Leaderboard

Popular Content

Showing content with the highest reputation on 04/09/19 in all areas

-

2 points

-

2 points

-

Today is the turn of .... Seiko 7a38-702a At some point I will remove the faded gold plating from the bezel and send it off to be re-plated.2 points

-

As long as the replacement does not play God save the Queen, however Scotland the Brave would be nice. Funny enough, this clock started life before Australia was discovered. Except in Brazil. I will take photos of the repairs on the music setup, I might have to make some bits also as there seems to be a few bits missing, I don't think Google can help me with what they look like. I did not do photos of the movement as there is enough on the forum and Web already about how to repair a movement anyway I ran out of battery.2 points

-

Hi All I'm still learning the basics. My latest watch, like all others I've worked on, has low amplitude. The latest is a Bulova 11BL. The dial up amplitude rose from 185 to 220 after the cleaning and dial down stayed low at 170. I disassembled and cleaned in a solution of distilled water, ammonia and cascade (recipe from this forum). Rinsed in alcohol. The ultrasonic would be considered a very low end device for cleaning jewelry. I added a new spring but didn't lubricate it. I've read that they come with some type of dry lubricant?? I added a tiny amount of Moebius 8000 to the jewel cups and touched the exit pallet stone with 9415. I did remove the cap jewels for cleaning and used 8000. I've read here that I should strive for 270 https://adjustingvintagewatches.com/pallet-jewel-lubrication/. Any suggestions? Also, if the rate is good, is amplitude of 270 still important?? Thank you Charlie1 point

-

I have the cheap Chinese version with digital screen. It works well for me but I spin the scope 180 degrees so that I'm working off the table rather than the little base. This makes it top heavy so I have a tin of lead shot on the base to balance it. I usually use an A4 sheet of card with a couple of datum points marked on it to place the job on so that I don't have to move tiny parts around trying to get them under the scope.1 point

-

1 point

-

It really doesn't take much to zap amplitude. I had a JLC 838, which I've worked on numerous examples of and is a very good running caliber, with about 220 degrees in horizontal. Professional cleaning machine with professional cleaning solutions (I'm a professional), everything looked spotless. Readjusted the escapement, got a few degrees, extra better cleaned the balance jewels and pivots and the roller jewel and fork slot (the roller jewel and fork slot are classic "last thing I checked" culprits), no change. Let it run a few days, no change. I know this movement, I have a routine, it was frustrating as heck. This is a very thin caliber so no cheating slipping a slightly thicker mainspring in- they don't exist. Well, the one thing I forgot that's in my normal routine was pegging the jewels, in particular the fork hole jewels. Easily enough done without bothering anything else, and whammo I had 280 degrees. They looked great before, the same after, but there was a good 50 degrees of amplitude hiding in those hole jewels. Good pegwood is a must, and it's good to sharpen with a razor type knife (we call them Japanese knives, like thin box cutters). Blade needs to be clean too, or you just contaminate the wood and then the jewel. And yes, resharpen between jewels. Lc130, if you don't know how much oil you put on the escapement that's a pretty good sign that you may or may not have over or under oiled most everything, and overoiling can very much lead to problems like low amplitude. Did you oil the fork pivots?1 point

-

Thanks for your help. I know you've helped me out in the past, and it's very much appreciated.1 point

-

Such evidence of fault at jewel and shock assembly, can usually be tested by switching lower and upper jewel assemblies, just to see if the effect moves along with the jewels. This ofcourse is suitable if both jewels looks the same. If the effect didn,t move the fault is likely to be with the pivots, if did move!!! with the jewels or chatons. Thats presuming if jewels are not loose inside the housing under shock springs. Thanks to jdm explanation that end shake on staff and pallet arbor as well as escape, amounts to disalignment at relevent jewels with the escape wheel, or fork horn and roller coming into contact. I havn,t faced shortage of problem giving advice when it comes to end shake, some members seem unfamiliar with the subject and its relevent issues and how to analyse the test results, even worse the test to see if the combination end shake and pivot length are letting pivots to jump out of jewel hole, in cases the movement is shock protected. Best wishes.1 point

