Leaderboard

Popular Content

Showing content with the highest reputation on 04/17/19 in all areas

-

3 points

-

Like to help . If i have the parts. But don't like the ones that always ask for parts. And not contributing to the forum. I ask for help sometimes and it's great to get some back. Scratch your back and you scratch mine2 points

-

1 point

-

The crown wheel was loosened by turning it cw but the ratchet screw should be a regular thread...I think... I’ll see if I can get a little diesel fuel. I’ll try the heat thing too. Thank you for the suggestions. I promise not to use WD40...1 point

-

They are not that difficult to service. You can completely disassemble and re-assemble, but that isn't generally necessary with the old Timex mechanical watches. Roughly speaking, here is a brief run down of the "ghetto" "Dunk-an Slunge" no date complication Timex service. Tools required. 1. Suitable small screwdriver(s) 2. Suitable tweezers 3. Lighter fluid or watch cleaning fluid. 4. A small polythene bag 5. A small jar with a lid (the little glass single serving jam pots that are popular in coffee shops perhaps). 6. Watch oil. You could use sewing machine oil I suppose. This is a Timex after all, not a Rolex. 7. Suitable magnification and good light. Un-case the movement. To do this, back off the screw that holds the winder catch by a couple of turns, then pop out the winder. If you remove this screw entirely, it doesn't really matter, but you can usually get away with leaving it in. Pop the hands off. I usually do this with a polythene bag over the hands, and gentle pressure to carefully remove them, either with hand removal levers, or two jewelers screwdrivers, or even with a small pair of tweezers. Remove the dial. This is held on with four metal tags, a bit like an old tinplate toy. Treat these with care, as they are easy to snap. Bend them very carefully back, just enough to remove the dial. Take care when re-fitting too. Gentle pressure, not full two hundred pound gorilla. The service manual suggests you also remove the balance, but this is generally not necessary, and you risk mangling the hairspring, loosing the pin, and re-assembling woefully out of beat. Pop the movement in the small jar of lighter fluid/watch cleaning flid, and leave it there for an hour or so, (longer if it is particularly grubby). Swirling occasionally helps to loosen the dirt. Remove from the jar and allow to dry for 20 minutes or so in a warm dry location, for example on a sunny window ledge or on top of a radiator, but bear in mind that lighter fluid is obviously a fire risk, so avoid sparks and naked flames. Oil all of the pivot ends with a tiny drop of oil placed there from the end of a pin. Also oil the winder stem, and add a couple of drops to the spring. Add a tiny drop of oil on the balance pivots too, but don't get any on the hairspring. Re-assembly is the reverse of disassembly. Don't forget to screw down the stem catch again, when you fit the stem, or you will find that the winder annoyingly pops out when you pull it to change the hands. Wind, set, enjoy the loud ticking of success, but take care, if this works, you could be on the slippery slope towards watch repair addiction.1 point

-

1 point

-

Uncase it and have a go, the pin pallet movements, as well as agricultural are pretty robust too, no fragile jewelled bearings and there's something strangely enchanting about the clunky tick once running. The only bits that have a tendancy to get damaged are the click/spring. Your's looks pretty clean and unmolested also.1 point

-

Hi Jim, welcome to the happy factory. Loads of excellent advice on this forum from some really knowledgeable people. The answers are just a question away. When I said lots of knowledgeable people I wasn't including myself.1 point

-

Should be pretty obvious if it’s the wrong size. You can’t really do any damage and it’s good practice at handling cap jewels. Sent from my iPhone using Tapatalk1 point

-

1 point

-

here is a cuckoo clock story ; the one and only, and ever, I had accidently switched the bellows ! it was an ook - cu. I then put into the wood stove. vin1 point

-

So.. the way I figure... to charge my Kinetic, I might be better off taping it to the top of the spin dryer next time I'm running a full cycle, rather than putting it in my watch winder...1 point

-

Show us a couple of pictures of the movement, and we may be able to identify it.1 point

