Leaderboard

Popular Content

Showing content with the highest reputation on 08/27/17 in all areas

-

@measuretwice The barrel arbor hooking isn't pressed on- it is machined integral to the piece.. don't pick at it any further! This piece would take a GOOD couple of hours to draw up, machine, modify to fit, heat treat and polish. @jdm Yes- me! 12 yrs working with Schaublin 70's (alongside other nice machinery) every day as a precision prototype engineer for industry. (also an MBHI watchmaker)3 points

-

Very nice jog.... i love the 'drastic' set up and think you have a great result. I use double sticky tape and my polishing machine but the resulr does not exceeds yours.... well done2 points

-

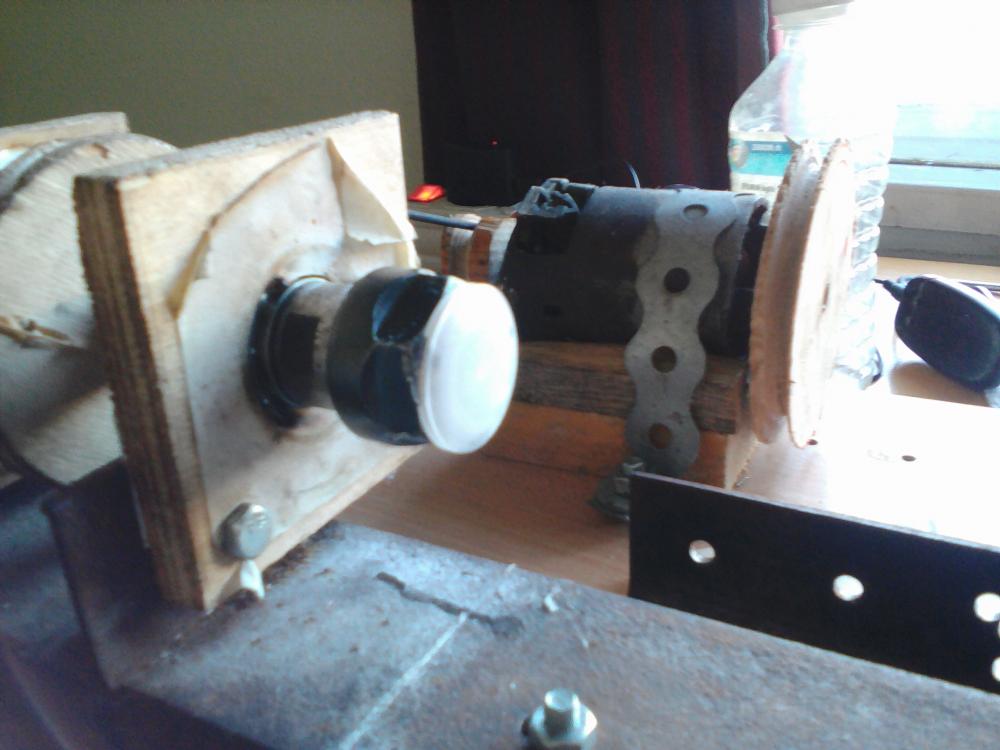

