Leaderboard

Popular Content

Showing content with the highest reputation on 03/03/20 in all areas

-

The two attached videos show my adventure in making a Unique Pivot for a Hamilton 21J Railroad grade pocket watch. The problem was in using the traditional way in making a new pivot and failing in drilling a .28mm hole in the shaft. So I woke up the next morning and thought, “why don’t I make a sheath that fits over the wheel shaft and then tapers to a pivot at the end...where the Seconds Hand fits. 1 small piece of blued steel, 1 lathe and a lot of measuring and it worked...the second time. Here are the links: Sent from my iPhone using Tapatalk Pro2 points

-

Jeezumpetes. I just got a Baume & Mercier chrono, was serviced 6 months ago by B&M, 800 bucks. Stopped. Sent in for warranty, they said it was dropped, not covered. Ends up on my bench.... 2892 with Dubois Depraz module. Straight away, auto module was barely screwed on. Get to taking the dial off, one dial screw missing. Found it in the chrono module, put it where it belongs, double checked all the other screws, and it runs great. And the brands don't want to distribute parts because us indie guys are hacks. Hahahahaha.2 points

-

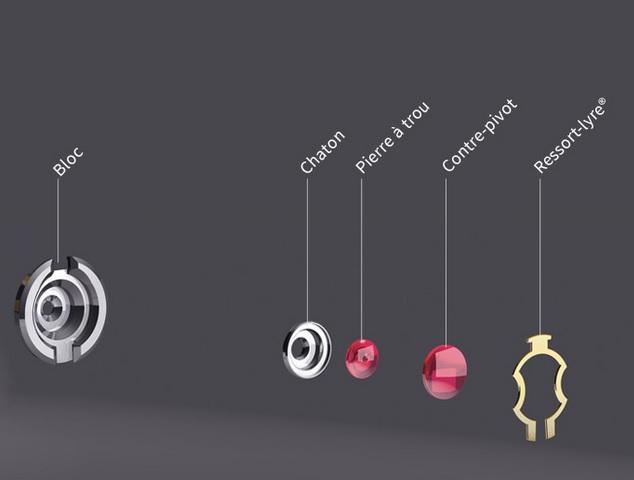

Yes, the "chaton" as Incabloc calls it (in the pic the hole jewel is out of the chaton but it's friction fitted in and never comes out) is what I mean by hole jewel, those and the cap jewels go in a little basket, and then like you say the cock as you've pictured goes back on the mainplate. The balance, pivots, and spring will be A-OK in your Elma.2 points

-

Hi Put a drop of vinegar in the hole and let it soak Being acidic it should hopefully eat the rust a little.2 points

-

I treat the pinion and spring with epilame, the oil both ends with 9010. The spring does need a bit of tension, or the hand will be unstable. I personally hate this system, and there were elegant alternatives that don't eat amplitude. Beware when you fit the seconds hand, you'll want to put a bit of old mainspring or something between the pinion and tension spring and set it all down on a bench block while pressing the hand on. Otherwise you can easily damage the spring.2 points

-

1 point

-

This can help, but you'll want to clean out the oil first. Don't get the vinegar anywhere but in that hole! Sometimes alternating between tightening and loosening can help, if it moves a tiny bit then get more oil in there and go slowly. Rust takes up more space than the original steel; the oil will help move the rust out of the threads as you go.1 point

-

Note: Indian tools usually are made to look like the real tools. Frank1 point

-

I didn't catch how you accommodated the extra length at the shoulder (sorry, I had to skim through)?1 point

-

Just for a test, drop a used faulty gear- arbour assembly in vinegar, couple of days later, you would find the gear damaged to a point that arbour has come loose. I sometimes use vinegar or soak parts in it, but no longer than thirty minutes.1 point

-

Here is the video with the new successful JD Pivot:) Sent from my iPhone using Tapatalk Pro1 point

-

good show. 2 points off - if you got blood in the mvt.. vin1 point

-

Made the crazy wheel shaft cap pivot and it actually workswill post YouTube video I made. So you folks need to name this the “JD Pivot” Sent from my iPhone using Tapatalk Pro1 point

-

Thank you guys for your suggestions. I do have a soldering gun so I'll try that. I also have some vinegar but never thought I would use it on any of my watches though.1 point

-

Sorry, didn't see this earlier! The tension spring should be the same when you put it back; that is, if it is adjusted well now, it still will be. And true, if the tension is too light, the seconds hand will flutter, and seem to stop sometimes, then catch up; if it is too strong it will zap your amplitude. As for the casing, it's hard to say. As always, just proceed slowly and force nothing. There have been cases where the "metal" ring is more or less part of the case, but not sure on that one. You may be right that the something need to rotate, may be the movement itself. Get the case screws loose, and see. Beware the case screws may tighten the movement in place by loosening them, my suspicion there comes from the gap near the word "eighteen".1 point

