Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/21 in all areas

-

5 points

-

Hi, Just wanted to show a before and after of a recent project. I completed Mark’s online courses a few months ago and have done a few small projects. Mainly servicing and repair of movements. I am an Omega collector and wanted to acquire the Seamaster Racing 1974 due to the Cal. 564 movement. I bought this on eBay for $500 and yes it was as rough as it looks. Rust, corrosion and badly maintained movement. I managed to find a NOS replacement crystal and bezel. I serviced and repaired the movement back to Chronometer specs. Unfortunately, I can not take credit for the dial as I sent it to Bill & Sons. But I will take credit for saving £200 off the bill by getting the Cliche for the outer race track on the dial done myself. I never liked the leather strap or the original one from Omega. Wanted a modern version of a beads of rise look but polished to match the watch. Also wanted a fully mulled double clasp. there are the final results today after assembly.2 points

-

2 points

-

Remove the minute hand, place it upside down on a flat wooden surface, slide a wooden stick over its back to flatten the hand, work streightening each horizental bend at the very bent section. You shouldn't think all bends can be fixed with one push at the tip, its streigthening at each bend one at a time. Soak in water clean in ultrasonic or by brushing the back. Tons of Good luck.2 points

-

2 points

-

I love Timexes! It must have desiged to be an insult to the Swiss watch industry. It's a real paradox. It's so simple yet so complicated. Anyone who is trained as a watchmaker would find them frustrating. Some are really ugly, some are simply elegant. Just look at their dials. Even after 50 years, some still look as good as the day it left the factory. And they are all held on by 4 metal tabs folded over the bottom plate. Many of them have really taken a beating but just keep on ticking. They may look like crap on a timegrapher but would still keep good time. They are just great fun.2 points

-

Hi All Time (no pun!) to introduce myself. I'm Mike, a 50-something hobbyist tinkerer - as the loverly wife calls me. Long story short, my first career was with a certain Gerald Ratner (until he made his famous speech), moving around with Ernest Jones and others until early 2001. I gained an appreciation and passion for mechanical watches during this period, although my 'tinkering' at that time was limited to battery changes, bracelet adjustments and the odd mainspring release (incorrectly, as I've now learned!) Now frontline NHS I've spent the last six months building up a nice relaxing, therapeutic hobby as a release from the daily madness. It's been something I've thought about for a long time. In Autumn of last year I took the first of Mark's courses, then promptly blew the budget on purchasing equipment & tools and setting up a DIY work area. Photos available if anyone is interested ? I've a real interest in the late 1990s Oris watches, having sold them for a number of years along with the big Swiss players (not at Ratners!) I've a small collection of Swiss and Japanese mechanicals which I plan to learn to service properly myself. Also a couple of gorgeous Garrard stopwatches, and a 'Services' Army pocket watch on which to learn my skills. I may have some questions in due course with the latter; pin-lever movement and original - broken - mainspring and glass to consider. The last few months have been brilliant - I love it. Should have done this many years ago! All the best, Mike1 point

-

My google foo found this site allwatchparts.com. They advertise domed plastic watch crystals in 0.1mm increments. This seems too easy. Has anyone used them as a source for acrylic watch crystals?1 point

-

Hi Poljot's Picture explains it very well, The inpulse pin marked in red, should rest in the fork in a straight line when the power is removed and the fork/pallet is centerd and stay there if it moves either left or right on its own after being centered the balance spring will have to be adjusted.1 point

-

I order with CousinsUK, I like their website best. Ultimately you are looking at crystals from the Sternkreuz and GS calatogues, and ordering those items from a distributor, so it's good to get to know those catalogues. There are some older brands that are available sometimes like BB and Stella, I think it's just NOS. Simple round dome crystals are not usually a problem, like @jdm notes, you can get them anywhere1 point

