Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/17 in Posts

-

7 points

-

4 points

-

Greetings all! My first post here so I'll try to start with a good one... I've been fixing and servicing watches full time for a few years now but this one that came in recently is probably one of my biggest saves. It belongs to a guy called Paul who's a pretty serious Seiko collector and sends me a couple of watches each month for servicing. He spotted this 6105-8000 on ebay which appeared to be in good cosmetic condition but was listed as non-running / needs a service - There was no picture of the movement with the seller saying the back was too tight and he didn't have a case back tool. Paul took a chance on it but when it arrived the case back was only hand tight and this is what he was greeted with - Now obviously Paul wasn't happy with what he'd bought and was going to raise a case with ebay, but in the end he decided to keep it and send it to me to see if it could be saved. Now I mentioned that Paul is into his Seiko's but he's also a great customer. When he sends a watch that needs a new crystal for example he sources it first before he sends it to me which then saves me having a partially finished watch on the bench while I search for a crystal and then wait for it to be delivered. Most customers won't even think about this but if you fix watches or cars or whatever for a living and a customer comes in with all the parts needed it saves you so much time and hassle. With this one he had a good stash of 6105 parts so they were sent with the watch - So onto the strip down... The dial side wasn't too bad but pretty much all of the screws on the train side were rusted in place, so the movement was placed in a tub of penetrating oil and the tub was placed in the ultrasonic cleaner to agitate the oil. It spent about an hour in the cleaner like this and soaked in the oil for 24h - So after soaking for 24h it was time to start the strip down. The auto winding bridge came off easily enough but the train wheel bridge screws were very tight and I couldn't get enough grip on my Bergeon screwdriver, so I used an electricians terminal screwdriver and ground the tip down to size on an oil stone for a bit more torque on those stubborn screws - The click spring had dissolved with rust and turning the screw on the ratchet wheel only turned the mainspring so it was out with the Dremmel - The strip down wasn't totally straightforward as the heads on two of the screws had corroded away. One of the screws was on the train bridge but there's still two other screws holding it in place so not a problem and the other one was the dial foot screw, again not something that is critical to how the movement performs. The main thing was that the main plate could be salvaged as this is the one movement part that isn't readily available. With everything stripped it was back into the cleaner again and then inspection. Obviously a lot of parts would be replaced but it wasn't as bad as I'd initially anticipated. The parts above the mainspring in this next picture are all reused and below it are the scrap parts - From the state of the movement I suspect it had suffered a crown gasket failure, taken some water on board and was then left dial-up for the movement to soak for a few years, as evidenced by the back of the movement being a rusty mess and yet the front and dial were pretty much unscathed. The state of the train wheels would back this up with the top pivots being corroded yet the bottom ones were fine. The balance was the same and I thought I might at least be able to save the hairspring but there was some rust or rust residue on it and it was beyond mine and my cleaning machines ability to remove it. Not a problem I thought as Paul had supplied a complete nos balance but it wasn't going to be so easy - I tried straightening it out and got it looking like this - Not bad but far from perfect but when viewed from a different angle it looked like this - I've fixed a few bent hairsprings before but twisted ones are beyond my ability, so it was into my own spares stash to harvest a hairspring from a 6139. The only thing left to do now was to put it all back together - The movement scrubbed up pretty well cosmetically but the amplitude was only 200 degrees dial up and there was around 30s variation over four positions. I tried a different barrel and mainspring from a 6309 that was previously putting out around 230 but it made zero difference. I then went about pressing out the fourth wheel and barrel arbour bushings from the train bridge and replacing them with the bushings from the 6309 movement, and the third wheel bushing was replaced with one from a 6139 (the 3rd wheel bushing from the 6309 was a smaller o/d so not interchangable) but still no difference. At this stage I was getting kind of tired with it - I could have bought a new mainspring and/or complete balance in an attempt to improve the amplitude but it was running again and keeping reasonable time for a 47 year old watch, plus I'd already spent around 4x the time on it than I would on a regular 6105 service, so all that was left was to relume the hands and bezel pip (the dial lume was in good condition so wasn't touched), fit the new crystal and get it cased up. I also fitted the nos crown that was supplied and was glad to see it passed a 60m pressure test - If you know your 6105's you'll notice that the hour and minute hands aren't correct and are the same as what you'd find on a 6139-6002, but it appears that Seiko fitted these hands to 6105's when they came in for service. I know that Paul is currently trying to source the correct original hands and when he does then I'm sure I'll see this watch again for them to be fitted, but I'm pretty happy to see how it's turned out regardless. If you've got this far then thanks for reading! David.3 points

