Leaderboard

Popular Content

Showing content with the highest reputation on 01/06/20 in Posts

-

The screw for the stud in your cock looks to have been drilled slightly off, and it's causing the stud to twist, this is causing a lot of your out of center condition. A little push on the spring where it enters the stud will get you close to centered, then you may need to touch it up at the end of the terminal curve to get it right on. When these movements were made it would have been assumed that whoever might order a replacement balance would do such corrections (and set the beat) as a matter of course and for a trained watchmaker it would take just a moment. So not an indication that it's the wrong balance necessarily, but a bit of a challenge if you aren't comfortable with adjusting hairsprings.3 points

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM2 points

-

2 points

-

Can be done . But maybe better to not remove . Could clean up good anyway . And he could oil the jewel from the backside if needed.2 points

-

Pin gages (sometimes called plug gages) are used to measure small holes. Some watch tool makers and supply houses offered small sets back in the day, they often were in 0.02mm increments so not particularly precise but will get you close. Cary is the main maker of these tools in Switzerland but a box of 50 in 0.01mm increments is about a thousand bucks... Of course you can find them secondhand but they still command a high price. Many watchmaking schools used to have students make a set of pin gages from about 0.05mm up to around 0.25mm. You see the sets on Ebay sometimes, usually in nice little trays with holes for the gages with the school name and each gage numbered by size. As for using a reamer to measure the hole in the plate- for jewel holes, Obama was a German watch tool maker that made a tapered pin gage, like a long precise smoothing broach. The taper pin was in a handle which had a scale on it, you put the jewel on the taper, retract the pin until the jewel touches the end of the tool, and read the size. You can approximate the same thing if you have small smoothing broaches: slide the jewel on the broach, then press it into pithwood (fat side of broach first) until the jewel sits on the wood. Remove jewel and measure broach where it exits the pithwood. You won't be precise within microns but pretty darn close. So yes, you can use the same technique for finding the hole size in the plate.2 points

-

This is not the most common Sumo, and I thought it could brighten this page. As it happens with most of my pieces it's going to a new owner already2 points

-

2 points

-

I have a few Camy watches and couldn't resist this Camy 'Silver Cloud' on ebay despite its non running description (it was cheap, £11 inc p&p) On arrival it was soon obvious that the movement was the old faithful FHF96 and balance spring was FUBAR'd I had a quick check around and found that I could get a new balance but couldn't justify paying the £30+ on this watch. What I did find though that I could buy a 'good running' FHF96 equipped, re-cased and dialled 'Oris' from India for £13 inc p&p.... Well the 'Mumbai Special' arrived and I was suitably surprised with the obviously totally rebuilt movement in it (probably a new Indian built copy) Not wanting to 'sully' the Camy with this movement, I settled for just swapping over the balance assemblies. I fitted the Camy with a nice new genuine alligator strap from Vietnam and the result is one nicely running vintage Camy and lots of FHF96 spares, total outlay, including the new strap, less than £35 including all carriage costs2 points

-

Did something similar with this Seiko 7548-700F (Stormin' Norman)... Rebuilt the movement using a 7546 dress watch movement as the basis...(one of these days I'll probably fit the original movement bridge back, to get the jewel count, at five, correct again..) And cleaned the dial as best I could and replaced the hands and bezel insert with OEM Seiko SKX 007 parts... I find resurrecting basket cases very satisfying2 points

-

2 points

-

2 points

-

Is this a clock or watch? As you have a balance wheel and say clock I'm thinking carriage clock? Sometimes clock springs do a sort of "shudder", it's not a big deal. If your balance won't run at full wind 99.9% sure it's not a spring issue but worn pivots/ bearing holes etc. Most any clock will run with the feablist of power if the gear train is in good order.1 point

-

Hi If its the simpler one or two barrel clock just take it down carefully, remove all power from the movement before splitting the plates. Photograph each stage for reference. The balance will just unpin and put aside safely. Can you post a picture of the clock front and back, it makes it easier when we can see what it is. Cheers1 point

-

Thank you all. I think I found the case for it. I will put it aside and when I am more comfortable with simpler movements I'll try this one.1 point

