Leaderboard

Popular Content

Showing content with the highest reputation on 01/07/21 in Posts

-

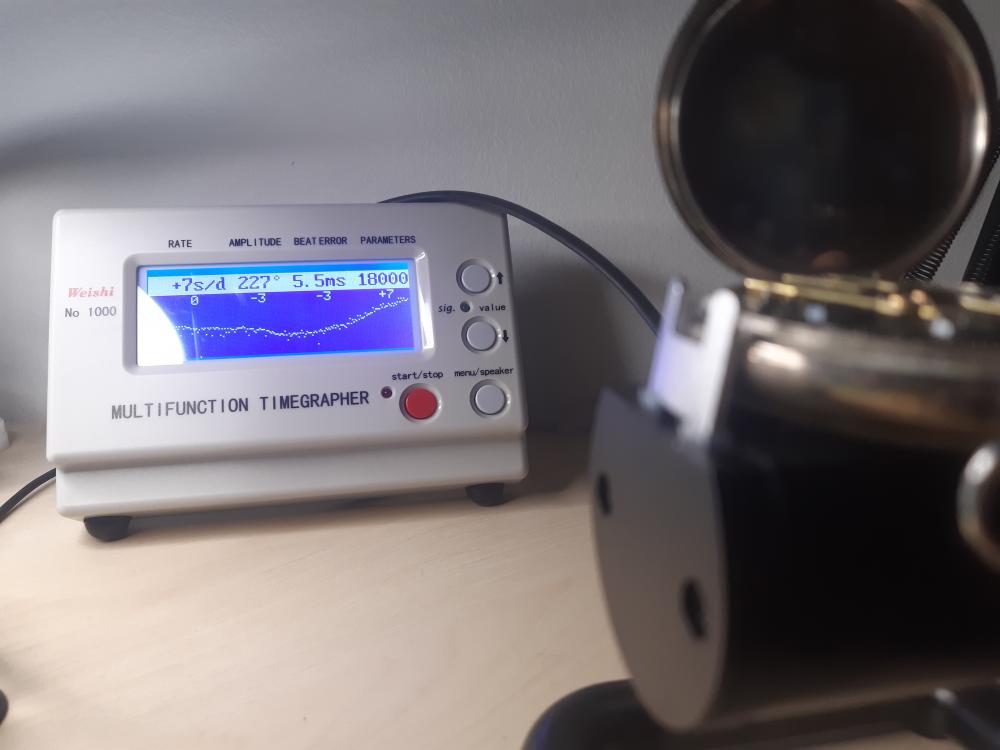

I bought a slightly modded Seiko SKX007 off of eBay, about which in general a more experienced man than I here aptly quoted Obi Wan Kenobi: "you will never find a more wretched hive of scum and villainy." LOL. To be fair, the watch was accurately described cosmetically, more or less, but I didn't take the time to read the description. One thing that wasn't entirely accurate was the representation that the watch "works well." Well, it did run, but not to expectations. The amplitude was low, the beat error high and the rotor felt sluggish. So what's a newby to do? Well, a full service of the 7S26 is still a bit beyond my skill set. So I replaced the movement with an NH36, which meant removing the hands and dial from the 7S26 and mounting them on the new movement. I also discovered (last to know) that the crown and stem were not a clean "switch over" between the two movements so I measured, cut, and filed the new stem that came with the NH36 movement and epoxied the crown on to it. Now I know that this hardly qualifies as watchmaking, but I have to admit feeling a bit proud that the watch is now better regulated, that I managed not to bend or lose the hands, that the epoxy is only on the intended part and that the thing is back together with no extra bits sitting in the tray. Or, more precisely, you have to celebrate your small triumphs along the way to some level of actual competence. Remember that feeling when you first got parts to play well together to resemble a functioning timepiece? Well it's been a pretty good morning so far. My family appears to be tolerating this with an air of bemusement, as in, "I wonder what crazy scheme Dad's up to now?" But you all will get it. Happy Wednesday . . .3 points

