Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/15 in all areas

-

You must have this on your drawers ?http://www.amazon.com/Jaipur-Market-Decorative-Ceramic-Drawer/dp/B00WOV3AGY/ref=pd_sim_sbs_60_3?ie=UTF8&dpID=51HU5TO-MCL&dpSrc=sims&preST=_AC_UL160_SR160%2C160_&refRID=0V9T8MD1MFP0E7GCF6QJ3 points

-

2 points

-

2 points

-

2 points

-

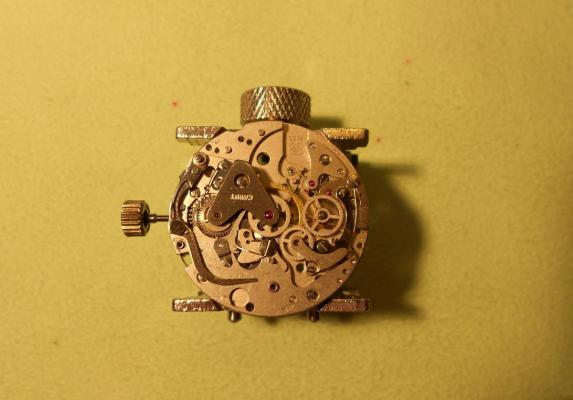

I was away from work the last couple of days with a cold, but there was a bright spot on Monday; I got a package in the mail from Komsomolsk, Ukraine, containing this little item: It's a "Signal", which was apparently a Poljot under the skin. The markings on the dial indicate that it was made by the First Moscow Watch Factory in Kirov. I'm not sure of the date, but the vendor estimates sometime in the 1950s. Speaking of dial markings, note the "15, 30, 45" between the hour indices. These are intended as a reference when setting the alarm via the upper crown and the hand pointed at 4:00 in the photo. It has two separate mainsprings, one for the movement and another for the alarm. With the alarm spring wound, it sounds at the specified time, sounding like the watch is blowing a tiny razzberry at you. As for the movement, here's a photo taken by the vendor: As you can see, the alarm works have their own bridge at the lower right. At bottom, you can just make out the star wheel that actuates a little hammer that taps the inside of the case. It whizzes pretty rapidly, and when fully wound, the alarm sounds for only a few seconds. To reset the alarm for next time, you just rewind its spring. I really like this one! The case is about medium size, smaller than my other watches, so it almost looks delicate. But I find it very interesting, and I look forward to wearing it regularly. Cheers, Gryf2 points

-

I think you can find every tweezer there is here . https://www.dumonttweezers.com/Tweezer/TweezerStyleList/312 points

-

Sorry for the extremely bad picture, with bad lights the mobile phone just does not cut it... meanwhile I already polished the glass so it looks way much better...2 points

-

1 point

-

A friend of mine that sells goods at the swap meet told me that he had 3 watches that weren't working and asked me to take a look . They were a Seiko Kinetic , a Citizen Eco-Drive , and this Seiko 5 Sportsmatic Deluxe 25 jewel automatic from March 1966 . The Kinetic and Eco-drive were power problems but the automatic was stuck , ...the balance would swing when the watch was shaken but no movement from the drive train . There is a regular crown for setting and a push button that I didn't know the purpose of . Both the crown/stem and push button were rusted stuck . I found out that this model has a hacking feature that stopped the center wheel via the crown/stem and because the crown was in the setting position , the hack was engaged holding the gear train in position although the balance was free . The push button changed the date wheel when pushed....if it wasn't rusted . I also found out that I could not get the tech manual for this caliber , but a member from another forum sent me the tech Info from a Caliber 7606....which is close but not the same . I told my friend that I would fix the Kinetic and Eco-Drive at my cost if I could keep the automatic and he had no problem agreeing to this arrangement . I installed a new capacitor in the Kinetic and it was happy , and I left the Eco-drive in a sunny place for more than 16 hours ...and it was happy . I removed the movement from the automatic and and let the parts sit in a bicarbonate of soda and water solution for a couple of days alternating with a spa treatment in the ultra-sonic to take care of the rust problem . The small cir-clip on the pusher was toast , and after searching for one on the Bay with no luck , I was able to rob one from a Seiko 7T32 chrono that's now a donor . A service on the movement and a very light buff of the case and bezel , a light polish of the case , bezel , case back and crystal and now this puppy's Happy . :thumbsu:1 point