-

No advertising or sales, OK to ask for help locating, as well to offer parts for free or postage like many generous members do. Anything else is better discussed by email.1 point

-

Unlike an automatic where the mainspring is wound no matter the speed at which the rotor turns, Seiko Kinetics accumulate charge from short, intense electrical spikes coming from the normal mov.t of the arm, something that normal winders don't reproduce. Kind of a well know fact by Kinetics owners.1 point

-

Hi Darak regarding the coil these can be repaired using a silver impregnated epoxy available on the net and ebay, usually used for repairing circuit board tracks when cracked I fixed an eta using this epoxy ok.. as far as the charge loss there was a note on the net about using and making you own charger from the tooth brush charger all it is is a induction charger using a magnetic field. Might be a cheaper alternative before rushing off and buying the real thing.1 point

-

I hope my previous post didn't come across as being picky, but I felt it was important to understand the relative physical scale of what we are dealing with in order to better understand the problems involved. The face of that jewel for example is probably of the order of perhaps 1mm x 1.5mm, and the wear, I would estimate is probably of the order of around 1/10 to 1/20th of that in width, and roughly the same depth. i.e. of the order of a tens or hundreds of microns. This is sufficient to have a very measurable effect on the performance of the watch. Shifting the height of the pallet fork by a few tens or hundreds of microns would be possible (assuming the geometry of the pallet fork allows this, without snagging on other components), so this might be a feasible, if tricky solution. Automated manufacturing to 1/100 mm or better is relatively easy, however hand working and machining to this kind of tolerance takes considerable skill. For example most low cost FDM 3D printers (the plastic squirting kind ) are only accurate to 1/10mm at best (and that, typically only in the Z axis). For comparison, a state-of-the-art ultra-high-resolution laser lithography 3D printer is typically capable of layer thicknesses and detail sizes well below 1 micrometer. So if you wanted to 3D print these watch parts, it would be technically possible, however, probably not in a suitable material. The technology is fast evolving though, so perhaps in a few more years, those unobtanium parts for rare watches will be a mere click or two of the mouse away. For comparison, the legs of this 3d printed object are approximately the same width as the wear pattern on that stone.1 point

-

Talking about 2824 stems one should always specify if actually (and more likely) is 2824-2. Stem is not interchangeable across the two versions.1 point

-

Of course, my mistake. Nevertheless in watchmaking the use of the hundredth of mm is commonly used, where the first digit after the decimal point indicate microns. E.g. Bonus info: the table above shows a fact little known: the very popular SII NH36 is actually available in two heights, and the numbering of the relevant parts.1 point

-

Check pinned thread: I don't doubt that software based ones are good and cheaper but I like an always-ready instrument on my bench, no fiddling and it gives me with a good stand which makes easy to regulate and switch positions.1 point

-

Hi Darak, Screwdrivers and tweezers! We spend so much time with these items that it is totally worth investing in good ones. I learnt that the hard way. I wasted lots of money on cheap tweezers before buying Dumont and a bit in cheap screwdrivers before buying AF. Make the jump and you won’t regret it. Sent from my iPhone using Tapatalk1 point

-

For time graphing, I use the open source and free tg-timer - https://tg.ciovil.li/ It works fine, and will even give acceptable results using the built in microphone on my Lexmark ThinkPad laptop.1 point

-

1 point

-

You can use the mic part of iPhone headphones as well, plugged into your computer. There are tricks to boost the mic if you are running windows 10. Sent from my iPhone using Tapatalk Pro1 point

-

Yes, thanks Roger. They arrived today (nice stamps). I finished the watch and just have to give it back to it's owner (unless I can buy it off him). This is not my thread though.1 point

-

There should be a cap jewel. Not sure they are red as they usually are thought . Seen white ones and you hardly see them. I have some poljot parts left if there is anything you need . Did the setting lever arrive as it should?1 point