-

Extra care not to damage the jewel beneath the wheel, handle as if a balance wheel, in ultrasonic or brushing. If removed / reinstalled the wheel usually tend to fall off in a couple of months or wobble which developes an old culprit, stops at low wind. Also I check ( before strip down) if balance is well in beat. If balance complete is previously repaired, excessive beat error seems inevitable. ( Generally so with fixed stud holder) . Good luck.1 point

-

Seems to me a good occasion to practice on that mov't. Learning from it will be worth the time spent, and any improvement on the timegrapher picture a reason for building pride and self-confidence.1 point

-

Straight out of China fake shop I'm afraid Sent from my ONEPLUS A6003 using Tapatalk1 point

-

FHF 150 is a common movement . So that is no problem if you break anything. Or need parts . What i think is rare is the extra wheel and parts for the center sweep second. So be careful with that. Need to pull straight up to remove that wheel. Problem with the presto puller is that is large . And be careful when you open the lower incabloc . They are rare to. Other then that go for it and looking forward to see the serviced watch. Warning to !!! Radium hands and dial so be careful .1 point

-

Hi Paul, DO NOT remove the wheel that indirectly drives center seconds arbour/pinion. Good luck.1 point

-

You don’t get much of a swing from the balance with this type of escapement; it is nothing like the swing of an anchor escapement. They are slow in comparison much like as you say a Verge. The ones I have worked on I think 3 or 4 after a proper O/H always seemed lazy in the rotation; it’s as if the balance wheel was too heavy for the hair spring. I don’t see much oil on the two club toothed discs, this might be to do with the photo. Not a very popular escapement, which might be due to its poor action.1 point

-

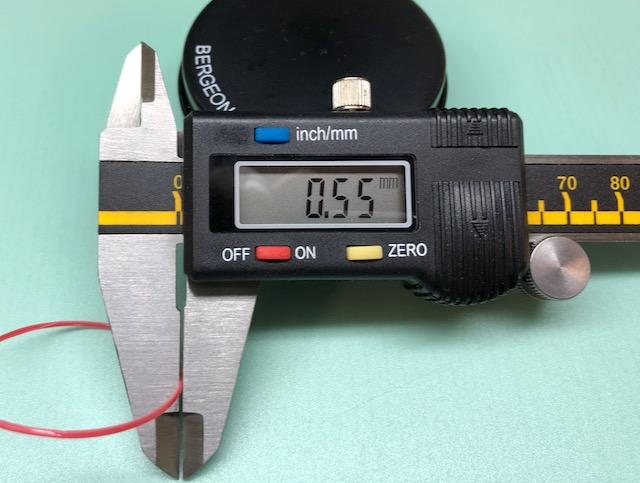

So - measurement of the aftermarket replacement shows the problem (or at least the biggest issue). It measure at 0.55mm. So far I have been unable to source a genuine replacement gasket or identify a suitable generic replacement, so a bit of fettling is called for. Sod's law now dictates that I will either find the correct gasket somewhere, of have dozens of suggestions offered... Time for a bit of fettling now. Thankfully (and extremely fortuitously), I had a small paint pot (for retouching clock and watch hands, etc) that magically had a cap diameter very similar to the internal diameter of the gasket. So - on with the gasket and I settled down for half and hour or so of patient sanding with some very fine wet and dry paper. The pictures show the before measurement - during sanding - and finally the after measurement of the gasket thickness. I know this seems like a lot of work for a piddling little gasket, but I really can't find one and it's for my son's watch. Again - I know - it's only a Seiko, but it still holds a bit of sentimental value between us and it would be nice to fix it for him. And at the end of the day - I don't make money out of watch fettling, it's only my hobby - so time spent is really not the issue. Now I just have to wait a day or two for my screw-down case press to arrive, then I'm sure it will refit just fine. Thanks again to all here for your hints and support.1 point

