Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/20 in all areas

-

According to my mentor, it's to remove the barrel lid - I suppose by prying in some way. But the only time I tried that on a desk clock, both for the mainspring and alarm barrel, it was clear that would have not worked and just ruined the lid. So I simply pressed on the arbor and removed the lid without any problem. Another possibility is that it's for lubrication?2 points

-

My personal opinion for quartz watches is that if it keeps good time and gives a good amount of life from each battery then leave it as-is. They do not suffer bearing and pivot wear like mechanical watches do. And some of the parts such as the hands tend to be flimsier and do not always handle repeated removal and refitting as well as more rugged parts. If you do need to clean it, then this is a simple caliber - the entire going-train is underneath the bridge with two screws holding it down.2 points

-

Hi, I hope you all are fine Those days I found an old omega f300 cone case sleeping on the drawer polished as a mirror when I bough it, many years ago cheap as scrap. I decided to give it a try and among other tasks, rescue it's finish, and discovered that it's impossible to do it by hand, each run marks his scratches in a different direction giving even worse impression than mirror polish, so decided to take the challenge of scratching it in a radial and homogeneous pattern. I read somewhere a post about redoing an Omega cone surface, and found it really difficult, doing supports, regulators and so on, and requiring even a grinding machine, impossible and not to inspiring for me. Saw even someone using a dremel that took the hell out of me. Below it's the simple contraption that allowed to do it, maybe you can find it useful for your projects, it's cheap, easy to build and makes the redo a piece of cake. All the secret is to guarantee that sanding paper (or whatever you use) attacks the surface always in the same "radial" direction, this is impossible if you grab the case or sand paper by hand, any minor deviation will shine as a photo flash ruining the look. So to do it you may elaborate a complex rotating support, or take a simpler approach. As the watch is round, almost any "support" that "fills" the case will allow to rotate it around that position keeping the angle and relative position of the case. So with just a few sticks laying around I've been able to "build" a really simple "fill" to firmly support the case in a fixed position, allowing it to rotate freely but preventing any displacement up down, right or left, so keeping the case in the same relative angle no matter how much you rotate it. The second challenge was to make a sanding "device" to scratch the cone wall without any lateral displacement, so, just up and down motion along the cone wall, with any lateral distraction. Again an old lumber piece and a single carpenter clamp did the trick. Below are a few photos of the job, cheap, easy and efficient, I hope you find it useful. It was fun to repair a watch case with lumber, sand paper and carpenter tools, still thinking what use give to the hammer. My apologies, but don't know how to lay the photos in their place Ask if any doubt. Cheers and take care Ricardo1 point

-

I am "hammering" one right now! Elgin pocket watch. Another tip: do notice roller's and hairspring stud's position in relation to balance wheel. Usually someone already made orientation marks to simplify life for you. Good people... kind, friendly ?1 point

-

Personally I think overhauling a quartz is important. This is because I've seen worn bearings, over oiled calendar sides that spread to the day date wheels, rust forming, moisture or grease on the dial outer edge where it meets the chapter ring that can pull paint in future if worked on, worn centre wheel holes that may require jewelling, it helps battery life, it helps lower circuit consumption which may increase life span and is just a good thing to do to maintain these things even if not subjected to the same wear as an auto. There is still wear and good reason to check all is well, imo.1 point

-

this might be worth a look at https://mitka.co.uk/2019/11/22/service-bifora-115-skin-diver/ cheers1 point

-

1 point

-

No, just gently compare by hand the force needed to bend it to an half circle or so.1 point

-

Mark use a Platex but the principle is the same . I use the same method. So far it has worked fine. I cracked a balance wheel some time ago. But not sure it was my fault.1 point