-

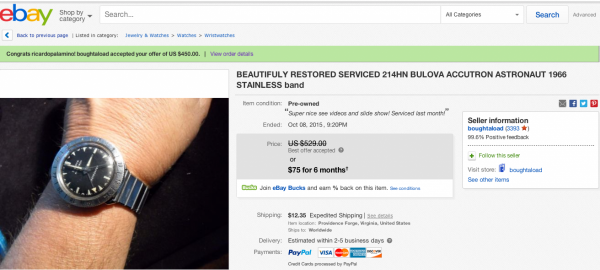

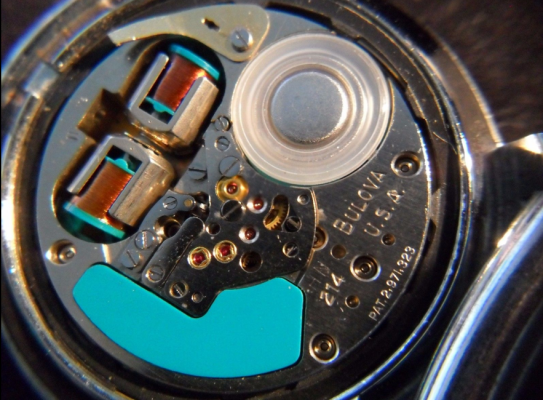

Hi All . Well I finally got an Astronaut !! I had been searching for a while , and bidding once in a while , but just missing on closing the deal at the last seconds a couple of times . I had this one in my Ebay watch-list and decided to pay a little more for one that had just been serviced by a watchmaker that specializes in accutrons , in New York . I made an offer that the seller accepted . The seller lives in Virginia . When I got the watch I could not set the hands so I contacted the seller . He in turn contacted the watchmaker who said he guarantees his work , so send it to him and he would take care of the problem . The seller paid for the postage and $500 insurance to New York and the watchmaker paid for the postage to get the watch back to me . It was delivered today and runs great . I had a new crystal waiting for it and I Installed it this evening .... I'm stoked . The attachments are the sellers pics ....... The watchmaker installed an Accucell 1.35 volt battery , which is the original operating voltage for the Accutrons . The actual watch with new crystal and the watchband look much better than the pics .1 point

-

Hello! I had a great summer, but school is giving me a thorough thrashing now. I have not been able to post much these days but I very recently got my hands on this and gave it a complete overhaul. It is what I am wearing today and wanted to share it. Got it for a good price and working flawlessly after cleaning. What say ye? Regards, JC1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Fantastic final result George! Really a beautiful watch! You deserved it! Congratulations!1 point

-

"Try using a vacuum cleaner with ladies tights stretched over the end of the hose!" I don't know about this. I tried it but my wife was annoyed and got a cramp while I pulled the tights away from her leg and used the vacuum. :)1 point

-

Hi Mike, As most of the others have mentioned.. this is a fine watch and really requires a proper service. However I noticed that the regulator is set at "fast" where it really should be in the middle of the scale. 1 minute a day is well within the correction of the regulator and by bringing this back to the middle you should see some improvement. Look at the balance cock, see that curvy bit of metal? the tail of that piece is pressing on the regulator adjuster. You need to screw in the screw that fits sideways (to the left of the 2 screws which hold the curvy metal bit) bit by bit so that it moves towards the centre of the scale. Don't try to get the regulator into the centre of the scale in one go. screw a bit (half-turn) and use the watch for a few days to see how it works out. then adjust again if neccessary. Caution : be very careful !! It is easy for the screwdriver to slip and this will damage the hairspring!!! Anil1 point

-

When using a timing machine to diagnose watch problems there is several things you have to remember. For incoming watches the timing machine may possibly give you a clue as to what the problem is or it may give you incorrect information. Timing machine relies upon listening to the sound of the ticking watch. It has to pick up the signal clear and cleanly to display all the things correctly and do all the calculations like for amplitude. So for incoming watches that are need servicing just have to accept that the results will be different and you can’t rely 100% on exact diagnostics. Then if you are doing diagnostics with a timing machine you should do it correctly and time in more than one position. So dial-up, dial down at least one pendant/crown position preferably four positions. This way can pickup bad pivots on both ends of the balance wheel not just one and other things can show up in the pendant positions. So when I look at your timing machine results the amplitude seems extremely outstanding the waveform does not. So I suspect visually when you look at the balance wheel amplitude it’s going to match the waveform specifically it’s going to look really bad. Your first picture interesting in that you appear to have a repeatable pattern? Some faults in a watch will repeat themselves if you can determine the rate at which it repeats you can figure out where it is. This is sometimes an issue with the modern liquid crystal display as we don’t have enough room to look for patterns. This is where timing machines that used paper tape beat out liquid crystal displays as they have a infinite length display. But some modern timing machines will do a different kind of the time plot that will also let you look for things like this.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

The great chef " Broad Arrows " famous for his punctuality :D , I like that . Well we have to admit that the moon watch looks also gorgeous .... :startle:1 point

-

That is another really nice watch. It looks like it has been presented to a North American Indian chief called BROAD ARROW. :D1 point

