Leaderboard

Popular Content

Showing content with the highest reputation on 11/30/20 in all areas

-

2 points

-

2 points

-

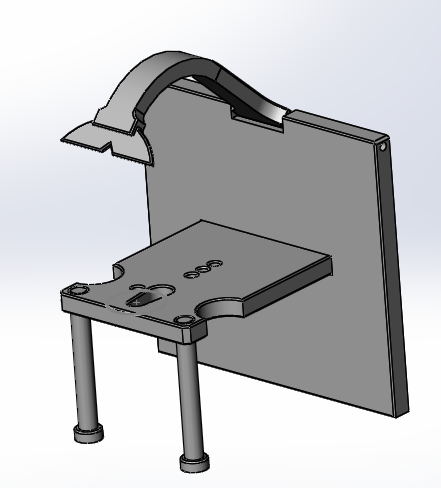

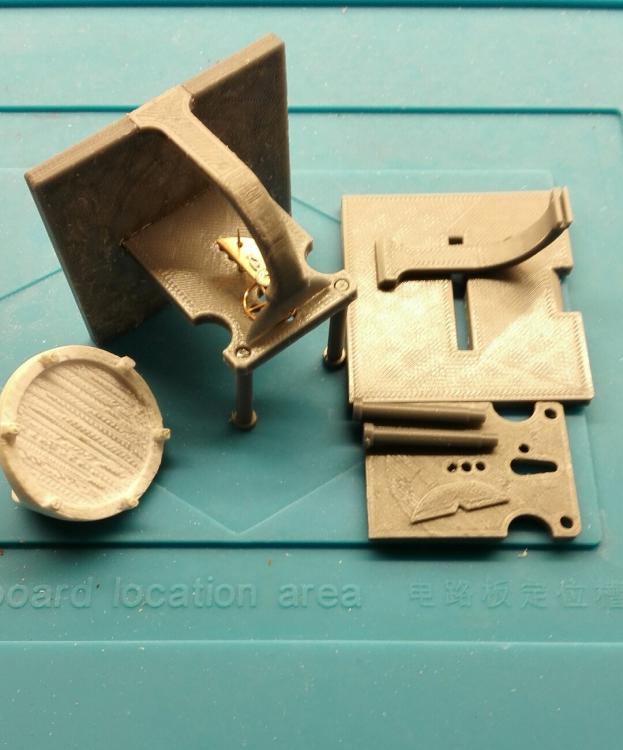

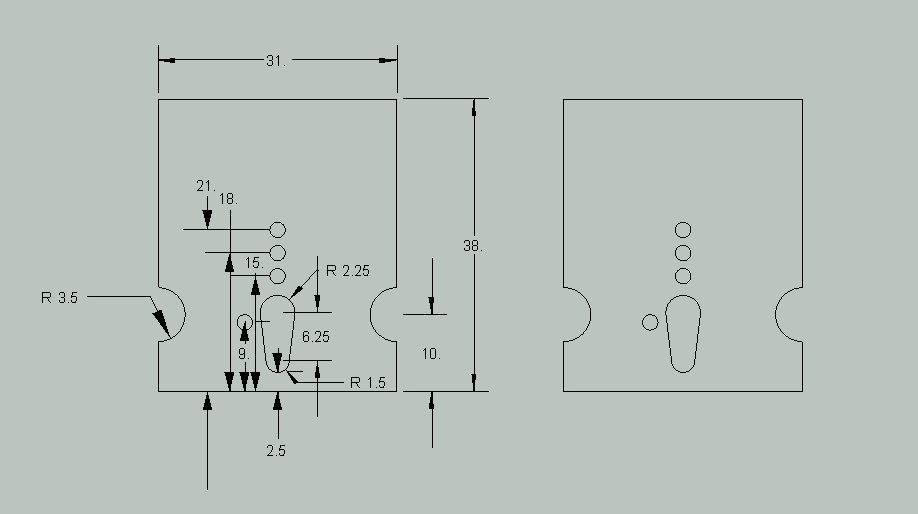

Ok I didn't make a 3D model or anything, but laid out the most important part, the plate. The back piece is 40mm x40mm, the arm can be anything hinged any way just so that it comes down over the balance rim. The support piece for the inside of the rim can also be anything, on the old tools they were V shaped and pressed into a hole, on my friends it's a simple pin that has a notch filed in it. The notch/V permits whatever bit of screw that is sticking out inside the rim to be unharmed when working on it. The threaded holes for the pins are a 2mm thread, but anything near that would be fine. You can see in the pics that there were different ways to hinge the arm, either with a hole drilled all the way through the 40mm back plate and the arm recessed in, or with pressed in hinges, both would have been a test of the student's patience, not becuase they are necessary. A simple hinge from a hobby store for dollhouse work or whatever is fine. I don't know what the pin sticking out the front of the tool is for. They all have it, but?2 points