-

I would clean the seat to press in a new 1.5mm thk glass, which I believe, comes with I-Shaped gasket (no need to get a gasket separately). At least 1.00mm Thick - Flat comes with "I-Gasket" - Mineral Glass - Sternkreuz MSI. In any case, such Glass and Gaskets are dirt cheap. Get two in case you crack first one ? The cost of such press in Canada will be around $30 CAD plus another $10-20 in shipping cost.2 points

-

I didn't find the specific watch tech sheet but I found this. It talks about the balance jewels system or basically all of them. Then it covers a whole bunch of other information related to citizen watches that you should find useful. 1971 Citizen Technical Information - 03 Watch Movement.pdf2 points

-

2 points

-

Hello fellow watch lovers, I have just completed a build from part sourced from various sellers. It turned out to be the best build for me yet and I have really amazed myself and the skills I had to exercise on this timepiece. I have impressed myself with this one and it is a stunner with a salmon dial. The NATO strap is very lovely on this timepiece. I apologize for the lack of details on this beauty, Enjoy2 points

-

This is my (modified - gilded hands) everyday beater! Thanks for the pictures "comrades"! I never saw that 31 КАМЕНЬ Komandirskie dial before. Absolutely amazing! I feel warm ar heart these watches are finally getting some love here on WRT. I've been waiting for it, and I couldn't agree more @Poljot, these watches seem able to run, and run well, no matter how dirty and neglected they are. If you would take the dirt from a well ticking Vostok not having been serviced for a decade or two and distribute it evenly among a hundred Pateks, I am positively sure it would bring all hundred to a dead stop. The historic perspective is fascinating as well as these watches were never designed to meet a free market, but to provide reasonably precise and personal time keeping to the masses. Still then to see all the love and creativity go into the dials of these watches is pretty spectacular. To quote Sting: "We share the same biology, regardless of ideology".2 points

