Leaderboard

Popular Content

Showing content with the highest reputation on 09/27/22 in all areas

-

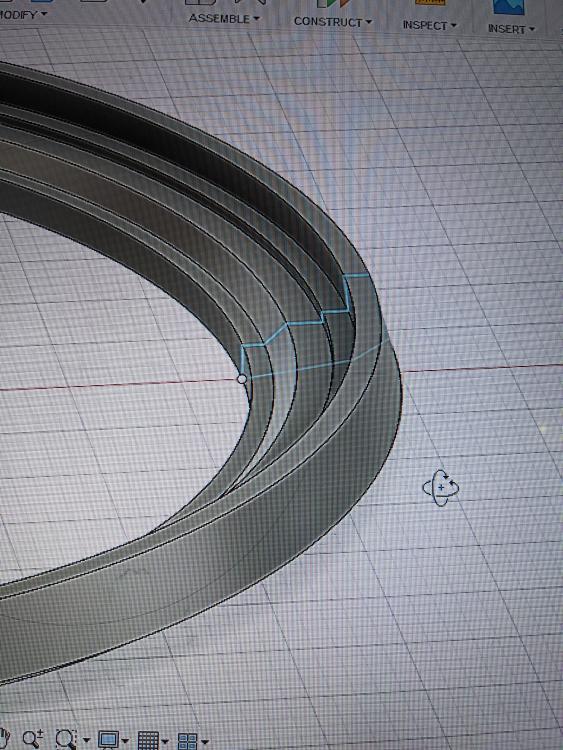

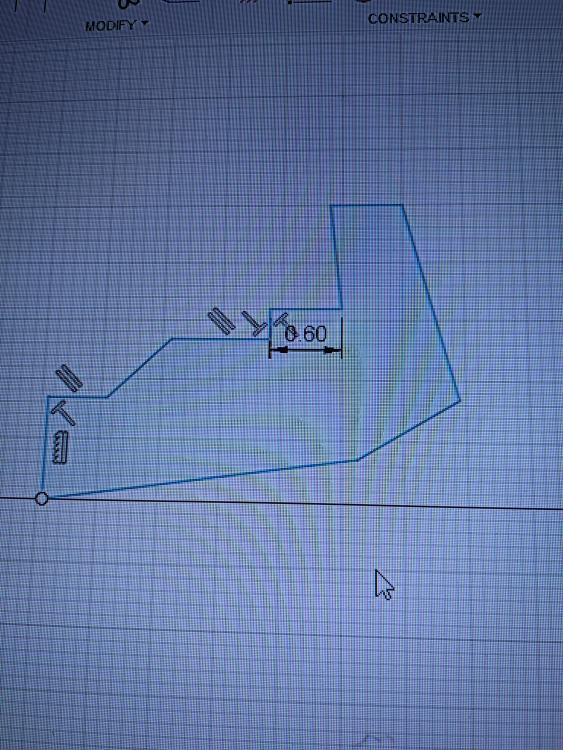

As part of my watchmaking journey I decided to replace some bezels on a watch that bezels are very hard to come by. I was able to pick up a donor watch with a bezel that I am taking measurements from. I am slowly learning fusion 360 and printing my prototypes. Once I have a working prototype I will manufacture them from either titanium or aluminum. This is where I am now on these orient dive watches.4 points

-

I agree with this, but often the screw size is too small for the smallest setting of the tool. You can then make on your lathe new bits, or use a jeweling tool. Make a pusher and stump in unhardened steel that fit. Clamp the (hard steel screw) between the two, and unwind the stuck bit turning the plate around. Has worked for me more times than the (well conceived) Bergeon tool. The unhardened steel grips the hard screw quite well.3 points

-

Yeah, he certainly blew it when stating the magnification. I hate it when videos spread bogus info, even if it's an honest mistake. Makes it so much more confusing for people that are trying to figure this stuff out. Rather than hovering in front of the eyepieces, I got some eyecups for mine. Since I also have eyepieces that that have diopter adjustments, I don't have to wear my glasses when using the scope. Makes it much more comfortable. The eyecups are not expensive, and I find the scope much more comfortable to use this way. As to bench height, a watchmaker bench at 38 -40 inches is too tall, unless you have a very tall chair or are standing up. I set my adjustable bench at 30", it's lowest setting, and that works OK. I still have to adjust my chair height sometimes, depending on how I have the scope set up. Cheers!3 points