-

1 point

-

1 point

-

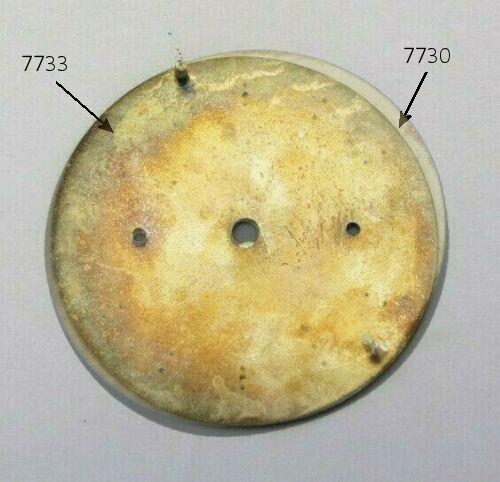

I appreciate that the original post is a little old now, however thought I'd share some info to assist this and others that may have similar questions. So I have a couple of Cal 7733s and a recent purchase of a 7730. As called out in previous responses, there are two variants of the 7730, with either a flat or beveled pillar plate - mine is the beveled, the later version. Being the newer beveled version, I was expecting a 7733 dial to fit nicely, however it does not. Whilst the dial feet are in the same positions and the sub dial pillars line up nicely, the bottom dial foot (midway between 7 and 8 clock) is marginally closer to the centre of the movement that on the 7733. So in summary a 7733 dial does not fit my 7730 movement. I hope it helps..1 point

-

If you are really in to light houses, you also have the option of staying at one (once the covid restrictions are lifted of course). "Rua Reidh Lighthouse, near Gairloch in Wester Ross, stands at the entrance to Loch Ewe, at one of the most dramatic and remote locations on the north-west coast of Scotland, with breath-taking views across the Minch to the Isle of Skye, the Shiant Isles and the Outer Hebrides" .. or of course there is the Scottish Museum of Lighthouses.1 point

-

Hi I have seen somthing similar at Fraserburgh lighthouse, now automatic, along with a small mechanical turret clock nice mechanisms well cared for as you would expect, the lighthouse is an museum now and worth a look.1 point

-

1 point

-

1 point

-

1 point

-

That presses against the movement ring to hold it steady. No case clamps on these.1 point

-

Punches should be hardened at the end that does the work, and soft at the hammer end. I just checked my K&D staff removing punches and they are dead soft on the hammer end, and a little harder at the business end. I was actually surprised it wasn't harder, but they are definitely heat treated. They also measure 4.69mm, which is normal punch diameter (nominal 4.7). The K&D punches should turn fine. My Star punches and anvils have to be annealed to turn them.1 point

-

Bezel, the metalic ring in which the crystal fits is to be removed if this is a front loader.1 point

-

Hey Poljot are they sapphire crystals? I agree don't get me wrong I'm just throwing in a bit of humour at my expense. But thanks for the link to the crystals ?1 point

-

Woolshire, a common way of realising a stop work in a watch is by having a maltese cross and a finger wheel installed on the barrel cover. First you let down the mainspringing. Although there is still half to one turn of power in the barrel you dont't need to worry. It won't reach the going train because the stop work stoped it. Take out the barrel and clamp it by the barrel arbour in a vice - barrel cover up looking at the stop work. Now turn the barrel with left hand thumb and index finger just a bit to free the stop work. Take out the finger wheel with a pair of tweezers. Still grabing the now free barrel let down the last remaining power carefully between your fingers. Assembly is the same backwards. All the best from Hamburg Alex p.s. carefully make a note or a picture of the stop work wheels start position.1 point

-

Btw, you can skip "measuring hole diameter" step: Hands 1.50 x 0.90 x 0.25mm Just measure each hand's length1 point

-

Remove all hands, measure them (hole dia, and length from the centre of the hole to the tip). Search Cousins or eBay to find what you like. Alternatively, try to straighten it - should not be too complicated: use tweezers, but protect the surface to avoid scratching it. Using heat will remove / damage paint.1 point

-

No problem. If you would like to continue with this hobby, then you better invest this $30-$40 hard earned dollars into purchasing K&D staking set. You can get one in the States fairly cheap (around $200). It would help you to fix your pallet fork / staff issue.1 point