-

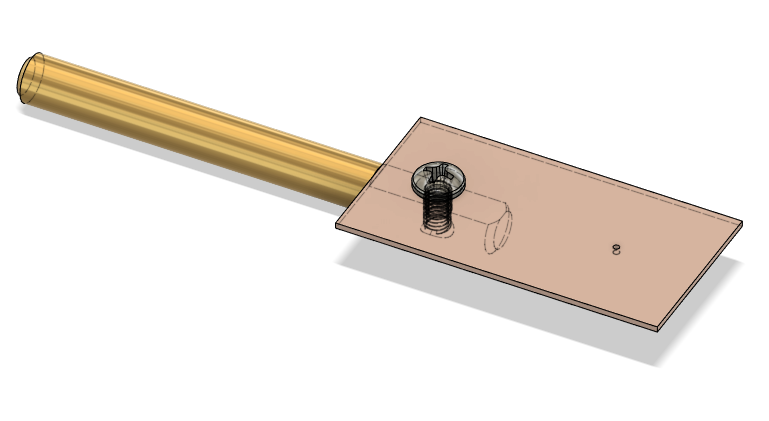

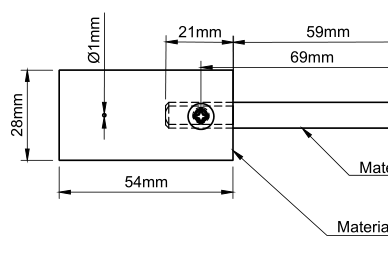

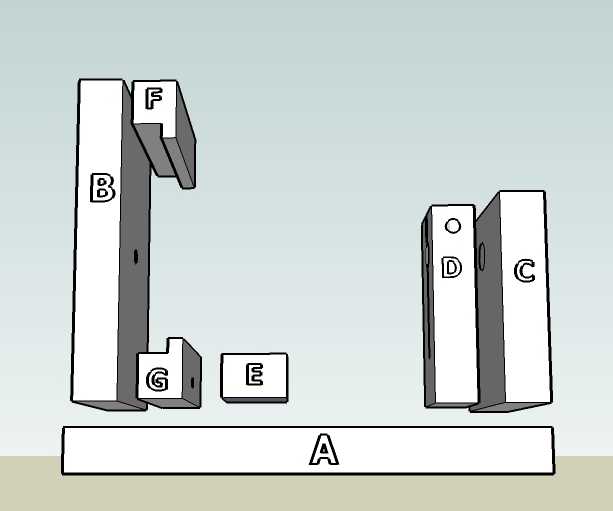

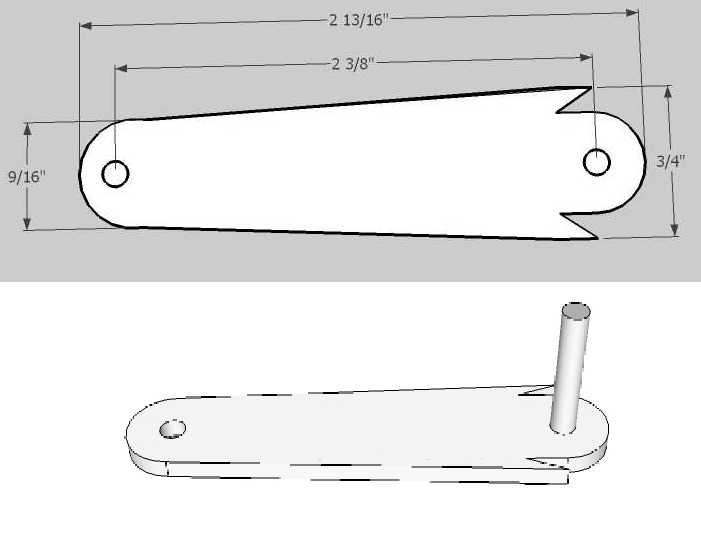

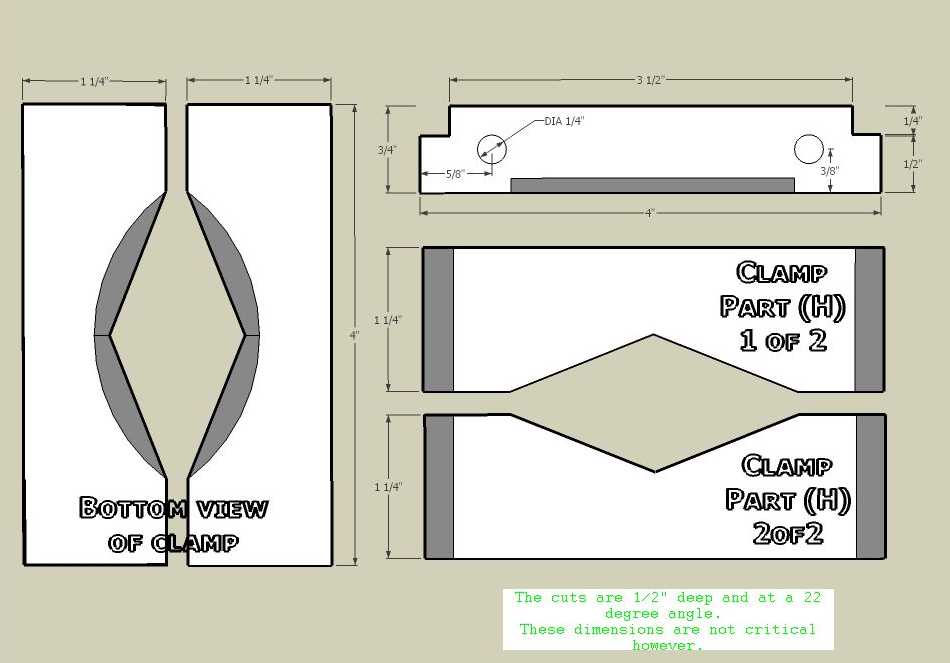

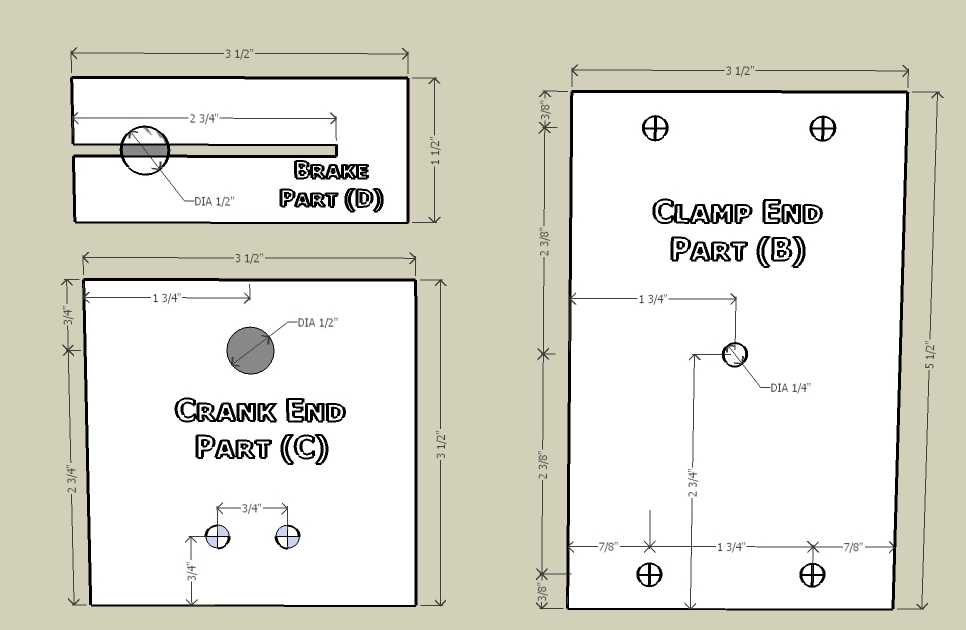

Editing a video on the construction at the moment. Need to reset the pallet stones in a vostok which was loaded up with too much shellac. Unfortunately my pallet warmer is missing - searched high and low - I suspect it's in pallet warmer heaven. So I made a new one. Hopefully this will be an interesting video for some. In fact - I made two. Will do a giveaway to a winner for one of them. Details will be announced in my next video which will show how I made these and the video after that will the Vostok restoration where I will demonstrate how they are used. In the meantime - if anybody wants to build one themselves, I have attached the plans to this post. If you do make one then post pics Pallet Warmer Plans.pdf1 point

-

Being a pirate is no longer a requirement on immigration application. Arrr1 point

-

And also, please take time selecting proper size dies, and use glasses cleaning cloth to protect the glass.1 point

-

Or instead of x-large triple/triple you can get small coffee ? Selecting a glass and gasket can be a bit tricky, you may want to purchase two sets that are close in case you have doubts. The bottom line is that you should not be forcing the I-shaped gasket inside the seat. It should just land almost without any pushing and bending. And the glass DIA should be the same or extremely close to gasket's ID. Also, the seat must be perfectly clean and flat, and the glass should be also set flat (not under angle) before you press it in. Otherwise you will hear a cracking sound and that would be no good. I am installing TAG Heuer glass tonight (10 GBP small Sapphire). I don't believe you need to spend that much for your watch. Go with Mineral Glass.1 point

-

That's a half round plier. It's used for wire bending. Probably used more for jewellry making. It could possibly be used for bending click springs.1 point

-