-

1 point

-

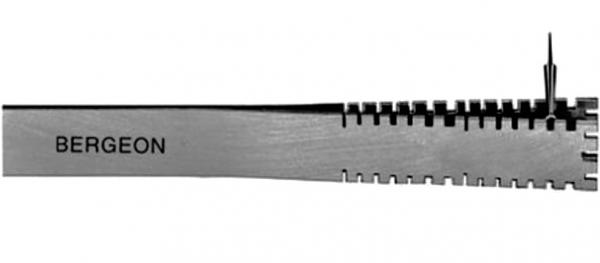

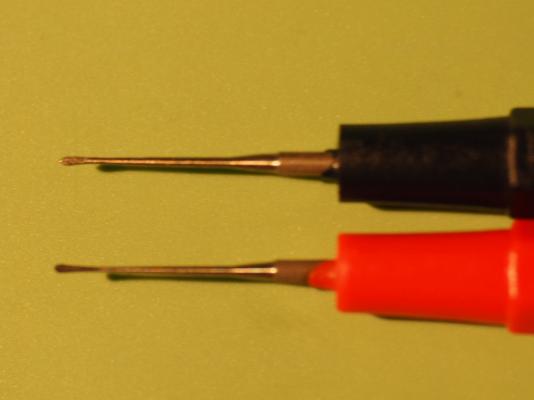

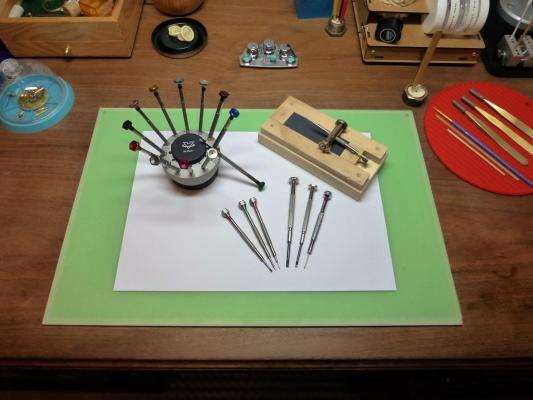

As others have said, it's the quality of the blades that's the most important factor. However, I decided to treat myself to a recent birthday present with a set of VOH screwdrivers, they are an absolute pleasure to use (and have a nicer feel than any Bergeon, Horotec or AF that I've used). But I also use various other screwdrivers where one of the VOHs isn't suitable, these are mostly tailored and dressed for individual tasks, here are about half of them :biggrin: And also as others have said, shaping and finishing the blades is critical to maintaining good tools and reducing the risk of damage to scres and other delicate bits.1 point

-

1 point

-

1 point

-

To continue on atimegoneby's theme, heres another refugee from the Soviet Union I found recently in a flea market in Seremban, Malaysia. Cost me all of MYR15...this works out to around GBP2.25 at today's rate..! When found it wasnt working but I really liked the hands and figured I could transplant another movement if it was beyond fixing. The problem was much simpler in that the intermediate setting wheel was missing a few teeth and the set lever had came off its slot. Once I got the set lever back in place and gave it a few winds it started right up! Gotta love these tough russians! This watch is powered by a Raketa 2609H and I had a spare which yielded the damaged wheel. I didn't even bothered to service it as it was running well! I've heard this model referred to as 'Copernicus' and I think the name fits well...what do you think?1 point

-

1 point

-

1 point

-

Second try: The raw piece of stainless steel Milled and ready for the Deckel The machine The form of the case in scale 3:1 After MANY runs, the depth is correct! Starting to look the part! Drilled lugs Lugs getting "plugged" .....getting there The sides lapped to 3 degrees and the holes are "gone" Routing a bezel Getting painted/lumed Making the caseback (press fit) ......and the result1 point

-

1 point

-

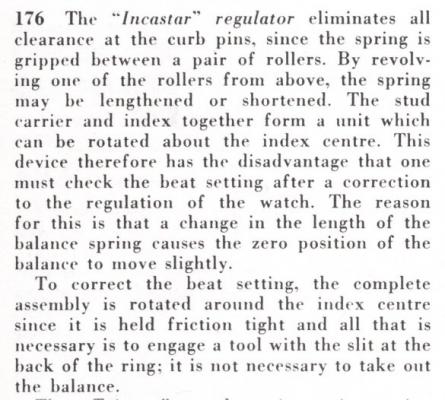

One of the interesting aspects of watch repair is the discovering of variations. Not just case variations dial variations the hands but movement components. The watch companies seem to have an endless supply of ideas of how to do things giving us an incredible quantity of things to torture us with. Although I'm not sure they were actually specifically designed to torture the watchmaker they can end up doing that. So the links below have additional information lots of pictures lots of variations of using this regulation system. The third link if you scroll down far enough has a picture of the inside of the case back which has the setting instructions. http://forum.chronomania.net/mix_entry.php?id=120965#.Vh6V9viyJyx http://www.ceasornicar.ro/forum/viewtopic.php?f=13&t=6234 http://goldsmithwatchworks.com/MAY-2012/ERNEST-BOREL/1954-ERNEST-BOREL-14K-GOLD-CAPPED-STAINLESS-STEEL-CASED-LUXURY-WATCH.htm Then I've attached a image for an advertisement for another system called a triostat1 point

