Leaderboard

Popular Content

Showing content with the highest reputation on 08/17/19 in all areas

-

Unitas Calibre 6325 Service Walkthrough Pictures - Disassembly (Please sort the pictures by name in ascending order) For the disassembly sequence to make sense it is very important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be removed in its position on the movement and the following picture shows the removed part separately. Unitas Calibre 6325 Service Walkthrough Pictures - Assembly (Please sort the pictures by name in ascending order) For the assembly sequence to make sense it is very important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be assembled along with any screws holding it in place. The following picture shows the section of the movement where that part is to be assembled along with my lubrication suggestion, and the picture after that shows the part when assembled on the movement. The Unitas calibre 6325 is very similar to the Unitas calibre 6498 which is the course movement on watchrepairlessons.com. Unfortunately, due to its increasing popularity, the Unitas calibre 6498 is becoming more and more expensive, although there are inexpensive Chinese clones. So, in my opinion, Unitas calibre 6325 is an excellent and inexpensive option for the course. As a matter of fact, there is a version of the Unitas calibre 6325 having a bridge configuration that looks to be identical to the Unitas calibre 6498. You’ll find plenty of watches housing the Unitas calibre 6325 on eBay. Unitas Calibre 6325 links: bidfun-db Archive: Watch Movements: Unitas 6325 - mtr-Ranfft Unitas 6325 - 17jewels.info „Wehrmachtswerk“; Unitas 6325 - Junghans Vintage2 points

-

I have a Witschi Chronoscope S1 (1st gen, no touch screen), with automatic mic I bought new about 12 years ago. Before that I used a B200 with Gradoscope for amplitude for years. I needed to print out the tidy little sheets with timing in 6 positions for a big client so there went 7000 of the best bucks I ever spent on tools (and I have literally tons). Would have about 10,000 cycles on it at an average of 3 per day which is pretty conservative, quite likely more like 20k. It's industrial gear for people who make money with it. They rarely come up secondhand because they rarely break and folks just use them and use them. I'd hate to have to go back to something less. But obviously it's way overkill for someone who works on watches for fun. Unless they have the cash and enjoy top level gear (I know a couple of collectors who have Witchis). The new Chinese stuff is great, and it's about time. Before it was available a serious collector or watchmaking enthusiast had to mess with computer programs and all the hassles of interfacing the watch to that, or dig up an old paper tape machine which still command more than a weishi if functional.2 points

-

Shock spring KIF 6-1 has gone awal after coming loose when servicing Bulova Cal 5BD. This is the smallest KIF Ultraflex (overall length is 1.60mm) and is indicated as obsolete at Cousins (my normal source), and no luck with web search. Can anyone help with another supplier name or spare. At least I now have a very clean workbench and floor1 point

-

The jaws (anvil and spindle officially) are notched, and fine (thin). The notches allow easy measuring between shoulders on an arbor. The table allows setting parts down like jewels and checking diameters. On a staff with a broken pivot you can get the staff between the jaws (and on thd table, using tweezers) and visualize the needed extra usually within 3-4 hundredths. I have a bunch of mics, handheld, vertical, horizontal. I use the handheld the most, then horizontal, then vertical. I wouldn't be without any of them.1 point

-

Thanks JDM the video is fascinating, the high definition course sounds intriguing I will be checking that out for sure.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Fantastic! You did a lot of work on this but the results are worth the effort. Great pictures and I love the little arrows showing where to oil and what oils to use. It will be a very helpful reference to someone starting on their watchmaking adventure with this movement.1 point

-

Hi guys. My name is Dylan Tilley and I recently joined WRT after ages of lurking. I've been a watchmaker, jeweler, and gemologist for several years now and still love learning new things. I'll do the best I can to be a contributing member of this great forum when I'm online and if anyone needs something I can offer, feel free to reach out. See you around the forums!1 point

-

I'm guessing, as these are all the parts I have for the barrel there is more than the spring missing. I will layout the parts of the watch later in the hope that we can identify if the watch is worth putting back together. So far I have found it was in a CH (Charles Horner) case which is assay stamped and the seller was R.Richardson Middlesborough Serial # 21769. Circa 1897! It's definitely not a Fusee or one of the American makers, so the UK maker remains a mystery. Any help would be great. As I have already cleaned the solid silver case.1 point

-

I bought a 2nd hand Witschi Watch Expert years ago for around 350 euro, it was from 1999 but still did a terrific job. Today I have upgraded to a newer Witschi as a guy at a watchfair offered 550 for the old Witschi...1 point

-

Welcome on WRT, I practised what I learned on a Chinese copy of the ETA2836 and 7750...as I didn't want to mess up my ETA's....1 point

-

1 point

-

Chinese movements are completely foreign to me! Pun intended. Love learning something new! Keep the input comming!1 point

-

Thank you to all those individuals who posted a reply. I believe the issue lies with the hour hand being pressed down to far on the pinion thus raising the hour wheel and thereby shortening the minuet pinion. Secondly, I wasn't able to secure the minute hand possibly because the metal will not form a quality friction fit on the pinion. I've reverted to using the minute hand that came from the movement (for now). Please find pictures attached, and thanks again for all your efforts and pictures. Michael1 point

-

cheers weasol and andy. Finally 10 weeks and 11 watches later i have finally removed and refitted the balance cock. And it works. Small steps i know. but means a lot to me. thanks everyone who has answered my some times simple questions. cheers gary1 point