-

You will also need a crystal: https://cdn11.bigcommerce.com/s-iic0hc/images/stencil/1280x1280/products/41441/70958/aluminum_box_tins_15.0252__38087.1477097411.jpg?c=21 point

-

Thanks John. Yeah I noticed how 721 seemed to just reference the fact it was a balance and that it was the universal number that just referred to balance part on a movement in general. So basically no matter the movement the balance would be listed at 721 like you said but trying to find the additional reference numbers for the part was impossible. Thank you for helping me out with this and I got really lucky with someone I trusted having the part because if I had to start shopping other sources I had no numbers. I was going to do the balance staff but they do not use a standard Collet but it’s more of a collapsed piece of thin metal and a three star pattern so when I tried to remove it I ended up damaging the hairspring a little at the attachment to the collet. It was hard because when using my Collet tools it was not possible to have any large surface adjacent from each other to lift up on. I have played around with repairing hair Springs but I really want this watch to be tiptop so I ruled it out. Not to mention I’ve never repaired a bend that close to the Collet. Fortunate for me I was able to source a balance complete for a zenith 400 series from Blake at Scotchwatch. Like you said it was pricey but it was better than the alternative of sending it off to have the service just to get the part. Happy to say I got it back together and it’s running with about a five to six second variation in positional error, Not quite chronometer spec but I’m OK with it.1 point

-

1 point

-

Might be worth contacting Rich Askham, I can recommend his work, having had several watches serviced by him?... The first being this one about 5 years ago...1 point

-

Haven't you noticed? There's over 8,000 of us right here. Just ask us. We'll tell ya. ?1 point

-

As the saying goes: "Where can I find a watch repairer?" "Under the table of course!"1 point

-

1 point

-

1 point

-

Hi like I said before just take your time and don't get frustrated, because putting a Timex back together can be frustrating. Lining up all the wheels and dropping on the plate. Pinning the spring will be a bit daunting first time around but gets easier with practice. all the best1 point

-

Metamec becomes radio active. The electric mechanism on the second Metamec has a blown coil, so while I figure out if I am willing to try stripping the motor down and repairing the coil (unlikely, but I may give it a bash), I thought I'd see if I had any quartz mechanism in case I need a plan B. After much rummaging through spares and a quick trawl through the junk in the attic I found what I was looking for. An "Atomic" (Radio controlled) quartz module with the correct reach to fit in place of the old workings. I fitted the radio quartz module to a piece of clear plastic sheet, cut to match the outline of the original module which allows me to re-use the original brass screws to centre it and avoid drilling any more holes in the woodwork. Naturally the original hands don't fit, and since they are what gives the thing the majority of its character I'm going to see if my 3d printer can produce something sufficiently similar to the originals to make it look the way the designer intended. If that fails I guess I could attempt to etch some from brass sheet paint them the correct shade of off white. Until I get some traction with either the coil rewind or replacement hands, I've put replacing the missing piece of woodwork on hold. So now I have an even less complete Metamec that is accurate to the second (but not the hour or minute). Nobody is perfect I guess but I'm willing to chalk that down as progress... of sorts.1 point

-

Yes, you can. Blame it on Covid19 and get the cheque from the Government. What you can do is to practice on this "curly thing" how-to remove the hairspring from the balance and put it back on. It's very therapeutic.1 point

-

One can see dials as these at Ebay marked fitting 7730 or 7733 but as you say seldom together. Probably not to get a too many franken watches beeing built. I have non of these needing service right now so I decided to make an experiment. Take a random picture from one who sells a dial to a 7730 dial and one who sells a 7733 and superimpose them over eatch other. A fun excersize on a sunday. The result except from a slight skewness in the pictures shows the dial feet are at the same place.1 point

-

7730 was basically a Venus 188 7733 was completely redesigned but same fonctions as 7730 I think the position of subdials are the same but I'm not 100% certain ... Envoyé de mon moto g(7) power en utilisant Tapatalk1 point