There is the tiny possibility that they deliberately put plastic parts into upset watchmakers. Or it could be because they're easier to manufacture then the conventional way. Unfortunately making watches is all about doing it cheaply and plastic parts are unfortunately cheap. It would be helpful if you had the technical communication it explains the lubrication. Problem with engineered materials which is sometimes a clever turn for plastic is plastic doesn't like a lot of things. I would use a water-based cleaner like may be simple green. You may build a follow up with alcohol rinse but. Then of course no heat air dry. Then alcohol rubbing alcohol should be fine but if it's not fine you use at your own risk. 618_ETAF04.111.pdf1 point

-

1 point

-

@DanteFalcioni I think you can get by with the cheap dip oilers for now (the set of 4, although you probably won't use the big ones). You need Moebius D5, 9010 (for 4th and escape pivots), 8200 for mainspring, and 9415 (for pallet stones). You also need some heavy grease like Molykote DX for the cannon pinion. About the movements, personally I would start with a manual-wind with sub-seconds and no date complication. Just the most basic watch, if I can put it that way. It doesn't have to be a 6497. For example, the ZIM 2602 is dirt cheap (although again, it may not run that good to begin with because it's an old Russian movement). The upside of the 6497 is that it's a pocket watch movement, and the parts are nice and big. Not that you won't get a calandar mechanism back together with enough pictures, it's just going to be more of a challenge and not that illustrative while you're trying to understand how the basic machine works. I would also do yourself a favour and buy a combination India stone or Carborundum stone, plus one of the little wheely screwdriver sharpeners. It's easy to nick or break the blades and there's no sense replacing them every time. Mainspring winders are something to keep a look out for, but not absolutely positively necessary as they are expensive and you can teach yourself to wind the mainspring back in by hand. This is generally frowned upon as it tends to distort the mainspring, but if you're focused on the expenditure right now then it doesn't hurt to learn the skill. Some people may disagree forcefully with this. Good luck! It's an exciting thing - just savour it!1 point