-

1 point

-

David, Yeah - I received mine on Friday. I set it up over the weekend and I am thrilled with the results. Very sharp and distortion-free field of view. I will probably have to set up a separate - lower height - table for the scope though. As the working distance and height of the scope don't match my regular work surface height. But that's not hard to solve. I am just happy that I have a really nice sharp, comfortable view to work with. The AmScope "SM-1BSX-64S" is a 3.5x to 45x zoom with a nice bright (adjustable) LED ring light. The magnification range can be altered with accessory lenses, but I don't think I'll need to do that. I can see where using one with screen display would nice. As you wouldn't have to have your head positioned over the eyepieces. Which means no effect on your seated position or work surface height. -Paul1 point

-

Blue steel can't be cut with a jeweler's saw but can be filed. That used to be how they checked the repivoting exam for clocks back in the day- saw bites, fail, file doesn't bite, fail. The commercially available blue steel bars watch and clockmakers typically use is very hit or miss. The nomial size is often way off (not such a big problem), and the heat treatment can vary between too soft, uneven, or sometimes actually ok. I have some and use it for pins and such. For staffs, stems, pinions- anything from steel- I use oil hardening steel in its annealed state. The standard in Switzerland is Sandvik 20AP, probably not so easy to find in small quantities elsewhere. In the U.S. O1 would be the closest thing (and is a fine steel for watch parts). Parts get hardened and tempered after machining, with generally the last 0.01mm or removed in finishing for bearing surfaces. For a staff I cut everything right to size except the pivots which are a good 0.10mm oversized, and I leave the taper for the roller table straight and oversized. After heat treatment, holding on the now straight roller diameter the top pivot is brought to 0.01mm over final size, the surfaces polished, rivet formed. Flip around and do lower pivot, roller taper, polish. Finally finish pivots in jacot. Heat treatment is a little different than most books or schools teach. I use an iron tube welded to a long thin bar. These are actually CO2 or N2O cartridges from selzer or whipped cream bottles with the neck cut off (about the size of the first two digits of an index finger). This gets filled about 1/3 with fine wood charcoal powder, parts go in, filled the rest of the way. The whole thing is torch heated until glowing orange, then the contents dumped in oil. The parts fished out with a magnet, and they are a nice grey color and very clean. After cleaning off the oil they are blued in a pan of fine brass filings over an alcohol lamp. With the above method there is rarely any deformation of even long thin parts, and no pitting.1 point

-

Have you ever worked on an automatic watch? The whole thread is about the spring slipping prematurely, which, as explained above, can be due to numerous issues and some barrels have 6 or so notches (which are radiused) some are smooth. OP has smooth. It has worn through the original plating, showing brass. Moebius has a braking grease just for brass, which is incidentally their "strong" braking grease. It's all in the thread. OP also posted a pic of barrel without spring already btw.1 point

-

1 point

-

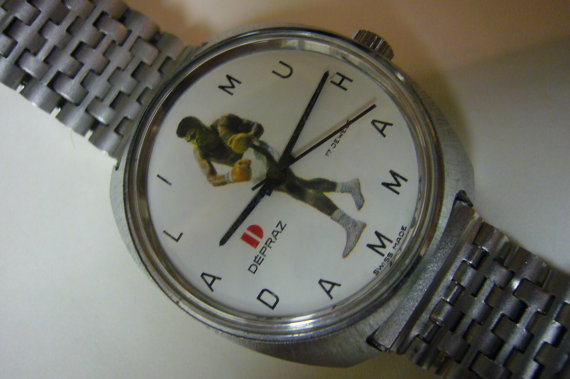

So today I opted for a salvage job, I've had a 1971 Mohamed Ali Depraz watch kicking around for ages that was missing the dial when I got it so I have just fitted a generic dial and re-cased it. It might now be a Frankenwatch but better than just sat in a plastic storage box awaiting a part that I am probably not going to come across anyway, I think I much prefer the generic dial to the original anyway and at least it is now wearable. Above is what it would have looked like when it started life in 1971 and further below is what it looks like now.1 point

-

1 point