-

1 point

-

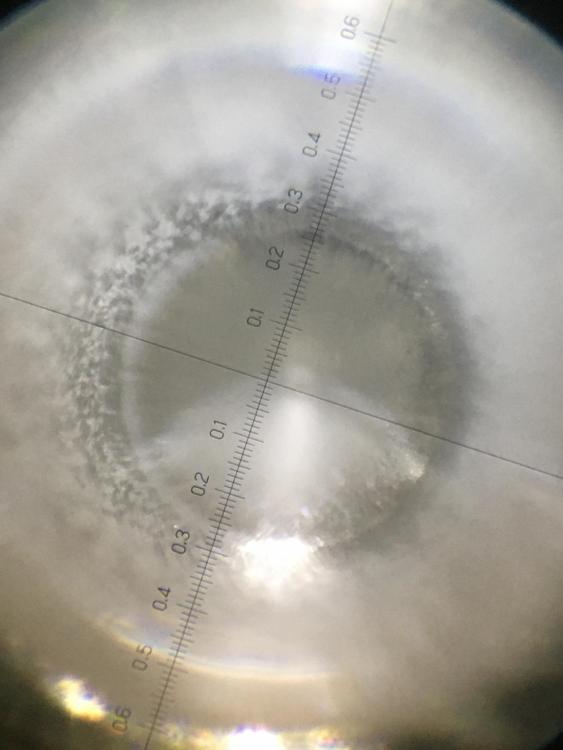

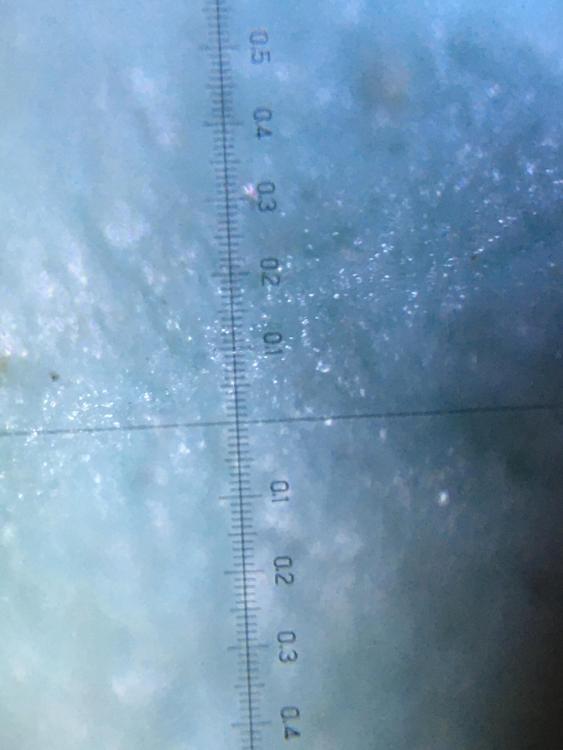

I forgot to add the photos of the jewel itself. I reckon it’s possibly just a very small (and expensive!) sapphire burnisher. That said, I tried it and it appears to work. My only question surrounding it is the suitability of the radius it creates for different widths of pivot, but we shall see. Two photos attached - one is straight into the centre of the jewel, and the other is looking off-centre at an angle to capture the surface.1 point

-

Yes that tool just needs a little oil to work. Abrasives would only damage it.1 point

-

lubrication equipment like the dip oiler and the cup you put the oil in yes you can get those for less than $50. But if you want to include the lubrication in that $50 then that isn't really going to happen. We could recommend some super cheap lubrication but it's kind of like buying a supercheap watch tools it's not really a good solution it's a waste of money. To give you an idea you can look through the pages at the link below. I would initially just skim through the whole thing don't worry about the fine print and then you can go back and decide which ones you like the best. That's because there's a lot of ideas opinions and views on the subject. https://www.watchrepairtalk.com/topic/83-lubricants/1 point

-

1 point

-

I would only recommend changing the back cover gasket and crown wheel gasket / O-ring, and apply Seiko silicon grease to make sure your watch is water/air tight.1 point

-

Probably here: download your parts list https://www.cousinsuk.com/PDF/categories/3127_Seiko 7546A.pdf1 point

-

Completely closed.. It was a very strange place: the guy was fixing watches and frying eggs & sausages next to his workbench :-). Did not look very organized, but was busy ?. I should be in Edinburgh now as we visit Scotland every year in December, but this year is different. There is very fancy place on 87 (?) George Street. They sell nice watches now. Used to be called "Brook and Son", I believe, and about 100 years ago they were selling first Submarine wristwatches by Tavannes (watertight - how do you like that, Rolex? :-).1 point

-

I think this top has been covered in great depth already. As a bare minimum, I would say you could get away with using a light oil like 9010 and a heavy oil like D5. And you’d need at least one fine oiler and preferably also a thicker one.1 point