-

I think i would also be trying this route first. Mechanical before chemical, mechanical approach more predictable? For me personally i would say yes, you can stop at any point.3 points

-

I thought I'd share this although small I still think it's an achievement, for me anyway. Very skeptical of the superglue and nut technique, thinking the glue bond would give as soon as applied pressure, but I was left with no other option as it wasn't working with my case back tool. Kept slipping. To my astonishment it held, and I started to get movement on the back, not without incident though as I managed to break one of the movement holder posts.2 points

-

Bremont is a fairly new brand, positioning themselves as "in house" makers (at some point). But I, as an independent watchmaker, get a watch back 10 months later with dry Incablocs, redo the service even though my intermidiairy assured me they left the watch on the dashboard all summer long ( still I believe epilamed properly oiled escapement should hold up).* It comes down to service / serviceability. If I was positioning myself as a new brand, I'd make service #1 priority. Blaming customers, -100% priority *it's rare but if I get a customer who isn't happy I do everything to make them happy. One unhappy customer is baaaad. (but some are never happy...)2 points

-

Heh, true as nuts you’re right. I went to go check my scope (I have the same head as his, just with the double arm). Evening my man, going good hey. Just running around as it’s payday which suck if it’s your own business haha. Yeah, I did a poll on my channel a few days ago and 80% of people wanted me yapping so I guess that’s what I’ll do on the next vid (which I’m busy with now). But thank you bud, much appreciated! The proper optical Amscopes are great. I’ve had mine for 7 years and no issues hey 100% agree on the eye cups, I use them as well. Perfect reference to rest my fore head against in despair when a freshly cleaned cap jewel joins its friends in never-to-be-found-again-ville.2 points

-

I'm surprised they won't service it under warranty, even if it received a great big impact. Do you remember it taking a big knock? I had a Maurice Lacroix in a while back; customer sent it for factory service, month or two later it stopped working. Sent it back, "sorry, we see that there has been a shock to the watch, it's not covered" (there was a ding in the case). So it comes to me- every single screw was loose, and one of the dial screws was floating around in the chronograph module, which is what stopped the watch. They SHOULD have at least looked inside (ML) before blaming the customer. I think Bremont should do the same.2 points

-

This guy does make errors and to perfectly honest I was not listening to the magnification quotes but he does show how to achieve a good working space without purchasing a specific microscope by using a Barlow lens. Wish I had known that before I purchased another scope!!. The main point he is making is that owning a scope improves your your watch repairs. Parts that you thought were clean are not, hairsprings that you think are breathing perfectly are not etc etc.2 points

-

But don't listen to his magnification values. That scope only gives 7X - 45X magnification. Not 450X.2 points

-

If you can reach to screw from two sides you could also try with a screw extractor. I bought this tool some time ago and it worked really well. However, be aware that the tip of the extractors is very sensitive and easily deforms. Luckily the extractors are replaceable. Not cheap, like anything Bergeon, but as I said has worked well for me.2 points

-

I have used 12% sulphuric acid, sold as Vissen by Bergeon, on nickel (German silver) parts to remove broken taps. I noticed that if the part wasn't super clean the acid could stain it, clean no problems. If you have discoloration like Frank describes, often rubbing wet blanc de Meudon might restore the original color. This is a white powder also called blanc d'Espagne which is readily available in Europe but not sure elsewhere. French chalk works the same. It's also used in ceramics and as a base for gesso so art supply stores may have it.2 points

-

Sounds like they didn't open up the watch to assess it, just put it on a timegrapher. If they are going to say the warranty is void because of misuse/damage, showing case damage isn't sufficient. I would want them to be specific about how the movement was damaged. I'm never happy, but I try not to take it out on people who are trying to do good work Cheers!1 point

-

According to Nicklesilver that is exactly what it is called. The jaws are actually recessed so a lot thinner than they look. So my curiosity sparked up and i had a measure. A fraction under 0.7mm. I am guessing but i think Nicklesilver is the only other person that has one here. Never heard them mentioned until i was wanting to know what it was. At least you got it sorted with some good initiative and a sprinkling of bravery . What all good watch repairers endeavour to acquire1 point

-

Here we have an interesting discussion regarding the use of a particular tool and a problem encountered when removing a set of hands. The same has happened to me but not on an expensive watch so did not cost an arm and a leg. I understand Paul80's concern and passing on the information so as to help others doing the same thing or be aware of the fact it can happen and its possible prevention by using a particular tool. Dissemination of information is essential in any forum, cheers for that Paul80.1 point