-

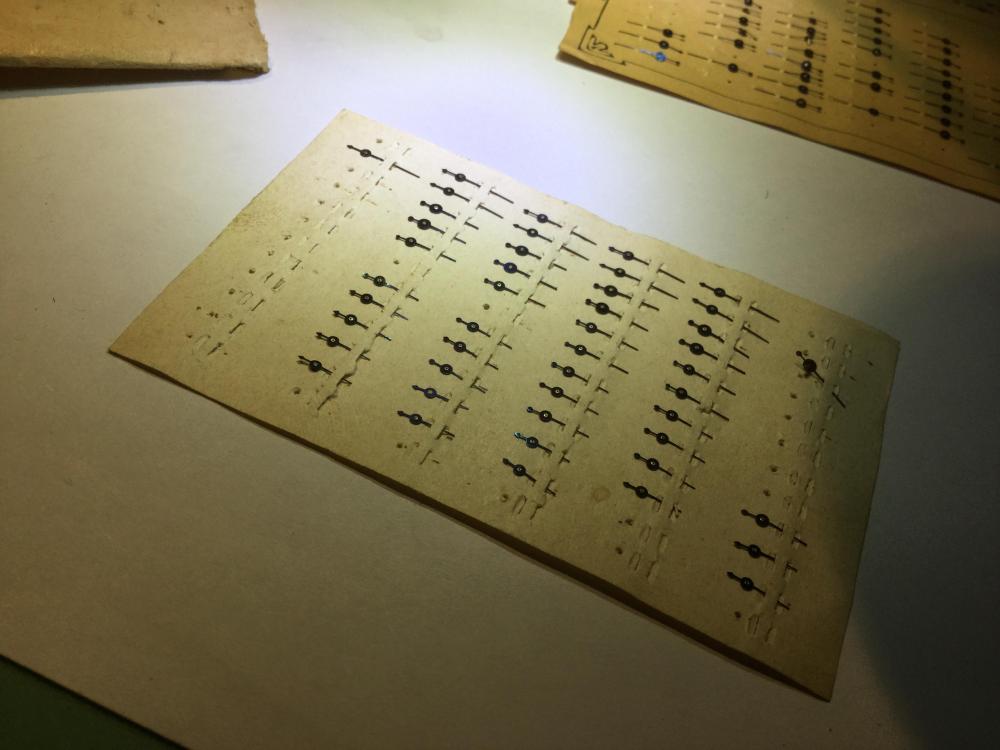

Here's a set you don't see very often Favorite Lathe Yes, it's expensive, but it's very complete, and these are really good machines. I sold one about 15 years ago that didn't have the milling attachment, wheel chucks, the simple tailstock with pivot drilling discs and with a smaller set of collets for 2500 and that was a friend who bought it. It's pretty much exactly the same as a Schaublin 70, just smaller. If you tried to piece together that set it would take possibly years, and possibly be more expensive. I wouldn't say not to go for that Pultra. It's a really nice setup at a nice price. You've probably already tracked down the page on Tony Griffith's site, but here it is anyway Pultra. You can see down the page an adapter for going from 10mm to 8mm, which Tony admits may have been shop made. If you got that Pultra, and were smitten with lathe work, it's likely you'd end up getting some other lathe down the line as well; as this is based on the WW pattern, while it's fairly certain tailstocks wouldn't interchange with another maker (the WW or Webster Whitcomb pattern was used more as a guideline than an absolute standard by most maker), the slide certainly will. It can be very handy to have two lathes at times. Tony's site also has a for sale page, often with a number of interesting lathes for watchmaking listed.1 point

-

1 point

-

What you have here is a Vienna regulator Timepiece clock, with dead beat escapement. When it comes to fitting a new line you will have to take the movement to pieces. You will then have to take the barrel to pieces in order to fit a new line. Any good clock supplier will be able to provide you with the correct line for a Vienna clock. I can give you more assistance in this repair if needed.1 point