-

1 point

-

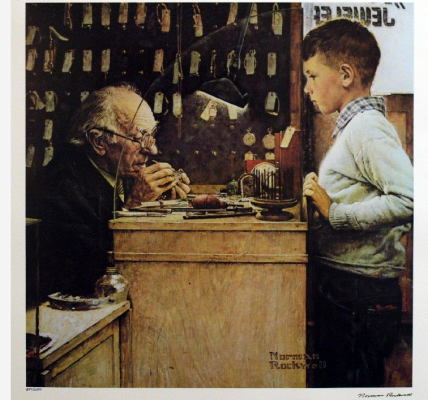

To look at and to work on.... AndI feel like that little kid (only some decades older....)1 point

-

1 point

-

This i a wonderful thread and a great forum. It's such a pleasure to see enthusiastic and positive feedback for this restoration. As a clock guy who has been slowly learning watch restoration in the past 5 years or so, I find that the parent videos and this forum give me a boost. I'm looking forward to seeing a pic of the watch ticking away! Dean1 point

-

Hi Geo, I would be very good if that was the case, but unfortunately the spring is a write-off, as when I was trying (stupidly!!) to force the incabloc spring to its location with a 0,6 mm screwdriver, that (of course!) slipped into the hairspring, "killing" it instantly!! ( I don´t dare to put any photo of this disater, as I don´t want to cause any health trouble to sensitive watchmakers!!) P.S.- I have already discovered why I was encoutering such difficulty to put the new incabloc spring into its location: a tiny, almost invisible part of the prevoius one that I broke trying to remove it, was still there preventing the new one to get in.1 point

-

Nice work, what's the translation of the writing on the caseback? I have a slightly older sibling, a 7619-7010 from September 1965 (with the obligatory rattly rotor): Sorry didn't notice your request on the other site or I could have sent you this: Seiko 7619A.pdf bit late in the day & its only the parts list.1 point

-

Oh that's a nice piece, well worth the effort. I've been working on some scrap Seiko movements for practice lately, and it's deepened my love for the brand, made well, with a design that's really nice to work on, specifically the click springs and calendar jump springs, really watchmaker friendly, they don't fly off to the moon if you're not careful.1 point

-

The VALJOUX 7733 is ticking again!! After the precious help of GeorgeClarkson for fitting the operating-lever on the chronograph plate, I went on assembling my chronograph. It was not easy for the rookie I am, but after several "try-error-try again" events and some hours spent on it, I finally managed to see it working again. The main issue was getting the different operating-levers working together in a synchronized way. My conclusions about the way to get it working: I) The position in which rests on the plate the operating-lever (the one actuated by the start-stop button) before putting in place the so-called hammer is important and should look like this: II) The hammer (piece B in the next photo) should be fastened in the plate so that the hammer-cam jumper be in position 1, (that is in the normal chronograph working position after pushing start button). III) After having assembled the operating-lever A, the hammer B, the hammer-cam jumper D and the fly-back lever E, the correct movements of all the system when pushing the start/stop and fly-back button must be verified, prior of assembling the coupling-clutch C. IV) The coupling-clutch C should be assembled with the hammer B in position 3 (the actual position in the photo) corresponding to the return to zero position after pushing the fly-back button. V) After completing all the remaining assembling operations (putting in place the driving-wheel flush with the couplig-clutch, the balance wheel, etc,), and after getting the watch ticking, you can use, if needed, the cam F to fine tune the depth of the gearing between driving-wheel, clutch wheel and crhonograph second counter wheel. (of course I took care of all the lubrication tasks for the different parts during this assembling procedure) I can not guarantee that this is the best or the easiest way to get the chronograph levers operating correctly, but this was the way I managed to do it. And now I only have to overcome two more issues to get the Cauny complete. The first, I already told you about, is the chronograph minute-counter hand (I'll follow CKelly sugestion to overcome it), the second it's again my fault as I broke the Incabloc spring in the balance wheel pivot when I was trying to get it off !! ...Natural for a newbie, isn't it ?! (I apologize for not having taken more photos during these procedures but I was so entertained with the job, and anxious to get a result that I forgot it!)1 point