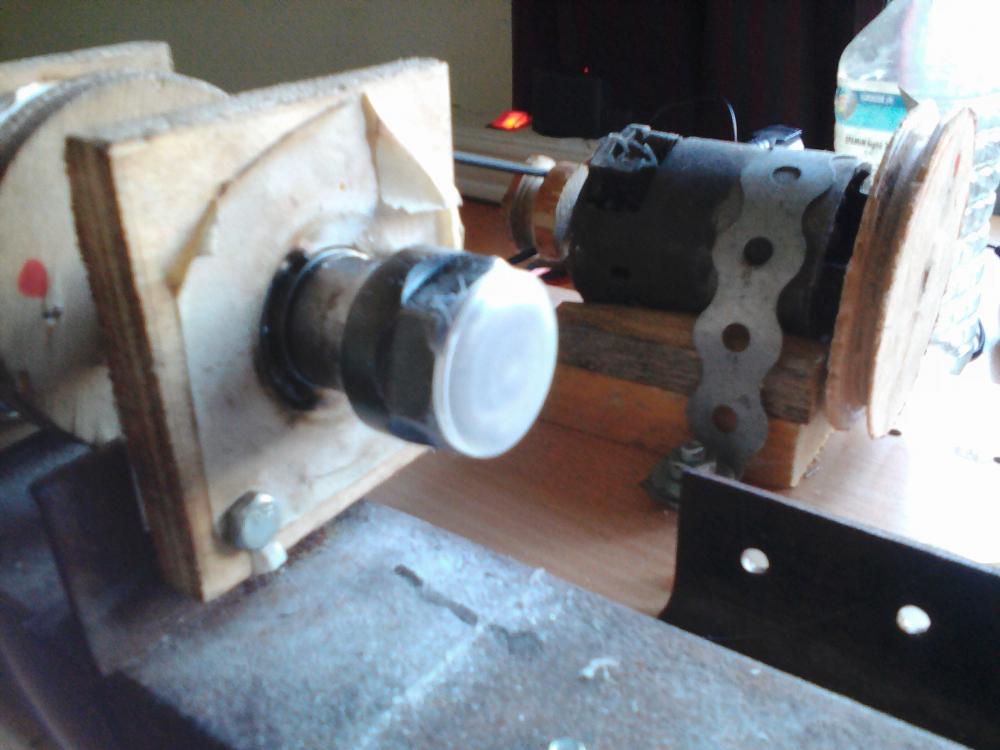

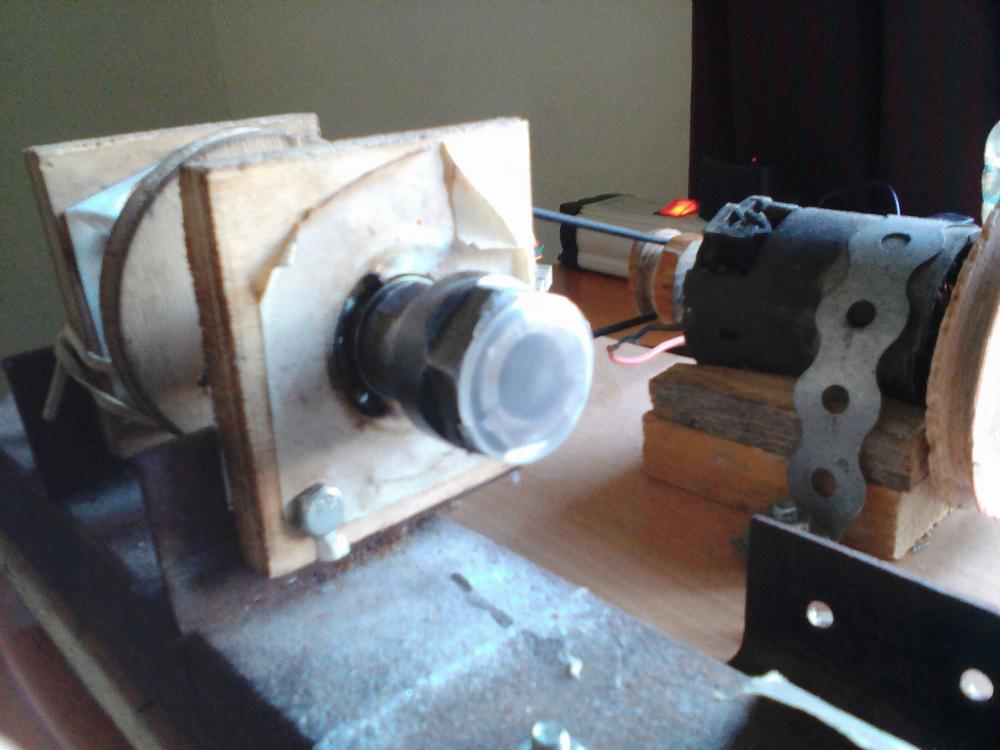

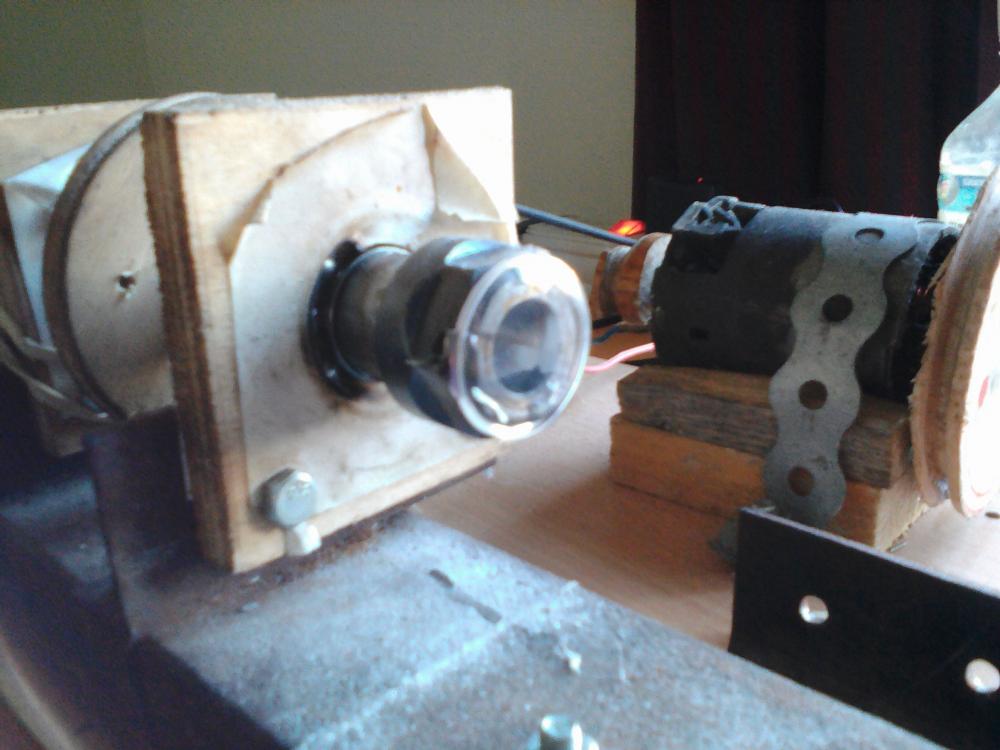

I was not hoping that it will turn out good but it did so no video of this only some bad pictures. Komandirskie crystal was mounted on the spindle chuck nut with hot glue. Sandpapers and diamond paste up to 10000 grit were used to polish the crystal. It was full of scratches, deep dents and there is also a crack. The latter is of course still there but this was my experimenting pice. The whole project took only 15 minutes !1 point

-

1 point

-

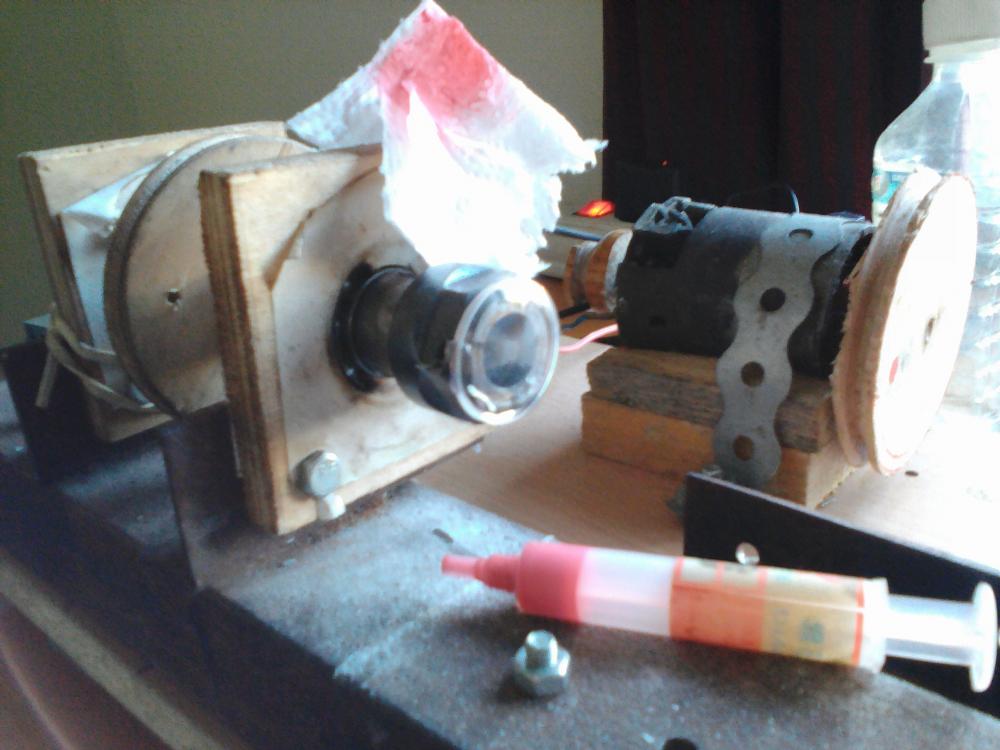

Im more of a manual labourer. One of these to remove scratches and flatten acrylic.... Then Polywatch and a Terry towel to bring back the clarity. Sent from my Honor 5c1 point

-

1 point

-

There's a step by step guide to making one in DeCarle's book, The Watchmaker's Lathe. Send me a pm with your email address and I'll scan the pages over to you.1 point

-

I love these vintage Molnija's...great job. I would surely look for another dail to replace this one....well done.1 point

-

1 point

-

1 point

-

There is a big difference between a watch repairer and a watchmaker. A qualified watchmaker providing he/she have the correct tools would be able to make the part. A qualified watch repairer would find it extremely difficult even with the tools. I learned my trade and became a watchmaker clockmaker. I was lucky the workshop was set up to make parts.1 point

