Leaderboard

Popular Content

Showing content with the highest reputation on 04/06/22 in Posts

-

First thing I would try is to reclean and oil the Incabloc. Have a really good look at the pivot sticking up in the setting while it's out too, preferably with a microscope but at least a strong loupe. I readily admit to having had a similar issue more than once in the past and came to find that a piece of dust had placed itself on the pivot, which stuck it in the Incabloc jewel, and bing no more running.3 points

-

One common error is using the wrong screw for the pallet fork bridge. The correct screw has a very flat head to clear the hairspring. Using a wrong screw will cause the arm of the balance to hit the screw head. The pallet bridge screw not being fully tightened will also have the same affect. rgds Anil3 points

-

If you remove the balance cock and complete balance you can touch the pallets with(I suggest a clean not to thin oiler or peg wood) and watch the action, the escape should be clean and swift. As I have said before the movement should work no matter what angle you have it even upside down it should work. This is a good way of making sure the depth is correct on the contrite wheel to the escape wheel and the correct end shake to the balance. The contrite wheel should be loose to rotate but with no end shake, so no matter what angle the movement is at the depth is still the same.2 points

-

I once had a piece of dust stuck in the hole jewel. Had to floss the hole jewel with a strand of hair, and benzine. The flat end of the cap jewel should be the oiled side, with the domed surface of the cap jewel facing outwards. If you flip the cap jewel the wrong way round, the domed face of the cap jewel can press down on the pivot and reduce the endshake.2 points

-

You have to have the right depth on the escape wheel which engages with the contrite wheel. You should have a screw adjustment on one side of the pivot of the contrite wheel, you also have a small amount of movement with the platform. Have you checked the teeth on the contrite wheel. When it stops mark it, start it again and see if it stops in the same place, if it does you know its a tooth that is causing it.2 points

-

2 points

-

Hi to all Watch Repair Talkers. I am a newbe! possible watch collector by default. Allow me to explain: I recently became a custodian of approx. 20 gents & 5 ladies watches. One of which is a Tissot Martini Racing chronometer, 1992 vintage. The back has a red hard plastic seal & is loose, not fitting properly. I fitted a battery, but is not working. The leather strap has had its day & needs replacing, but only if I can get watch working. The strap has unusual connections, ie: one narrow 2 lug 13.3mm width, the other like a Cartier single lug 12:7mm fitting. Will continue later with the other watches. Roy1 point

-

I just begin my journey into this wonderful hobby about a week ago when I was given my first couple pocket watches and a clock from my great-granddad1 point

-

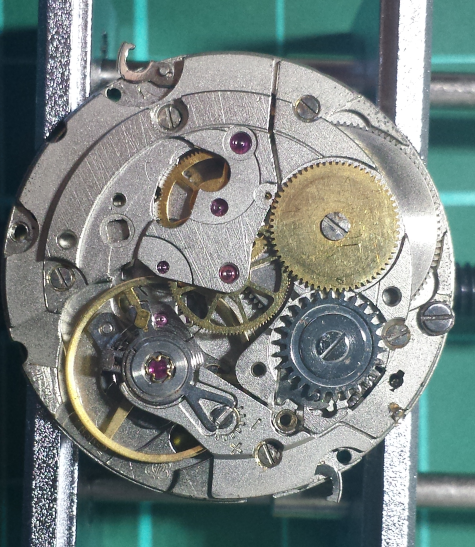

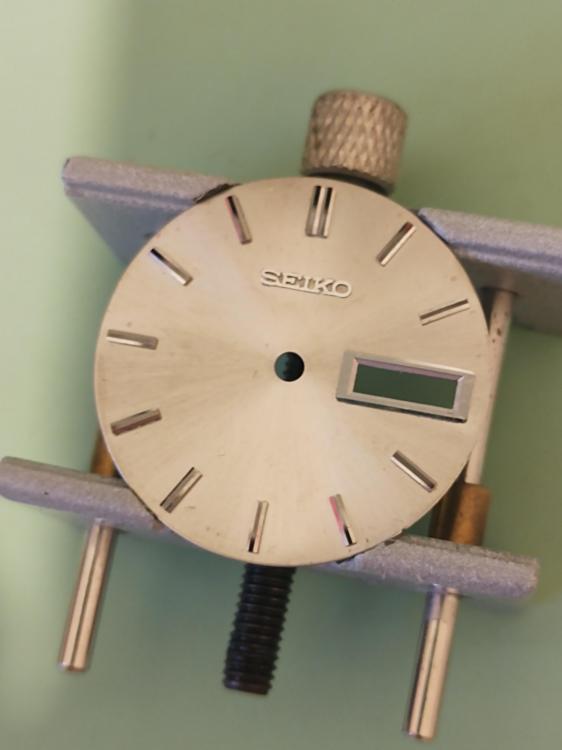

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

-

Tossot sea star 784-2. The mail part of this gear comes in contact with the escape wheel face is up but when face is down gravity pulls it down and gears no longer engage. Are the ridges on the tip of the shaft supposed to stop it from traveling too far into the tube? Very lose. does the end of the tube need to be closed a little?1 point