-

Hey Paul! Your posts are appreciated and I'd hate to see you go! I'm sure @Neverenoughwatches didn't mean any harm or was trying to degrade you. Perhaps he was just a bit clumsy. Now guys, shake hands and be friends!1 point

-

So another reason to get a lathe! I guess it will pay off in the long run. And if (when?) I get one I will probably wonder how I ever could be without it1 point

-

You should carefully inspect the hairspring! Something is wrong with it!1 point

-

Couldn't agree more! IMO, you do have a moral responsibility to check and double-check before you publish. It drives me nuts not being able to understand something despite giving it time and thought only to later find out it was all wrong. Especially when the information is presented with a tone of authority. If there's one thing I've learnt it is that if someone sounds like they really know what they're talking about, watch out!1 point

-

The previous generation of this one hey: https://amscope.com/collections/stereo-microscope/products/sm-4t-v2031 point

-

Seriously ? Some of those dings are minor. I have 70 year old vintage with worse damage than this that run really well for their age. There is one area that stands out but why flag the other very minor marks. Its possible that internal damage has occurred but its pointing to leg lìfting to me. Has this been redialed and handed , it doesn't exactly ooze quality and i dont mean the damage, why does it have damage ? I know Bremont isn't top end luxury but i would have thought a better dial tbh.1 point

-

I would have thought that the pin vise might damage the pinion leaves, but that gave me confidence to try using my MC cannon pinion remover as I wouldn't think it would use more force than a pin vise. It worked!1 point

-

Summer school brake has a disastrous effect on my watchmaking carrier. I am still recovering, but I managed to bring a Greiner Micromat back to life.1 point

-

the rule and watch repair is never modify the watch to fit the replacement part. Sometimes the rule has to be modified but you what a modify the replacement part to fit the watch. you need good reference material like going to this website looking up whatever it is you're looking for http://cgi.julesborel.com/ you should also have the bestfit books they're available as a PDF somebody will tell you how to get those I just don't have the link handy right now. the reason you what these books are you can look up parts but you can also look up dimensions of things like balance staff. finding parts understanding what you're looking for looking at to learn that is just as complicated as watch repair. then since were talking balance staffs you go to a website like this you can look up the staff you need and you get dimensions of the staff. You never replace a balance staff without measuring the old staff and the new staff and make sure they're identical. You want to avoid a problem before damaging the roller table or hairspring https://www.balancestaffs.com/product.php then you can look up your caliber number you get this link https://www.balancestaffs.com/a-schild.php?caliber=970 notice the only get six balance staffs here then if you click on each of the different staffs you get the complete dimensions of that staff1 point

-

Hi welcome to the forum, It depends on the nature of the damage incurred, If the case has had an impact the balance pivots can get damaged unless they are shock protected, the Incabloc etc may have been displaced enough and not re set properly, and also the train wheel pivots may get bent. They dont need to be badly bent to cause a problem. There may be other reasons to consider. Is there a possibility of getting some pictures of the the case and its damage and also the watch movement1 point

-

At a normal table height, it's good. I'm on the short side (5'6" / 1.6m), and I have to sit up straighter than I normally would, but that's probably a good thing. I could also just raise my chair a little... To answer your other question, it varies depending on what you're doing. I'm currently set up with the 0.5X Barlow for maximum working distance, and 20X eyepiece (non-watchmaking work) but the height changes from there for focusing. I took a tape measure to it just now, and the center of they eyepiece (so eye height) 15 1/4" / 38.7cm. Also, echoing the comments about his magnification math double counting the eyepieces. 45X is the quoted magnification as configured on the AmScope site with 10X eyepieces. The maximum magnification available with that scope head and without looking around for extra special lenses is 180X (2X Barlow, 20X eyepieces). That's just enough to see some of the larger microfauna (i.e. tardigrades), but not enough to see anything like bacteria. Long story short, it's the wrong tool for the job. A chef's knife where you need a scalpel and vice versa.1 point

