Leaderboard

Popular Content

Showing content with the highest reputation on 11/08/20 in all areas

-

After the loss of my wonderful girl Cookie around 10 months ago. I have taken the plunge and on Friday 6th I received my two 9 week old black and white kittens. So I welcome you to say hello to Freddie & Buster. Freddie is the one with both black ears and very pink nose. Buster is the one with one white ear and his nose is pink & black. Here are a few photos of the little devils.4 points

-

4 points

-

I am a father of four. And I am still coming 'round to the fact of my oldest daughter, Sophie, having turned 18. She will be the first of them to graduate high school, with honors at that. She has been offered "free rides" recently by a couple universities based on her grades, and has chosen Ball State for its computer science program. And, being eighteen, she immediately registered to vote so that she could (pardon the political post) vote the orange-haired fascist out. She and her friends and fellow classmates seem determined to undo all the injustice, unrest, and damage that has had such a terrible effect here in the states. Those whom I've met in this next generation have a real fire under them. It's been giving me hope.3 points

-

2 points

-

This is odd. The only time I have ever seen anything like a watch suddenly gaining time was from over oiling. The lubricant migrates to the hairspring and the coils stick together increasing the rate. Suggest that you remove the whole balance cock and clean it with naphtha.2 points

-

Buy an inline fuel line filter used for cars. Use a syringe/pump to pass the IPA through the filter (note arrow on filter for direction of flow) and collect in container and use again. If really particular, pass through a second filter (not the same one. Can run them in line).2 points

-

Hi there MechanicMike, they say that the Elgin 328 is an st96-4 movement. I have checked on ebay and there's plenty of parts available, including what you need. Hope that helps http://www.ranfft.de/cgi-bin/bidfun-db.cgi?12&ranfft&0&2uswk&FHF_96_42 points