-

I have a Panerai much the same with a miyota clone movement but, oddly, I'm planning on fitting a Tissot chronograph movement to it.1 point

-

UPDATE: I bought the part (the 2556.1) and it is exactly the same as the original. (The movement is a FHF 905, not a 90.5). Unfortunately it hasn't resolved the issue- seems to be something funny going on with the date jumper...1 point

-

I knew I had a more recent Newmark. I just wound this and popped it on for comparison. This is probably early seventies, judging by the square styling. As I recall it is EB8800 based, so no longer "Made in England", but Swiss. The blue dial looks much better in real life than in this picture though.1 point

-

It is not like any problem (of amplitude or other), can be resolved by insisting on cleaning or redoing lubrication. And, as you found yourself, if one stuffs a soft material like wood into jewel holes, that can cause leaving particles there, which certainly one doesn't want. The mantra of "pegging holes" is to be applied only when there are evident very stubborn residue of dry oil that won't go away with a cleaning solvent alone. As it was indicated above already, a large amplitude difference between dial up and down indicate either a problem with the supporting stone and pivot - causing friction, or excessive end-shake, causing the pallet stones not to contact completely the escape teeth when in the bad position Instead, a problem with the pallets lubrication would happens pretty much the same in either dial position.1 point

-

Clip 1.ogg.vob This one is particularly loud. I can check the timing of the watch with it on my wrist about a foot away from the laptop microphone.1 point

-

Last session for now, all back together again after 2 cleans and rinses. I now have a problem, obviously this being a rather old movement made by Baumgartner, although copious amounts of searching on the net brings up nothing for this movement, even Ranfft draws a blank. Anyway I am now getting over banking, I can only put this down to a freshly cleaned and lubed movement now having more power put through it ( same power as before but now with no resistance ). i shall let it run and see for how long before it overbanks again and in what position it is sitting in ie pendant up etc. 8B643348-B7DE-450A-826A-4450F9CEB8C3.MOV1 point