-

1 point

-

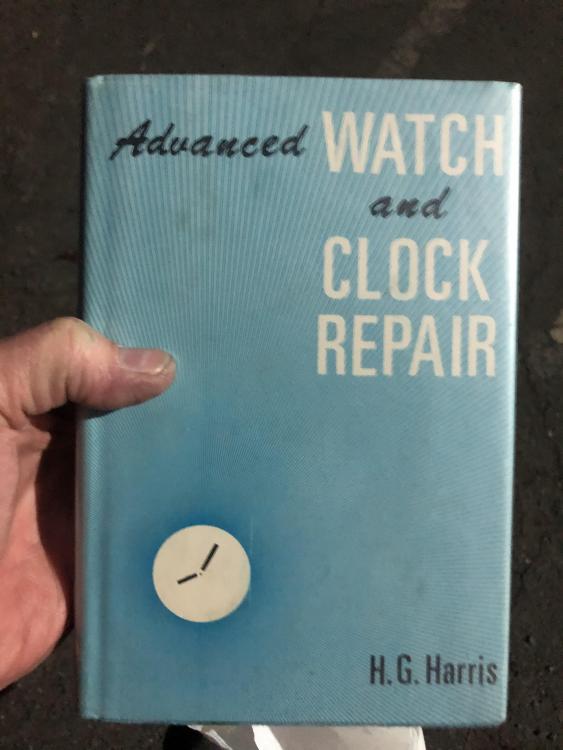

There are countless movements that get posted on here for I D many that don't have any markings at all, the only way is by looking at the keyless work or going on line, not many on here have old reference books. I posted my Bestfit catalogues some time ago on here for people to download but even so they don't have everything. Its a must, so who ever you are make it happen.1 point

-

Welcome! But, you will never stop collecting tools... they just get more obscure and more expensive.1 point

-

This post brought back memories. That's practically the exact same movement that was in my old '76 Chevy Camaro. Man, I miss that car. It was a blast. And yeah, with the clock I had to add a couple bushings, and I made a new brass contact, a bit of grease, and then it worked fine. And it was fairly accurate too. I remember you always knew the clock was working because, every now and then, you'd hear the solenoid quietly go *thunk*. I wish I still had pictures of that car. It was a hot rod by the time I got done with it.1 point

-

Initially I had it on a fairly boring tan leather strap, which sort of worked with the red, but then I grabbed this midnight blue one with red stitching. It actually echoes my ThinkPad laptop's styling pretty closely too. I'll leave you to decide if Timex were ahead of their time, or Lenovo are harking back to a different era.1 point

-

Landed a trio. Paid $0.99 for the two Hiltons, and the seller threw in the Benrus for free. Shipping was $15, which is my personal absolute limit for shipping, but I figure $0.33/watch makes up for it. Plus, they're all fully jeweled Swiss movements in stainless cases, and one was even ticking on arrival (with a wind). Another started ticking after I opened it up (must have shook something loose). The Benrus is DOA so far. It's open through crystal, and the movement looks decent enough. Didn't investigate at all, and just closed it back up though. Had to cook up some dinner before play time.1 point

-

This recently joined the club, and I posted about it when it arrived. It went back under the microscope this evening, having mysteriously stopped dead. The culprit was a tiny fibre which had worked its way into the balance, causing it to be wildly out of beat. Once removed everything was back to normal. I've included a mystery mechanism shot, since I couldn't actually identify what rather pedestrian pin lever is powering this one. It is stamped [RE], One Jewel, Ingersoll YY, 1513 Swiss, none of which elicited anything useful from aunty Google. I previously stated it had no jewels, but it apparently has one. It is also remarkably quiet for a pin lever. Often you can hear them from the other side of the room, but not this one.1 point

-

Another 1p watch. This time a "Beta" LCD Chronograph. This is from the early era when LCD modules were made on a ceramic substrate. Later watches use more conventional thin FR4 fiberglass circuit boards, but this has the military style silver printed track ceramic substrate type of board. There were quite a number of issues, including a corner of the substrate which had cracked off taking one of the tracks with it. You can buy conductive silver paint for this kind of repair, and a little superglue and some silver paint, and that was fixed. The zebra strips were also filthy, the battery contacts covered with the usual assortment of alkaline metal salts caused by a leaking battery, and the case and glass were pretty beaten up and heavily scratched. There was only about a couple of inches of the original strap with it too, so the one on it is a "new old stock" replacement. All of the issues have been attended to (although I drew the line at re-plating the case), and now it is quite presentable, and seems to be running just fine.1 point