-

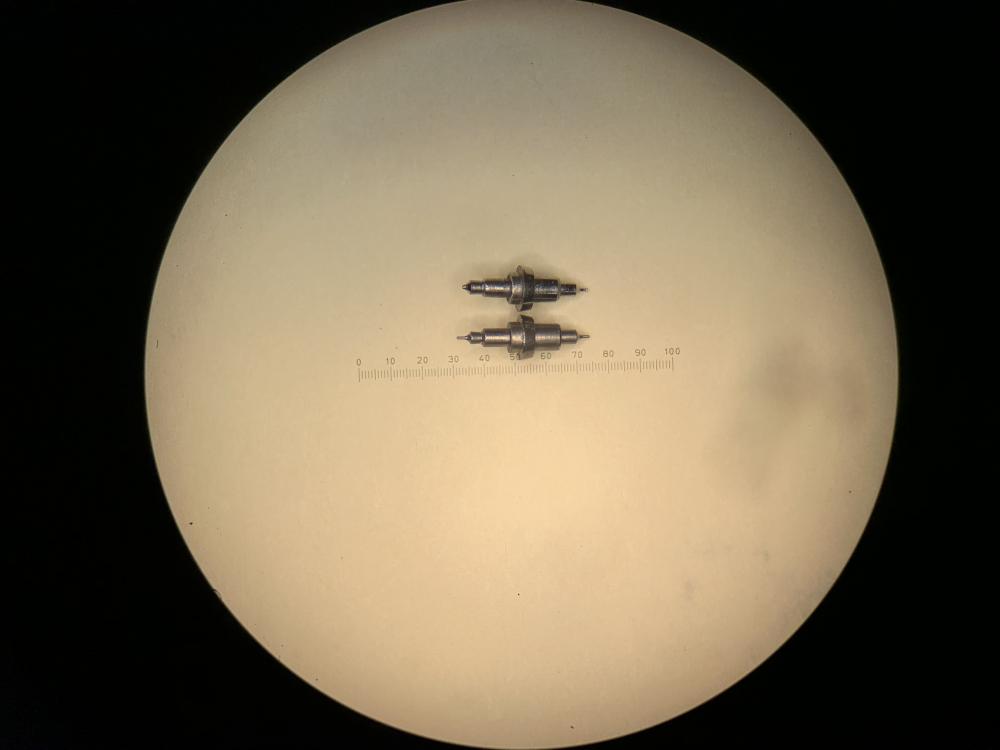

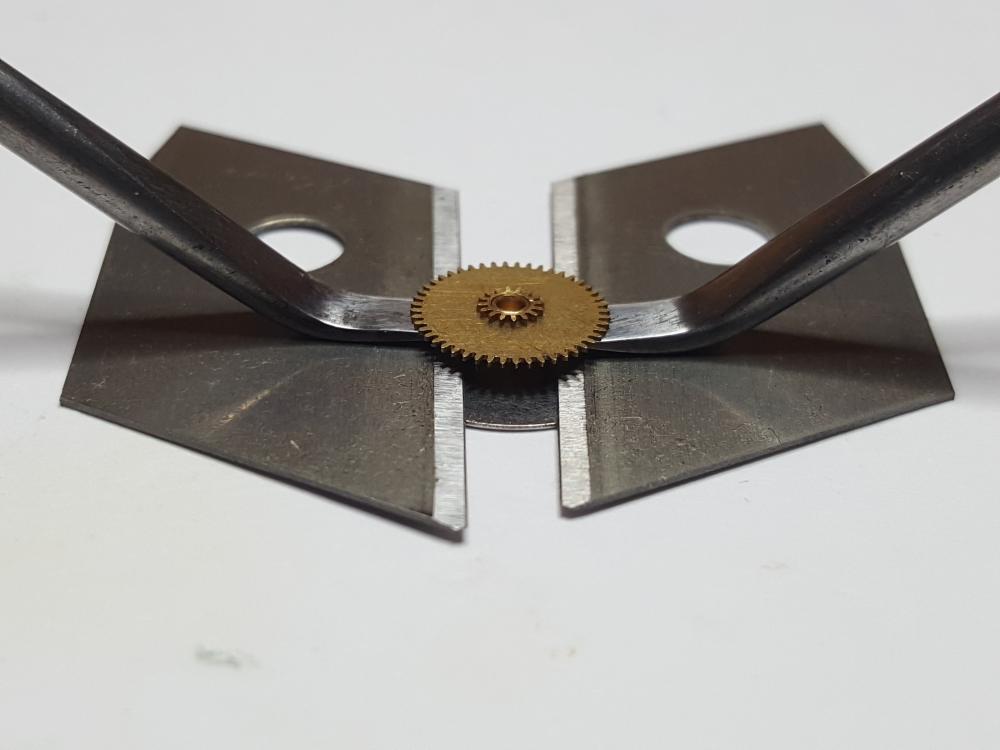

We made a balance tack in school, but aside from that time I haven't really used it. A much handier tool is this one which was a standard tool made in watchmaking schools here. The "tack" is a threaded pin which can be placed in one of several holes (usually 2 or 3 sizes of tapers on several pins). Choosing an appropriate pin and hole location, the balance isn't hanging as it sits on the table, so no risk to the hairspring. The overarm presses down on the rim, which is supported from the inside by the little "V" so that work can easily be done on screws (it's a non-screw balance in the pic but you can see how it works). Access is also easy and safe for moving hairspring collets to adjust beat. Bergeon made a similar tool at one time but it hasn't been available for some time. If mine ever disappeared I would stop work until I had made a new one, it's that handy.2 points

-

This is really nice! Can 2-d drawings be made from the solidworks model? If so, I can quote having these made. I certainly want one, and the more we do, the less per they will be. Aluminum will probably be the least expensive, but brass is what I would like to use. Perhaps chromium plating after polish for that over the top look (although we might want to lightly sand blast the top plate so it does not glare at us when working). Anyone interested? PS I think the pin sticking out is perhaps a guide for the file?1 point

-

Anyone with a boat here in the US should be able to put a dollop in a baggie, in a baggie, in a baggie, and ship it over to you. Should be enough for 1,428 watch movements, 827 clocks and that pesky door hinge that just won't stop, with enough left over for "other" projects. Of all the money-sucking hobbies I have, boats is not one of them...1 point

-

One of the missing ingredients as gleaned from the various - Extra Virgin - Swiss gold bar pressings oil - hazmat data sheets found online, that might be worth investigation is barium sulphonate. This is used as a rust inhibitor. I suspect it is probably not strictly necessary, since not all of the hazmat sheets mention it. If it can be found relatively easily, then a few drops (1% or so by volume) might provide a small measure of additional protective not so secret sauce for my "Horse Lineament" branded not so Swiss substitute. It also seems to be a common additive in motor oils, so it should be fairly inexpensive. I'll need to do a little digging around to see how easy it is to obtain. Maybe it might be worth checking that it doesn't have some other nefarious use. After all, I don't want to end up on a "watch" list somewhere ?. (Feel free to groan and throw soft fruit).1 point

-

1 point

-

I also thought so as some numerals do have a hint of what used to be lume, but others are perfectly clean. It could be luminescent that fell off the minute and hour hands, or they were in fact lumed... No one seems o know for sure as there was no Internet in 1930s... people did not snap gazillions of pictures of their watches and did not post them on-line ?1 point

-

1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. There are two main striking movements with cuckoo clocks rack striking and count wheel striking. As KarlvonKoln mentioned could you show the movement the back plate will do.1 point