-

Lol. I am actually very sentimental but mate i was joking. I left a laughing face. It just came across as rather funny, he came looking for help thinking he had something of value and was met with 4 disappointing replies Its obvious this person just wanted a valuation and didnt get the answer they were looking for, even more obvious by the fact they haven’t returned to reply. The forum gets used and abused like this all the time, I've seen it over a dozen times in the short time i have been here. They ask, they dont get an answer to thier question, or they do get an answer and dont like it or maybe do like it . They disappear never to return unless they need another valuation. What can you do1 point

-

Hi all the pivots as usual and all other pivotable parts like the rack , lifting levers etc, Min wheelpost all the strike parts, and a smear on the star wheel that lifts the hammer, and I put a smear on the Gathering pallet surface where the lever runs. If yours has a chime mechanism the same applies there also. Use the oil sparingly/ I have not found any lubrication charts for clocks yet although the Hermle Manual has instructions for their clocks which may transpose. If I fins any at all I will post them. Hi Here are a few guide sheets from the manual, should cover most points. cheers H1.pdf H2.pdf H3.pdf H4.pdf Hi Willow I found This , you might find them useful some time. https://r.search.yahoo.com/_ylt=AwrIS.Yk9zJjYRcACkF3Bwx.;_ylu=Y29sbwMEcG9zAzMEdnRpZAMEc2VjA3Ny/RV=2/RE=1664313252/RO=10/RU=https%3a%2f%2fwww.abbeyclock.com%2foil.html/RK=2/RS=JP4XjnRE8aAXw_5VhLYcGCzY0u0- There is a lot of useful information on this site. BTI-The_Practical_Lubrication_of_Clocks_and_Watches.pdf1 point

-

Hi for the oil use Windle's, and for the grease I use Horoglide from Meadows and Passmore. both work very well.1 point

-

I can see a difference in colour with this photo, so not sure what its like close up looking at it. I f it was mine I would try and match the colour.1 point

-

1 point

-

1 point

-

Welcome to our little group! I also can say I have encountered a few watches in my time that tested my patience. And I tend to have a rather mild temper. All I can think of to say is: be prepared. Some watches can be difficult. I always try to remind customers up front that some repairs take time and must not be rushed. More mistakes happen when we hurry. I try to take a break when I begin to feel rushed or frustrated. I also try to prepare in other ways. One of the most aggravating things that can happen is when a click spring, in the process of being removed for cleaning, goes "ping" and shoots away so quickly that you have no idea where it went. So, I now place the movement in a clear plastic bag when removing them, and I have stocked up on a large variety of click springs of all kinds. I have done the same with screws, because they can go missing too. I have lots of screws. I have learned that if the part is small, and cheap enough, it is good to have many in stock, because they are often the things which go missing most. That really is all I can advise: go slow at first, do not rush. And be as prepared as you can be for what may happen. That, and some very good screwdrivers and very good tweezers solve a lot of problems up front.1 point

-

Haha. Maybe not the kind of approach to have, you desperately need to get this out of your system, if you are even thinking this way and ok maybe not acting this way then you are going to struggle with watch repair. Things have to remain calm and relaxed in your head at all times as it will effect your work without you even realising it. As with everything our decision making is based entirely on our mood and emotion at that particular moment. Favourable positive decisions and outcomes are the products of a serine mind. And before you ask no i am not religious in any way, just smart, logical and experienced in life. If you feel something rising in you head because the repair is not going well then back off for a while and grab a cuppa. I myself have a wicked temper, over the years have i learnt to control it, not easy sometimes but more than worth the effort and much better than the negative outcome. Oh by the way welcome swiss2k, this is a great helpful friendly forum. I actually rate it the best watch repair forum in the world obviously as i am member, a few of the other members are ok too, sort of1 point

-

1 point

-

1 point

-

Haha. I just realized what you are referring to. That is the exhibition caseback with the glass porthole.1 point

-

No. Zoom magnification range is 0.7 - 4.5. Multiplied by eyepiece magnification of 10X gives 7 - 45.1 point

-

I very rarely put up vids from YouTube but this one is so informative and true it’s worth watching., It gives all the info you need with regard to microscopes and I agree 100% with his conclusion including the one to avoid.. Why? Well I purchased one https://www.youtube.com/watch?v=tAtATqwI5A41 point

-

I usually just grip the upper pinion in a pin vise, hold the wheel in my left hand and twist and pull it out gently.1 point

-

@NeverenoughwatchesPerhaps someone else can give reasons rather than just observations, but yeah these always seem to start out very pathetically weak, but just let them sit a day before worrying about it.1 point