-

The real problem is that in most cases these are just bits on the screen, one can gather all possible numbers and references and that wlll not help a ready part materialize. The good news is in this case, Japanese lady watches, donor watches are very cheap and easily available. Like USD 2 a piece for a lot of 10. The best place to get them is Yahoo Japan auctions via a buying agent. Note the most advertised agent is not the best or cheapest for sure.1 point

-

You can likely recover most of your content. Formatting only touches tables not data. There are good recovery utilities even before going to the paid ones. Good luck.1 point

-

I am sure you did not expect Russians to rely on Moebius oil supply, thus they had, and still have, an excellent watch oils selection: МЦ-Н replaced МЦ-3 МН-30 replaced МЗП-6 МН-45 replaced МБП-12 I also have МН-60 for use in -60C to +50C (in case you are visiting North Pole and then Global Warming hits you hard ... unexpectedly) I will definitely read your service walkthroughs for 24xx calibers. Thanks! Those in Bold are mineral oils, no longer produced (i believe).1 point

-

Thanks so much for the reply John! I'll definitely have to look into getting a working movement to practice with, I actually already have a Seiko 6349 23J (which actually might just be a 6309 17J but with the 6349 bridge) that is running, do you know if this movement is easy enough to start on compared to the ETA 6497 clone? I'm looking into getting a good set of screwdrivers now, I might go for the Horotec set. On the subject of oiling, do you have any personal recommendations for oiling tools? I've seen a variety on Cousins and they don't seem too expensive in general unless you opt for the automatic ones.1 point

-

Amazing info. Thank you! I had no idea Russian watch oils were available and could be ordered ?? I Wouldn't be surprised if they account for a good part of the "punishment" these watches can endure! In case you've missed it, here's a link to another favorite Vostok of mine, plus my "declaration of love" for the Vostok 24XX calibers. Vostok 2409 Service Walkthrough - Your Walkthroughs and Techniques - Watch Repair Talk1 point

-

I have to agree with this whole heartedly because coming from a guy who has always worked on older waltham/eglin movements this is almost always the case even when using the same grade and calibre. However I have swapped parts between 554 movements and they are supposed to be interchangeable but as John stated they rarely are. My rule of thumb is always keep the wheels and top plates together as much as possible. Its not always how they were made but how they had worn down in the last 80 years. Some pivots could have worn down much more or even differently than others. But not sure why you have to swap these because I have used civilian curved 554s and 555s with a flat military dial and hands. I suggest you keep the nickel black movement, service it, then just swap the balance only. I would test the balance first to make sure there is no variances in the jewel heights, because that is also an issue. But its an issue that can be rectified with shimming or jewel pushing. The Mil-spec nickel black movement should be preserved esp if the watch is military. the hands should also be interchangeable.1 point

-

I knew you would ask! ? Here is choice of oils for Poljot, Vostok and similar watches: 8200, 8141 and МН-45 (Russian letters М & H (H is N) ? "Масло часовое МН-45" http://www.zarechie.ru/catalogue/oils/instrument/mn-45.html I could not get replacement for 8200 and 8141 to be Moebius-Free / Independent, but 9010 has been successfully replaced by MH-45. No complains at all.1 point

-

I have worked on very few mov.ts with Incabloc, on the second one the hinged spring spontaneously left the block. The problem become not that it got lost, but to refit it without moving the block AND without breaking the spring. That and too many other "unfortunate" episodes have taught me to never leave anything to chances.1 point