-

1 point

-

This was a variation of Debaufre's escapement, which was interrelated with several others all trying to deal with the massive recoil of the escape wheel in the verge escapement. There is a good description in Paul Chamberlain's It's About Time. Like a cylinder or most any frictional rest escapement amplitude is normally quite low and you may find that there is a pin on the balance to prevent it going too high- though perhaps not on a stationary clock like this. One interesting thing with frictional rest escapements is they are somewhat self regulating regarding isochronism, as when power goes up the friction during the non-escape time goes up too, limiting the amplitude. 60 degrees seems a bit low, I would imagine about double that if everything is in good order and lubricated. But if it's working well it's not really a huge issue, the fact that it self starts right away is a very good sign. There is a good chance there is some sort of adjustment for the depthing of the escape wheels to the impulse table on the staff; most verge escapements had this too. When one escape tooth has just "escaped" the following tooth should land on the flat surface of the impulse table. If it's landing on the sloped surface the depthing is too light.1 point

-

@oldhippy do you recognise all those ETA movement i.d.s? What sizes are they, please? 2000? 2671 = 6.5 dia. 2235? 8200? 8500-1? 8500-2? 3135/2824=11.0 C07111? 7750=12.5 2892/2836=10.5 or 11.0 @vinn3I know how to do it, but especially with the small ones I'm concerned about deforming them. I can't do it with finger cots, they keep getting trapped in the coils, so I end up contaminating the springs with scrapings from my fingernails. Best avoided. Putting a new spring in is for me the most reliable and economical solution, given it's a hobby and I might service around 10 watches in a year. So I would continue to do that if saving money was the object. But if I wanted to splash out?1 point

-

I have looked at this winder set before and it looks good value. Personally I have struggled fitting a watch mainspring by hand so use a winder. As oldhippy states they will work with other caliber watches as well.1 point

-

What are case opening and gasket size when fitted? Maybe you can try sanding the outer face of the gasket slightly.1 point

-

Hi Books By Donald De Carle, Practical watch Repairing. are a good starting point There are many to choose from, On this site Mark has produced many dood and instructional videos (uTube). Give them a close look and move on from there.1 point

-

OK your watches are due for a service, your post was extremely stressful to read don’t take it the wrong way but your doing it all wrong. Shaking your hands, automatic watch winders and karate chops is not how you test how well your watch is winding and its power reserve. you can manually hand wind these movements, Starting with a full wind will give you more accurate results. both eta 2824 or sw200 is 28800 bph with a 38 hour power reserve. Any COSC needs to be within +— 3 sec per day. =- 5-7 sec per day for non cosc is acceptable in dial up and dial down positions. You will need a timegrapher to confirm this there are other ways but this is your best and most accurate option. The amplitude should be around 270 in DD/DU positions and a little less in 4 other positions. Then you have beat error. These are things you need to check before and after your service. If you never serviced a watch before please consider practice on a much cheaper movement, like a Vostok or something. I promise you will lose or screw something up and these aren’t cheap movements.1 point

-

You appear to have slipped through the Oldhippy / Nucejoe net, but you are just as welcome as all the other new members! You have come to the right place for friendly, helpful advice. There are some real experts on here who are very patient and willing to help the keen amateurs like us. Definitely read the stickies on screwdrivers and tweezers in the tools and equipment, as you will need good ones right from the start. There are some good threads on workspaces and benches if you use the search function. It's important to have a dedicated area. Here's mine: Done on a budget, it's an Ikea bookcase, with an LED strip light fitted in the back. I open the doors and use them as elbow rests. As you can see, space is limited and gets cluttered easily, but for hobby use it is OK.1 point

-

Did you pin the spring to the stud yourself, or did it come assembled like that? It looks to me as if the spring is pinned too far away from the end. Maybe that's also why you had to rotate the collet? Try it pinned at the end, with the rate adjuster running on the terminal curve section. What Nickelsilver suggests is also true, and will probably be necessary in any case.1 point

-

I bought one with a single die, ebay so chinese that stated for Rolex. Going on that one diameter isn't what matters only the fit of the "knurling". I only use it to change the battery on an oysterquartz and my recollection is that it's a little smaller in diameter than the case back. It's ok to use providing that enough downforce is applied but it fits well. John -1 point

-

No, not as far as I'm aware. If you have an existing jewel with (a known diameter but) an unknown pivot hole diameter I guess the only way would be to drop the jewel on to the pivot and then gently manipulate the jewel with your tweezers to get a feel for the side-shake. Anyway, it's just an idea which I've never tried so I don't know how well (or badly) it would work. Hopefully someone else is more informed or have a better/more correct method for determining the diameter of jewel holes.1 point