-

Yeah, I saw the post about the balance staff behaving like it's too short. On the surface, it does sound like cutting a new staff is in the future. Rotten turn of luck there. I do wish you luck on that balance; here's hoping it turns out perfect. And I have to say, without the prongs of a "moustache" to snag on things, a round counterpoise is probably easier to deal with. But even still, it's just *one more thing* to bump against other parts on the way back in. And I was tired. And the Elgin is running well, so I didn't want to start from scratch with that. But I have to say, there is something indescribably *different* about the sound of the Elgin's ticking, compared to all my other old pocket watches. It sounds more...definite somehow. Just different. You'd have to hear it. It's hard to put your finger on.1 point

-

The clock has been running, chiming and striking happily since Saturday night. Hopefully it'll continue working for 8 days. Now I'm looking for a floating balance clock like a Smiths or Hermle.1 point

-

You are NOT going to mess with the hairspring at all! Remove the balance and place it upside down Loosen up Balance Cock screw (side) by a turn or two (do not remove it completely) and separate the balance from balance cock Now you gained access to those two screws1 point

-

You will need 0.5mm screwdriver ? to remove two small screws to release top / cap jewel. Just make sure to remove the hairspring (one screw) to avoid any damages while removing these two tiny ones. Clean both, hole and Cap jewels (peg-wood gently, soft brush, then place a tiny drop of light oil on back side of the cap screw, and install it. Flip the bridge, secure both small screws - you are done!1 point

-

I would cut another balance that fits. Buying one is a gamble as it may never fit.1 point

-

Good job! A long time ago I bought a "set" of three old pocket movements for spare parts. But... decided to simply repair them. One of the movements was same as yours. Last week I finally replaced the broken balance staff. Obviously, someone previously already went through this exercise leaving hammering marks on the balance. After some truing & poising things look promising. Did you install GR6880-TB mainspring?1 point

-

1 point

-

1 point

-

1 point

-

I don't know of any real name for it. Here it's "the school balance holder thing", or le truc de l'ecole pour tenir le balancier et pont haha. With all the options for placing the pin there's never a risk of stressing the spring except when you get lazy and don't move it. I use it on pocket watches all the way down to Lecoultre 101- no way in a million years I'd touch a 101 balance without this tool! With all the interest I'll take some better pics and try to make a dimensioned sketch for those who want to make one.1 point

-

Yeah, not much help. Trial and error. you know the discs both move anti-clockwise, so correctors and springs need to accommodate that. It should click that way, and not turn at all clockwise. I’d just try it every which way until I got it. SOMETIMES the parts illustrations show the parts as they would look in the movement. That can help with “which way up” questions.1 point

-

Is there a picture, no matter how poor, at the top of the data sheet, which shows the dial side? I suspect that 2572 and 2566 are both placed incorrectly. 2572 may act on 2566 but I’m not sure. That poor picture may help. I might do better if it was in front of me...1 point