-

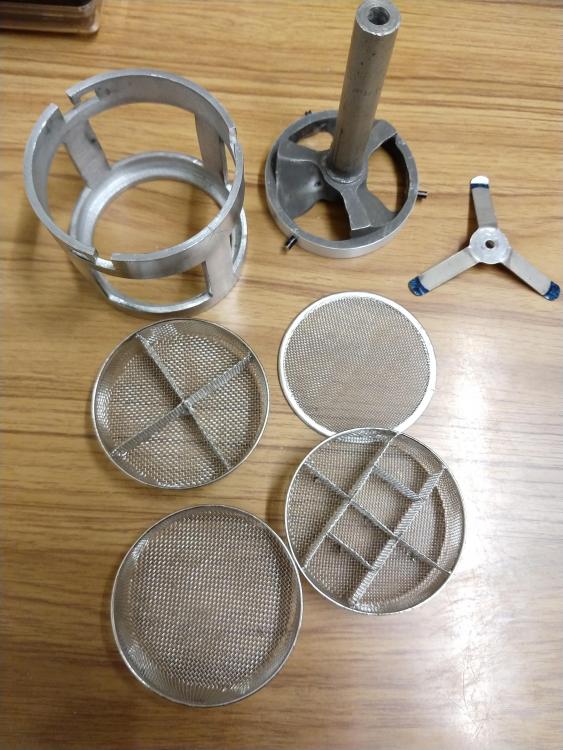

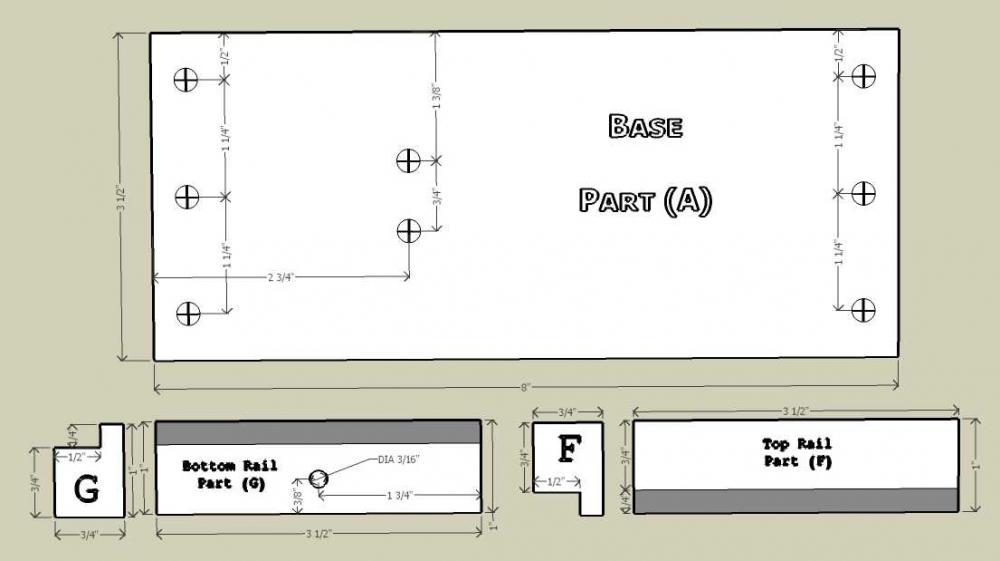

Good Morning,Well as promised I enclose photos of my basket set up after modifying a spare National Watch Cleaning Machine basket shaft.I turned the head down from 66 mm to 64 mm to accept the Elma basket frame.I have to trim the spring down to size to hold the baskets firm but otherwise it's turned out fine and after cleaning the internal dia of the shaft from all the corroded alloy it fits my machine like it was made for it.Regards and keep safe during this tough time Seth.1 point

-

Probably a good idea to loosen up one screw and remove the stud from the balance cock. It would be easier and safer to clean the hole jewel and to remove the cap jewel holder. These things could be tricky to remove. Two photos of the balance, one from each side would be helpful. Good luck!1 point