-

I have done some research and these watches are high end and seem complex in construction. I would not change the battery or use any other repairer other than the manufacturer or a specialist. In my opinion it's not worth the risk.1 point

-

1 point

-

1 point

-

Do you have a lathe and mill? Making such a small and complex part is a very advanced task for today's (low) standards of watchmaking.1 point

-

the odd part that came with the movement is the Contact point spring. The PDF manual below explains about what it's for, not found in all cased movements though. Then if you're concerned about whether the circuits actually charging or not in the manual explains how to test the charging circuit. Then minor confusion the early kinetics used capacitors later there was an upgrade to a lithium battery this one specifically is designed only for the lithium battery. The lithium battery has a much longer running time but also takes way way more swings to charge up which is why having one of Seiko's automatic charging units works really nice if you could find one. then the charge indicator also explained in the manual. So five seconds is between one and seven days. 10 seconds is between seven days and one month. So as a wild guess when you're attempting to charge it up if you're on a borderline is why you might see it drops so fast back the five seconds because you really didn't get very far into the 10 second charge indicator. The manual explains how we are supposed to swing and it appears to be if I'm reading correctly once the secondhand is stepping at one second increments between 200 and 250 swings gives you one day. so if you want to go beyond the five second indication mark it looks like you need the swing the watch a minimum of 1400 times in the proper fashion. http://www.seikodigitalwatches.com/5XXX/5M6263A.pdf1 point

-

1 point

-

I do not think you will be lucky with this. The whole balance missing it will be like looking for a needle in a haystack. I do not have any reference books anymore I sold them all. You need some movement that has a balance complete that is compatible to yours to have any chance of it ever going and keeping the correct time. The only place I can think of is ebay.1 point

-

Top photo is a setting lever spring off a 10.5 L FEMGA 500 a 520 setting lever spring would look almost identical wether the two are interchangeable i dont know1 point

-

Only replying as this is a very rare part and will be near impossible to find elsewhere. We have the Omega part, VP2075, measures 258.5mm square, curved along the edges, omega symbol in the middle. £30 + post and vat.1 point

-

Did find it but it's not in super condition. Maybe i can find some other one It has a small mark because the thread for the crown was damaged.1 point

-

1 point

-

Hi SSteel Could you give me a bit more info if possible regarding the name of your machine and the eBay link if possible Thanks Peter Sent from my iPhone using Tapatalk1 point

-

My very first watch repair was a non running fleabay bought Landeron 51 I paid $48 for. I bought a set of screw drivers and some tweezers and a head loupe and commenced to dissemble it. As I did it I took pics of ever step and just reversed the pics when I put it back together. I was successful and it running. I ended selling it to a guy in Switzerland for $120. You just have to really be mechanically inclined and have the drive to do it. Now, I am not afraid of the little parts or losing and breaking anything because I can just order more. Besides, its just a hobby and I am not losing anything but time and no matter how many watches I own I still don't have enough time.1 point

-

Bobs classes are videos you can get on DVD or download the video to your hard drive (used to be able to download, I took the course in 2010), then you have access to them all the time. Most sections are made of 5-10 videos and most videos are 15 mins, but he uses a CAD/CAM type of program system to explain some parts and videos of the work being done for other. If you do a youtube search for Bob Tascione, he has portions of some classes posted for people to sample, I would suggest to go through those videos first, they are older videos and I think he is working on a new release of his classes. Also Bob and one of his former online students just released a new course dealing with Hermle Chime Clock movements repair, the former student William Porter also has some videos posted on youtube, although Will's youtube channel deals mainly with clock repair.1 point

-

While I have not taken the Time Zone classes, I have take Bob's course and found it very much worth the cost, I service both watches and clocks based on the foundation I received from his course. Using supplemental aids such as books, and videos like Marks have increased my knowledge and skill level. When it comes to these classes, regardless of which one you go with, I have found the main key is repetition of the skills starting from the basic use of tools, to changing a roller, there is no shortcut for hands on repetition of the skills you learn from any video or book. Also you have to understand, while Bob course includes a forum to ask you question, you do not have someone standing behind you looking over your shoulder helping you through those tough moments. Which is why I have added books, forums like this one, and bookmark youtubers like Mark, Steffan Phalow and others who give me exposure to new skills and watches that I would not other wise see.1 point

-

I know someone in Canada who took recorder lessons from someone in England; so it works for that. I'd imagine one would need special equipment to do watches on Skype; something like what Mark and others use for videos. Dave1 point