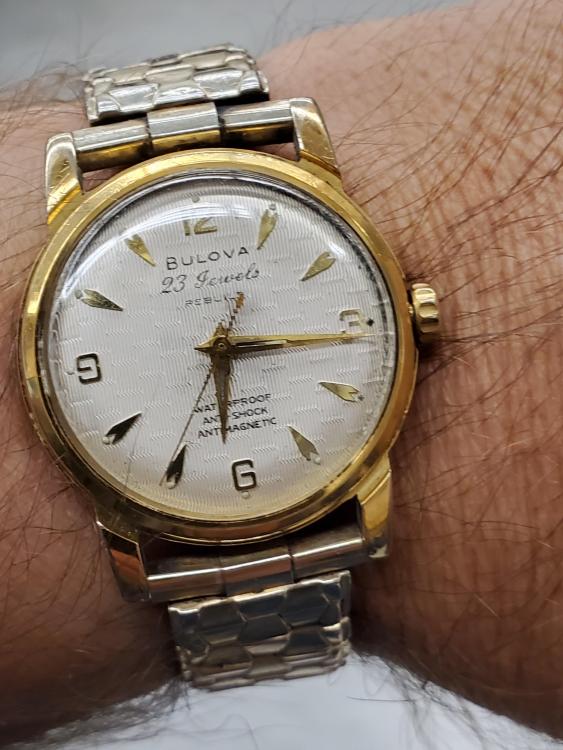

Just got this one. Great condition. 1942, Gold Splashed movement because of WW2. 21J Railroad grade and running strong. Thing of beauty. Sent from my iPhone using Tapatalk Pro1 point

-

You might find what you are looking for here. https://drive.google.com/drive/folders/0B-IKHN7WFKiwLVFQRjQyUUV0bmM Try to avoid cross/double posting. Your second post is in the correct post. Moderators, feel free to remove my post, and perhaps the one above. I have put this answer in the other post.1 point

-

1 point

-

That is lovely I’m getting the hang of it but the industrial machines we use try to run away with me. I’m getting the hand stitching sorted and mainly doing repairs taking the load off the main guys in the workshop. My biggest problem is that I struggle to keep in mind the repair is just that. It does not need to be as good as new so I’m spending too much time trying to make it as perfect as I can. I’m learning though and loving it1 point

-

If you are in an uncarpeted room (most working on watches would want to be!) you will find that adding a small carpet away from the bench helps with dust surprisingly well. At one place I worked there was an about 2.5 meter long removable carpet in the hall outside the clean workshop; the boss decided it must go, "it's a dust magnet!!"... well, it was- immediately our benches were dustier. Put it back and it was 10x better. I experienced the same in a workshop I had for a while which had a tight weave industrial carpet; at first I hated it (and couldn't change it), then I realized after several months that nothing, anywhere had dust on it.1 point

-

1 point

-

1 point