-

did remember to scan the book made it into a PDF. You notice the watch goes by several numbers but it is the same number on your watch so this is the right watch. Choose disassembly and the parts list. You'll notice the so-called barrel nuts do not come off in the disassembly and are part of the main plate in the parts list. At least I'm not seeing him as a separate component so you can leave them on. Waltham timer.PDF1 point

-

1 point

-

Hi welcome to the forum, In answer to your question "balance not moving" you mentioned its had water in it, yes. How long ago and did you dry it out properly, because if not the movement may have rust present stopping the watch. Or it could be a legion of things, broken staff, broken pivots, dirt , congealed oil ,the above mentioned rust, broken mainspring, seized train wheels, Have you dismantled the watch, ? so you see the possibilities. first can you post a picture of the movement out of its case less dial and hands, front and back so members can see the state of the watch as is before attempting a diagnosis. cheers thank you1 point

-

Good question. I once removed a screw with alum solution from a nickel plated chronograph plate. After, the nickel had considerably changed its appearance and looked different from the rest of the movement. I will not (and did not) do that again! Frank1 point

-

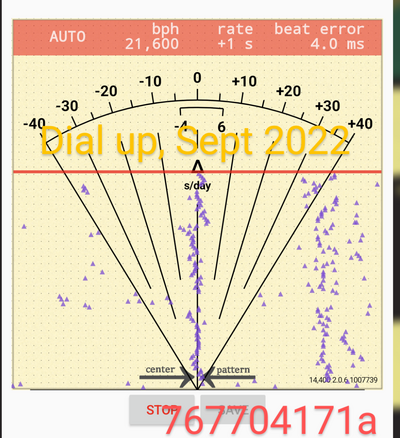

Leave it as it is. Beat rate spot on, even trace, great amplitude. If you need to fiddle with it, the crown tube could use some cleaning and since the back has to come off to remove the crown then a new caseback gasket as well. I imagine you know about the stem release for these watches? the crown needs to be in the time-set positiion and the release pressed in only as far as the slots on the side. Any further an you will need to remove the hands and dial, keyless stuff and daywheel to reinstall everything. Anilv1 point

-

I think you are right burnishing in both directions may even out the surface better . Dragging the surface in one direction only may give the pivot a different finish. Now I'm wondering if the pivoting machines use both direction. I've found this one made by junghans. https://www.ebay.co.uk/itm/115534361435?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=pLbdQDSpSL-&sssrc=2349624&ssuid=tBiLZaCfRb2&var=&widget_ver=artemis&media=COPY Sorry not junghans, i cant find that one.1 point

-

When I was in school we had a guest teacher (who became my main mentor) who had worked in Switzerland with the likes of Dufour and Derek Pratt. He was a major fan of using a piece of elastic from the sewing shop attached to the back of the bench, with a bit of around 7-10lb test fishing line at the end to go around the pulley, with a simple split keyring at the end to drive the Jacot. Sounds pretty much like what VW has. I like that method, but ended up needing to be more mobile with my Jacot work around the shop for a couple years and just got used to a bow. Either works great1 point

-

Thanks to everyone who's been assisting me here the last couple of months, I have two Timex projects I finally completed tonight and are ready to go to new homes. The first is a 1969 Mercury whose numerals I found really striking. It was a non-runner and looked much worse than it actually was on its original expansion band (which is now clean and usable again). But it really only needed service, a new crystal, and some patient cleaning, and now I think it looks amazing. This is the kind of watch my grandfather would have worn for special occasions and treated like a treasure. And next is the 1971 sort of rally diver Timex Electric I had a bunch of questions on in this thread. I received it as a non-runner, badly gummed up inside with a crown that just barely turn. Thorough cleaning and service didn't quite get it running because it had a bad copper coil. A donor balance finished it up and with a new crystal & mint dial & case, it looks sweet. Only the worn plastic bezel shows its age. It's only in want of a better strap now. To my surprise, it was pretty much bang on for a Timex, and I didn't have to touch the regulator. The noise on the right is I think because the seconds hand only advances on one direction of the balance swing. (But these early 70's Electric movements are are kind of frustrating to work on and with super slow hand setting gearing and no date quickset, I can't see myself jumping to do another unless it is really unique looking) Thanks to everyone who helped on these!1 point

-

Art deco period for sure. However a first for me a three barrel Westminster chime clock with a platform escape1 point