-

For the past few months, I’ve been working on a custom dial project. I’m still not ready to show my first production examples, but the project has gotten to the point where I’m comfortable sharing my progress. I’ve been documenting this process, and am committed to sharing my process notes. I believe in open source information, and I’ve benefited immensely in watches (and in life generally) from the wisdom and experience of other people who have been willing to share what they know with me. My hope is that by sharing my process notes, I might be able to encourage other folks to take a risk and try to make something cool. I’ve never attempted anything like this, and even if this project is ultimately unsuccessful it has been a ton of fun. I'm sharing my progress and process notes on this forum because folks here have been incredibly friendly and patient with me. If you have any questions about my notes, please feel free to let me know and I'll try to explain things better. I'm happy to answer any questions, and I'll be sharing more photos as I can. I've received a number of comments from people I've been corresponding with that essentially conclude that "this is too hard to pull off". Bur for the serendipity of finding a source of half-height Seiko dials and having free access to an incredibly expensive precision saw, I would have agreed. If anyone has suggestions or concerns that I'm missing something key, please let me know. Background: Seiko & ETA 6498 Custom Watches My project started with customizing my own Seiko watches, and with assembling several custom ETA 6498 watches using available parts from Chinese sellers on eBay. I greatly enjoyed manufacturing my own ETA 6498-1 based “marine watch” using high quality components, and produced a watch that is nearly equal to the Stowa Marine Original I wanted but couldn’t afford. I could have saved more money using lower-quality components, but instead assembled a watch using high quality components (heat-blued hands, an especially nice 41mm case with a sapphire crystal, an elabore-grade ETA 6498-1, etc.) to build a final product that was high quality but still significantly less expensive than the Stowa. Here's my 6498-based "Marine Watch" On the Seiko side of the house, I’ve built a couple of custom Seiko watches using some of the really amazing dial and hand combinations available from lots of internet sellers. (My favorite seller is called Lucius Atelier.) In browsing the offerings of several different Seiko part dealers, I saw that some suppliers sold higher-end dials made out of meteorite, damascus steel, carbon fiber, and other neat things. Knowing how much I enjoyed building my ETA 6498 watch, knowing how many people enjoy modifying their Seiko watches, and being generally fascinated by exotic dial materials, I realized that it might be possible to design my own watch dials. I enjoyed reading many articles on restoring dials using decals, and thought a lot about using electrolytic-etching or laser-cutting to customize brass dials. It was at this point that I stumbled across fordite and fell in love ... Fordite Several months ago, I ran across a limited series of very expensive TAG Heuer watches that featured unique dials made out of “fordite”. There's no way I'll ever be able to afford once of those £5,500.00 watches, but I couldn't get the idea of working with fordite out of my head. (Here are some quick shots of my first fordite samples, to give folks an idea of what it looks like in unpolished slab form.) Fordite is also known as “Detroit Agate,” and it’s actual industrial waste. Back when car manufacturers used to spray paint cars by hand, they generated a lot of overspray. This overspray accumulated over the years, and hundreds of layers of overspray built up into large chunks of waste material. This stuff was repeatedly heat cured at the same time the painted cars were heat cured, and the resulting chunks of waste are durable and nice to work with. I don’t know the first time it was discovered that cutting open the waste chunks revealed beautiful and psychedelic patterns of paint, but for some years jewelers have been using lapidary techniques to create bizarre and fun jewelry with fordite. One of the things that I find particularly fascinating about this material is that it’s possible to source fordite from specific assembly lines. Consequently, one can obtain fordite in Jeep, Corvette, Cadillac, Peterbilt, and other colors. I’ve even obtained some fordite from the “Cadillac Ranch” in the Mojave Desert. It’s much softer and more fragile than “normal” fordite, but it also has a wider variety of colors and textures. In order to work with this specific soft fordite, I'm going to need to stabilize it using some cool lapidary techniques. Heat-Blued Steel I have been enchanted by heat-blued steel watch components for a really long time. I started researching how I might myself heat-blue steel with an eye towards designing and selling heat-blued steel watch hands compatible with Seikos and other watches. For quite a few reasons, this isn’t feasible (yet?), but I’ve enjoyed polishing and bluing steel pocket watch hands. As my dial project progressed, I realized that it wasn’t practical for me to add applied hour indices, and there are some significant obstacles to using film-free decals on the dials I'm making. I realized that some manufacturers of exotic-dialed watches got around the problem by attaching a short chapter ring directly to the watch dial. This solution really appealed to me, so I set about designing a chapter ring that could be cut out of very thin (0.01” or 0.254 mm) high carbon steel, polished, and then glued to the dial face without risk of fouling any of the watch hands. I worked with an engineer on Fiverr, who converted my really rough sketch of a chapter ring design into a DXF file. My first 20 carbon steel chapter rings are currently in production at a laser-cutting facility. I don't need to share photos of the steel I've heat blued here to prove that it's a work in progress. Temperature control is critical, and I'm going to be switching from a propane camp stove to a precision digitally-controlled laboratory grade Cole-Parmer StableTemp hot plate to get consistent, high-quality results. I know that large manufacturers, including Glashütte Original, are doing essentially the same thing: In this Glashütte Original watch assembly video, one can see them using a $50 digital soldering-station with a brass attachment to blue screws. I'd go that route myself, but my chapter rings are a lot larger and so I want a larger heating area with better temperature control. I'll specifically be using a 1" thick 4" x 4" block of aluminum mounted on the hot plate's ceramic heating element to ensure uniform heat distribution. Chapter ring, from concept sketch to technical drawing to first prototype. Obviously, I'm going to need to do a lot of polishing before I re-blue these for installation! [Continued ...]1 point

-

Hi this type of problem can occur if the watch is worn during golf or any other activity where the arm incurs violent movement suggest keeping it in the pocket for a week and see if it happens then, If it still occurs we need to re think.1 point

-

AH WIVES, what mine does not realize is the patience I have with watches is merely training for dealing with her.1 point

-

I do believe the elgin 328 to be an ST96, about as rare as cow patties in Texas.1 point

-

well Paul, sounds like you've got some tinkering ahead of you. now that you've got us all lathered up about it you'll have to let us know what you find. keep us updated. -Mike1 point

-

You have the other winding gear and clutch. best of the two go in building your new movements. Take it from an old timer on this , you will get a good movement out of the two. I always do.1 point