-

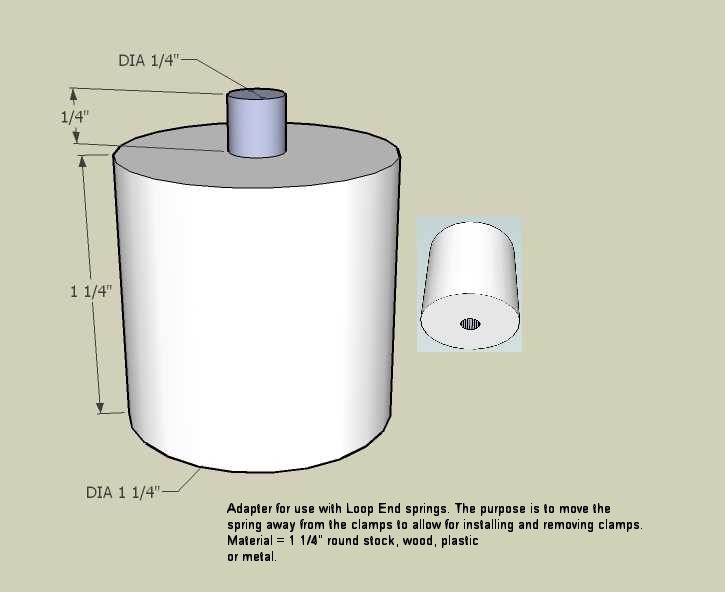

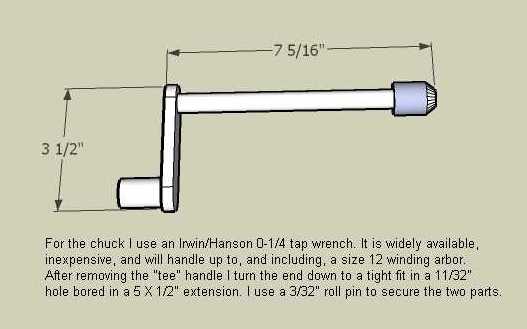

Letter from Joe Collins, Thanks for inquiring about my mainspring winder. I do not make the Winder any longer. Here are the Plans I do not supply the sleeves for capturing barreled springs. These can be bought at Merritts Antiques for about $40 US. (9 piece, Ollie Baker type) They can also be found at TimeSavers and other materials outlets. A video of the winder in use can be found here: http://www.youtube.com/watch?v=6uOsZ_ZIvLc Thanks again for the inquiry, Joe Collins Email: [email protected] @@@@@@@@@ Update from Al, Here is a gentleman that built a winder that explains what he chose to do. I do not like his copper clamps for the barrel, they may scratch the barrel. But if lined with leather or made of wood is another way to accomplish the task. Use a Tap handle which has a 4 jaw chuck to grip the four sided mainspring arbor. https://www.youtube.com/watch?v=S5XxM5PwSNM&t=149s And another variation on a theme using mechanics tools. https://www.youtube.com/watch?v=Qczmx8I1zzI He also shows the purchased components from stores. There are many other YouTube video's in case you want to browse other clockmakers solution to a problem. Clock repair supply houses: Merritts.com Timesavers.com1 point

-

1 point

-

sure did. nice work. Enjoy! Feels pretty good, don't it. Warning: Addictive!1 point

-

1 point

-

You can get a bearing/gear puller from AliExpress. They are not expensive.1 point

-

What a combo! Made in USSR & USA flag! ? Very well done! Ideology comes and goes, and in many cases someone else's ideology is being pushed on other countries "for fun" and to allow it "self-destroy" and get robbed and reduced. What did not completely work in the Paris Commune 1871, was tested on Russia in 1917. Who's ideology that would be? Russian? I don't think so, unless these three names are Russians: Friedrich Engels, Karl Marx, François Marie Charles Fourier. BTW, do you use 9010 on Vostok balance?1 point

-

Hi I figured out that the regulator was stuck because, the two screws holding it, were too tight. It works now. But nevertheless, the cap jewel seemed to be a wrong size and I guess it broke due to the tightness of the mentioned 2 screws. Moreover, when I loosen the screw, attaching the balance and spring to the balance cock, if looses time as well, wherefore I get better timekeeping but obviously only on one side, as I need a new jewel. I wonder if Cousinsuk have such in stock.1 point

