Leaderboard

Popular Content

Showing content with the highest reputation on 04/05/19 in all areas

-

I add power to the barrel manually. Just push to turn the barrel in direction it supplies power, If the amplitude flies, power supply is to be checked and MS tested. If the amplitude remains the same or BW locks up ..etc, the issue is with the escapement. Also check if end stones push on pivots.2 points

-

We made quite a few tools in school but here's some more recent and useful ones I've made. A puller for strike cams on typical german clocks, a simple turret for 3 tools on the lathe (I often have small series of parts that need drilling and tapping: center drill, drill, tap), a collet holder for the polishing tripod as I have a good assortment of these little collets and they make polishing screws a breeze, and a dividing head for my mill. The latter is mostly modification; the mill is a Sixis 101, the spindle is a w20 model from a hydraulic automatic machine, the dividing head from a Schaublin 13 mill. Managed to strip the hydraulic spindle down and find a conventional drawbar, a bit of fanagling to get the head fitted, and now it's used mostly to make direct dividing plates for another gear cutting machine.2 points

-

No, I don't collect the vintage character watch series made by US Time and Timex. But I have restored a number of them and typically the strap is missing or well worn. Some had very distinct straps and trying to find a suitable replacement is not easy. Ah but, what if you could find a NOS? Not so easy to do and I thought I never come across one for the Hopalong Cassidy. You know the one with the big buckle and metal tip. Than I get in a huge NOS lot from a retired salesman and found this >>>>1 point

-

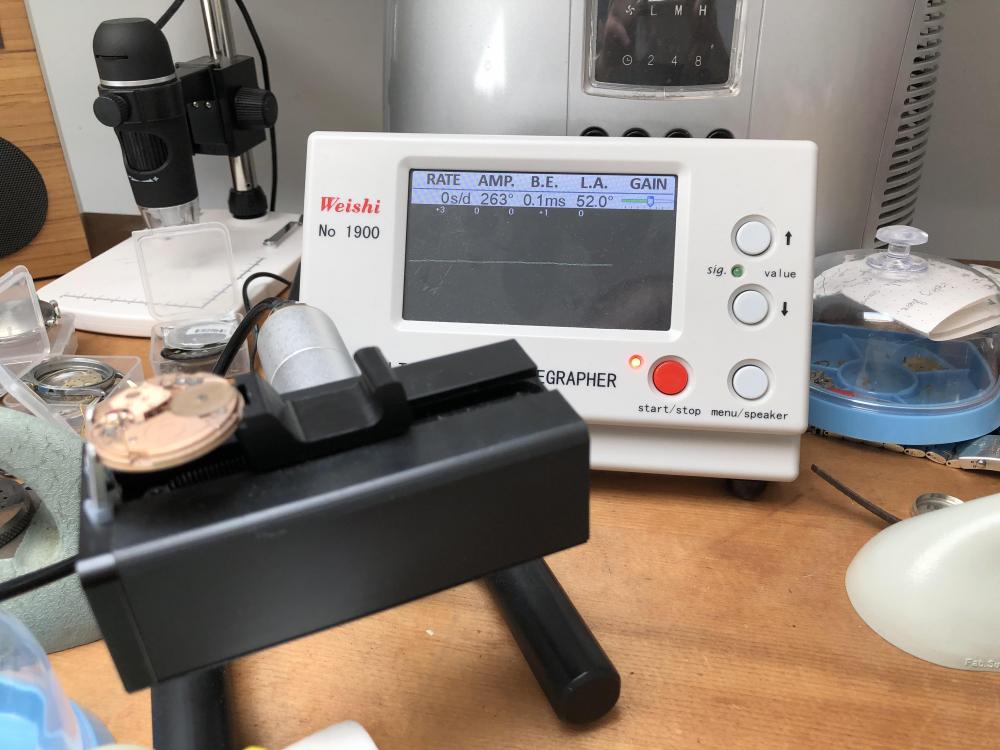

you have friction somewhere, most likely due to dirt and/or dry pivots/mainspring. this watch needs a full service. new mainspring, cleaning and proper oiling. the watch is still slightly out of beat a little more work and it will be good to go1 point

-

So the watch ifself is our living datasheet. Before getting to this, I must repaeat I agree with Nickelsilver. I agree with Nickelsilver. Once it came down to replacing the HS. The watch itself is a living datasheet. No problem to fly a new HS with this BW, inside the watch. Regards1 point