-

Sorry I didn't mean scrubbing with dry powder, use a drop of tap water on the powder, just enough to keep it wet at first, gradually add more water brush to a foam, then you can brush as much as you like. You should get a perfect shine on this as it isn't really rust.1 point

-

The fault is very likely to be found, if you are set up to show a close up vid of coil oscilating.1 point

-

We just have to wait until you unvail the keyless and date mech, to make sure you get exact same parts, as many parts as it needs you best bet would be a scrap, no big deal.1 point

-

hi GB pretty new and I'm guessing here-have you checked for magnetism, dust, nicks or dents you might have missed? is it an overcoil hairspring or flat? is it concentric? check that regulator pins are not bent, loose or missing and their gap is correct and that the spring is running thru them, centered. are you able to regulate it? hairsprings are a whole different animal and skill unto itself. I shake my head even as I type this...I try to avoid them if i can and only tinker with junk ones, you know? good luck!1 point

-

The ones I bought are NOS imported fourty years ago, nowadays you get brand new ones made in India for about the same price or less, actually with improved hairspring. What parts do you need? joe1 point

-

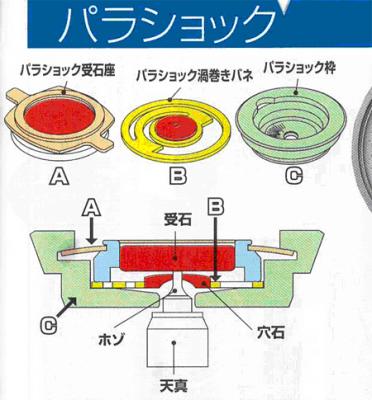

ST96, FHF96 and ST FHF96 are the same calibers. ST96-4 variant has date complication, regardless of complications the base comes with various type of shock systems and different shape of keyless parts and that is what you should pay attention to. 1-Keyless parts 2-Shock system and shock springs. Hairsprings metal differ between old and new models too( I think), newer types are improved and less damagable. joe1 point

-

an aHA! moment. there's the missing piece of the puzzle! on one reference I had seen, I saw the 96-4 number but the chart didn't say what it was. also, the ONE place I didn't look-ranfft. figures. this is the very reason why this forum is the best IMHO. grazie, Graziano. I appreciate it.1 point

-

Just stumbled upon this thread and had a read though. I don't mind admitting I shed a tear for all your friends that have been lost over the years. I've been there a few times, it never gets any easier. We currently have 4. Lorenz (Lorren), Sierpinski (Spinney), Mandelbrot (Delli) and Rusty. Can you guess the one my wife named? At the beginning of lockdown I made a cardboard tank for the cats. This is now Delli's favourite place to sleep.1 point

-

That is correct elgin 328 bridge layout too is exact same as st96. Bought 5 new movements for 30bucks a piece, Not bad ha.1 point

-

You may be interested in the tool I made from nail clippers. Do a search on the 'tools' part of the forum for 'Cannon Pinion Tightening Tool' by 'canthus' on 24Jan2020. Would insert a link here but don't know how to !! I have used it several times, not perfect but certainly gives more control over amount of nip. Use an eyeglass to check that the jaws sit in the correct place before nipping.1 point

-

Hi Mike managed to find a parts listing for calibers 321 to 360 for you as yet the only other tech is on Ranfft which the guys have already posted. cheers Grade 321 to 360.pdf1 point

-

While the parts are readily available for the FHF96-4 in the UK, with my similarly driven 'not running' (balance spring FUBAR'd) Camy , I found it far cheaper to buy one of the 'rebuilt' Mumbai Specials on ebay, with the same, apparently new, FHF movement and I swapped the whole balance assembly out of it. I think it cost me about £13 inc carriage. The Camy now runs great and I have an almost complete movement left as spares....1 point

-

Welcome to the forum Freddie, you too Buster and good luck both of you, tearing up all the furniture in the house. Rest assured you are the luckiest cats in Great Britton. Regards joe1 point