-

So you changed the adjustment nut which means you've changed the end shake adjustment that as clockboy pointed out in his post was factory adjusted now you're going to have to adjust that because if you don't have enough play in the balance wheel it's not going to oscillate. The reason I ask about the wording is your describing putting the balance wheel in getting the roller jewel where it's supposed to be which is a problem. Then possibly an entirely separate problem you're saying the watch doesn't run very long once it's balance wheel is back in which conceivably could be an entirely different problem. So if the roller jewel is where it's supposed to be engaging with the fork you can manually rotated in either direction from its at rest position. If it's on the wrong side then you rotated in one direction but the roller jewel will crash in to the fork on the other direction will not rotate it's really quite noticeable. Other minor little things you replace the spring for the shock jewel assembly? When you disassemble the jewel assembly the cap jewel did you put it back correctly? From their website the color image which I've attached notice the jewel looks to be flat on both sides? Although on the technical drawing notice how it's flat on one side curve on the top? It's very easy if not paying attention with a curve to put it in upside down. If you do that there is no end shake and the balance wheel conceivably will not freely rotate. So let's verify you don't or do have an end shake issue first. Remove the pallet fork so the balance wheel is not being influenced by that. Puff of air start the balance wheel oscillating does it move freely? If you have no end shake it will not move very well if there's too much and shake it's going to oscillate I'm sure that will generate some other problem. Rolex has very exacting specifications of the balance wheel end shake and they even have exacting specifications of how much each nut will change the end shake. Which is all pointless if you don't know what you're looking at or doing. Other thing that affects balance wheel rotation is make sure the hairspring is where it's supposed to be and it's not rubbing on anything such as the balance wheel arms perhaps.2 points

-

Shellac has many advantages over other types of fastening products. One big advantage is it can be drawn into thin hair size strands that are stiff enough to control. Watch parts are very small and a thin strand of shellac can be precisely deposited on the desired spot. A drop of glue on a watch part could cover the part in areas where the glue was not needed or wanted. Another advantage is, once the shellac cools an extremely small amount of it will permanently hold the stone in place. When you wish to remove the stone you only have to reheat it. Since alcohol dissolves shellac old shellac can be easily cleaned off before replacing another stone. david2 points

-

The Girard Perregaux is complete and wore it yesterday for first time. The dial is a little worn, but original and it has a nice 36mm size. The movement is the manual wind GP 03 calibre that has "adjusted" stamped on it, but not known what type. Special thanks to @RyMoeller for sending me a pair of very hard to find vintage hands that came in very..uh...handy! JC2 points

-

Im getting close, decided to incorporate the oilers into the station. Still got another day or so on it, but im further than I was...lol......gonna make a place for the balance tool to sit in when not in use so it doesnt get messed up....may move it to one side instead of the middle....any thoughts?2 points

-

Here are bracelet pics, (before/after) after masking off center high polished links, used same pad to create satin look finish, returned to give center links a bit of work, I found spare movement now just need a dial and chapter ring to fit. I'll be sending out for new crystal today, so it'll be some time before I can get back to it.2 points

-

Hi guys and girls! I have recently dug into a AS1730- movement. While putting the automatic winding assembly together I noticed that the bridge had two capped jewel holes. Looking at them through a microscope (pictures attached) one can clearly see that there are some fluid residing between the jewels and the caps. Probably fluid left from the cleaning? Now I need to know how to pop the assembly open to remove this fluid. Maybe I can push the entire assembly out with the staking tool or something, hoping for it to come apart?1 point

-

Chaton!! I always struggle to remember that word I have one of the H-Drivers - exactly what I was thinking. Would really suck to be wrong though - could do quite some damage. But I just don't see another solution....1 point

-

Threaded chatons are not common, but they do exist http://people.timezone.com/mdisher/EHElgin/EHElginPt2.htm Sorry I don't know if that's the case here.1 point

-

1 point

-

Threaded? Hmm, maybe. There are some circular scratches around the bezel that could indicate it has been unscrewed with a screwdriver before? That would however require the bezel to be raised above the jewel (or some special tool to unscrew it). I can try to get a picture from a different angle of it.1 point

-

Yes, the slots are probably important for the disassembly somehow. I'll back of the staking tool for now1 point

