Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/19 in all areas

-

Hearsay and misinformation is why I replied to that video. If you are going to present yourself as someone with knowledge or a level of expertise you better have your facts straight. Well that is unless you are running for political office. Peace and happiness!4 points

-

The Bergeon micrometer and the Feintaster, even though they look very similar in form, are very different tools. The Bergeon is a screw type micrometer, whereas the Feintaster is more like an indicator, which means less pressure on the part. The Bergeon is the one that risks deformation of small parts unless you have the worlds lightest touch.2 points

-

THis video on youtube has many mistakes. - https://www.youtube.com/watch?v=s6_o05HKFeE and here is my reply to him - You made three major mistakes in yoour facts. 1) the Marlin was not introduced in the 1960's , rather it was introduced in the 1950's. 2) there are more screws on the dial side to allow the movmentment to be taken apart. Did you try to take the dial off? 3) Timex watches very much can be repaired. Well there are more points to be made as to why Timex watches are popular with collectors. Need more information? just aks JerseyMo and I'll be happy to explain.1 point

-

1 point

-

Nothing wrong with assembling a watch from parts. After all they were all once parts of a whole .far better they are assembled into a functional watch.1 point

-

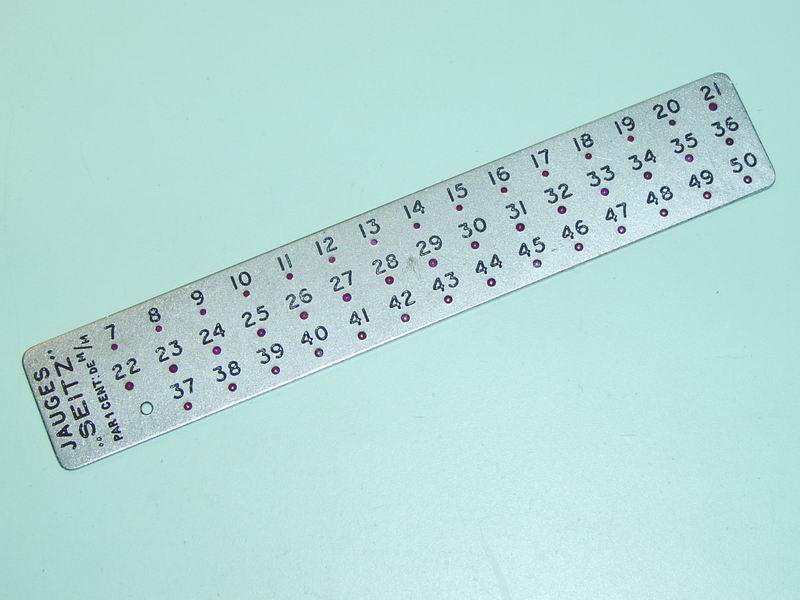

The issue with a screw based micrometer is the massive mechanical advantage the screw gives. An indicator type measuring tool has a spring inside that provides the force. This is generally quite light. But an indicator based tool that is calibrated to read in 0.01mm increments is generally less accurate than a screw based tool. The few Feintasters I messed with were actually pretty good, but I still prefer a screw based measuring tool. Vwatchie, if you keep your eyes peeled on Ebay you'll find a jewelled gage for a reasonable price. I use the Seitz staightener a lot because it has 0.0025mm increments and I frequently do staffs with 0.06something pivots (they have a supplemental version that covers the smaller sizes). I do mic the pivot as I'm turning in the lathe, and I do see the marks. But I leave a good 0.01mm to take off in the jacot and they disappear. There are at least two on the bay now for a decent price. Word of caution- the straitening tools shouldn't go in the ultrasonic. A friend put his in with normal clock/watch solution and it are into the metal and all the jewels fell out!1 point

-

One other thing. Sending the watches away, many just got replaced by Timex with a new watch for the price of the repair.1 point

-

Thanks @dadistic - that's where I was coming from. Just one last thing @VWatchie from me that I would say is good general practice when using a micrometer on anything very delicate: instead of screwing the micrometer into the item adjust the micrometer to a sensible reference and then check fit; repeat until satisfied. With jewels for instance we know that they go up in 0.01mm increments. So say you estimate a particular jewel hole is 0.10mm then you would pre-adjust your micrometer to this ... and then check if the pivot slips within the jaws of the micrometer. No? So you adjust to 0.11mm and re-check. Now the pivot slips within the jaws with just enough movement to rotate ... that's the jewel hole size you need. @nickelsilver makes a valid and excellent point but imho you should never be using a micrometer in a such a way you can damage a part. And of course with a jewel hole you want it just bigger than the pivot so you don't need to be squeezing the micrometer onto the pivot ... just keep to an increment.1 point