-

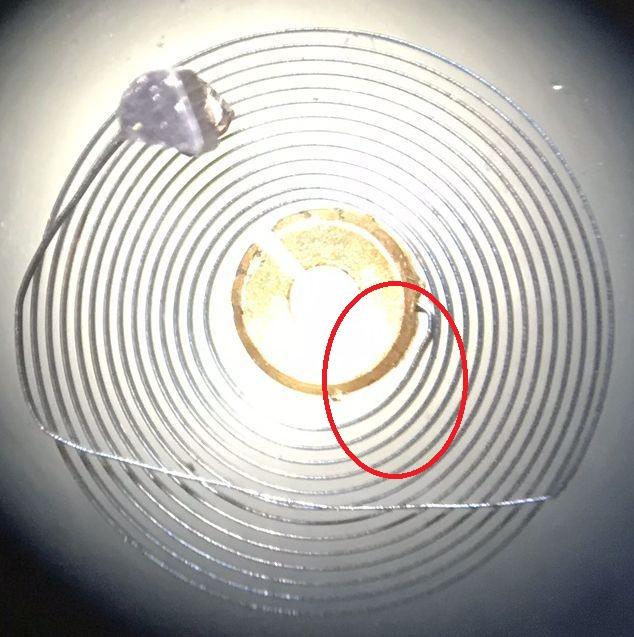

I have totaly missed this post but lets give it a go. Your escape wheel looks dirty but it isn't causing the pattern you see on your timegraph, except from the beat error the pattern looks much like a "sticky hairspring" the phenoma can come from oil or magnetization of the hairspring or a bad end curve on the hairspring. A bad pinion on the escape wheel should show a more slalom like pattern with almost equal up and down humps since it is oscillating. Here you can see a similar but in beat pattern and a quick fix since this time it was caused by old oil. Hope this takes you a bit further.1 point

-

1 point

-

1 point

-

I have been missing for a few days. My monitor packed up. I now have a nice new DELL 24 inch, I can also see the screen better as well. I have been using my antique laptop. Couldn't log in as I cannot remember my password. The PC I always use has auto fill and memory for my passwords. I have loads of emails to look through. Sorry if anyone has been waiting for a reply. At least you now know why.1 point

-

My lovely wife is in the medical profession and she brought me a couple hypodermic type needle things that are thinner than anything I had on my bench. I use them for oilers and although I'm no professional they work very well for me.1 point

-

Those Glashutte micrometers are really nice, but don't have all the features the JKA has. The JKA has a little table that is adjustable in height (great for checking jewel diameters), and has fine jaws which will measure between two larger diameters. My favorite though is the Bergeon 30112, which has a traditional micrometer head (instead of a dial indicator), and the little table and notched anvil and spindle for checking staffs and arbors.1 point

-

I thought this might amuse a few of you. The "Unique De Luxe" is so loud I can check its calibration using time-grapher on my laptop while the thing is still on my wrist. Its not that the microphone is particularly sensitive (it can't hear my Ronda automatic based Sicura Voyageur, unless it is placed on the microphone), its just that the one jewel wonder in the Unique is so loud that it picks it up about a foot away.1 point

-

Speaking of Scotland, and way too many clocks and watches, one of my childhood memories, one that inspired my interest in clocks and watches, was frequent visits to "the museum" in Chambers street in Edinburgh when visiting my grandmother in the capital. This would have ben mainly back in the 1970s and early 1980s (showing my age). There was a large clock at the west end of the main entrance gallery on the second floor, which was cased in glass with its inner workings exposed.This, and all of the other engineering marvels, the working engineering scale models of steam locomotives for example, kept me fascinated for hours, and led to me picking up various striking clocks and other gadgets from jumble sales, to take apart, and sometimes even fix. A good learning exercise for young hand and mind co-ordination I would suggest. The museum also showed several horological themed exhibitions aver the years, with lots of clock and watch mechanisms on view. I haven't been there in recent years. I wonder if they have anything of this nature planned in the near future.1 point

-

I would use two pair of tweezers because there is only one noch (the Novodiac has three). Do it under a zipper bag the first 20 times1 point

-

In no way I intend to steal the job of our Mark, from whom I only can get inspiration (both in making the videos and in servicing the watches), but I started some time ago documenting (silently) my services in a series of videos. all watches are mine to either keep or resell on the popular online platforms, funding in this way the purchase of more expensice, better mechanical watches. But that is another story... With this post I would like to introduce a series of parts of a video I made servicing a Seiko 7T32 quartz movement last week, and for the first time talking about it live (btw, I hate my voice...) The video was prompted from some friends on another forum which were wondering if it was worthwile servicing this particular movement, since it is all in plastic (well, almost all). The thing is that I like tinketing with this movement, even if it is deemd by experts as a waste of time, since it is usually swapped for a new one when it brakes down. I am though of the opinion that this particular series of quartz chronographs deserves a proper service, also considering that it is not in production anymore, and you cannot find them easily anymore at decent prices. Enough said, here the series of videos (6 parts in total) Part 1: Part 2: Part 3: Part 4: Part 5: Part 6: There will be a part 7, in which I deal with the dial side of the movement, but it is still in the works. Hope you enjoy the videos, and any comment / criticism is very well welcome. George1 point

-

Ronsonol lighter fluid is way better then One Dip. I just got better results. The lighter fluid is so friendly to watch parts. You can leave the parts to be cleaned in it for days, just make sure you have a screw on lid for the jar as it evaporates very quick. After cleaning I would take out the part place it on clean tissue, hold with tweezers and use my blower to remove any residue.0 points