-

Maybe you could put the gears in the watch and give us a picture so we could see what you're talking about. I have an idea but I really need to see the two gears in the watch.So maybe just put these gears in the escape wheel and so we can see you don't have to put the main plate on top1 point

-

1 point

-

Yes, I have it and have read it and it is very much like "Longitude". The author has quite the pedigree. He was the curator of timekeeping at the Royal Academy. My wife and I often go crazy at the small book stores at the beach and I just got this about 2 weeks ago, so my horological juices were flowing.1 point

-

1 point

-

The setting lever lifts free once you take off the setting lever spring. The date corrector is riveted on the main plate and you don't have to/cannot take it out. You can open the barrel and service the mainspring.1 point

-

A side view of the oscilator when running with focus on the coil , balance wheel , roller table, underside of the cock , whereever can possibly rub. Do you have the amplitude and beat error? could this be rebanking your hearing. Loose regulator and stud arm can also make a sound.1 point

-

1 point

-

Thank you for idea, but it's not the case here , when it's with face up will be bigger distance from the pallet fork bridge1 point

-

Omega parts are rarely cheap even second user parts, since SWATCH closed its doors for parts other than certified dealers.1 point

-

Welcome to the forum If possible please suppy picture along with your question as it helps members understand your query and provide help. Cheers1 point

-

The pallet fork will move anytime the balance moves, in or out of the clock. I agree with OH, this sounds like a depthing issue. It can be tricky to find the sweet spot.1 point

-

1 point

-

Yes, exactly. The best is Florida pithwood buttons, but they seem to have become scarce. The purpose is to mechanically clean the pinion; they can get surprisingly dirty considering they should be without lubrication. I usually put a little benzine on the pithwood to help. This is done in the pre-cleaning phase- then when they come out of clean solutions there's no need to touch them-- and there should be no residue from proper clean solutions.1 point

-

How much balance endshake is there? If it's too much the balance could touch the centre wheel or balance cock, or, the roller could be rubbing on the pallet forks.1 point

-

It looks to be a modern replacement (You can buy them in bulk on Ebay) - not the best quality and often thicker than the originals hence the need to spread the cock (which I believe is the unfortunate term for the suspension spring holder - it certainly is in long case movements) otherwise it looks to be in good condition.1 point

-

I use the L&R solution and pour used liquid back in to a used container, then take it to the local waste collection site. There is a section for oils and contaminated liquids, I was informed to leave it there.1 point

-

You shouldn't place the glass jar directly on the bottom of the tank. The jar should be placed in a basket or suspended in a frame. The bottom of the tank should not have anything resting on it or it may damage the tranducers and/or reduce the amount of U/S energy in the tank.1 point

-

1 point

-

Bargain doesn't begin to describe it....its coming to the US from Spain1 point

-

For you who encounter this problem, things have changed at least here in the USA, dont hesitate to try and correct your vision,my cataract surgeries were very easy , the vitrectomy WAS scarry to me,, they stick 2 needles in your eye and a light in the 3rd hole, and draw all the vitreous out that has all the old yellowed /stringy fluid/ floaters, blobs and what nots.mine were so bad they floated up in my vision blocking what ever i tried to work on, and driving was a booger. they replace it with a solution, I COULD NOT believe the clarity difference, i had no vision the first day, it did hurt a few days and i looked liked someone gave me a black eye but it all healed in a few weeks by the 3rd day i could see watch parts again!!, now i have 20/16 vision in my right eye that was 20/200 before, i had to wear glasses ALL of my life,, i am heading Back to have the left eye done in a few months,Take care of yourselves,,stay well, no one will do it for you,1 point

-

I don't think so. It says no acids on the bottle and it doesn't seem to react with rust the same way phosphoric acid does. The pH from the SDS is 6.0-7.0, neutral. Coke is supposed to be about 2.6.1 point