-

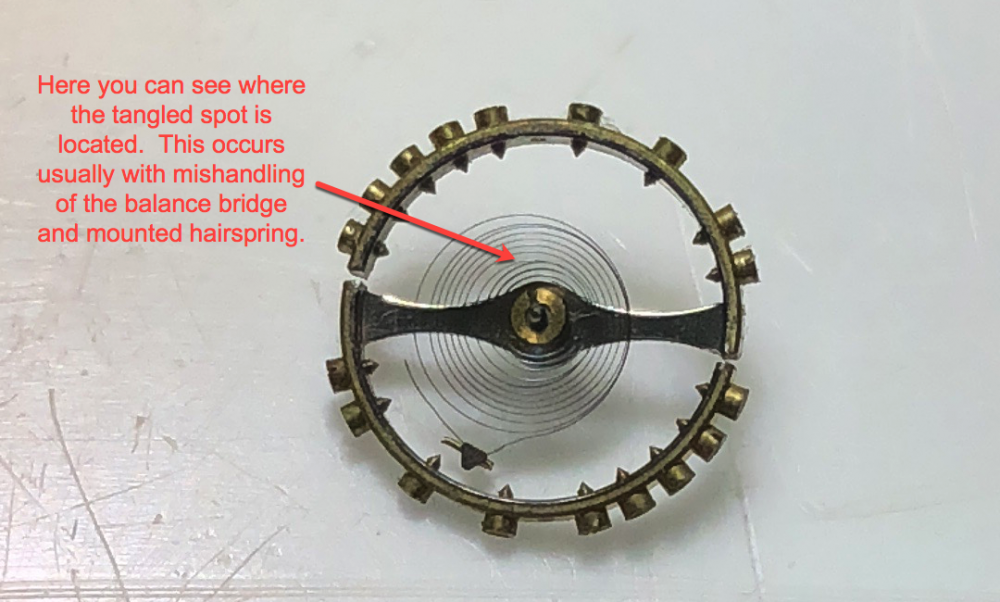

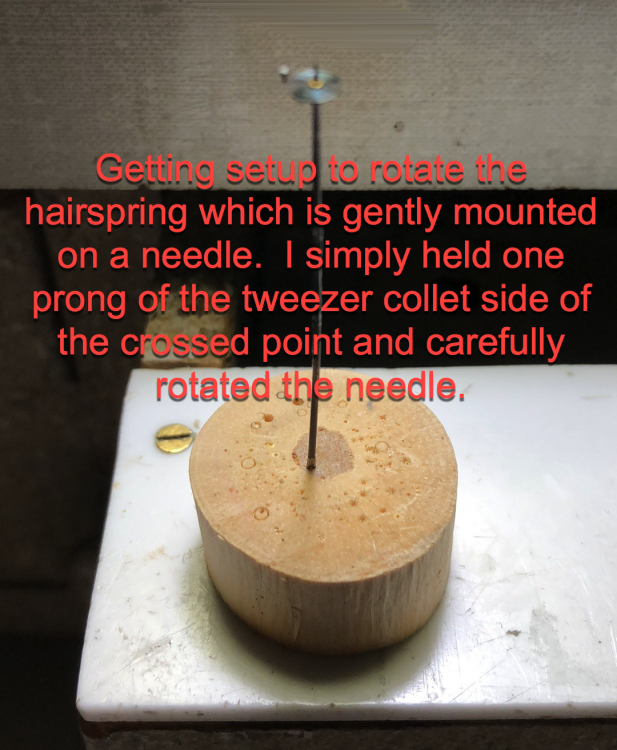

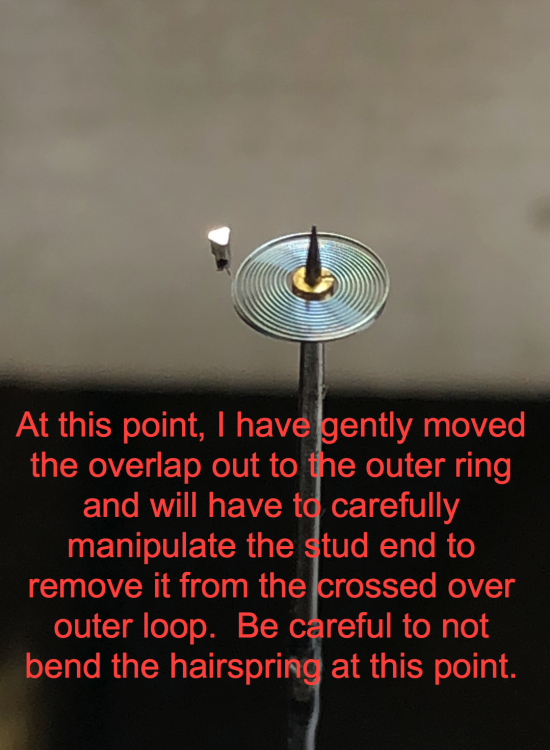

Hi Gina there is a time when the spring is beyond saving usually when its a rats nest or the kink is so sharp that the molecular structure of the metal is damaged and any further flexing will cause it to snap. Most soft distortions when the spring is not flat or the coils are not even causing them to touch and that causes rate errors are in all probability salvageable with care and deft use of the tweezers or manipulation tools. The subject has been covered before and the references can be found via the SEARCH box at the top right of the home screen. We have all managed to butcher a spring or two during our carees. Cheers1 point