-

I am not familiar with this jewel setup. From the pictures, it looks like the brass bezel has slots in it. Is it possible that this bezel is threaded into the bridge??? I would not recommend pushing on this unless you are certain as to the construction.1 point

-

Hi, if you have a Generale Ressorts (GR) Mainspring Catalogue please could you help me find a GR-code for a project. I am after a Height 1.45mm x Thickness 0.13mm x any longest length x any barrel size. I just need it for a project and will cut the spring to make a circular spacer, so length is not important Thanks1 point

-

1 point

-

1 point

-

Perfect. That's just how I started and I've done many, many watches since then. Mark's videos are the best and his technique is superb. JC1 point

-

OK that's a good plan. You'll need good lighting (either regular bulb or fluorescent/LED type) and quality 10X loupe (Bausch and Lomb or something good quality) and a general magnification visor with 4X. You'll also need at least one movement holder and a mat to work on. One more thing: a good set of tweezers! I got some from Ebay that are decent, but they must be Swiss because the quality is the best and you need good tweezers to work. JC1 point

-

1 point

-

Its a beauty! We'll get that going...I'll help you in any way I can and so will the other fellows here. They're all top notch. Have you ever disassembled a watch before? JC1 point

-

1 point

-

The 0.5mm will work in place of the .60mm and you'll see the difference when you use those sizes. I suggest you use the screwdriver that is closest to the slot size to prevent slipping. This happens anyway, but will be reduced if you use the proper size screwdriver. I remember I was tempted to use smaller screwdrivers on the larger barrel or winding wheel screws and simply messed up my small blades when they came up short on torque and slipped. Lesson learned! JC1 point

-

Hey Douglas, Welcome to the forum.In my experience, You'll need these 5 sizes to get anything done: 0.60 mm Pink 0.80mm Yellow 1.00mm Black 1.20 mm Red 2.00mm Green There may be a few brands that use screws sizes on either end of the spectrum, but these will get you through 99% of wristwatches and most pocket watches. JC1 point

-

I thought I was alone on this earth with this affliction. You have made my day .1 point

-

Gotcha. I have a little remote control/dimmer that can attach to my light and it has the same problem. Fortunately, full brightness works for me. Good luck! Sent from my Moto G (4) using Tapatalk1 point

-

Well, I ripped off a regulating pin trying to carefully remove a hairspring. The hairspring is fine but, of course, the watch doesn't work very well. I'm not even going to try to put another pin on the lever. Time to buy a whole new balance cock methinks... Years and years ago, I was a student when our music school class was invited to a rehearsal of Byron Janus playing The Emperor with the Winnipeg Symphony Orchestra. One of the students almost hung over him watching him play. During a short break she asked him, "Maestro Janus, how can you play so fast and play all the right notes?" He answered, "Hell, I don't play all the right notes!" So, there you go...1 point

-

1 point

-

1 point

-

Welcome to one of the friendliest and most helpful forums on the web. You're embarking on a hobby that puts your entire existence into one square inch for entire moments, interrupted only by hours on your hands and knees looking for pinged springs which are looking down at you and laughing an evil laugh from somewhere in the upper atmosphere. (Of course there is that rare aha! moment when you find the dastardly creature hiding in the crevice of your shoe.) Those are the moments you live for. Well, those and the even rarer moments when you see straight lines merging on the timing machine... but those moments come many, many springs later.1 point

-

1 point

-

1 point

-

1 point

-

excellent job, looking awesome....I bought a buffingmachine and I use it as I don't have the patience of doing it by hand...It really gives a great result on crystals as well as cases and bracelets. I don't polish them 100% as I like some wear and tear on a vintage watch.1 point

-

A year ago i wanted to make a new balance staff but i had no good gravers, lathe and experience (still dont have them ). But have found an article which occured to me now. The staff was turned from softened steel with HSS graver. The pivots were turned roughly. Then the piece was hardened and finally the pivots were burnished to size.1 point

-

1 point

-

Excellent explanation David. Because my eyesight is not that good I have a microscope above the lathe & very rarely use the cross slide because of the lack of feel & also setting up a cross slide takes a while i.e. getting centre.1 point

-

1 point

-

Aloha and Welcome Cody and Douglas , You're in the right place to share in our mutual interest .1 point