-

1 point

-

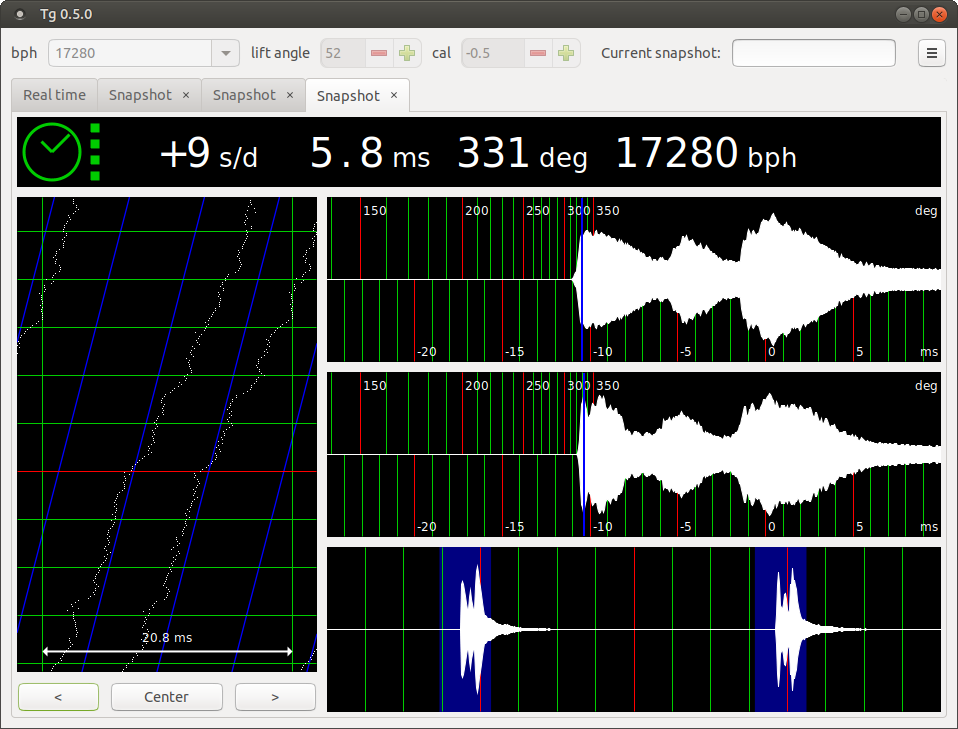

The movement looks to be based on the Baumgartner 677 series, with no shock protection to speak of, and what someone described as a "rather agricultural rate" of 17280 bph - I have no idea about the lift angle, so I estimated at 52 degrees, which will be in the right ball park. It arrived with the minute hand rattling about under the crystal and suffering from damp ingress, probably condensation rather than a dip in the sea. Its construction is pretty basic, so there is no dust or water protection to speak of. This is a picture after the first cleanup and removal of most of the rust on the screws and winding gears. I dived in a little deeper after this. There are no jewels to worry about, so it got a liberal dousing of kerosene and the pinion "bushings" got a poke with some nylon toothbrush bristles. They are collectible, but I doubt if there is any significant value in it. Unscrupulous sellers sometimes advertise them as WWII pilot watches or even trench watches, but they are neither. The factory was based in Croydon, and manufactured these from just after the second world war to the early 1960s. I believe they also sold other brands like Avia, and later Swatch. The company name, like a lot of others seems to have risen phoenix like from the ashes at least once, and a "Newmark" produced some much more recent watches. I'm not sure what the connection between the recent offerings and the original Newmark company is, if any. These watches were low end, and pretty popular. Similar to Smiths, Timex, Westclocks and the like. One more thing, if you like your watches to tick comfortingly loud, then this is the watch for you. I was surprised how accurate it still appears to be after nearly seventy years. Not bad for a bit of "agricultural machinery".1 point

-

Today, I'm sporting the latest "fixer-upper" from the 404 club. This is a Newmark "Aviation" from around 1950. A bit of digging around online suggests it might be slightly earlier, as later versions apparently had Newmark stamped on the movement, and this one doesn't. I doubt if it is WWII era, though it does have that vibe, since I think the company only started up just after the war, but information about them is a little thin on the ground. The crystal is a huge improvement on the condition it arrived in, but still has some pretty deep scratches. It beats at a rather languid but loud 17280 bph, a rate which the tg-timer software is not aware of, so I had to download the source and re-compile it. In the unlikely event that anyone else wants to do this, here is the diff between the online source and my modified version. This watch, like may others was dead on arrival, but after a good "wash and brush up", a little light rust removal, and a little lubrication, it is now working pretty well. It is sporting a period correct NOS leather band that also received a little cosmetic treatment and some leather rejuvenation therapy. The beat error appears high, but bear in mind that is a beat error of 5.8ms out of a very slow beat of around 0.20 seconds, so as a percentage, it is relatively low. The swing however is enormous.1 point

-

An update on the Heinz clock, The movement needed some work, however is running fine now, I have now worked out how it all went together and set it up on a temp board. The music cylinder is stuffed, however I have found a good one and should have it soon, just more work to convert it to fit. I will also have to rebush all the music parts and some are big bushes set in cast iron. It has 2 worm cogs and they are in good nick as is all the others. The fly need some work also however that is the last thing I will do. The person that made this had some skill as it was not a factory that produced it as I have never seen one like it before. I would say now that I have it that it was converted around 1880 to1900. I like it though something different!1 point

-

Possibly something is wrong with either the lower pivot or stone, these have have to be examined with an high magnification loupe, if not a microscope. Check balance end-shake also. Since you can have the watch running reliably even if it's impaired in one positions, it's really up to you to decide if giving more effort, which can be significant, to this one or move on to the next.1 point

-

1 point

-

Welcome Angelo, I used to own a house in Italy (12 years) in the region of Abruzzo. This is a very friendly forum a with no question too trivial. Lots of members here to help & advise. Enjoy "godere"1 point

-

Look out for 30 jewels variant of AS 1701 with detached manual wind. AS1701 were used in brands like eterma, fortis...1 point

-

Yes, it was fully wound. Thanks, will do a full service when i have time to sit down with this project! Wow, nice tip! Will definitly check this out, before starting a service. This forum is great, thanks to all of you! I’m learning a lot.1 point

-

1 point

-

0 points