-

I agree with nickelsilver... keep away from 10 mm collet lathes. Look for 8 mm collet versions, as you'll find more collets of that size. 6 mm and 10 mm collets are like unicorn poo! I have a WW type lathe, rather than a 'Geneva' type lathe, because it is versatile and can handle slightly bigger work, especially if I'm using a cross slide, but can cope with small stuff like re pivoting and pivot polishing etc. The good thing about WW bed lathes is, they have great tail stocks that help with drilling, rather than Geneva type lathes that don't. WW bed lathes also have a bigger clearance from the lathe bed, which is great especially using a face plate if I need to drill a hole in a watch mainplate to fit a new bush. I find them a lot more versatile, but that's just me. I know it's a minefield when it comes to buying a lathe. Go with a WW bed like JD Richard owns. So much better in all respects. If JD can't sort you out, I have one spare...1 point

-

The microscope is monocular and has a reticle with cross hairs and concentric circles. Objectives can be switched from 10x, 20x, 30x, 50x, and 100x. I use the 50x pretty much exclusively. It has an x/y table with very good micrometer heads on it, ball bearing slides. Easy to get down into the microns. It was a few hundred bucks, lucky find, but they are out there. Lots of different companies made them, Nikon (pretty sure), Mitutoyo, several I forget in the U.S., then the Swiss had Isoma, SIP, Hauser and others. It's super duper handy, I check my pallet stones on it before and after moving them, I find it faster easier and more precise than the escapement meters Bergeon sells. For projectors, there are lots of small ones. Similar bunch of makers to above, in the pics are a little benchtop Hauser and a floor standing SIP. I use the SIP, the Hauser is just so pretty I keep it around for its looks. Projector gets used primarily for checking gearing profiles and choosing/making cutters, but it's also useful for getting forms and dimensions from existing parts.1 point

-

The final of 3 antique shows was this weekend. I went yesterday ands I put myself on a time als money budget, $50 or one hour, whichever came first. I ended up with 6 watches this time, 4 Timex's and 2 misc brands. All vintage and all were serviced ands currently running and keeping good time. 1963 Timex Marlin 1950s Lucerne Chronostop (my 3rd, lol) 1969 Timex Electric (first year for this movement? ) 1962 Timex Viscount grey dial, rotor had fallen off, same as before, clearly a common issue. 1950's (57?) Enicar De Luxe 17 Jewels 1974 Timex Mercury In the end, very little work was needed to get these all running and keeping time. Stay tuned for November when the Antique Extravaganza returns.1 point

-

1 point

-

This may be a bad thing in some eyes, but in the past I've heated a paper clip or an old screw driver until red hot. Then hold it to screw head. This causes the screw to expand. when it cools it may break loose.1 point

-

1 point

-

1 point

-

Looking forward to my next clean (always the boring bit in my opinion) and ill try it out. ive been doing this for a while and i sometimes just forget to ask about other ways. An old watchmaker told me that there are 100 different ways and tools to do everything, not to mention the fact that incredible timepieces were created and maintained way before all the more modern tools we have now, your only restricted by your imagination. Really appreciate the quick response and wealth of information around here, I'm a long term member on other forums where the watch repair is a sub forum, this place really appeals to me so much more as i honestly feel that i've found my place full of like minded people. thanks guys...1 point

-

Absolutely. The jewels must then be washed to remove old oil residue and lubricated. I leave the jewels in place as this provides the maximum stability for the balance whilst it's in the cleaner. I hope this helps.1 point

-

I have always cleaned the balance mounted to the plate, with the jewels in place. That's how I was taught when I was an apprentice and I have been doing it ever since. Never once damaged a hair spring, never once broke a pivot this way. I have broken pivots in other ways but that's another story :)1 point

-

I've received a 2824-2 watch with the complain that it stops. Just looking at it in jeweler's shop I noticed: date misaligned date changes at the wrong time caseback opening scratches doesn't hack weight hardly turns Then while disassembly one casing screw missing both dial feet snapped flush and consequent double side tape lots of oil in the oddest places, like under barrel bridge missing stop lever barrel bridge screws lose, likely that's why the ratchet wheel left marks on it and it would not auto wind. driver scratches on the barrel One could think that was the result of an improvised repairer or owner. Not so, as it happens it was given to this small town shop which proudly has a sign outside: "master watchmaker". After a long time and much money the desperate owner wanted to try someone else to repair it. I hope to be able to.0 points

.thumb.jpg.a1bb09bd6274dd859fee41d02378c16a.jpg)

.thumb.jpg.7525563a60838096f6f11a058e3600ac.jpg)

.thumb.jpg.aa1a42102de6a22e94ec9a38a1af58b4.jpg)