-

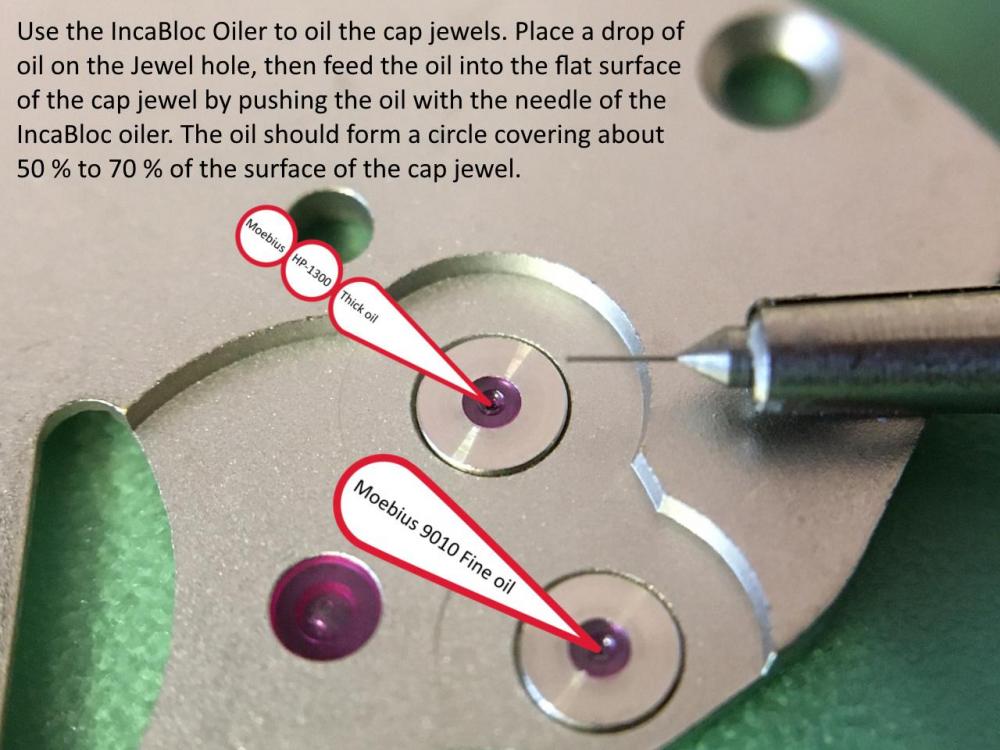

Couldn't the tip just be pushed into a clean piece of pith wood and then be blown off (like an ordinary oiler), or am I missing something here? Anyway, a disadvantage of the the automatic oiler that I have, the Bergeon 1A, is that the diameter of the tip is too wide for some very small jewel holes, like the those for the capped jewel holes of some Seiko and Orient watches (3rd and escape wheel). In those cases an Incabloc oiler (or similar) is really what's required. For anyone interested here's my video review of the Bergeon Automatic Oiler 1A. Here are some pictures of it:1 point

-

1 point

-

1 point

-

A vintage Starrett outside micrometer (150mm to 175mm) no 436m described as not working, locked up. This was pickd up for a 404 club price on ebay, but working examples go for around five to ten times what I paid, and of course I also get the fun of fixing it. The fault is probably just years of dirt (or someone has perhaps engaged the lock on it). 150mm is a little large for watch work, however I'm sure I'll make good use of it elsewhere. Mechanical micrometers have the obvious advantage that the batteries never go flat of course.1 point

-

Perhaps Apple (actualy the Chinese factories to which production is contracted) is the largest maker of smart watches. These have nothing to do with the watch industry, as they are just consumers electronics, and even less with watchmaking.1 point

-

A Trafalgar 25 jewel (almost certainly ladies) automatic, a minor radiological hazard in the form of an Ingersoll "Simba" with a broken hand, and a 1972 Timex Marlin which I suspect is missing its second hand, for a pound sixty six each plus postage. The Marlin is really the one I was bidding for, the other two may be interesting too though. I think I have some hands that might work with the Ingersoll, I almost certainly have a second hand for the Marlin, and I'm intrigued to see what lurks within the Trafalgar. Speaking of hands, I just watched this video from Vintage Watch Services, in which he turns a couple of hands for a Pavel Bure pocket watch (which he also services).1 point

-

1 point

-

There's a couple of recent posts on the forum about how Rolex have refused to undertake the work offered to them. If they're trying to hog the market then they at least have to offer a repair service. Not that I have Rolex money but this has really put me off the brand. Isn't one of Patek's selling point the fact that they will repair any of their watches, no matter how old or damaged... probably at eye-watering prices, but it's still an offering.1 point