-

Today I'm road testing the Gold Citizen Crystron that needed a bit of surgery a few weeks back. It was running a little slow, presumably because someone had been tweaking the trimmer capacitor on the pcb in the forlorn hope that it would somehow bring it back to life. I used tg in "Calibrate" mode to get a feel for how it was running as I adjusted the cap. tg doesn't appear to be able to graph quartz watches directly. Now it seems to be running much more like a quartz watch should.1 point

-

Its been posted before, but its as good as anything else for saying good Monday morning. Omega constellation stainless steel wirh ESA 9162. All original including bracelet and going strong. I have the box and papers for this one. Sent from my SM-J727T using Tapatalk1 point

-

1 point

-

the 19th century watchmakers bench was designed stop "pingers". used by students and gernymen, a small bench with 3 sides in glass. vin1 point

-

These Orients came in two sises, give OD. Genuine Orient crystals are rare, mass produced generic ones are slightly of inferior quality and do get passed on as genuine on ebay. You would know the difference if you examine two new ones side by side.1 point

-

Oce sure a new HS is the only option, I would try resonating a plain HS to get the right frequency, leave some extra length on.The overcoil is not as much pain as it is made out to sound. The old HS shows all the right length and bends, it is a model for sculpture. A good parts of the over coil shaping should be done inside the movement, you van see how much to raise and bend to get to impulse pin, end length curve is about the same and is to be done before the raise.1 point

-

Hello! I sent you 10$ as you requested. Have you checked my message??1 point

-

A new crystal isn't something that you would likely need to purchase from Orient. Remove the old crystal and measure it. On your side of the pond, Cousins UK will undoubtedly carry exactly what you need and likely at a substantial discount over the same item from the manufacturer.1 point

-

Hi again Johnnie , ...Do Look at the youtube videos first.... I can't tell if your watch has a removable bezel as that would be a small clue . Some crystals are held in by the bezel . Some are pressed into a rubber or nylon crystal gasket . Some are held in by a tension ring [armored crystal ] , that is either silver or gold colored ,...Etc . Having said that and trying not to confuse things , you don't have to get a crystal that is a branded original . The tension ring type is an example . Measure your old crystal and case seat with a micrometer and order the size and ring color you need . In the United States I use Esslinger.com , or Jules Borel . In Europe , Cousins is the go to place but there are many more resources so you have to do good searches .1 point

-

Never mind. Going thru the scrap heap yielded a damaged hairspring with stud. Now for a suitable taper pin. There's a reason to keep your scraps. RMD1 point

-

Assuming the watch is fully wound, I would suspect the low amplitude may be associated with a weak or dirty mainspring, or dirt somewhere in the power train.1 point

-

Hi Johnnie , are you going to do the crystal change yourself ? If so do you have the tools and skills for this procedure which may include measuring the old crystal and case among other things to purchase the correct size you will need to order and install your new crystal . I would look at a few good youtube tutorials to help . Good Luck .1 point

-

1 point

-

I was really pleased with this service and it's the first time I've worked on an Omega. It was a 1030 movement from the 70s with a broken mainspring. It looked like it hadn't been serviced in decades. Terrible reading as you can see. It was really nice to work with compared to the scrap I'm usually trying to rescue! I cleaned it, oiled it, replaced the mainspring and regulated it and just look at the difference! And it's within 10 seconds in all positions. Just made me happy so thought I'd share :)1 point

-

That S-emblem is really a 5-emblem, by the way. The Seiko 5 line is a rabbit hole all of it's own.1 point

-

I'm not sure that I would try and do anything with the hand still attached, I'd be too frightened of marking the dial or bending the pinion or something; so I'd agree that as you are taking the hands off anyway best to do it then. And also, yes! It's a great and interesting hobby that just keeps getting more interesting the further down the rabbit hole you go!1 point

-

Bend slowly and carefully, inspecting as you go to make sure you are straightening and not putting a correcting bend in if you follow me. And yep, I’ve had loose emblems and hour batons. Always apply glue from back and leave for a couple of days. And post pics of how you get on Sent from my iPhone using Tapatalk1 point

-

Many times. No idea what kind of glue they use. Think any glue will be fine. As long as it's not a big bloob of glue. Superglue works fine . As long as you let it dry before you put it back. To avoid the "glue fogging" I didn't look properly. I thought it looked black. But when i look now i see that it's silver. Then it's no paint on it.1 point