-

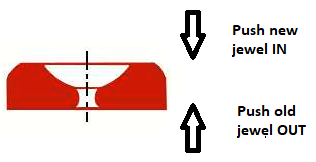

Re. your question in italics above about jewel pressing: a jewel will have a proper/natural way it should sit in the movement. A damaged jewel will be pushed out; a new jewel pushed in ... using the appropriate pusher shape. I've attempted to illustrate below: I've also tracked down a couple of PDFs which might make interesting bed time reading: http://www.nawcc-ch149.com/149files/seitzmanual2.pdf and https://www.mybulova.com/sites/default/files/file/Joseph Bulova School of Watch Making - Unit 9b.pdf. [Edit: @Marc just beat me to it with his helpful reply above but since I was in the process of finishing this reply I've posted the Seitz link anyway!]. I don't have as much experience as other respondents, like @nickelsilver and @jdrichard, so best they respond on your thoughts. The only things I'll throw into the mix are: 1) Jewel hole sizes go up in 0.01mm increments. It would be interesting what other respondents think but I'd also consider a Feintaster gauge which is very delicate and can measure down to (at least) 0.01mm accuracy so you could measure a pivot size to determine the jewel you then need. See some interesting info here: http://watchmakingblog.com/2008/01/29/measuring-tools/. You probably won't get much change from $400 but, unless you have money to burn on getting every tool, this does have the benefit of general purpose measuring. 2) Whilst measuring the outside diameter of your jewel to find a replacement with a micrometer is good there may be times when you want to double check or where the jewel is shattered. I usually do this kind of thing using known precision drill bit diameters. Since the OD of jewels is typically in 0.1mm increments (0.8, 0.9, 1.0 etc.) then you can double check an evacuated jewel hole's size with a reference drill bit.1 point

-

You may find the link below useful. https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=6&cad=rja&uact=8&ved=2ahUKEwiDj5eRxoXmAhVLi1wKHcl-DCQQFjAFegQIBBAB&url=http%3A%2F%2Fihc185.infopop.cc%2Fhelphand%2Fpdf%2Fseitz.pdf&usg=AOvVaw3x-g5ww2TKzpZAU2fLPV0_1 point

-

That's for choosing clock bushings. It does go down to 0.10mm but the increments are 0.05mm which is way to much to be of any use.1 point

-

Straightening pivots can be done with a plate of tweezers if you are very careful. Sent from my iPhone using Tapatalk Pro1 point

-

If your serious about making balance staffs in the future, I would buy the jewelled pivot gauge. This one looks ok for simply sizing pivot ends for purchasing a new staff. Sent from my iPhone using Tapatalk Pro1 point

-

Well done. It may not be pretty but if it works ... ! You get MacGyver award of the week!1 point

-

You can mic the pivots but when you get below about 0.12mm there's a real risk of forming flats on the pivot. The screw mechanical advantage in the micrometer is so great that by the time you feel it "stop" you've made the flats. This is where the jewelled pivot gages shine. The best are the Seitz 'straighteners' that are gaged in 0.0025 increments. Down to 0.06mm if you get lucky. Not cheap, worth every penny.1 point

-

I have made a few in the past using old hacksaw blades as the stock, annealed and ground to thickness on a bench stone. Then use CA glue to glue the two broken parts of the original to the stock in the correct orientation. You then have something to hold onto (in a watchmakers hand vice) and a template to file and drill to. Once done the piece then needs hardening and tempering, which is the tricky bit to get right without the thing warping, and then finishing. It's certainly doable if you can't purchase a replacement or just fancy the challenge.1 point

-

1 point

-

Hi As jdm explains its not always the tools ,I have been using a moderate set of drivers but a set of dumont tweezers and had no problems over many years, Its more down to patience and aquiring the technique and dexterity required and that comes with experience and time, the more you do the better you get and you will not even realise how adept you have become it just sneaks up on you. well done on you first attempt.1 point

-

I made a mistake in my last post, I got the the setting lever spring and click spring confused. It was a clickspring that I replaced, not a setting lever spring.1 point

-

Sometimes the bezel is threaded on, if not pop the back and see if there are screws going through to it. Posted same time as marc haha.1 point

-

Unscrew the bezel. The bezel and crystal will come away and the rest of the clock will come out the back.1 point

-

No way soldering or especially glue will get that back together. There's a book by W.O. Smith available from AWCI called 21st Century Watchmaking that shows a pretty simple way to remake such parts. I did quite a few back in the day (I cnc them now). How expensive are the replacements you've found?1 point

-

Today I'm wearing my Accutron Hummer. It is a 1974 218D. This is technically a resto-mod as I sourced the movement, case, dial and hands separately though they are all period correct. The strap is a super comfy aftermarket leather one with a butterfly clasp. It's a bit finicky to keep consistantly running. It definitely needs a proper service by an experienced Accutron person. It will randomly stop humming and it takes several taps on the side of the case to get it started again. I have an Omega Hummer on layaway that I should have in my possession by December, I'll be sure to share that too.1 point

-

If you are wanting a good book on the maintenance of the lather I recommend Archie B Perkins book 'The watchmakers Lathe and How to Use It', not cheap buy very useful, or for a cheaper book that is useful but more limited Donald de Carle's book 'Thw Watchmakers and Model Engineers Lathe'1 point

-

I have a jewel hole gauge and a pivot gauge similar to these: The problem is that these are VERY expensive tools. You can also measure the pivot using a micrometer. You will need a jewel with a hole slightly larger than the pivot. Of course you also need to know the measurement of the outside diameter of the jewel in order to make sure it can be fit into the plate or chaton. You may need to ream the hole to a larger size. You will need a jeweling set for reaming and pushing in the new jewel. Are you certain that the jewel is friction fit??1 point

-

These videos are important to look at before you start polishing. Morten1 point