-

watchweasol mentions these guys and I agree. These are the best to start with DeCarle, Laurie Pennman and Brian Loomes. Loomes is the one if you want to learn all there is to know about Longcase clocks (grandfather clocks). I don't know if you can get this in Australia. Here in England we can buy this each month its called clocks magazine. Many years ago I had a few papers published in there magazines. You won't find anything better. http://www.clocksmagazine.com/1 point

-

Too bad you can’t get tool steel cases and flame blue those... USFA does a true bone blue on some of their offerings that is just beyond gorgeous.1 point

-

I have grown to appreciate dedicated movement holders. The ones I can’t buy, I just make. But this design looks much better than the burgeon one I have (and no longer use). With four points of contact, it always seemed to be putting pressure where I didn’t want it, or blocking something.1 point

-

1 point

-

1 point

-

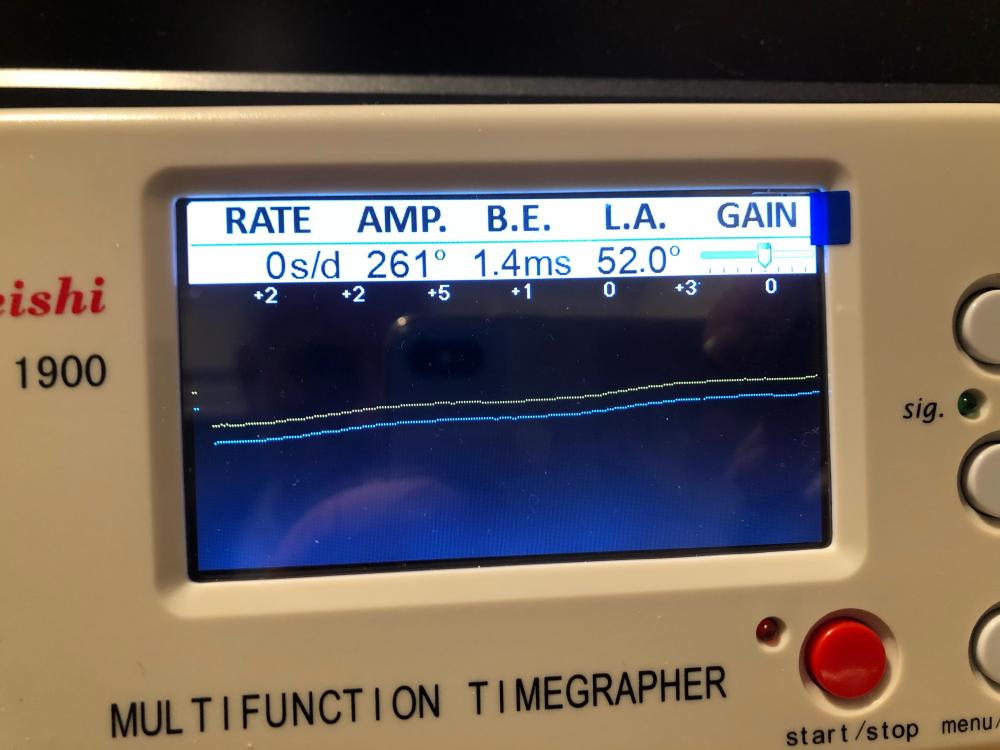

Hi! Haven't had much time for watchmaking practice, for way to long time!! But finally!!! Well almost done with the st 96 project. First started. And first finished. And, im very pleased! I have to say, it was very frustrating at times. Many small issues. Most done by my own "fine" work.. ? I did source a replacement balance. Or, I got offered by a gentleman. So, I did install it. But the watch did not run very clean at all. With low aptitude. Was a bit concerned, to say at least. But I managed to get it to work reasonable on the timegrapgher. So I decided to but the cannon pinion back, diel and case it. Well.. It isn't going to be easy, is it? ? Somehow, I do not really now how. The tub shaft on the center wheel. Was wrong.. I have no clue. But the cannon pinion was rattling loose fit.. When I realized. Well. some cussing did happen.. ? So, thank god. There is a donor movment to rob parts from. Bit disheartening to have to strip it back again..But decided I will improve the running quality, as much as possible. Well, at my skill level anyway.. ? That had to be the goal. And the possibility to "play" with my new ultrasonic cleaner. So, stripped it down again. Inspected it all carefully. But could not see any obvious problem. Put the wheel train and bridges in the sonic boom cleaner (sounds funnier, as an old aviation techie) So far, I have no real Watch cleaning fluid. But tried som 3M industrial cleaning fluid. Dunked a bit in a jar. And set the heater to 50 Celsius. And let it sit for 20 minutes. Rinced it carefully in isopropanol. Have to say, everything came out cleaner and shinier than before. Tried to clean the jewels with peg wood. But..he.. How do you guys get that done? Tried to sharpen as fine tip as humanly possible. But couldn't get it tru the jewels.. Assembly went well. Except the train bridge. Took a long time to get the timing wheel to align. But when that was fixed. Everything whent fine.. Now, having a beer, watching the timegrapher ticking a way with a slow variation of +- 4 seconds average. With that, Im a very happy camper!! ? Casing, dial and hands. Is tomorrows project. And BIG! thank you to all who has cheered on, answered my nooby question. HSL has to be mentioned extra nice ty! As he as donated a spare movment. Extra screws.. (don't ask.. ? ) Cheers all! And I wish you all a nice weekend with no pings! ?1 point