-

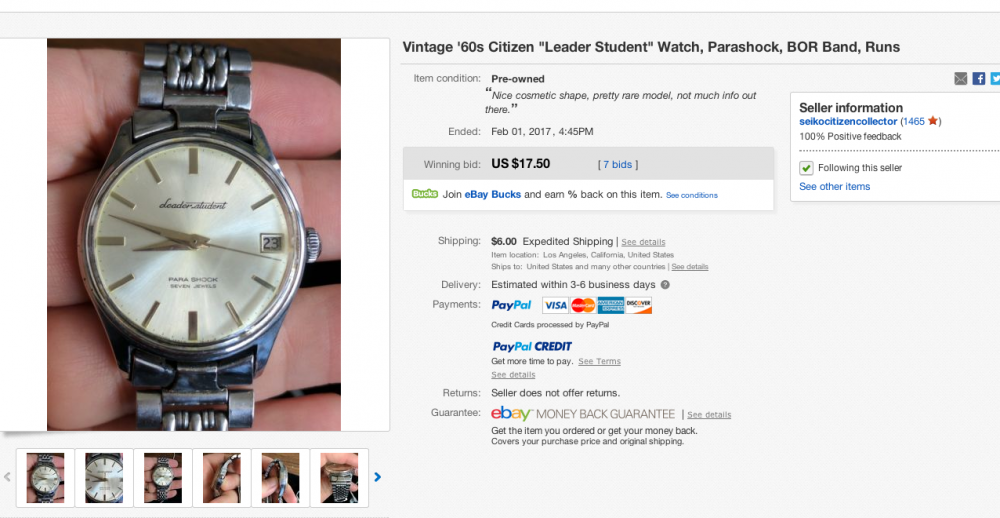

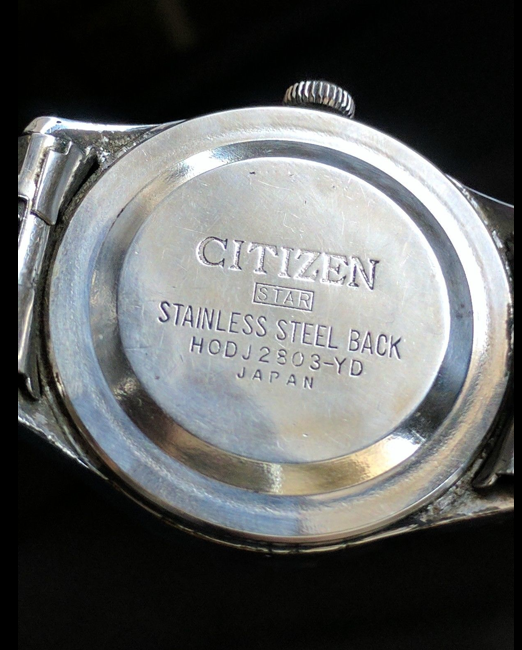

Very nice Anil , I agree about the Eagle series. Not as appealing as some of the other models . I like and have a few V2's , Crystal Sevens , and Homers . I just bought this Citizen "Leader Student" watch on ebay that one of the members from the Seiko Citizen Watch Forum had up for auction . It is a JDM watch and comes on an AM Beads of Rice watchband from Japan by manufacture "Bambi " .1 point

-

Like my father-in-laws tractor? After he fixed it and it was running just fine he showed me a box of parts that he told me the tractor never needed in the first place. Dave1 point

-

I have a Chinese version of the Bergeon which also has this chart. To be honest I have never bothered to work out what the chart indicates. I just use the winder to check that the auto is functioning correctly over a period of say 48 hours & also to give a better indication of how a watch is performing.1 point

-

Looks excellent, Nice sharp edges on the sides. Do you have the rest of the watch to build back up?1 point

-

1 point

-

Just woke up. But this was my wind down last night Sent from my iPhone using Tapatalk1 point

-

Most of you are probably already in bed by now, since I am six hours behind you (in Texas). But this is what my son bought me (see attached photo). Haven't cracked it open yet... probably won't until the weekend. There's a really good bourbon called Bullit that I like to mix with Coke. I don't drink often, but when I do, I like a good Bourbon with Coke and lots of ice. (I eat the ice after I finish the drink and pretend that will hydrate me enough to stave of a hangover...lol).1 point

-

In this video You can see how to alter a jewel to preferred dimensions. Recently i ordered a jewel lot from Redrooster UK so i was choosing one with good external diameter and thickness. 0.17mm hole was drilled, oil cap was burnished and the flat side was polished. Ugly video but i hope You can find it usefull.1 point

.thumb.jpg.4c150623c07d65ae8c710143f971642e.jpg)