-

Hi Have a look at Watch O Scope sit there is a lite version which is free but no printing, you also have to build or obtain an amplifier and stand I have build both and they work ok no problem worth looking at for sure1 point

-

Depending on your ability with computers, there is free software that should be able to do everything you might want from a timegrapher, https://github.com/vacaboja/tg I found the microphone from my phone earbuds works quite well.1 point

-

For a starter screwdriver set, one of the six packs of the French-made ones worked well for me starting out. I think it was 30 USD a couple of years back. I just added sizes later as I needed them. I still use them as I've dressed them for wide-slot screws. I use another set of Horotecs, which I prefer, for narrow slotted screws.1 point

-

Hi Helvetia tech sheets are hard to come by the only reference is the one you posted Ranfft. I will have a trawl round but not hopeful.1 point

-

I find the timegrapher extremely useful but it is not essential at the beginning. You need to get good screwdrivers, oil, and a way of applying oil. I have a Horotec set of screwdrivers that has proved itself very useful. Don't skimp on the screwdrivers or tweezers especially! You also need some way of cleaning parts - a small jar of lighter fluid and a paintbrush should do it. pegwood would also be handy to get old oil out of jewel holes. One thing that is important to say is that the Timex may not be the best choice for the first one to work on. They are not designed to make service easy - in fact, I have heard they are quite difficult. I would strongly recommend getting a Chinese clone of the ETA 6497 / 6498, which can be found on eBay for less than $50. I don't recommend trying to fix something until you can get back together and working something that was working in the first place - if you have no idea why something isn't working then it will not be clear whether you have assembled it properly or not.1 point

-

There are plenty of videos on you-tube describing how to remove springs without a winder, but you should not be tempted to emulate them pulling the spring out with pliers cause the spring to cone, this will not enable the spring to be replaced without it pushing up onto the barrel cap, causing it to rub on the cap when wound and running, power delivery from the spring will be uneven and regulation or the clock will not be possible, I have had to replace quite a few springs that are coned it can cause excessive wear to both the barrel cap and hole. If you have not got a mainspring winder you could remove the arbor and soak the barrel and spring in a water free solvent for a few hours dry with a hair dryer, it will not remove all the gunk this way but it should be cleaner. If you do decide you may be doing quite a few clocks there are threads on this forum that describe how a mainspring winder can be made quite cheaply or there are commercially available winders, a Ollie Baker, or Webster winder are the best of the bunch for ease of spring removal, I have a Ollie Baker and it is sturdy enough to remove large fusee springs but requires quite a bit of effort, normal springs are easy to remove with one.1 point

-

Hi mike, Merry Christmas and a happy new year. Circles appear non-concenteric, might need more than a tweak since we don't see the portion hidden under the cock. I routinely remove the balance complete, the two little screws and end stone to clean and check the condition of the jewels and lube. Soaking the cock in Coca-cola 24-48 hrs never faild to penetrate the thread of little screws which gurantees their safe removal with incrediable ease. A close up of coil's top view be useful. Regs Joe1 point

-

I had a need to safely remove a C clip holding in two pusher buttons and thought I would share my method on the forum. I had a spring bar removal tool with a solid pin on one end and a scalloped forked end on the other. I placed a small bit of rodico on the bottom side of the clip and turned the C <- gap facing up. As you can see in the picture, I simply used the forked end that was the perfect gap to push off the c clips. I installed by getting the clip in place, C gap facing down, and used a #200 flat screwdriver blade and carefully pressed down to lock in place. I used the case wall to keep the c clip and push button slit in line. Don't attempt to push the c clip back on with the button pressed all the way in, use the wall of the case to help keep the clip straight in line. Hope this helps someone.1 point

-

1 point

-

So, my external hard drive was just about full. It holds all my watchmaking files, from various makers, a lot of it no longer findable out on the net. Also, years of photos, including the raw magazine articles that were eventually published; all the support work for my BMW engine swap manual.. Literally like ten + years of research and collections, including lots of irreplaceable stuff. The driver/cause was a new external drive. The plan was to move all but the watch stuff over to the new drive, and take the old one home for use where I do my watch work. The new drive had a problem while formatting, and while trying to sort it I inadvertently formatted my old drive. So, if that doesn't make you feel better, not much will.0 points