-

unfortunately there isn't any standard test procedure other then setting the hands and seeing how tight it feels. Sometimes when you're putting the hands-on though if you push on them gently and they move effortlessly that's not a good sign. Or when you're setting the watch if you feel nearly zero force required to move the hands that's not a good sign either. Just as when you're setting the hands it feels like you're going to break something that's also a bad of being too tight. But a lot of it just depends upon the particular watch as to whether it's going to be acceptable or not.1 point

-

1 point

-

Granted, it isn't an Omega LCD Speedmaster, but you can't argue about the price, and it does show some signs of life. Then again, if it was an original authentic ST 186.0004 Omega Speedmaster Professional Quartz we would be looking at something like $3,000 to $4,000 Two Alaska IV Prototypes (sold as a pair) went under the hammer for $47,500 in December 2015. This is an eye watering amount for an LCD watch produced in 1978 or thereabouts. So keep an eye on those junk lots, you just never know what you might spot.1 point

-

1 point

-

Using a bolsa wood slab I can bring back the shine and thoroughly clean watch parts. The purpose of the balsa wood is to adsorb excess fluids and it is so soft you can punch diverts in for wheel pivots, then scrub away the tarnish using jewelry cleaner or lighter fluid. Then into the ultrasonic for final clean. No mess and reusable many times over. I have had great success with this method for vintage watches that have tarnished.1 point

-

I see I forgott the pratical videos, these are a perfect compliment to watch with your loved ones on a Friday night; just make sure you have enought chips, popcorn and something to lubricate yout throat with ! Instruction Videos, General -------------------------------------------------- Lubrication Control – Part 1 (OSUIT Watchmaking) https://www.youtube.com/watch?v=eMJiX0MA-Wg Lubrication Control – Part 2 (OSUIT Watchmaking) https://www.youtube.com/watch?v=rlMW5qMHaNc Cap Jewel (AWCI, live lesson) --------------------------------------------- https://www.youtube.com/watch?v=rOKWMQ7di-M Barrel Wall on Automaic (perplxr) ------------------------------------------------------- Auto oiler ------------------------------------------------------------- Bergeon Automatic Oiler 1A (The one and only VWatchie) https://www.youtube.com/watch?v=oEQ83E4E8ik&feature=youtu.be1 point

-

1 point

-

amazing work, well done. The heavy drawers are a bit overkill imo but it really looks good. Like Vwatchie I was looking for the Ikea Bekant table which was around 450 euro but I was able to buy a watchmakers heritage with a few professional workingbenches and a ton of parts. Sadly the family, who were not in contact with their father, only had eyes for the gold and gemstones and had already thrown away at least 20 movingboxs full with parts, books, tools ect....0 points