-

Also look at this previous topic: https://www.watchrepairtalk.com/topic/9116-eta-2824-2-stem-question/1 point

-

ETA 2824-1 is like that. I think the idea is that the twist helps the setting lever in keeping the castle wheel pressed.1 point

-

Indeed this is one of those movements that uses a twisted stem... No worries. Usually I've found these on ladies calibers... Never on men's but who knows...1 point

-

To start with it is described as vintage (vintage today doesn't mean what it used to be) I have seen clocks made about 10 years ago called vintage. This is a set for E T A movements, it doesn't mean that you should only use them for there movements,but on there movements they will work better and be a better fit. For what its worth I couldn't get along with watch mainspring winders, so always wound them in by hand.1 point

-

I was a long time member of the previous Timex forum to which I owe much gradtitude. So I am always happy to help with vintage US Time \ Timex as best I can.1 point

-

Just an FYI that the Electronic print on the dial identifies that watch as a model 51. What makes it different than a model 41 is the inclusion of a diode in the balance assembly. Lanco? no you mean to say Laco as being the company Timex purchsed for the battery operated watches?1 point

-

1 point

-

Hi Charlie, I put the balance cock assembly on the main plate, it balance turns right , roller pin & fork do their number, you can be 95% sure you got the right one. Push on HS near the stud to get the coil circles lay Concentric.1 point

-

Well done , always more then one way to skin a cat, sorry snowflakes its just a euphamism.1 point

-

Hi I take it you have not resorted to the super glue and nut method. first get a large nut and superglue it to the back and let it cure (over night) then with the appropriate spanner unscrew the blighter. To remove the nut fill the inside with acetone(nail polish remover) and leave to relase the nut. I have used this method on one or two stuck backs and it works, just clean off the caseback .1 point

-

Unfortunately with Rolex backs force is not the answer. You must have the correct die or it will slip. I speak from experience.1 point

-

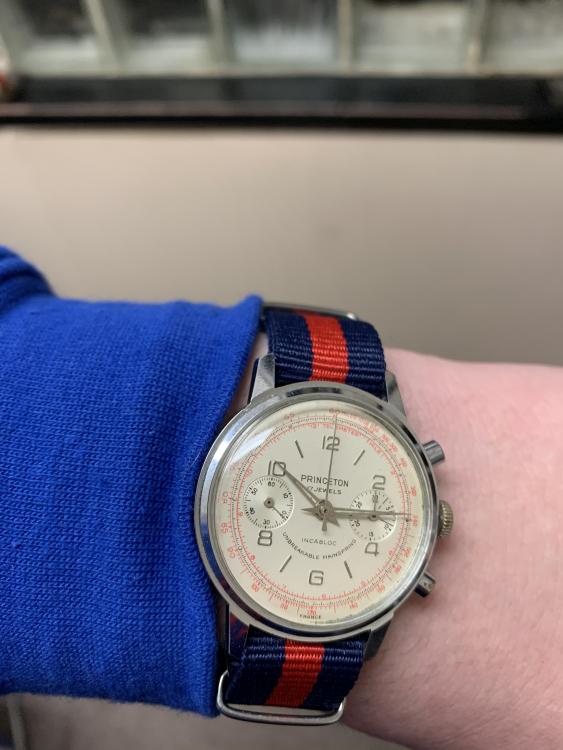

It wasn’t very expensive, not in the grand scheme of things anyway. I paid 215 for it, and it’s running good. Someone’s selling a similar Clebar with a bit more patina that I wanna grab next, though I really want a seamaster, and every other watch I buy just delays that. when I got it I they sent a few extra straps, I’m not a NATO fan so I didn’t own any, but it came with this blue and red one that works perfect with my cubs hoodie and cap, and matches the red in the dial. last night I won a lot of 35 various Swiss movements that are supposedly all together. They’re my practice! This morning was my first ever tear down, a broken Vostok I’ve had for many years now. Turned out the balance spring was broken. Now I’ll try putting it back together. It doesn’t have to work so there’s no pressure lol.1 point

-

This should help. It shows how to remove and fit hairspring. Same principle for a Seiko.1 point

-

1 point