-

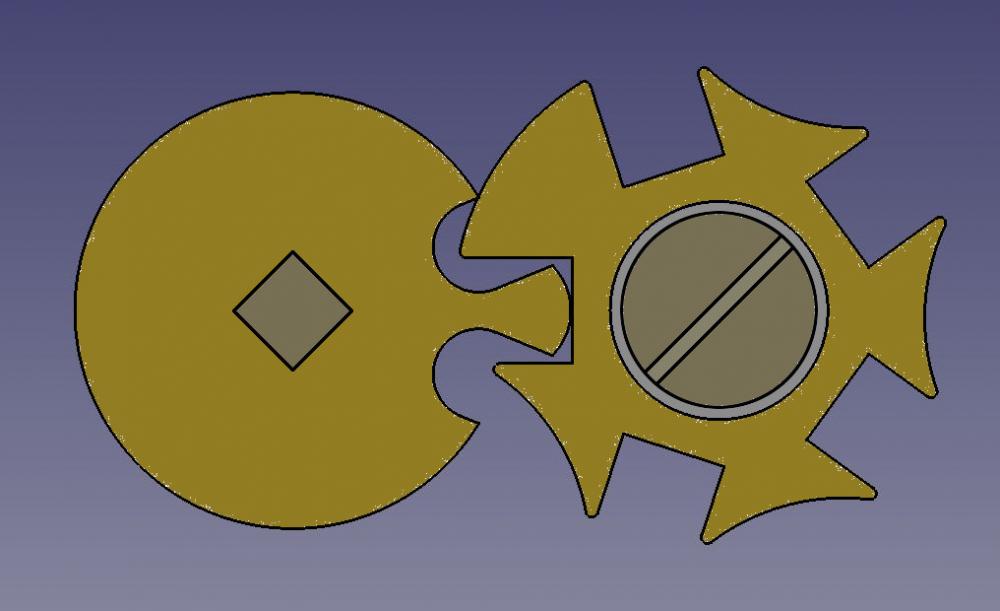

I had a look through my various books and a trawl round the internet. The way I understand the Maltese cross stop works is as follows. When correctly positioned, the stop works will allow the barrel to be wound a complete revolution for each square cut out in the cross. In the case of the one in the diagram above that would mean that the cross allows four complete revolutions of the barrel before the stop works is impeded by the lack of a further cut out, assuming the barrel cam is turning counter clockwise and the cross therefore turning clockwise in this case. If this is the correct, then the cross needs to be returned to the zero position if tension is let down on the main spring, otherwise, if the spring was previously fully wound, then the cross will immediately impede winding as the stop works would still be in the stop position. In other words, there may be nothing wrong with the main spring, it may simply be the case that the tension had been let down at some stage before I received the watch, and therefore, with a little light lubrication and the correct re-positioning of the stop works, it may in fact be fully functional. Does anybody know if my analysis is sound? EDIT: I also noticed that most of the pictures I have posted of the case have a very white/silver appearance. This is due to the cold white of the light I use for inspection. The case is in fact a much warmer rose gold coloured. I'll see if I can get some good pictures in daylight once the watch is running.1 point

-

More in that particular subject. I took a little time this evening to see what ails the little ornate pocket watch I mentioned the other day. Quite a lot it seems. The hand setting spring for the crown/clutch arrangement was broken, the canon pinion appears to be welded in place, and as a result I can't extract the barrel to see why the mainspring wont take any tension. I set about the spring first, and that seems to be OK now. I don't have the correct stem, but I have something close, and I'm going to dig through the rest of the junk pile at a later date to see if I have anything better. If not, I may set about trying to make one. (That way madness lies no doubt). I also spent a little more time straitening and cleaning the hands, and while they are not perfect, they are now quite presentable. So one step forward and two back so far. But... I re-examined the case, and it has a squirrel on it, which means that it was manufactured post 1880 and the K14 plus the squirrel means it is almost certainly 14K Source -> here <- So one squirrel rather than two, but I'm not complaining. I must admit I suspected it was, as an awful lot of effort has gone in to hand engraving the case. Too much perhaps for a plated one.1 point

-

1 point

-

Hi As explained by Nicklesilver eplilame/fixodrop is a lubrication aid heve a read at the attached document for its uses and data sheets. epilame.html1 point

-

just FYI, we have a section here where is considered polite for new members to introduce themselves.1 point

-

1 point

-

Today I'm letting may father's US government issue GG-W-113 stretch it's legs. It has a genuine Hamilton 685 manual wind with hacking. I got this for him last year as a father's day gift. The date on the back of the case is June 1969, the year he was there, and exactly 50 years since he was there plus the month Father's day falls on. I can be thoughtful... No matter what my wife claims! It had random issues that I thought were minor, but then it flat quit on him. It has been on my bench since before Christmas waiting on me to troubleshoot it. Yesterday, I finally had some time to dig into it. Turns out the lower balance jewel Chaton had moved and just needed to be pressed back some. I had to guess as to how much to move it. Unfortunately I don't own a jewel press, very nerve wracking trying to push on the Chaton and not over do it. But it seems much better now, no stalling or anything. It's keeping excellent time. I gave the Crystal a better polish too. My first attempt was kinda half assed. So, I'll hang on to it and let it run down and sit for a week or so and wind it to see if it takes off. Fingers crossed.1 point

-

Just because it's not in the book Every stone has a statue inside it's up to the sculptor to find it .1 point