-

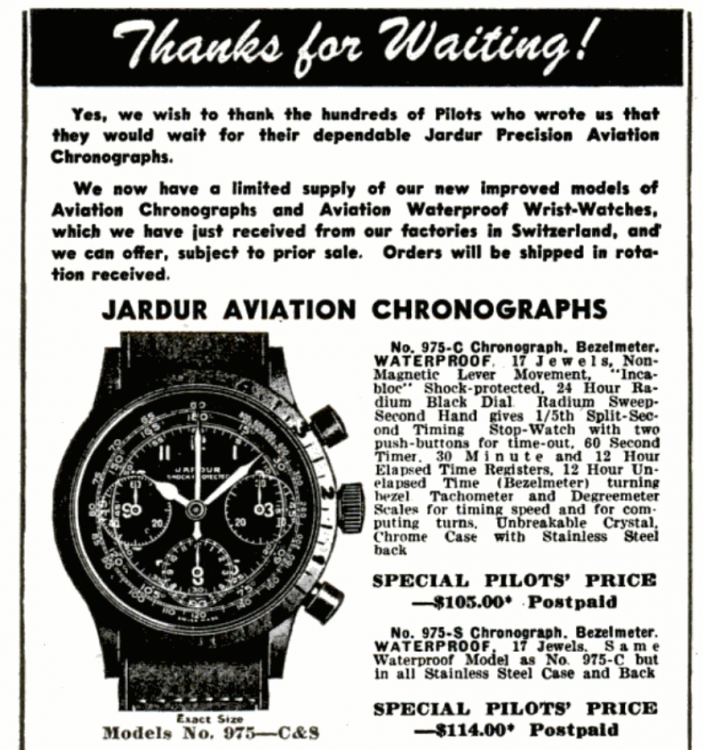

Apologies for being uncouth- I've not put in enough effort in the community lately due to a relocation, health issues, children schooling from home, and just the general "2020 malaise" but I've got another beauty in hand that I'd like to share. This is a Jardur Bezelmeter (model 960), probably from around 1945, which I picked up from eBay this week. It cost a pretty penny too but it's a piece that's been on my wishlist for a long time and this particular one ticked all the boxes. The Bezelmeter has an interesting history- from what I have read it was marketed primarily to aviators and military personal during the 1940's and according to legend was commonly sold through military post exchanges. Collectors seem to believe that the watches often served active service members. Advertisements from the period make it clear they were marketed as tool for the adventurous professional. Introduced more than a decade before the Navitimer and Breguet Type 20, it was certainly a watch ahead of it's time. It's quite a large watch at 38mm and exhibits all of those traits we usually associate with a Pilot Watch- luminous hands, blackened dial, tachymetre scale, and of course the chronograph function. Specialty features include the countdown bezel and 180 degree scale on the dial (useful to pilots executing a standard rate of turn). The movement is shock protected, the case is stainless steel and water resistant with a screw down caseback and cork seals; all fairly unusual features for a watch of this age. All the Bezelmeters I've seen house either a Valjoux 71 or 72 movement inside. I prefer the former as the earlier Valjoux 71 Bezelmeters had slightly larger cases and sported the more elegant cathedral hands. The movement in my Bezelmeter needs a service (naturally) as it only runs for a few seconds. I can't wait to get to it but unfortunately I've already got a line of other watches to clear out first.1 point

-

It's hit and miss. Some GR mainsprings come nice and shiny / clean, some in questionable condition. By questionable I mean black dots on the surface, dry / old looking packaging, which appears to be very fragile and not air-tight. I can clean them and install - not a problem as long as they are not "tired". How come that a new spring looks identical or worse in shape than the 40-year old one? That's why i was curious to see your old mainspring from 268 calibre. After reading your comment about GR mainsprings being supplied prelubed, i will cut down ? on lubrication. However, i never overoiled any mainsprings in the past. A tiny drop (not even a drop) of 8200 in three locations 120 degrees apart, and some closer to the arbour. I also put a tiny-tiny drop on the inside surface of the barrel's top cover. My biggest challenge is finding proper cataloguing information about the mainsprings for vintage watches, including Omegas, Tavannes. GR shows some conflicting / wrong info about Strength, and ID of the barrels. Marshall's catalogue is no better, unless i am missing something (would not be the first time ?). And about lume: why would Omega apply lume on the Hands Only? Was it common practice for Omega?1 point

-

Rodico works. You can also put the watch+movement holder inside a clear plastic bag, punch your tweezers through the bag to work on any fidly flyer. Mastering this ends loosing springs.1 point

-

1 point

.thumb.jpg.c3bad07d9c07214b3feed6be57856513.jpg)

.thumb.jpg.512a98d2f31fb0e62815775a2dcfef58.jpg)

.thumb.jpg.c3c10347c22a8805d05894f6831ed4c4.jpg)

.thumb.jpg.64f89d53ec799cc12d889de0a1d95d60.jpg)

.thumb.jpg.0fa62ae5732188fdc470006e0d5eb56b.jpg)

.thumb.jpg.bb3d329de86f763d62b575af8b8fec9e.jpg)

.thumb.jpg.c9d0adac64760de6f05ee2ce12653f0f.jpg)

.thumb.jpg.796f86233d594b9944f4949506b5e439.jpg)

.thumb.jpg.9940a1cd9b1ec9e8f4a09d3a4445ddac.jpg)